Archive

Proving or Proofing?

I am currently working as part of SWC’s (contractor) design team on the Melbourne Airport Terminal 1,2,3 ‘Elevated Road Network’ and have been managing the proof engineering process. Under the D&C contract, SWC have traditionally acted as an intermediary for information exchange between the principal designers (PD) and the proof engineers (PE), with limited direct communication between the 2. This information comes in the form of a PE ‘comments register’ which goes through a continuously cumbersome back and forth issuing process. Furthermore, the volume of comments on the registers can be unmanageable and it is often the case that high priority design concerns are lost amongst a sea of quick and easy fixes, such as minor drafting errors.

This is further compounded by a culture of ‘one-upmanship’ between the PD and PE, with accusations of pedantic commentary and inadequate justification coming from both sides. The sceptic would say that this is amplified by both having a desire to partner with SWC on future D&C tenders, both keen to ‘prove’ themselves as competent designers. The dangers of such a culture spreading are obvious and it is paramount that the proof engineering process is returned to its original intentions i.e. ‘to verify the integrity of complex engineering systems for compliance with the NCC. In the context of the building environment, verification means review of calculations and design documentation prepared by others and may also involve checking by independent calculation’.

To aid with this, I have been chairing regular PE review sessions which allow for open and frank discussion of previously agreed and prioritised review items. This is helping with the integrity and efficiency of the process and decreasing the level of ‘keyboard warrior’ critique that had been taking place on the Excel registers. However, there is still a deal of sensitivity around certain items which can be challenging to resolve.

I wonder if anyone else has experienced something similar? I should stress that overall, the value of the PE process is still being realised and some good design refinement has come as a result.

Quantity Surveying Using Drones

I’m currently in my fourth month of a site attachment with Seymour Whyte Construction (Melbourne, Australia) and involved in the upgrade of a 5km road. Undoubtedly, one of the most utilised (and cost-effective) tools we have at our disposal is the drone. No one reading this will be unfamiliar with the use of drones for aerial imagery capture. However, I wanted to share my experiences of how we have been using this data for engineering specific purposes.

Our software of choice is Propellor (propelleraero.com), used for drone-based data collection, processing, and analysis of earthworks. As frequently as required (usually once a month), our survey manager sends his drone fleet on a pre-determined flight path, covering the entire 5km site within an hour. The data is then uploaded to a cloud service and processed using photogrammetry to create a realistic, fully interactive 3D site model.

