Archive

Parapet Installation

The installation of the parapets got off to a slow start last week which I expected as every bridge seems to have had its issues. There have been over 2000 parapet sections installed across the project so I initially tried hard to bargain with the superintendent to get the seasoned parapet crew to install the Dickson Rd parapets. It became apparent by Fri that I couldn’t rely on their availability if I were to keep to my own tight programme so we made sure we had prepared well and installed them ourselves using a hired in 20T Franna crane and a trusty Kiwi labourer. We only managed to start at lunchtime on the Mon due to the initial anchor bolts being slightly out of position and had only 2 in place by the end of the day. When I went to inspect the work it looked a little off to my keen eye and after getting the surveying out to re-check the positions it became apparent he had marked the entire western side out of position by 90mm at its worst. Equipment failure was blamed but little harm was done as we managed to catch it early. The next day we only managed another 2 and I had planned for all 24 by Fri. At this point I decided to hire another 20T Franna and got the two most competent guys I knew from the FRP subcontractor on Dayworks to start installing parapets from the opposite abutment and side. This paid off as we managed 9 parapets on Wed and had them all installed just after lunch on Fri.

Concurrently to this we worked in with another subcontractor to install the water pipe through the walkway and fixed the top matt of steel on the walkway as well as some of the traffic barrier steel. I timed the barrier steel to be delivered at the start of the week as we have very little storage space with the road works racing ahead but not for the first time the steel scheduler did a poor job and so I am still waiting for some of the barrier steel which was forgotten. Unfortunately this is the steel for the end transition barriers which we need to fix and pour first so that the type F barriers which are being slipformed can butt up against these.

I managed to get the slipforming subcontractor back on site again mid week and he agreed to carry out the barrier extension work next week, the week before I leave for holiday so I will at least see the paving machine in action and as it stands at the moment I should complete all the concrete works by the end of next week. The only outstanding work will probably be the metal work installation consisting of the traffic railings and throw screens.

Just a short blog but I will post again at the end of the week and again next week to tidy up a few issues as everything starts to wrap up.

Cracking the whip.

The reality is that the bridge would be complete by now if the initial backfill had been completed within the programmed 6 days and not drawn out to 6 weeks by the Civil Team but as it stands we are on course to complete before xmas. I realise I haven’t blogged for nearly 4 weeks and I am not sure where that time has gone, I did have good intentions during the week but with a TMR to write and trying to push productivity on site before I know it its 7 in the evening and with an hour commute I should be getting home if I want to remain married. The last 2-3 weeks have been extremely exhausting if I’m honest, I go on holiday in 3 weeks’ time and I am trying to push for the bridge works to be complete by then which if I can achieve will be 12 days ahead of programme. To the credit of the subby they have bought into my vision and stepped their game up and we have now completed all abutment retaining walls, both approach slabs and will start installing the pre-cast parapet sections next week. I feel like I am constantly badgering (persuading) people to work that little bit faster or smarter and feel like I actually own this bridge and want to see it come to fruition before I leave. As a result I have at times lost complete confidence in the supervisor as he has no interest in working at the same capacity as I currently am and I have found I have taken on more of his responsibilities in order to keep momentum when I should be gradually giving him more responsibility. Most of the supervisors from what I hear have a fairly poor work ethic and rarely supervise anything at times, this has been an immense cause of frustration for me coming from a background where a SNCO is generally highly competent and can be left alone to manage quite complex tasks to having a supervisor who can barely spell and will spend 2 hours at lunch shopping. The main issue is how JH trains his people, which is adhoc at times but largely non-existent. The supervisor I have for instance is a really nice guy and we do get on very well but his work effort is sporadic at best, he has good weeks and then it seems he needs a bit of a rest before he gets another wind. I have often had chats with him about how to improve how he operates and to his credit he takes it on board and he has improved as a supervisor over the last 8 months. This is largely due to the fact he received no training to be a supervisor in the first place and received a field promotion form leading hand to foreman as there was a slot to fill. The majority both supervisors and engineers seem to be on contract for this project only and so have no job security and most have been applying for the next employment over the last 2 months since all contract staff will be gone by xmas. The constant message from JH is that there is no work probably until the end of next year and by the way your all off the project by the end of Nov but will try to find you work if we can – this has not had a good effect on morale and most importantly productivity.

Well, slight rant over I’ll get back to the bridge. At present we are about 4 days ahead of programme with a key activity coming up which is installing the parapets. In reality we should be able to install the 24 panels at a rate of 6 a day but that is only if we get the prep work right. Each panel weighs 3T and is held in place by three L shape brackets that fix onto the deck/wingwalls/retaining walls. The fixing anchor as you can see from the diagram has been cast into the appropriate element and there is a levelling screw at the back edge that can be adjusted and sits on a steel plate that is epoxy glued on to the concrete. This has the potential to take a long time if the prep is not right as the tolerance is only mm between each panel. Once the panels are in the traffic barriers are formed over the bracket which tie in the panels and form the parapet barriers along the length of the bridge. On Eastwood Bridge we had one of these panels move out when we poured the barrier which gave us issues when we installed the metal traffic railings and throw screens which sit on top. I think this was due to the anchor fixing slipping as the bolt sits through a slotted hole and I think the additional force generated from wet concrete caused the bracket to slip which tilted the panel outwards as opposed to the bracket actually failing. To remedy this I intend to weld all the nuts and reinforce the brackets with straight bar diagonals welded on once all the panels are installed and we are ready to pour the barriers.

Other issues last week were with the approach slabs where the steel was wrongly fixed. I went out to check the steel 2 hours before we were meant to pour as I couldn’t get out earlier due to end of month cost reports due that day and the Project Verifier was already there who also spotted the mistake which I didn’t think looked good. The supervisor should really have spotted this when they started but it seems no one decided to look at the drawings beforehand. The chief steel fixer is a grumpy git but extremely good at its job and it has been very rare that he has got something wrong although I have picked up a few things recently. I can only assume he thought the steel was the same arrangement as the RW bases which have the larger dia steel bars at the top of the slab due to the increased tensile stress at the top generated from the wall resisting the backfill. The approach sabs have the larger dia bars at the bottom and so at the 11th hour we had to strip both approach slabs which lost us a day which is quite crucial at this stage. It also means I lose a day on the parapet installation as I need to be able to traffic the slab early in order to get on the deck to install the deck parapets. Looking at previous concrete strength we have achieved 80% strength which is required for loads over 15T at around 5 days. As a result I requested an extra cylinder to be tested at 5 days as well as the usual 7 and 28 days which will be tested on Wed next week and I can make a call as to whether we can traffic the deck or wait until 7 days.

