Archive

Managing H&S risk during NHS strikes

Has anyone had experience of works being reduced / canceled due to lack of medical cover?

Last week I attended a Balfour Beatty Vinci (BBV) HS2 site to conduct a bridge assessment. The assessment was being conducted during the midst of the ambulance strikes which included the local ambulance trust. In receiving the morning brief and emergency procedure / actions on injury briefing it was mentioned twice that the ‘immediate action’ on injury was to call 999 and request an ambulance. When I questioned if high risk activities had been stopped for the day due to the strikes I saw a moment of panic on the on the BBVs engineering staffs faces who, after conferring amongst themselves stated ‘that’s probably an oversight and we will review that now’.

The Dee Railway collapse – the importance of Free Body Diagrams and understanding the basics

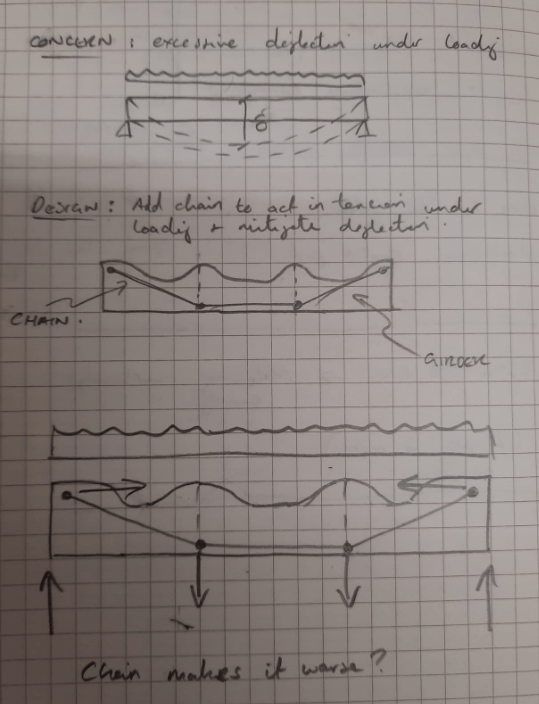

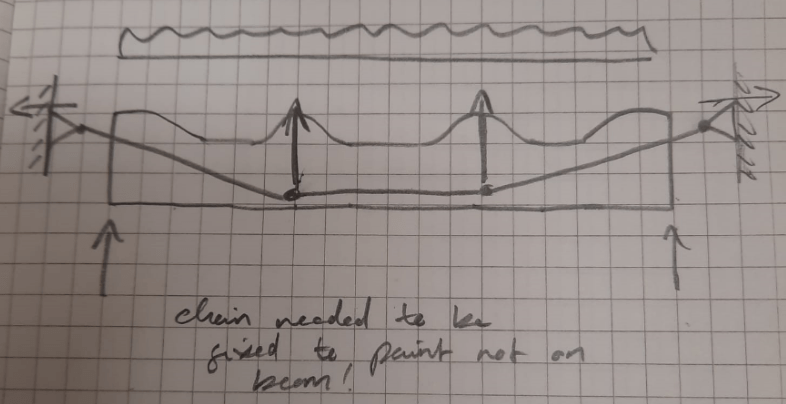

I recently attended an I Struct E lecture at Cardiff Uni on the Dee railway collapse in 1847. The main reason for its collapse was almost immediately obvious from a slide showing an image of the girder design. A quick sketch of a force diagram in my notebook showed, without the need for any math’s at all (hooray!), that the design was fundamentally floored (unsure if my scribbles below will make sense to anyone but me?).

The lecture went on to explain that the engineer responsible (the esteemed Robert Stephenson) had failed to recognize that by fixing the chain to the girder as he did, it was not acting as he intended but was actually exacerbating the problem he aimed to mitigate. This was the main cause of failure, along with other factors including insufficient restraint against lateral torsional buckling.

This reinforced to me the importance of understanding the very basics, understanding how and in which direction forces are acting and dare I say it the use of free body diagrams before I get carried away with any detailed cals. on any project I’m working on.

Interestingly enough, following the post collapse investigation the structural analysis that identified the floored design was conducted by Capt. (later Field Marshal) John Simmons RE, who was ‘inspector of railways’ at the time. Perhaps the PEW staff can search the archives to confirm but I like to think he was on PET(C) 001 completing his Ph 2/3 placement with Ye Olde Network Rail at the time.

Mental health, bullying and the construction Industry

The aim of this blog post is to start discussion about what others have experienced on their projects

“we don’t want them if they are too weak”

“he’s too weak to deal with the stress”

“would have probably been a sh*t Forman if he can’t handle the pressure”

“we don’t have room to carry weak people”

“He’s [the PM] not that bad, sure he’ll rip your head off and shout at you but he will forget the next day”

These are all phrases I have overheard and challenged in the last two weeks.