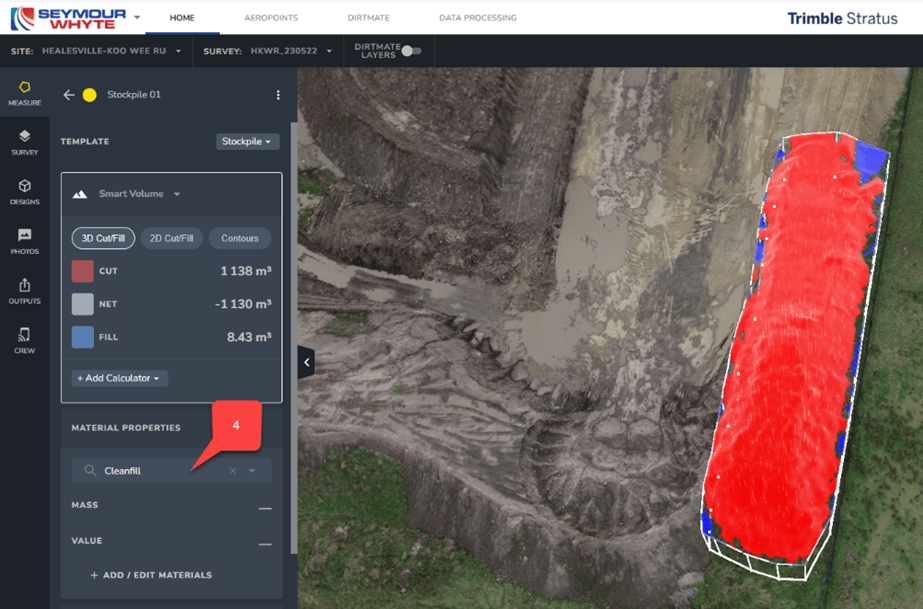

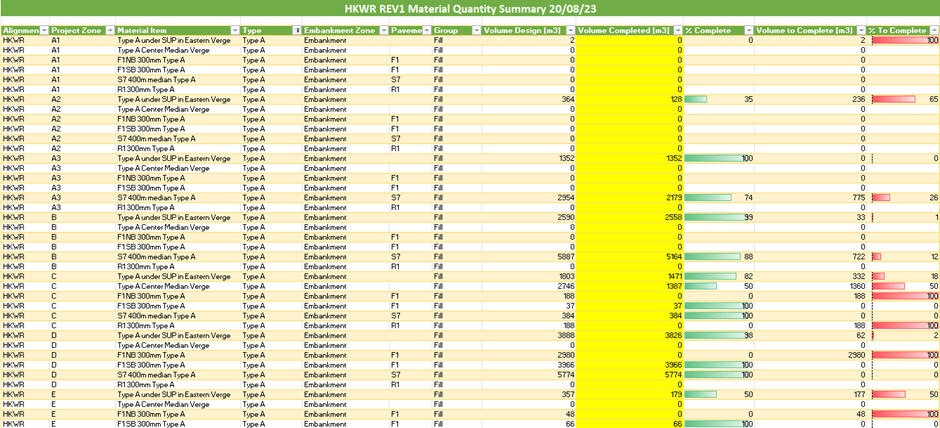

We then use this model for a variety of measurement and management purposes. One of the most useful (and time efficient) processes is the production of quantity take off spreadsheets for end of month financial reviews. The software is able to identify total quantities placed (broken down into specific material types) during the given financial month. We then subtract these quantities from final design quantities to determine what is remaining. Each material type and corresponding construction methodology has a cost rate associated with it (per m3). Once the quantity remaining value is updated, our financial forecast to complete automatically updates.

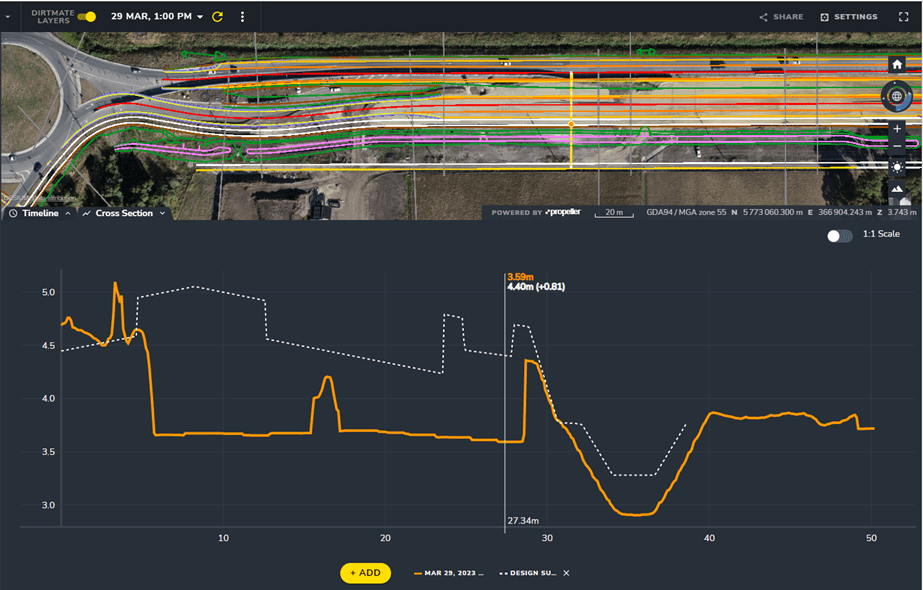

Coupled with machine tracking systems (Spotlight on DirtMate: How Does it Work? – Propeller (propelleraero.com) we can also use this data for daily progress tracking, cost tracking and material stockpile measurements. With the ability to cut 3D cross sections across the live site model, Propeller can also be used to overlay design drawings on the section, allowing for quick visualisation of material level against FSL.

I wonder if anyone has had other experiences of quantity take off for the purposes of EOM financial reviews? Should our surveyors, and by extension PET students, be learning about some of this technology during Phase 1?

Given that drones are now commonplace in the military context, should we be investigating the potential uses of ME specific drone data processing software? An immediate thought is the benefit of 3-dimensional drone measuring for the purpose of crossing point reconnaissance or for the automation of cut/fill quantities as a planning tool for military earthworks.