The remaining work on Dickson following the parapet installation will be the traffic barriers, walkway (including services installation), traffic railing and throw screens and the type F traffic barriers that extend out from the parapet barriers for a further 25m on both sides and abutments. I am still negotiating with a slipforming subcontractor to do the type F barriers in 2 weeks’ time so I can see it done before I go on holiday as I have done a lot of leg work (plus a TMR on it) and would really like to see the process in action.

Aerial photograph taken of Dickson Rd Overbridge for the recent edition of the project newsletter

Aerial photograph taken of Dickson Rd Overbridge for the recent edition of the project newsletter

As for work on any of the other bridges it is all on hold at the moment and I don’t intend to get side tracked from Dickson to carry out any further defect work. I have been told that will fall to someone else once I have left but I am still costing 9 out of the 14 bridges on the project. Luckily I have just done that for the last time last week although I only managed 6 within the 24hrs we were given to get the forecasts in. The only major movements of money on the bridges are primarily Dickson Rd but this should also start to slow as the major structural work is now complete.

In other news little Ethan is just about walking and is enjoying his new found freedom. We went to the international fleet review at the start of the month and managed to get a prime view of the fireworks display (which was apparently bigger than new year’s) right in front of the opera house and harbour bridge. Ethan managed to stay awake until the last big fireworks crescendo which you would think would wake him up a bit. The bush fires in the Blue Mountains have been pretty horrific with the air full of smoke at times even in the city centre. The project is not that far from some of them and coming into work last mon you could taste it in the back of your throat. It also affected visibility around the local roads. One of the girls in the commercial team lost her house after leaving in the morning to take her daughter to a hospital appointment she returned and it had gone but her neighbours 2 houses down were untouched. Apparently the embers can travel for up to 50km and still burn your house down.

Time is tight.

It has been a few weeks since my last post and lot of has happened since. The bridge deck has been poured on the 22nd on possible the worst day. No rain, still, but it was well over 30deg and the wind was right on the limit for operating a boom pump. The wind on the deck which is 9m high gave us curing issues as the surface started to dry and crack very quickly. As part of the pour plan I had worked out roughly what the rate of evaporation would be in accordance with the spec and with the wind gusting over 60km/h we had to constantly apply alcohol in a fine spray as soon as a portion of deck had been screeded. A bit of woeful mismanagement by the supervisor meant that we didn’t have hessian, plastic sheeting and the water hose ready to start curing the deck as soon as we should have and by the time we got it all covered there was a lot of cracking on the initially poured section. We have moved swiftly since as we stripped the scaffold on both sides over the next few days so we could start the backfill to the first Abutment RW levels. As a result we havn’t been up on the deck for the last couple of weeks so I have yet to see how bad the crazy paving effect may be. We backfilled both sides by 1.35m and poured the four base slabs for the first RW’s swiftly followed by the stem walls the week after and this week we have started the next stage of backfill for the next RW which will take us under 2m below the top of deck. I should have insisted on wet curing for the lower RW’s as all four bases had a fair amount of surface cracking on yet another windy day which means I didn’t learn my lesson the first time but more truthfully means I just couldn’t give the pour the required time or more accurately the planning time it required relying more on the subcontractor to do the right thing. I have found this has been the case on a number of occasions, when I was purely a site engineer at the start of the attchment I had the time to comprehensively plan a concrete pour and direct it but with multiple sites and a crippling amount of paperwork to produce I have to rely more on the supervisor and the subcontractor. It has often reminded me of what Richard and John would say regarding knowledge of those you work with and to never assume they know what they are doing. I have frequently been surprised at how little knowledge of concrete the FRP company demonstrates who now frequently ask me what or how they should do something which 7 months ago would have been laughable. My supervisor is similar but tends to know what he should do but hasn’t a clue why – I felt exactly the same in JM lectures except I didn’t even know what I should do!

Abutment A wingwall shutters

Abutment A wingwall shutters

Backfill to next RW’s on abutment A

Backfill to next RW’s on abutment A

The aim is to open the bridge before xmas which is achievable as per the programme rewrite the other month but means I have practically zero tolerance for inclement weather or unforeseen problems. Having really pushed the subcontractor over the past few weeks we are a few days ahead in the programme but the critical piece will be the next backfill stage this week. We have a public holiday coming up which means no trades on site this weekend or mon, tue next week so we need to finish the next stage by this fri. This has already been compromised as the general superintendent ordered all machines to stop and knock off for the day over concerns of the dust levels which has meant we have lost a half day. The rail systems continue to be installed and all track has now been laid. The earthworks on the northern approach are now complete and the southern approach is probably only a week away from getting up to level. All this activity has meant it has been very difficult to build a bridge, it is almost likely other teams view the bridge as a hindrance and not the actual reason they are working in the area in the first place. The earthworks team seem to think they are special – which they are but not in the way they think! We did have a crossing point for plant over the tracks which got ripped out yesterday without any communication whatsoever which means to get from one abutment to another we now have to drive round onto the public road over Eastwood bridge and through the opposite gate which is a slight embuggerance. The sooner we get the backfill up to level and are able to traffic the bridge the better.

I still have responsibility for the eight other bridges along the alignment but as I have no more resources this has been mainly confined to administrative work regarding NCR’s and RFI’s. We have completed the substation work with the exception of two LV pits along an access road. Conduit issues still continue although the issues at Scalabrini and Kemps Creek have been resolved. I managed to cut the conduits cleanly enough for the HV cables to be pulled through today. The problem had been the limited space (40-70mm gap) to get any cutting equipment as deep as 700mm to cut the lower conduits. In the end we encased the conduits in mortar and got a concrete cutting subcontractor to come in to wire saw flush to each walkway slab face. This was fine for one side but when trying to cut the other side only 70mm away the wire saw tended to find its way back to the original cut so we ended up using 50mm core drill to stitch cut the other side which made a little messier but we were able to tidy up any buring and sharp edges to the clients satisfaction. Cowpasture Rd viaduct has now experienced the same issue as when an attempt to pull the cables through was made an obstruction was found. CCTV cameras showed some form of blockage so we a subcontractor has been employed to break out the conduits in the walkway to investigate. Having done this with the top conduits we haven’t found any blockage so far – could be a waste of money!

