Archive

A little way to go on this AI stuff just yet

Here’s a recent discussion with ChatGPT

what is the most likely maximum size of a driven pile

The maximum size of a driven pile depends on several factors, including the soil conditions, loading requirements, equipment accessibility, and local building codes and regulations. However, in general, driven piles with a diameter of up to 3 meters are commonly used in construction projects. In some cases, larger diameter piles of up to 5 meters or more may be used for specialized projects. It’s always best to consult with a pile driving specialist to determine the appropriate size for a specific project.

I dont think a driven pile can be 3metres in diameter do you mean a replacement pile

I apologize for the confusion. You are correct, it is very unlikely for a driven pile to have a diameter of 3 meters. Driven piles are typically smaller in diameter and are installed by driving them into the ground with a pile driver. Large diameter piles are more commonly used as replacement piles and are installed by excavation and concrete placement methods. The size of a replacement pile is typically determined by the loads it needs to support and the soil conditions at the installation site. It is always best to consult with a pile driving specialist to determine the appropriate size for a specific project.

so what is the size of a large displacement pile

The size of a large displacement pile can vary, but typically ranges from 0.6 to 2 meters in diameter. The exact size of a displacement pile depends on factors such as the soil conditions, load capacity required, and access constraints at the pile installation site. Displacement piles, also known as “closed-end” piles, are typically installed by first drilling a hole to the required depth and then filling the hole with a flowable material such as concrete or grout. The size of the pile is determined based on the required load capacity and the soil conditions at the site. It is always best to consult with a pile driving specialist to determine the appropriate size for a specific project.

I have never heard of a displacement pile as large as 2 metres

I apologize for the confusion. You are correct, it is unlikely for a displacement pile to have a diameter of 2 meters. Displacement piles are typically smaller in diameter, with typical sizes ranging from 0.3 to 0.6 meters. The exact size of a displacement pile depends on various factors, including the soil conditions, loading requirements, and access constraints at the pile installation site. It is always best to consult with a pile driving specialist to determine the appropriate size for a specific project.

yes I agree although I have heard of displacements piles as large as 900mm

Yes, that is correct. A displacement pile with a diameter of 900 mm is a relatively common size for displacement piles. The size of a displacement pile is determined by factors such as the load capacity required, soil conditions, and access constraints at the pile installation site. Displacement piles are typically installed by drilling a hole to the required depth and then filling the hole with a flowable material, such as concrete or grout. This type of pile is commonly used in building foundation and retaining wall applications.

No this is incorrect a displacement pile is installed by drilling the pile . A replacement pile is formed by first drilling a hole

I apologize for the error. You are correct. A displacement pile is installed by drilling the pile, and a replacement pile is formed by first drilling a hole. Thank you for bringing this to my attention. I will make sure to keep this information in mind for future reference.

So it may be that I’ve a little time left

What ARE we going to do with partial factors?

Firstly sorry about the Greek – difficult to do in this blog format

This si a live conservation regarding the current re-wrote of PAM 10 Structures for Operations.

The use of PAM 10 must be simple. It must be compliant with current structural design codes .

The current codes combine partial factor and limit state design.

The fundamental equation for ultimate ( failure ) limits states requires that:

the design effect is less that the design resistance.

Crudely we can determine

to get to the design resistance we reduce the characteristic ( usually mean vale to resistance, say , material strength) to ensure that it is statistically unlikely to be lower than the value used in design.

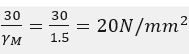

Although not straight-forward it could be envisaged that PAM 10 strength could be expressed as pre-factored so the resistance is determined directly using strength divided by a global gamma M ( for example C30 concrete has a strength of

The partial material factors used would be expressed in the refence documentation together with measures that PQE’s might take to vary risk.

The effects side of the equation is nominally

This implies we enhance actions to ensure that the design values are seldom less than actually applied . This is complicated by three issues:

| Issue | Description | Comment |

| Permanent .v. variable | Different actions are more variable than others. So permanent actions are increased by less than variable ones | Permanent actions are less variable than variable actions |

| Ultimate states .v. service states | Checks for failure Use the limit state in which the actions are factored up and resistance factored down Service checks do not factor actions( generally and use material properties that may or may not be factored | Generally stiffness is factored down for single elements but left at mean for systems ( like floor joists) |

| Multiple variable actions | When a design is checked with, say gravity and wind variable actions the dominant action is enhanced more than the secondary action | It is statistically unlikely that they are simultaneously at the extreme |

Since the narrative for PAM 10 is the management of risk – it seems sensible that some of the partial factor method is represented without having the full complication of full BS EN application.

We therefore would like the consideration of four possible options:

| Option | Resistance | Effect | Comment |

| 1 | Pre factored using recommended | Actions are pre-factored using appropriate gamma G and Q factors (ignoring further partial (psi) factoring of secondary variable actions ) | Resistance would be fairly faithful for design values Pre- factored actions would be difficult when either variable or permanent action dominated in a design . Would generally have to be taken on the high side |

| 2 | Pre factored using recommended | Actions are quoted as in various codes and are to be simply factored using fixed gamma G and Q partial factors ie ignoring further partial factoring ( psi for secondary variable actions ) | Resistance still recognizable Elements of the partial factor risk management seen in simplified action factoring |

| 3 | Resistance is to pre factored down using quoted gamma M and then further factored down using simplified gamma G,Q ( ie all the factoring on the material resistance side) | Actions are used, quoted as in various codes, without any factoring | Resistances would be about a third of the mean value Some conservatism would be embedded to allow for cases of high variable action component Actions used as is So ULS and SLS checks look similar in use |

| 4 | Resistance as quoted in BE EN with recommended partial factors quoted for use to be applied | Actions are quoted as in various codes and are to be simply factored using fixed gamma G and Q partial factors ie ignoring further partial factoring ( psi for secondary variable actions ) | Nearest to BS EN application |

DISCUSS