To set the context for this post there is a staffing shortage on my section of the project. This is true of both the engineering staff and foremen, with the project struggling to recruit and retain both.

Just over two weeks ago one of the sub-agents left work and has not returned since, I have been told unofficially that he has had a mental breakdown due to work related stress. Last week the stand in section foreman gave his morning brief to the other site foreman and then immediately drove home calling the team Agent to say he felt sick with stress. Yesterday morning the new foreman for my site quit having only started the day before, telling HR that having thought about it overnight he did not want to work in this environment as he had concerns for his mental health.

As I met and showed the new foreman around the site and the various elements of works ongoing he had expressed how surprised he was that the main contractor had not employed a foreman for the works associated with my bridge previously – he then witnessed the PM scream and shout at a section engineer for laying down steel in the wrong place, an honest mistake that took less than half an hour to rectify.

This got me thinking about my own experiences and what I am witnessing. Whilst I am used to operating in high stress environments (as we all are) when deployed on operations and on exercise on the face of it the construction industry (and my project) should not be inducing this level of stress in the team. No one is making life or death decisions and putting soldiers in harm’s way, there is no enemy, no one is throwing bricks or petrol bombs at us, you will not get blown up driving to site – so what’s going wrong?

Whilst researching this I have been shocked to learn that the reason the UK construction industry is ‘the UKs deadliest profession’ is not due to on site accidents but in fact due to the prevalence of suicide amongst construction workers “more than one construction worker every day [being lost] to suicide”, with 450 suicides amongst construction workers in 2016 alone (The Guardian, 2019) and 26% of the workforce considering suicide in 2019 (CIOB, 2020).

I have gone on to read that contributing factors include being away from home (weekly commuting), the physically demanding nature of being on site, financial pressures and job security. Many of these pressures exist in the military so what’s different?

I think there are two key factors. Firstly, and most obviously all service personnel are salaried and so job security is not a concern. Whilst there is a definite and enforced Chain of Command this enables unacceptable behaviour by superiors to be challenged without risk of losing your job. There is also a strictly enforced discipline process to correct behaviours and a complaints process open to all. I have read that 21% of construction workers experienced bulling in 2021 (HSM, 2021). In my opinion the PM for my section is a bully. He will forcefully bully those he is able to into agreeing with him, and is very derogatory towards those he does not agree with or respect. Most worryingly he received a company award at last month’s summer function for “the person who always delivers results”. Whilst he certainly delivers I wonder at what cost in the long term?

Secondly, there is a welfare support network available to every soldier. Firstly, through the chain of command, with Army wide policies on mental health and welfare as well as unit policies for management and implementation. Service personnel also have access to support independently through the welfare department within each unit in addition to a plethora of service charities. This is not the case for most construction workers with the CIOB finding that “56% of construction professionals work for organisations with no policies on mental health in the workplace” CIOB, 2020). I have not been able to find any policy produced by the contractor I’m attached to (and am yet to find anyone in the company who’s ever seen one for a contractor they have worked for in the past).

Feeling insecure or unable to raise concerns, and having nowhere to turn to when struggling to cope is seemingly proving to be a fatal combination for construction workers.

Is what I’m witnessing an exception or a sad industry norm? I am curious to know what other people are experiencing on site? Do your companies have policies on mental health? Are people you work with confident / feel secure enough to call out unacceptable behaviours?

References:

https://www.theguardian.com/society/2019/aug/13/why-do-so-many-construction-workers-kill-themselves

https://www.hsmsearch.com/Survey-reveals-impact-bullying-construction

Design & Build – or Build, Design & Re-build?

The project I’m working on is using a ‘Mutual-Investment-Model’ (MIM) form of contract, which is a Welsh Government type of Private-Public-Partnership (PPP). As such a special purpose vehicle (SPV) (Known as Future Valleys Construction – FVC) has been formed with the main contractor (FCC) and designer (Atkins) both being part of Future Valleys Construction and operating a ‘design & build’ system to deliver the project. The Welsh Government has a minor equity stake in FVC and so any profits are in part shared between the Private and Public participants in the contract.

A key benefit of Design & Build contracts is that they allow for works to begin rapidly – in theory this should reduce the overall project duration, reducing cost, as design can keep pace with construction and issues be resolved as they materialise or are realised on site. In addition, from a client point of view the risk lies with the main contractor as a price is usually agreed up front for the delivery of the project – in the case of the A465 widening this is set at £590m.