![IMG_2179[1]](https://pewpetblog.com/wp-content/uploads/2013/10/img_21791.jpg?w=225&h=300) Cowpasture Rd viaduct Combined Services Route (CSR) walkway

Cowpasture Rd viaduct Combined Services Route (CSR) walkway

Having spoken with John Reddie last week and again today I think we are close to finally confirming my design attachment with SMEC. SMEC have designed all the bridge structures on this project and I am hopefully heading to the bridge design team but SKM is a back up company which could be an option.

In other news, our little man managed to take 3 unaided steps last week which I managed to witness having come back from work an hour earlier than normal. He has done bugger all since so I don’t think he is in a rush to walk and quite frankly he can take his time as its hard enough keeping track of him in quadrupedal mode. My wife organised a group 1 year old birthday party for her baby group at the weekend on the park at Coogee beach which was great fun with about 60 people turning up unfortunately I had to take Ethan and myself home early after he projectile vomited over me 3 times for good measure – it was not a good look! Also finally got caught speeding the other week having missed my usual turning on the motorway (half asleep) I failed to see a cop car parked behind a forest as you do who clocked me at 90km/h in a 70km/h in the middle of nowhere on a straight road. He took pity on me fortunately as I explained I was a tourist in an unfamiliar area which took the fine down from $450 to $250 which is still scandalous, he looked genuinely disappointed when he realised I had a UK license and so he wouldn’t be able to award me any points. Having been here for 7 months and only just been caught speeding considering that is the only offence the NSW police enforce is not too bad but maybe they should focus on reducing the amount of shootings that go on here.

Backfill issues

The last few weeks have been hectic to say the least trying juggle sevral different sites. Dickson Rd Overbridge progresses but not in synch with the programme. I have re-written the programme which has been scrutinised by the Construction Manager and he concedes that a completion date of 20 Dec is realistic. The issue here is the backfill, we requested the backfill to be done quite specifically (recall my sketch in an earlier post) which battered back to the level of the top RW. We intended to step up to the next RW level by forming up shutters and vertically blinding with snape sand to the required RL then we would repeat for the next one. This was the method used at Eastwood Rd Overbridge but with hindsight we should have just backfilled to the level of the wingwalls and then backfilled to the formation level of the next RW as we progressed. Because Eastwood Rd has displayed signs of settlement due to poor backfill/compaction the Construction Manager has stressed to me that we must get it right this time and so I have decided to prioritise the deck so that we can backfill against the blade wall before starting the RW’s. We have currently completed the wingwalls at both abutments and will pour the deck/diaphragms in one pour this week. Once the deck is complete this props the structure so that we can start to backfill either side simultaneously up to the RL of the first RW’s. Meanwhile I hope to prefab the steel for the first RW bases so that we can lift them into place once we have backfilled, excavated part of the batter and blinded the area. We can then keep alternating from abutment A to B backfilling and pouring the RW’s in pairs. This issue with the battered back backfill means we have significantly reduced our working areas at either abutment which coupled with the fact that we have rail track through the span means the requirement for craneage (if that is a word) has significantly increased and will continue to do so. I had no choice but to hire a 130T crane the other day to strip the shutters from abut A wingwalls and move them over to the abut B purely because of reach where normally I would use a mobile 25T Franna crane – the cost was $7000/day compared to $3000/day and this will be typical from now on as we complete the RW’s. The batter also means the backfill at the edges will not be adequate enough and we will have to excavate and then re-compact.

Eastwood Rd Overbridge is showing signs of settlement on both sides which has been attributed to poor compaction by the civil team doing the backfill – not the first time this has happened. As this bridge is open to the public I am currently monitoring to see if it still moving which early indication says no it isn’t. However there are some worrying looking cracks on the traffic barriers as you can see from the photos.

I have also had 6 x LV pits and conduit runs to build at Cowpasture Rd Substation. These look simple but have been an absolute nightmare, they seem to be massively over designed and the 200m walls are practically full of steel. We have poured 4 of the 6 with the 2 pits that lead up an access track to a utility metering panel not yet started. The lids are placed on top at the moment but we will need to concrete them in and over them but I plan to do all 6 at the same time as I will have to order a small quatity of our usual 40MPa mix but with agg of 10mm or less so that the concrete will form into the metal lids. I have had to get another FRP subcontractor in for these pits as the one I was using also works on Dickson Rd and I need all their available manpower for the bridge. Their steel fixer practically refused to do another one after the trouble he had fixing the first two and the constant moaning that came with it I was happy to hire in another subby! All this work is on dayworks which I estimated to take 650 hrs, I last calculated I had about 100 hrs left in the budget to complete the last 2 but with a bit of JH labour in reserve.

I also have a number of Non Conformance Reports (NCR) and associated RFI’s to deal with on practically all the remaining bridges and a few retaining walls but nothing exciting. These are mainly crack repairs, patching work and out of tolerance ‘as-built’ surveys. Settlement at the approach slabs on just about all the bridges has occurred up to about 30mm which is noticeable on the pre-cast parapet sections and on Cowpasture Rd viaduct the approach slab has settled showing a gap between the walkwy and slab which you could get your hand down. This has bee recorded by the client but has subsequently been covered over by ballast and tracj by the rail team so if any remedial work will be required it will be a complicated job. The RW’s in this section have also settled and a gap has appeared between two adjacent panels. The movement has been 70mm back and 20mm down which the designer has said is acceptable has they were expecting movement of up to 100mm. The rectification method will be to fill the gap with a grout but this is on the back burner for now as I have no manpower or time to invest in it at the moment. There is also the issue of improving the access track that is below the wall so we can carry out the work. This small RW (RW14Ua) sits on top of a larger RW (RW14U) which has also settled but the corner of the wall rests upon the corner of the pile cap to Byron Rd bridge. This has resulted in the corner of the wall being crushed and the concrete has broken away. This is also another job on the list but will require the corner to be broken out the ‘stiffjoint’ material and appropriate gap reinstated between the wall/abutment/pile cap and then the corner re-formed. There are also another two corners which have not crushed but will have to have the same treatment so that if the wall does settle on that side then it will not crush. The fourth corner does not rest on the pile cap.

