Archive

Melbourne Skyline 2012 vs 2020

Question – How do I get the best and fastest work from a subby?

If you have any thoughts, please let me know in the comments. Here’s the reason for asking:

In a recent job, I had 5 days to get a number of activities completed, one of which was a bunch of test pits drilled and samples supplied to geotech labs. I had employed a geotech company to complete this work on a lump sum contract, and they sub-contracted out the drilling work to another company.

The subbed drilling company found out that they had a 5 day window, and went about ensuring that the job took this amount of time. I am not sure of the motives for doing this, but that’s what they did. The first few days was ‘real slow going’, the last few days they completed drilling and able to knock off 8 hours into a 12 hour shift.

I didn’t have a problem with any of this until I realised all the things on days rates that I had on site supporting their activity.

- They ended up the last company on site, and so I had traffic management just for them.

- Labourers with excavators and dump trucks to move spoil away from the drilling areas.

- My supervisor was costing this job per day.

- Rail safety supervisor.

- Me! I wasn’t costing the job as such but I did have other locations I wanted to be!

There were more but these were the biggest things. So to my question. Instead of a lump sum, would a pain/gain clause work here, noting that the traditional Pain/Gain doesn’t work at this low level (what do ‘we’ gain?). And how does ‘pain’ work? I am cognisant that too much pain and I might put a small company under.

Could I offer them more money to complete a day or two earlier?

How can I write into a subbies contract something to incentivise them to get the work cracked out and get off my site?! Is there something I can tell them on site? Does anyone have any experiences?

A night in the life on a rail project: how much time do you have to work on the night shift and how many people does it take to do anything? Spoiler: not a great deal and flipping loads.

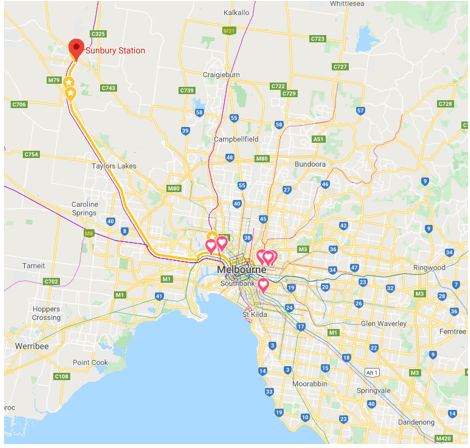

As part of one of my ongoing jobs, I have been asked to facilitate and manage the surveying and site investigation of Sunbury station and surrounding areas for a future upgrade and track widening.

As part of this project, there was a requirement to capture the last 10km of track from Sunbury towards Melbourne digitally. This involved mounting a machine onto a ‘hirail’ modified ute and driving up the track. The data capture is akin to google street maps but captures enough data to create a 3D model of the surrounding area and skinned with high quality photography. Accurate to about 5mm. I can write another little blog on this kit if people want to get their geek fix. Photo below shows the data capture machine mounted to the rear of the ute.

The hirail modification can be seen in the photo above too. The ute operates like normal, but once over the rails the steel wheels that are raised in the photo at the rear of the vehicle then lower and engage with the track. The ute’s normal wheels drive the vehicle forward, the rail wheel keep it on track.

Working on the track is called an occupation (occo for short; Aussies abbreviate everything). This type of occo that occurs over night is called an ALBF (After Last train at night Before First train in the morning).

Originally, I had thought I would need a lot less manpower and have a lot more time than I actually did for this simple job. I’ll run through what we actually needed.

The Plan

Manpower and Resources

- HiRail Ute

- TVO (Driver)

- Data collection wizard (Veris)