Across the A465 widening scheme, and in particular on my site works are beginning before ‘for construction’ drawings have been issued and designs finalised. Work is being done using ‘for information drawings’. I have been told that this is to save time and allow the overall programme to be accelerated. However, I have come to question this logic.

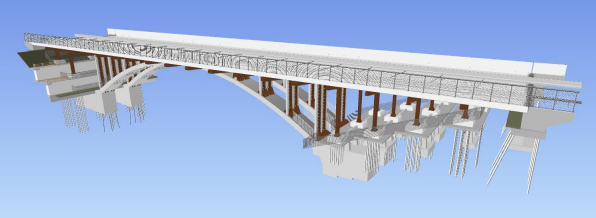

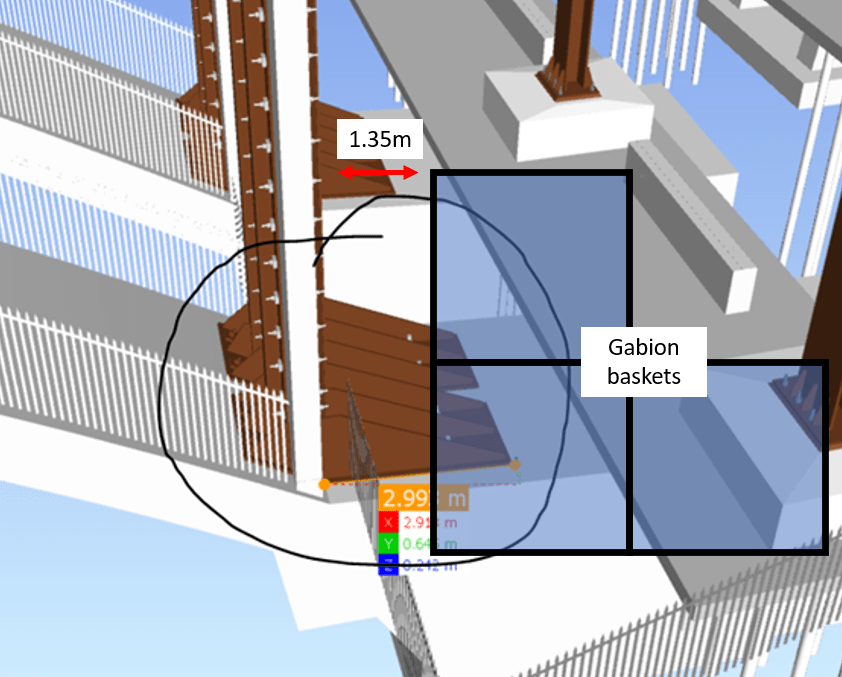

My project is a bridge strengthening and widening. In order to keep pace with the programme for the overall scheme, piling works must commence on my site on the 1 Jun 22. Pressure has been applied to start earlier. Currently on the East bank Gabion retaining walls for piling platforms (temp works) are being constructed and on the West Bank an access track cut so that retaining structures can be built there also. Both of these packages of work are forecast to be complete by late April (over a month in advance).

What has come to light since is several clashes with the permanent works which has forced a redesign of the temporary works. I have conducted my own initial review of the designers proposed solutions and believe that if they are accepted its likely that everything that has been built since my arrival on site may now be stripped out and rebuilt (which is equally soul destroying and comical). Not all of the materials used will be recoverable, meaning waste, environmental impact and cost. Plus the subcontractor executing the works has been charging day rates – further wasted cost. This is not only a significant financial expense, but also cuts into any profit share for both the public and private sector partners. In summary we have added significant cost and saved zero time – yet are still on track to be ready for piling on 1 June 22 so will not affect the overall programme.

To make matters worse, a 3D model exists of all the permanent structures on this scheme – by modelling the temporary works in the 3D models these clashes and issues would have been painfully obvious. Having asked why this isn’t happening I’ve been told ‘because the temp works change all the time its hard to model, we would have to keep re-modelling them’ – I was left pretty amazed by the reply, this is exactly why they need to be modelled! I am a complete convert to BIM for design and see just how beneficial it is to the industry. Having discussed this further with colleagues here I have realised just how unfamiliar any of the engineers are with REVIT or any other form of BIM.

I think for Design and Build to truly be beneficial and the benefits of BIM to be realised the process should be:

Partial Design (initial design) -> build virtually -> resolve issues -> build on site

What I am witnessing is this:

Partial design -> build on site -> identify issues -> re-design -> strip out and rebuild

Has anyone else had a similar experience? Has anyone actually saved time or cost in construction this way? What’s peoples experience on site been of BIM and modelling ahead of live construction?