The Scalabrini Creek Underbridge conduit issue continues. I have had acceptance from the client and the services designer to cut the conduits that do not have a joint for expansion providing that we have operational controls in place for installing the cables. This basically consists of liaising with the rail team so that they are aware of what we are doing and making sure that they have procedures in place for installing the HV cables with a gap of about 50mm at the EJ’s. As all the pulling ropes have been installed using a compressor that blows a sock down the conduit with the cable attached to its tale, the only real concern is any sharp edges on the conduits that have been cut. As the forces involved when they pull theses cables through can be quite high any burring on the edges could damage the cables along its entire length. The metal cover plates will remain off so that a visual can be maintained while the cables are installed but will be bolted back down once they are in place. The main issue at the moment is how to actually cut the conduits. Myself and the supervisor had a go ourselves last week as we had no other labour available at the Rail Team are hounding us to get this done so that they can install power to Leppington station ASAP. We managed to cut the top ones easily enough with a Panel saw from Bunnings (B&Q) but the lower 150mm dia conduits are about 700mm down within the joint and there is only a 70mm gap, not really enough to even get your hand down. I have had two different concrete cutting subbies out to have a look and one said they had a wire cutting diamond saw which sounds hopeful. The construction manager was concerned it might not give a smooth enough cut and asked me to look into Hydro dem (UHP water cutting). He hasn’t yet seen the handy work of the two oxygen thiefs I had to employ on dayworks the other day to cut the upper conduits on the other abutment – if he had he wouldn’t be worried about a rough finish! Having looked into hydro dem companies in the area and having seen this sort of stuff in action when cutting into bomb casings I really don’t want to mess around with that stuff for the sake of cutting a few UPVc conduits so I intend to give the diamond wire saw a go as soon as they can do it – which I was hoping would be this afternoon but they have now said next week.

More responsibility

The last 2 weeks has seen the stage 1 backfill at Dickson Rd Abutment A completed and I can finally get the subcontractor back in this week to erect the scaffold to then start steel fixing and forming the wingwalls. I estimate we have lost nearly 4 weeks from this delay but having spoken to the FRP subcontractor supervisor we are both confident of gaining at least 2 weeks back on the programme especially as summer seems to have arrived half way through winter!?

To be honest this delay has been useful as I’ve been busy with other work. The defects work on the three other bridges in my section are close to completion with minor outstanding work like handrails, anti-grafitti guard and underbridge drainage close to completion. The conduit issue at Scalabrini has been shelved at the moment as I have also taken over from another engineer who left last week. I now have responsibility for all the bridge works outside of the two stations which includeds a total of 9 bridges and 18 retaining walls. The majority of work is of course complete but there are a number of defects/issues to close out and some minor work to complete.

I have also been given a HV/LV substation to complete which I have been focusing on last week. This includes padmounts, conduit runs and 6 pits which are situated on the western side of a high pressure gas main. This gas main has been a sticking point for many months and has been the cause of delay of installing rail track due to the client having not submitted the appropriate notice for a concrete protection slab to be constructed. The gas main is highly sensitive and comes with a great deal of red tape but the appropriate clearance has now been granted so work can commence. This means we need to have the substation area complete by 9 Sept when work is scheduled to begin. We have managed to pour the padmounts easily enough and have poured the base of one of the pits and I hope to pour the walls and the base of another pit by the end of the week. An issue I realised on Sat when going through the drawings with a quiet few minutes was a small note that said the concrete for the pit must contain a Xypex waterproofing additive. The handover I got from the engineer who had had this job for well over a month consisted of very little but ‘read these’ and having been initially told two of the pits must be complete by the end of last week – this gave me about 4 days since being handed the job – I cracked the whip to get productivity up – looking back it was at the expense of knowing the finer detail. The fact that it wasn’t briefed to me on the handover made me feel that the pits would be straight forward so thought lets get some concrete in that hole. I also noticed that a betonite/asphalt tape was required to be wrapped around the conduits that entered the pits which would swell on contact with water and stop/slow any ingress of water through the joints. This also made me wonder way it didn’t mention it for the construction joints between the base and walls so I have decided to order more of it and place it at the CJ’s as well. I have been quite frustrated at the inconsistency and lack of detail of the drawings which has made a simple looking job a lot more difficult. The construction manager wasn’t too concerned about my confession this morning about the concrete so I will continue as is with the Xypex batched in with any further works.

Other major works in the future include a RW that has settled and the corner has been crushed as it sits on the edge of a pile cap of Byron Rd bridge. Remedial work will have to include breaking out this corner and re-establishing the joint to not only that RW but three others that sit on the Pile Cap which haven’t yet crushed but may do in the future. The RW above these have also settled and a 50mm+ gap has opened up between panels which also needs filling to maintain noise wall integrity.

There are also some slip form traffic barrier’s to construct at two further bridges but as I will have some further barriers to do at both Dickson and Eastwood which were initially in the scope of works of the civil team I will try to do all the slip forming works together around Oct time. I have to speak to the subcontractor yet and contribute to producing the contract with the commercial team before any of this happens so that will at least give me time to do this and to also write the AMS.

The concrete strength issue of Dickson Rd piles continues with a few developments. The main development is the Project Verifier (who works for RMS as it is a road bridge) noticed that on the third day of four a different concrete mix was delivered. I really should have picked this up when we poured but I was mainly loooking to see that we received B80 (RMS spec) 50MPa 220mm slump tremie mix which we did. What I failed to notice is the different mix code on three of the dockets so I must accept a small part of the blame. However, this was not the mix I ordered which I have proved and why they decided to change the mix on the third day and then revert back to the correct mix the day after is a bit of a mystery. Both mixes are 50MPa with the same slump but the ‘rogue’ mix has a higher cement content and lower w/c ratio. I looked back at all the 10 batches I received for the piles to compare them and you can see that the concrete supplier has fairly consistently cocked up the batching. The first two rogue mixes were batched identically to the previously mix so it appears even though it states a different mix code the mix is practically the same as the project approved mix. The third rogue mix batch was in line with the design mix and is probably the one which will cause an issue with the designer. The project approved mix should have a Total Cementitious Content (TCM) of 515 Kg/m3 with a w/c ratio of between 0.3-0.4 but as you can see from the table below most of the batches don’t conform to this. The one rogue mix that is actually correct should have TCM of 635Kg/m3 with a w/c ratio of between 0.27-0.32 but the project requirements state that TCM should not be over 550 for durability purposes so this is the batch that may be a problem. The origianal issue of strength inconsistency has just about been put to bed as the project approved mix is a 50MPa product at 56 days even though the designer states in the drawings that this strength must be achieved at 28 days. Since there is no 50MPa at 28 days product approved for this project the deisgener has taken the 56 days results, applied the corrective value to convert to 28d strength (1.19 for blended concrete) and is happy that the strength achieved is satisfactory. The issue of some of the results losing strength between 28-56d has largely been brushed aside as I expected and the test samples have been blamed. However with this new information which I submitted to the deisgner through the RFI process this morning we wait to find out what implications there may be. The main issue that has been raised is the potential of thermal cracking due to the high cement content in pile A3 and therefore the issue has now become one of durability where as initially it was of concrete compressive strength.