- HiRail Unimog

- TVO

- Signals Engineer

- Traffic Management

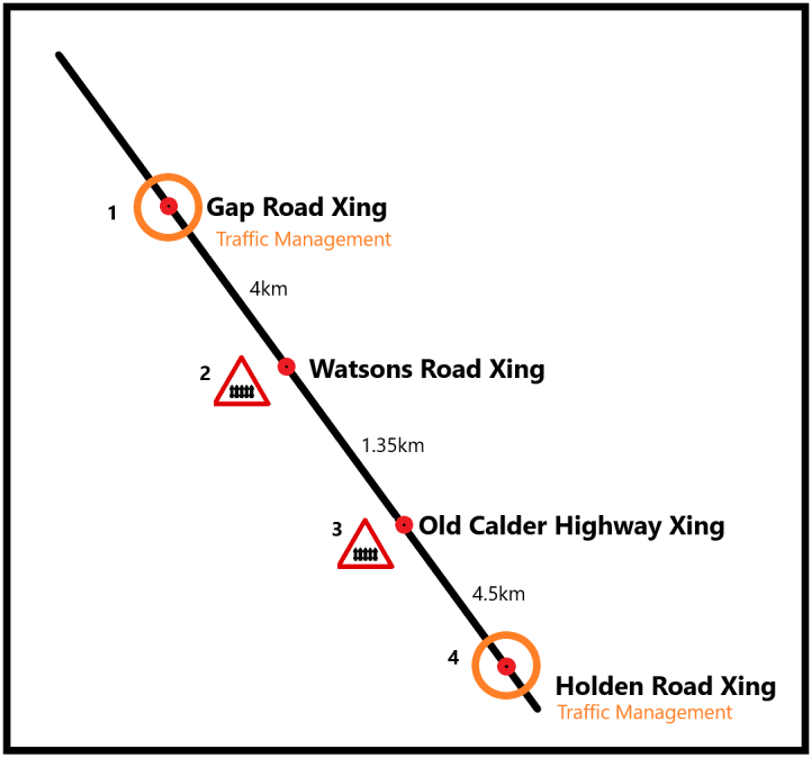

- 2x vehicle with 4 crew (Holden Road Xing)

- 2x vehicle with 4 crew (Gap Road Xing)

- Free running Vehicles (each in their own Ute)

- Project Manager (me)

- Track Force Protection Coordinator (TFPC)

- Survey Manager

- Track Certifier and Supervisor

- Level Crossing Controllers

- 1x TFPC at Old Calder highway

- 1 x TFPC at Watsons Road

Permits and Certifications

- Permit to Work

- 2 x HiRail Vehicles must be track certified, John Holland inducted, isolation checked and PlantGuard checked. (All different online systems, need VRN of vehicle)

- Each member must ‘sign on and have their ‘Rail Industry Worker’ Card checked for currency.

- 35 page Works Group document.

(Lets skip to…) What happened

At midnight I briefed the workforce of the plan, H&S and all that good stuff. Then they had a bit of time to get into position. When planning these things, you don’t actually know exactly when the last train will pass AND the safety team have put out their signage. The last train, I learnt, was 0130hrs, the works group plan told me that we must be off the track no later than 0400hrs. This gave me 2.5 hours to play with.

At the given time, the two HiRail vehicles would get onto the track at Holden Road under traffic management. They would start to move up the track, optimum speed would be at least 20kph, but for the first run on a new track the signal engineer had to check the signals were ‘ok’ (more info if anyone would like me to explain) before moving on. The two crossings would have the booms manually operated to allow the two vehicles to pass without slowing down. At the Gap Road crossing, under traffic management the two vehicles will turn around and return.

One loop (there and back) would be ok, but every other extra loop would increase the quality of the data capture and reduce the chance of repeating this work. A workforce that knew this and knowing their part and everyone else’s parts would give us the best chance at getting this evening to go smoothly.

We waited for the call that the rail line was clear to drive on. 0140hrs, 0155hrs, the time went on. At 0205hrs we got the call. Oh, and just before the formal briefing to the workforce I also learnt that we would have to be off the track at 0330hrs. My 2.5 hour window was reduced to 1.5 hours. Within this time, we just got in 1.5 loops which was acceptable. No one was hurt and we didn’t prang a vehicle, so I consider this a success.

Summary

For 1.5 hours worth of work and a simple plan, it took 12 vehicles and 14 people to enact. I spent 1.5 days in preparation as well as plenty of random actions to tidy up loose ends. I was massively surprised that this seemingly simple job took so long in planning and sucked in so many resources. Bed for 0430hrs, back in fornt of my computer by 1100hrs. zzz, apologies for any typos caused by sleepiness at the keyboard.