Archive

USACE Sustainability Resources

Today I discovered USACE’s Sustainability youtube channel. I though the channel would be of interest to PET students and PQEs alike.

I haven’t had chance to watch any of the videos/webinars (yet!) but have subscribed to the channel so I can watch later. The USACE/ERDC presentations are usually high quality and very informative.

Some questions to start some debate:

- How do you think we can make military engineering more sustainable?

- What should we do as a Corps to be better stewards of our resources and the environment?

- Can anyone provide examples where they have incorporated sustainability into Operational Infrastructure design and delivery? If so how did you secure funding and demonstrate value for money?

- What shouldn’t we incorporate into military engineering projects?

- For the students on attachment in Baltimore or about to head out that way – how do the videos compare to what you experience on site and in the District office?

Common Data Environments / BIM Discussion Topic…

Does anyone on the blog have experiences of Common Data Environments (CDE) or BIM to share from their Phase 2 or 3 attachments?

What was good / bad about it?

What system(s) / software / hardware were used?

What user training was required?

If the system was in the cloud how was information security assured?

Innovative Bolt Tensioning

Ever had issues on site with proving bolts are tightened correctly? Normally this results in using the part turn method or a torque bar/gun but often there are challenges determining the correct ‘torque’ compared to the required bolt tension. What if there was another way?

This American company (Smart Bolts) are offering smart bolts with an indicator that changes colour as the bolt is tightened. The colour change is based on bolt extension which is linked to tensile force (F = ke in the elastic range). Below is a video demonstration/sales pitch of how it works.

Pros:

- Visual indication when ‘correct’ tension is reached.

- Simplicity on site.

- Torque equipment or testing of bolts isn’t required.

- Bolts can be re-used provided elastic limit is not exceeded.

- Ease of checking during operational use/maintenance.

Cons:

- Bolts cost more than standard bolts.

- Codes/APoC may not recognise the installation method.

- Increased to me to verify each bolt’s colour change.

- Colour changes are at set increments based on bolt design limit and may not correlate to site purpose/requirements.

- Operational service life ‘over 20 years’ may not be long enough for structural steel applications.

I’m interested to see how this technology develops in structural engineering applications. There may already be some military engineering applications where the bolts would be useful. What do you think?

Long term lessons learnt?

Yesterday during the Comdt’s backbriefs the issue of lessons identified/learned was raised. This prompted me to finally write the blog post I planned to write a while ago and never got round to completing but with different conclusions.

The apartment I’ve been renting in Melbourne has 14 storeys above ground and a 2-storey basement. As far as I can establish, the building was around in 1996 so is at least 24 years old but could be older (internet research is currently drawing a blank).

Why is this important? Yesterday we discussed whether we are failing to truly identify and learn our successes or failures immediately after an event. Generally, the consensus was that we are bad at ‘learning lessons’. If we fail to do this in the short term, I suggest we are even worse at identifying our successes or failures further down the line… say 24 years later.

Our car parking spaces are on basement level 2 so approximately 6-8m below ground level. Following rainy weather, there is always water on the floor of the basement (Melbourne’s climate is similar to the UK so there’s a fair bit of rain). The water appears to enter the basement around the service penetrations (ventilation ducts) and through construction joints in the diaphragm walls and at the wall-column interface. I’ve taken a few pictures to show what I mean.

(Note the water penetration is from the vent ducting at the top of the picture and not the pipe.)

Why is this an issue? Well for me and the other residents our stuff gets wet. This is annoying but can be worked around. The bigger issue is structural durability because the ingress of water can increase the reinforcement corrosion rate and could lead to early failure of the wall. At the service penetrations and column-wall interface, there is likely to be sufficient cover to protect the reinforcement however at the mid-height wall construction joints there won’t be. I’ll hedge my bets that the contractor didn’t apply an additional protective coating to the rebar at this location meaning the reinforcement will corrode quicker.

So here are my thoughts on reviewing the construction/design issue 24 years later:

- Why were construction joints used at mid-height?

- Could the pour height have been increased so the basement walls were poured in one go? If not (due to concrete drop height or safety issues) could additional reinforcement be provided at the construction joint or a protective system employed to mitigate against corrosion?

- Was the ventilation service penetration part of the original design or was it added at a later stage?

- Was the sealant around the ventilation penetration fit for purpose and was it installed correctly?

- Has the sealant’s design life been exceeded and not replaced? Is poor building maintenance an issue here?

- Have any of these issues been highlighted to the Designer/Contractor to influence their future decisions/works? I suspect not.

My consultant does a lot of inspection of old bridges for asset owners which allows them to identify issues with historical designs that can be adapted or mitigated in their current designs, hopefully avoiding similar issues in the future. I’m not sure if the same exists in the vertical construction space but a feedback loop from building condition surveys to designers would be one way to improve future designs. I admit I don’t have the answers but hopefully, this post will spark some further discussion.

FPE Basics

I stumbled across this at work today. It’s an article published in The Singapore Engineer in April 2018 and is written by engineers who work in one of SMEC’s sister companies.