Outside of work we have celebrated our little mans 1st birthday which to be honest he may not have realised! We and friends had a good celebration anyway with cake, beer and champagne. We also completed the City2Surf run or walk in our case this sunday which is apparently the most popular run in the world. It is certainly one of the most scenic as you go from Hyde Park in the centre of Sydney and finish at Bondi beach. I registerd with JHG so got to wear a JHG running top and sun visor – I saved a visor for you westy! It all finished with a BBQ on the beach in the JHG/Thiess/Leightons corporate tent which was a good way to end the day. As Westy has mentioned we are doing Tough Mudder in Oct which I might add I signed up to before Mr West but I’ll have to share with you his text he sent when asking if I was up for it. It certainly confused me – not that I’m saying you wouldn’t do well in a model competition mate! Not sure I’ve been called Benjo before either!

End of month (EOM) costing and further defects

The last two weeks as seen painstakingly slow progress on Dickson Rd as the site remains in the possession of the Civil team undertaking the stage 1 backfill. By fri last week they were about halfway to reaching the underside of the wingwalls and so far a job that was programmed to take 6 days (each side) is now looking like taking close to 4 weeks which will have a massive impact on the completion date of the end of Sept.

The positive side to this delay is that I have been far too busy with other things to focus on Dickson Rd much anyway. Last week was the usual EOM frenzy which refreshingly didn’t take my weekend away from me because the various deadlines all fell during the week. I have become rather wily in ‘hiding’ money in certain areas and cost codes just in case I need it which when pressed I can fully justify but hopefully when I don’t need to utilise it the gain column will look a little healthier. Across the 4 bridges neither one is projected to come in on budget according to the cost reports I produce but I am trying to err on the side of caution and hopefully when I can start closing some of these cost codes in the next couple of months the projected cost to complete can drop into the gain column to level out the cost a little and I am confident in getting all of the bridges within $50000 of the original budget. You make think that any cost over the budget would be bad but currently 3 of the bridges are projected to be $200000 over budget due to the realisation of a very tight budget that was set at tender. It is common knowledge that the JHG tender price os $550 million was about $100 million cheaper than the next rival because of their determination to win this project which was seen as a stepping stone in winning the NW Rail Link – JHG won the tender for the groundworks which is worth $1.1 billion and hope to win the subsequent stages – and the transition of JHG becoming a rail specialist contractor. So, as this is a lump sum contract which was probably underpriced it would be very difficult not to exceed the budget, this just needs to be as minimal as possible.

The other issues of the last 2 weeks has been focused on defects. The conduit issue on Scalabrini that I mentioned in my last post is a bit of a thorn in my side at the moment. I invited the client down to an ‘unveiling’ of the expansion joint cover plates but without a ribbon cutting ceremony and was largely hoping they were ignorant enough for me to bluff them into accepting the conduits as they are. This seemed to go quite well and they left happier than when they arrived and they certainly didn’t insist on us carrying out any remedial action, what they did ask is if we could submit an RFI which would confirm that everything would be alright. The main problem is I have no way of knowing exactly how the conduits were placed as the subcontractor can’t remember or probably doesn’t care and the engineer for this site when they were put in was on holiday for that week. I do have an idea which I communicated to the designer through an RFI, I sent this to the structural designer though so it came back to me that the designer who designed the services (GHD) would be better placed to answer. In the meantime the JHG design manager sent a response stating that it is crucial this is rectified and that the conduits that seem to be restrained by both sides must be allowed to move at that joint. This is exactly the response you would expect but the cost and time that it will take to rectify will be painful. At the moment I have not formally sent the RFI to GHD who may have more to say on the matter but I need to discuss this with the Construction Manager (he has been on holiday for the past 3 weeks) before we start breaking RC out which will probably result in us further damaging the conduits.

The issue of the Dickson Rd abutment A dowels in the wrong position has also played on my mind for a few weeks. I have been told in the past to only submit RFI’s if it is fully justified as each one cost JHG depending on complexity. After requesting the Design Report and calculation sheets for Dickson Rd which at times was pretty hard to follow – their presentation score on a PET project would receive a consolation mark at best. I couldn’t see an issue with the dowels being set slightly out of position within the abutment width. We still have the correct amount of dowels at the correct horizontal spacing and the dowels would still be set into the middle third of the diaphragm therefore within the same reinforcement space. I wasn’t prepared to accept my prognosis without some form of official approval though considering the entire structure is propped through the deck/diaphragm interface. TPD (client) and RMS (eventual asset owner) have not noticed the error during their checks but there is a good chance they will once we start reo fixing the deck and I want to have a response ready if/when they do. I ended up phoning the senior bridge designer at SMEC to see what is opinion was and he was under the same impression that it wouldn’t be an issue but unless he received an RFI he wouldn’t be able to crunch a few numbers and give me a formal response. So I submitted the RFI which confirmed that the dowels are alright where they are. This would have probably cost about $10000 to rectify but more importantly doesn’t delay us anymore than we currently have been waiting for the backfill to finish.

Other issues have been regarding concrete strength results. I have been trying to close out the worklot on the piling works for over two months but as it is a 50MPa tremie mix I had to wait for the 56 day strength tests as per sepcification. Boral the concrete provider have stated that it is a 56 day product but the specification from the designer states that 50 MPa should be reached at 28 days. The 28 day results for 8 out of the 10 piles were under the design strength and at 56 days there were just one pile which had one cyclinder at 50MPa and the secind at 48.5MPa. Another RFI to the designer confirmed this as acceptable and can be justified as a sample defect but the results also showed a number of the 56 day results loer than thye 28 day results. To me the practiacalassumption to make would be again that the samples must have been compromised by either poor compaction or pre-test damage to the cyclinders. The RFI response instructed me to confirm that the concrete compressive strength of the mentioned piles was in fact increasing with time and not decreasing. My first thought was the ring them up and ask them if they could suggest a sensible way in which I could achieve this bearing in mind that piles in my limited experience tend to be subterranean and it is even more of a trend to build further bits on top of them – you could say like a foundation! I can only assume they thought we had more cyclinders available to test but this unfortunately is not a university lab with an abundance of concrete to crush for fun and tests cost money. What I have done is shifted the responsibility over to the concrete supplier to justify the results to appease the designer and finally close the work lot. I have had another sub-design strength result in one of the retaining wall bases which have a design strength of 40MPa but the 28 day result is at 37MPa. Current protocols mean that the second cylinder will be retained and crushed at 56 days. This result should yield a +40MPa result.

