Archive

Fire system site survey

Just had a meeting with the estate and facilities manager at the local university regarding their fire system and emergency lighting coverage. They require a survey followed by a design proposal for a possible upgrade if funds allow.

They have 4 buildings that require an upgrade but they do not know to what extent. As a cost saving measure they seem very keen to use any existing cabling (their suggestion, not mine). I explained that in theory this is fine as long as the existing cables meet the current standards but there is a risk as I, as the designer and individual who will conduct the survey, cannot comment on the integrity of the existing cables within the installation.

I have advised against this but they wont drop it, anyone else have any similar experiences?

Electrical Design Query

A few weeks into my phase 3 attachment and I am working on the design of the M&E install for the onshore facilities of an EDF wind farm in Scotland. EDF are the client with Skanska as the principal contractor. My design consultancy have been employed by Skanska to design the M&E. Unfortunately, General Electric and National Grid are also involved and have employed an independent consultant to review the electrical design. One recommendation that he has made is that all final circuits need to be terminated into a junction box in each room. The junction box is then to be connected to the distribution board via multi-core armoured cable. He believes that this will save time on the install and is more cost effective. I am recommending a standard install to and from the distribution boards and am struggling to see the benefits of employing his method.

Any thoughts from the M&E crew on this?

Can you trust a contractor?!

Just a quick question really guys, have any of you trusted the contractor to work to their own ITP. It might seem strange but during my site attachment the contractors were loathe to follow their own contractually agreed documents. I was just wondering if any of you had any issues?

The HAJ waste water treatment facility at HPC.

This will not be as long as any of Mark’s blogs

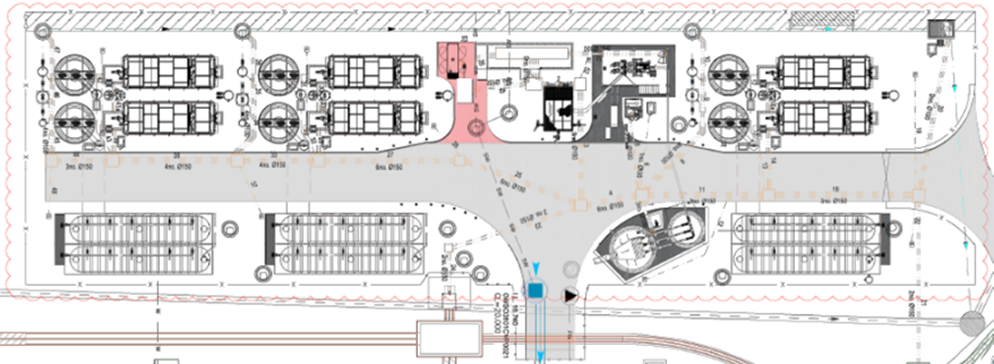

A large part of my time at HPC has been as the construction delivery manager for the temporary waste water facility, known as the HAJ. Designed to accommodate a peak flow of foul water of 33.8L/s for a peak of 9,775 construction workers. It achieves this through the 3 modules each consisting of a Primary Settlement Tank, Rotating Biological Contactor, Final Settlement Tank and a UV filter. Effluent from all 3 modules will flow into a final effluent pump chamber that pumps to a main header tank discharging through a pipeline of the end of the jetty. KBJV are the Tier 1 contracted to complete the Civil and M&E works, they have sub-contracted the main M&E installation to TES, a contractor from Northern Ireland who have in turn contracted much of the electrical work to Mike McDonald electrical services. Much of the plant is of the packaged variety supplied by KEE wastewater treatment technologies.

I arrived on-site after the main civil works were complete just in time for the M&E install, when I encountered my first issue (the first of many); feeder pillar 109.

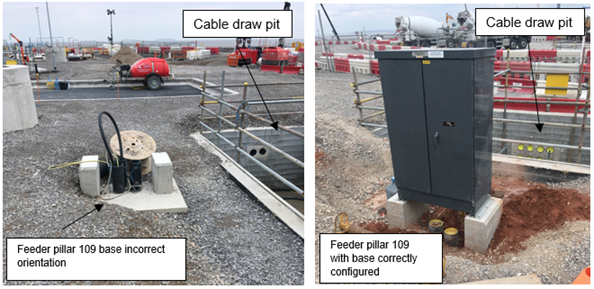

Firstly, the loading profile for the facility was stated as 600kVA requiring 2 x 300mm^2 cables to provide the supply. I noticed this was very large and queried the value with SET, through investigation it was found that this was a typo with only a 60kVA load required. I proposed that one 300mm^2 cable would suffice to meet the demand and allow capacity for any future expansion. The orientation of the pillar was also incorrect as can be seen from the images below and KBJV also used a 90 degree bend which was too tight a radius to allow the cable to be drawn through! TES, the Tier 2 contractor tried to play a contractual game stating that the change in cable size would result in a change in the specification for a number of electrical components within the facility. They did this to try and buy some time as they were (and still are) behind schedule. This was solved buy instructing them to increase the outgoing cable from 95mm^2 to 120mm^&2.

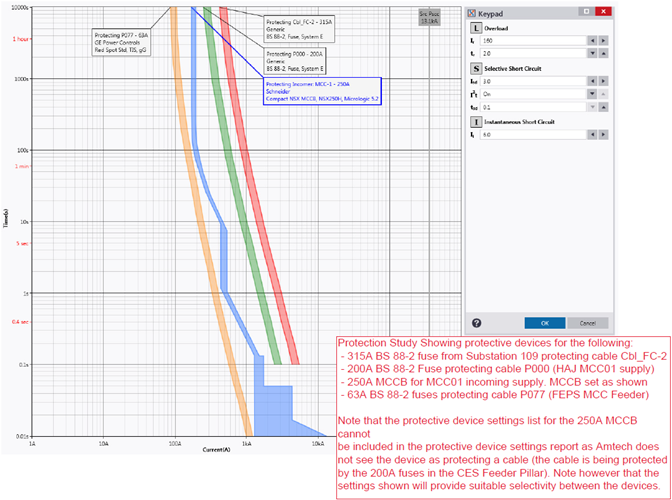

Having changed cable sizes I requested a grading study to be completed, TES and KBJV initially did not see the point, proving the the change in cable size would not cause any issues regarding the protection scheme, seen below. The end result is that all issues were resolved, but I learnt that competent contractors are not really competent and that you have to double check everything.

.