The article covers Singaporean legislation requiring buildings to be protected to prevent terrorist attacks. From what I remember of the FPE Level 1 training on RETCC and subsequent insights at 170 Engr Gp it also covers the basic FPE assessment process and principles.

I thought I’d share for two reasons:

1. As basic revision prior to the Phase 4 FPE Level 2 training.

2. So we can compare UK military practice to the civilian consultant approach. At this stage, I suspect they are very similar.

Protecting Infrastructure Against Terrorist Attacks – Surbana J (sorry for the poor quality of the images but a pdf print copy was the best I could manage).

West Gate Tunnel Project Contract Dispute Continues…

This week there was some interesting developments in the ongoing dispute between the WGTP Client and Contractor. As a reminder, Transurban is acting as the Client and funding ~£2.8Bn with the State Government funding ~£0.82Bn.

Australian Financial Review Article

In summary, Transurban is seeking an injunction at the Supreme Court to prevent ‘premature’ arbitration by the Contractors over the disposal of contaminated soil. In Supreme Court documents, the contractors have stated Transurban has engaged in “misleading or deceptive conduct…in relation to the extent of PFAS affected spoil likely to be encountered at the site.”

This case highlights the importance of ‘back-to-back’ contracts as Transurban have repeatedly approached the State Government requesting to terminate the Project Agreement if the Contractor’s claims of a force majeure event are successful. The Victorian Government’s response so far is “that no force majeure event has occurred”. I think the merry-go-round will continue to spin for a long time yet.

My assessment is that Transurban’s attempts to delay arbitration proceedings is to buy time to gain a better understanding of their predicament. More time gives the lawyers more opportunity to find wiggle room in the Project Agreement. Knowing where they stand with the Project Agreement provides increased certainty on where final arbitration costs or penalties could end up (quite literally passing the buck…). If Transurban enter arbitration proceedings knowing the Project Agreement is/isn’t going to be terminated, they will have a stronger negotiating position and will know how much they will need to ‘invest’ in the process and their lawyers’ fees.

Work on the project sites continues however job losses are now at 450 (~11% of the workforce) due to the impasse. Although initially targeting site operatives this month the engineering and management teams have been hit with further cuts at engineering level expected. On the day John Holland posted a ~£33M annual loss, its ironic that the only winners in all of this will probably be the lawyers…

Defence Lecture – Sustainable Engineering: Carbon Neutral by 2050

The ICE members will have recieved the June newsletter yesterday with an invite to online lecture on 22 June. For the E&Ms the good news is the lecture is sponsored by the InstRE so I’m hopeful you can also attend for free. As an added sweetener, Maj Gary Jackson (E&M) is one of the 4 speakers.

Registration is via the ICE website (link below) or the InstRE website (details to follow).

https://ice.org.uk/events/defence-lecture-carbon-neutral-by-2050-london

I thought this is an excellent CPD opportunity for us all as military engineers and is likely to be a dominant theme for the rest of our careers so is probably not one to miss! The only down-side is it starts at 0330 (3 June) for the Australian students but a more reasonable 1830 for those in the UK.

As military engineers are we asking questions like Why are existing MOD buildings not covered in solar panels? Why there aren’t more wind turbines in training areas/camps? and Can we make more use of rainwater harvesting across the defence estate?

Why do I think sustainability will be a dominant theme for us in future? Below are some references for your consideration.

ICE sustainability Route Map and links to UN Sustainability Development Goals: https://www.ice.org.uk/knowledge-and-resources/sustainability-route-map

How is DIO promoting sustainability? https://www.ukconstructionmedia.co.uk/features/dio-promoting-sustainability/

Sustainable MOD Strategy (2015-2025) https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/498482/Sustainable_MOD_Strategy_2015-2025.pdf

Sustainable MOD Annual Report 2017-2018 https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/754154/SustainableMOD2018.pdf

DE&S Sustainable Procurement https://www.asems.mod.uk/sites/default/files/documents/EMP/Sustainable%20Procurement%20V2%20Intro%20Guide.pdf

VR just a matter of clicking the right buttons?

Nothing too in-depth in terms of engineering but this article might be of interest as an overview of where current consultant thinking is with VR.

Concrete Repair Procedure

Sadly E&Ms this is one for the Civils but feel free to read if you want.

This week I was asked to assess a contractor’s proposed concrete repair procedure for precast concrete road barriers (similar to the central reservation barriers on the M25 or M6).

A repair procedure was required because the end stops had slipped during the pour resulting in 10-15mm excess cover at the ends of the barriers. The contractor’s proposal was to saw-cut or grind the concrete back to the design cover so the barriers met the precast dimensional tollerances. Having seen this done on phase 2 site for in-situ patch and crack repairs, I thought it was a reasonable proposal providing adequate H&S measures are employed.

After checking the project specifications for concreting and precasting I found no reason to reject their method. Prior to approving the Contractor’s RFI, a senior engineer reviewed my work and insisted that 3mm (min) of Megapoxy P1 mortar repair grout must applied to any cut or ground surfaces. He explained this is done to the ends of precast super T beams when they cut the prestress strands as 3mm of Magapoxy P1 equates to 50mm of cover.