Defects and deflection walls

The past couple of weeks has seen gradual progress on Dickson Rd as we try to complete the deflection walls so that the stage 1 backfill can start. We now have the two inner walls of abutment A side to ppur and they will be complete. It has been a frustrating two weeks to try and keep the subcontractor working at an acceptable pace and realistically we should have finished the deflection walls by the end of last week. The subcontractor is really trying to drag out the work at the moment and now seem to knock off at 1500 every day so that they are paying their workforce for only 8 hours rather than the usual 10 hours.

I have been liaising with the Civil team last week to organise the stage 1 backfill to begin as soon as the abutment B side deflection walls are complete which they now are. I mad it as simple as possible for them and gave them a sketch of exactly how I want them to do the backfill but to be honest they have a reputation for freestyling somewhat so I will have to keep a close eye on what they are doing! They will start to backfill on abutment B side first and once we have completed the delection walls on the other abutment side this week and the required curing period has passed they should be able to start on the other side the following week.

The majority of my time has been spent on closing out defect work on the other three bridges as last week was my first offical week with full responsibility for the section. These defects are mainly patching work but there are also a few outstanding jobs to complete such as abutment access stairs at Kemps Creek. I also have a rather annoying outstanding defect that is lingering about on Scalabrini which was raised by the client. This defect is simple but could cause a lot of remedial work in the not too distant future. It was originally a broken cable conduit between the Expansion joint (deck-approach slab) which was damaged during the stripping of formwork but has raised other issues as to whether we have installed the conduits according to the specification to allow movement. My supervisor being the pro-active chap he is went ahead and fixed the problem without infoming me of how and when as I am required to notifiy the client 48hrs before any remedial work is carried out. Sending this notification is a ‘Hold’ point and the actual message informs them of the ‘Witness’ point. In this case they wanted to know what our COA would be and I probably should have sent an RFI to get our approved solution verified by the designer although for something this simple I think it is debatable. The design shows the female connector cast in the approach slab side flush to the expansion joint and the male end from the deck side inserting stright into the female end. Any movement of the approach slab/deck is then not transmitted to the conduits as they are able to move in and out of the un-glued connector – fine for trains going down main but probably not going up main as the joint is pushed flush togther. The problem is the damaged conduit is right on this connector and the adjacent conduit clearly shows the join in the centre of the joint which poses questions about the other conduits and whether we have followed the drawings. We have stated that we have and it is hard to disprove as they are cast in the concrete so there would be nothing to see and we have said that the conduit with the connector in the centre of the joint is a ‘one off’ and that from a spec point of view it would work in the the same way as originally designed. A simple defect which may grow in size and at its worst lead to us breaking out part of the conduits to either prove or rectify the issue. Coupled with the fact that the joint cover plates, waterproofing and shock matting have now all been laid over the area ready for ballst to be laid could mean a lot of time and money for such a simple issue.

Regarding other news I decided to join the Sydney Harbour 10Km race last Sun to assess how unfit I have become since working 12 hour days and commuting 2 hours every day. I managed a time of 45.31 which is certainly not quick but was better than I thought given that I only managed to pass this 11 year old kid I had in my sights since the start at the 8k mark! I bought all my triathlon kit out with me thinking I must at least do one race while I am out hear but 5 months in and I been on the bike once to go to the park. I have signed up the whole family for the City2surf in Aug which is 14km from the city centre to Bondi beach but as Ethan will only be 1 its going to be more of a family walk with the buggy followed by a well deserved BBQ at the end on the beach courtesy of JHG.

Engineer and Accountant

I declined to blog last week as quite frankly I was too busy learning how to be an accountant coupled with the fact there has been little progress on site due to monsoon rains. It rained everyday last week which meant no work went ahead – the subcontractors seem to be very good at sensing rain long before it actually arrives and will often not bother turning up. One thing I have leant is that the weather forecasters over here are even worse than the UK, not even close at times!

Last week I reviewed the programme of the bridge build as when I arrived it said completion would be the first week of Sept. Last month we revised this to the end of Sept and knowing the FRP subcontractor and what effect the rain has on site progress I think we will be lucky to complete by the end of Oct. In order to keep work continuing at a steady pace I proposed to the FRP subby that we could start on the deck in between backfilling each abutment that way his steel fixers would have continuous work moving from the deflection walls to deck to wingwalls. He has told me that the company has very little work on in the Sydney area and that Dickson Rd bridge along with a few retaining walls at the station is just about all the work they have at the moment. I thought he would be keen to keep his work force going and initially he was. However the company owner came down and sacked half the workforce and so now they don’t have that problem! They say they will not work anymore saturdays – which is fine with me – and I get the impression he wants to delay progress as much as possible to take the job up to xmas. I asked him outright if that was the case and he assures me it isn’t and realistically it doesn’t serve them well to do so as this is a lump sum contract. If his blokes are not working he just doesn’t pay them so the quicker he does this job the quicker he can sack everyone if he wishes!

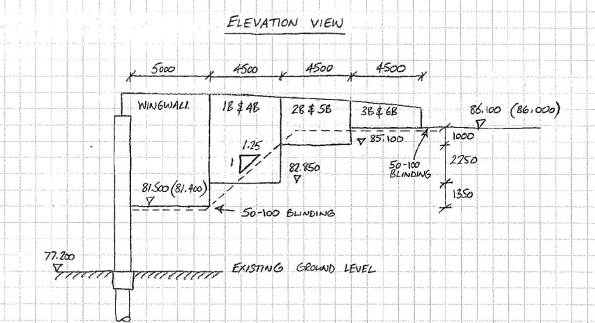

Anyway, I am going to attemp to get a little technical now with regards to the design. At present we are still constructing the inner portions of the deflection walls that butt up against the abutment wall and once we complete these we can then start to backfill material behind them. Depending on the concrete test results we are looking at about 4 days from finishing the walls before we have enough strength so that we can backfill. By staggering the work we can be working on one side while the other is curing and then backfill the first side while the other is curing. The bridge is designed as a propped structure which means we can not backfill the entire height of either abutment until the deck/diaphragm is cast, this then ‘props’ the abutments apart which reduces the bending length of the wall. We can backfill to the underside of the wingwalls without casting the deck slab but once we have backfilled we can then erect scaffolding on either side to access the deck while simultaneously working on the wingwalls. Once the wingwalls are complete we could backfill at a certain batter from the underside of the wingwalls out so that we (structures team) are conducting detailed excavation only of compacted fill for the subsequent retaining walls. This would add a surcharge onto the earthe pressure load although the backfill heigt is not going past the underside of wingwall height, so it may be sensible to cast the deck before doing so. Hopefully the below sketches explain where I probably haven’t:

I noticed in the design report for Dickson Rd that the end dowel joint arrangement was different from the AFC drawings and so enquired to the designer about why. He pointed me towards Eastwood Rd design report which has the same diaphragm/deck detail. The original design was for the PSC beams to have a slot for the abutment dowels to sit into with rubber spacer rings around the dowels to allow for movement. The dowels restrain the deck laterally and longitudinally and what I can figure out is that there seemed to be a concern over the combined effects of flexural bending and shear on the dowels. This seems to be why they repositioned the dowels to the rear of the bearing strip and out of the PSC beams. The debonded area at the end of the beams and the 50mm gap between beam and diaphragm means the beams can flex with minimal transference to the dowels. Consequently the rubber spacers have been omitted and a PVC conduit is placed over the dowel with a snug fit to ensure debonding and so taking away any torsional actions that could occur on the dowels.

The past week with the rain has mainly been spent on catching up on QA paperwork and the laborious task of uploading ridiculous amounts of paperwork for eack worklot onto the JH project pack system. I have also spent a great deal of time both work and weekend getting amonst the costing procedures I need to fully understand before next week when I will be the sole engineer on the section. My new responsibilities will include the costing of all four bridges which equate to about 62 cost codes – 15 on Dickson Rd which are all active but quite a few on the other bridges now not. The end of the month comes at about the 15th oddly enough and the forecast comes out a week after. For that missing week when dockets and invoices are not processed by the commercial team I am required to accrue work I know has been done and estimate what I think we will do until the actual end of month including what work the subcontractors may claim for so that JHG can put that money aside in their current account and keep the rest in their savings account! Invariably the estimate is not perfect and so next month you will have to place in the correct figures aginst your estimate. A week before the end of the month the forecast spreadsheets are published by the commercial team usually on a thu evening and by mon morning all Senior Project Engineer’s and me are required to submit their forecasts which shows all cost codes for all the bridges and make that it all adds up. A large part of this and what the Construction Manager is interested in is the cost at completion forecast. If any single cost code varies +/- by $5000 then you are required to explain why and I then produce a summary sheet for each bridge so he can see what state they in! Thi is also the time to ask for the budget to increase if you needed which is what we have had to do mainly because of the very low budget for craneage that was initially set aside at tender. It took me all fri to complete 5 cost codes and sat to do another 5 this month so I am not sure how next month will go considering I will have all 62 to do. Despite the extra work load I have found it surprisingly enjoyable intermingled with massive frustration when things don’t add up but I already feel like I have a very good understanding of costs related to the work I am doing and it has meant I have had to dive into alot of sub-contracts looking for rates which again is improving my contractual understanding. One thing I did pick up from the FRP subcontract is that the deflection walls have not been priced this has been forecast. I estimated the additional cost in the region of $150,000 but I am not entirely sure the subby knows that this work has not been included. Apparently it was not included in Eastwood Rd either and they have claimed for all their contract work but have mentioned nothing about the deflection walls. It will be interestig to see n a few months time whether they do realise as the commercial manager seems to think they haven’t got a clue and is secretly hoping to pocket a few hundred grand – it will certainly make my costing reports look very healthy if they don’t!

We have a bridge!

This week has by far been the most enjoyable and rewarding since arriving on the project as within 3 days the site now looks like a bridge – a somewhat unfinished bridge but we are now technically bridging one side to the other. At the start of day 1 of the lift programme I thought it was going to be one of the worst weeks so far as the 220T crane arrived on site 2 hrs before we were expecting the first delivery but when I asked to inspect the lifting gear in accordance with the lift plan they did not have the correct swift lifts. As the cast in lifting points are manufactured by a company called Reid we are required to use swift lift clutches that are also manufactured by Reid due to an early lift failure incident. Their swift lifts were not but they were also so battered they had no identifiable marks or inspection tags on them so I had to stop the lift from going ahead. When talking to the crane company head offfice they then said they don’t own any swift lifts manfactured by Reid and that then would have to hire them in. The fact that they had been told about this over month ago and the point had been reiterated to them on several occassions and the fact that this particular crane company does the majority of lifts across the project suddenly highlighted that this had been previously sweeped under the carpet, until they came across the ‘by the book army bloke’ as my supervisor jokingly referred to me as. To me there was very clear direction from the Construction Manager about the use of proprietary lifting systems following on from the lifting incident earlier in the year so how this hadn’t been spotted before I don’t know. In the end we managed to find technical literature about the Reid anchor points and swift lifts regarding the tolerances and compatibility of other makes and the crane cmpany delivered suiatable swift lifts with the correct certification and we had special dispesation from the Construction Manager under the guidance of the superintendent to proceed. We finally lifted the first bean at 1330 which was about 4.5 hours late with all the other extendabale flatbeds lined up down the main road. Once we got going we managed to rig, lift and place very quickly and we positioned the 9 beams for that day by 1600 so we made some time up but this did have an effect on later delivery’s.

This is not actually above my head! H&S has been followed.

This is not actually above my head! H&S has been followed.