I can understand why this is done on the super Ts however the road barriers have standard reinforcement (no strand) so is there really a need to apply Megapoxy in this case? I challenged the decision on the basis that it may not be required as that the original design cover would be maintained. In my view the Megapoxy P1 requirement is a potentially unnecessary cost (time and money) to the contractor. I was told if the contractor doesn’t like it they will let us know…

Does anyone have any previous experience of this? Is this another case of ‘this is what we’ve always done’ or is there another good reason to apply a layer of repair mortar?

Technology in Engineering

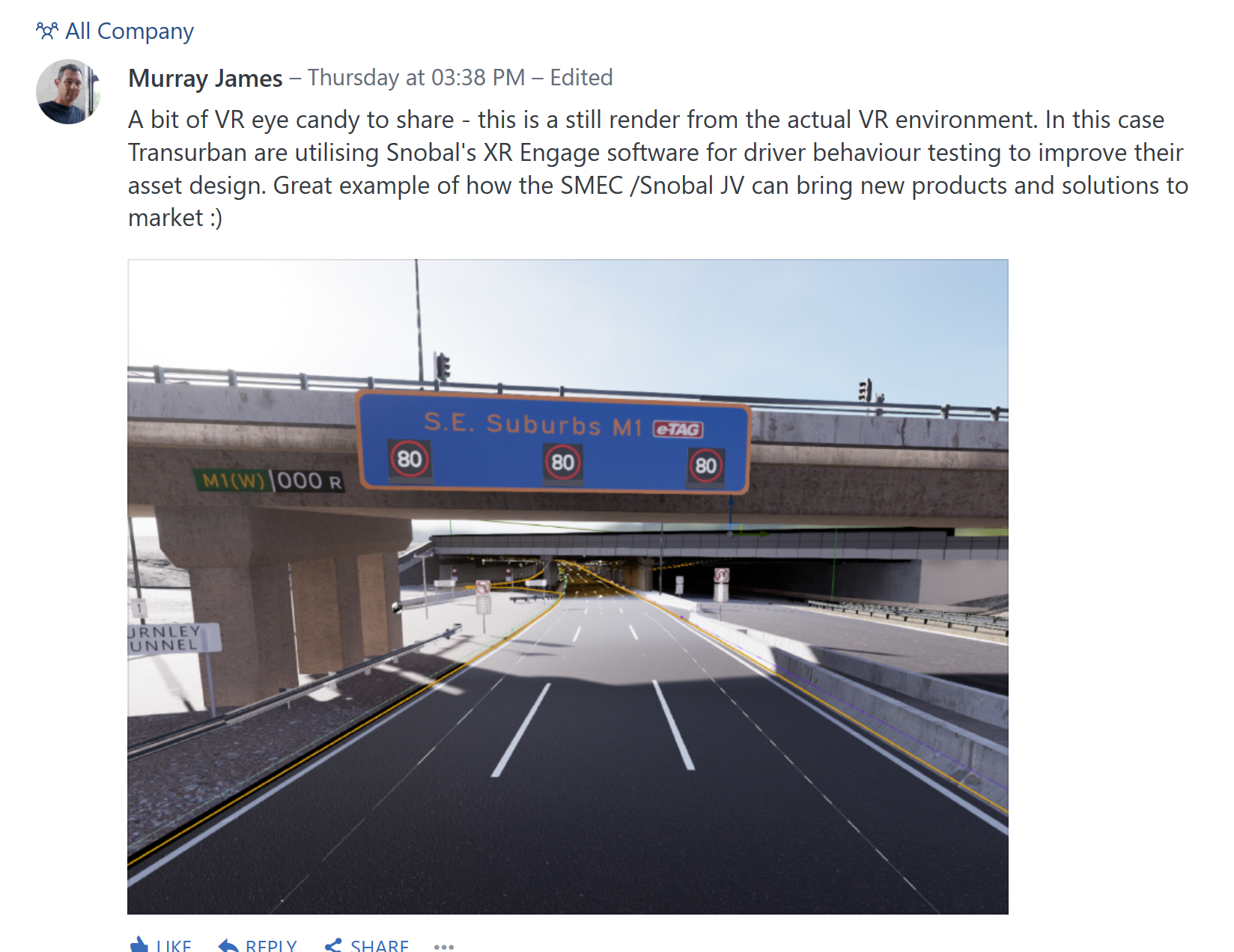

Tom I remember you asking about companies using VR technology. Below is a still from SMEC’s internal blog.

The image is a still from a VR model developed by Snowbal’s programmers as part of a JV with SMEC to push the boundaries of their current VR technology. From an inital glance it looks pretty convincing.

We have a team of programmers based in the office as well as VR technology including a driving simulator (think arcade racing car set up). This enables Clients to get a immersive VR presentation of a design or for the engineers to asses and improve different design options.

I can see this being really useful for highway/rail/building and services design. Is anyone experimenting with this on Phase 3?