The pre-cast yard told me later that day we would have 10 beams coming the following morning as they had managed to get hold of an additional truck. We actually received 8 trucks has they said because we had been too slow on the first day they had other priorities and so did not have time to load the last 2. Later on the second day they called agian saying the knock on effect would be they now couldn’t deliver the final 5 beams on sat so would mon be OK. I said that mon would not be OK at all and that they were contracted to deliver the remaining beams on the saturday and any additional costs ( the crane was $8000 per day plus a $6000 call out charge) would be forwarded to them. It then all got a little ugly and they refused to deliver on principle. It transpired they were trying to save themselves a little money by using a particular haulage company over the other and due to the time lost on the first day they didn’t have time to load the final trucks on fri afternoon. If they had loaded the trucks in the correct order or gone with the other haulage company which is based locally to them in Newcastle as oposed to the other in Sydney (3 hour drive) they/we wouldn’t have had this problem. They then said that we would have to pay for them opening up their yard on a saturday to load the remaining beams which we refused as by the second day we had made the time up and the first 5 trucks had planty of time to get back to the yard to be loaded. In the end everyone calmed down as they realised it was fri afternoon and we agreed to argue about the cost after the beams have been delivered. So the fallout of last week is that the pre-cast yard (civilbuild) want to claim for their yard opening on sat which they have unofficailaly quoted as about $4000 and we will be claiming aginst the crane company for loss of working hours and possibly the yard opening costs if it is decided we have to pay. The advice of the commercial team is that this is just civilbuild getting touchey at the end of their contract as they are trying to place a number of similar claims for past work. Considering we paid them a shade under $200,000 for 22 PSC beams of dubious quality (some of the finish and height levels are terrible and noted by the clients visits during the lifts) which equals about $9000 per beam they should probably stay quiet as we could make their life very difficult and insist remedial work is carried out on alot of the beams which we may yet do.

As the beams have now all been installed there is a sense of relief as rail can now come through without us getting in each others way. For me the pressure is about to increase as the Project Engineer who’s wing I am under is being send to another project so I am to receive rapid promotion by default I think rather than ability. I will be the only engineer on the bridge and there will be a few wrap up issues for the other 3 bridges so I seem to have jumped up to a Senior Project Engineer and will report directly to the Construction Manager. This really means I need to fully understand the cost/commercail aspect of what I am doing as I will be responsible for every dollar sepnt on the bridge and will have to justify it to the construction manager every month as part of the forecast and accrual process. We are currently about $50,000 over budget when compared against the tender costs – I just need to understand whether that is good or bad!

Abutments complete.

This week has seen more significant progress as we completed abutment B by thu and were able to strip the shutters on fri in time for the Queens Birthday long weekend which means no work on site until wed this week. The timings are now very tight to get the PSC beams in place over three days before we need to give the centre of the site over to the civil team to lay capping etc for rail to come through. Abutment A more than met the class 2 finish required and the as-built survey is all within tolerance except the position of the abutment dowels which I noticed when we were installing the dowels on abutment B. The stainless dowels are cast into the top of the abutment 210mm from the outer edge of the wall and 340mm from the centre of the wall, unfortunately the formworker placed the dowels with these measurements the other way around so that they are out of alignment by 130mm to far to the centre. As yet we haven’t raised an NCR as no one but myself has picked up on it but as it was my fault for not noticing when I did the pre-pour checks (a classic case of not seeing the wood through the trees) I informed the Project Engineer who’s repsonse at the moment is – we’ll have to cross that bridge when we come to it (I don’t think the pun was intentional!). The dowels connect the abutment to the diaphragm allowing lomgitudinal movement and then a further set of dowels are cast into the top of the diaphragm to the approach slab. I suspect we will place an NCR and RFI following the PSC beam installation as at the moment we don’t want anything to interfere with thoses dates. We have had minor surface concrete cracking of around 0.2mm on both abutments which we have had to submit NCR’s for but which are straight forward to rectify with a product called Megapoxy H. Although this is standard practice throughout the project for cracks that are out of the accepted tolerance (0.5mm post curing period and 0.1mm after 28 days) for us it still eats into time we don’t have waiting for repsonses to RFI’s and NCR’s in order to be ready to install the beams on wed morning.

As part of the AMS I have had to recce the route for the delivery of the beams and produce a Vehicle Management Plan for the drivers to aid the coordination of the trucks approaching and entering site. Eack beam is 18m in length and weighs 16T and will be delivered on extendable trucks. The access to site is not the best after the civil team have dug up various parts and placed piles of earth in odd places which means we have had to wider the route in places by ordering a few hundred tonnes of recycled balast to lay down. This has not been welcomed by the civil team who have told us we will have to make sure we get rid of it all ourselves as it is not the required spec for fill that they can use. This has been somewhat annoying as it is their job to provide the required access for everyone working in the area but as we can only really relay onourselves when we have a tight timeline we have eaten into our budget to make it happen. I have also been badgering the geotech to certify the crane pad where our 220T crane will sit. The outriggers sit on a 9m square area which is causing a few problems as although the ground in the centre is more than adequte towards the sides it becomes somewhat sloppy. I spent fri laying some more recycled balast down to all-weather the area in case we had rain over the weekend to the slight horror of the geotech engineer who would have rathered we left it as is. The ground is solid and there has been structural fill laid by the civil team but as we couldn’t get hold of a heavy roller we did the proof roll with a bogey (single truck) which comes in at 11T. We had the 55T crane still in the middle at the time so when they left and rolled over the crane pad the noticeable ruts it left didn’t fill me with agreat deal of confidence of a pass. Sure enough we have a re-show to do on wed morning by which time we have borrowed a heavy roller to properly compact the top layer.

We also managed to pour the outer bas slab of the final deflection wall and the wall part of the adjacent outer deflection wall which just leaves the wall of the recent slab pour and then all the inner wall segments that will be flush to the abutment walls. In order to proceed with those we need to alter the scaffolding once the beams are in place so that we can backfill the area up to the abutments. We comtemplated changing the programme again so that we moved straight onto the deck and diaphragms as the sub-contractor is now struggling for work. As this is the last structure to start and finish all the other strauctures are close to finishing with only FRP work required at Edmonson Park station. This has meant we have had a surge of manpower from them but the time needed to install the beams will mean they may go off onto other jobs leaving us short staffed for the reminder of the work as their priorities change. Construction work around Sydney is apparently not looking good (for them) so they have staretd to lay off alot of their personnel. In fact there only seems to be about 4 people left after the last cull which may mean I might have to get some concreteing qualifications pretty sharpish!

![IMG_2154[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21541.jpg?w=357&h=268)

![IMG_2129[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21291.jpg?w=357&h=476)

![IMG_2130[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21301.jpg?w=357&h=476)

![IMG_2144[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21441.jpg?w=357&h=268)

![IMG_2119[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21191.jpg?w=357&h=268)

![IMG_2122[1]](https://pewpetblog.com/wp-content/uploads/2013/09/img_21221.jpg?w=357&h=268)

![IMG_2097[1]](https://pewpetblog.com/wp-content/uploads/2013/07/img_20971.jpg?w=300&h=225)