Archive

History vs Modern Needs

Did anyone have any interesting issues thrown up during their phase 2 relating to historical artifacts or heritage? We had a few items discovered on my Batemans Bay project.

A key part of sustainability is reducing the negative impact of our engineering on society. I remember Dave and Tom providing earlier blog posts discussing the reuse of building facades vs entire reconstruction. On Sunday I came across this gem so thought I’d share. Sorry for the double picture but I couldn’t get it all in one shot.

This is a historic building that used to be a lead pipe and shot factory that now sits inside one of Melbourne’s shopping centers that is built above Central Station. Clearly there was some kind of preservation order on the building so the new construction was built around the old to preserve it and transition to commercial use. I’m sure there were contamination issues to overcome but an interesting way of preserving the building for the future.

A useful reference for any Australian PET Student

Hopefully, if I’ve uploaded the document correctly the link below should be a useful reference for any PET student in Australia dealing with reinforced concrete. I wish I’d known about the reference on Phase 2 as it would have made site works so much easier. I just been shown the reference half-way through Phase 3 and wish I’d been shown it at the start of my consultant placement.

Z 06 – Reinforcement Detailing Handbook

Health warning: the link above is based on AS3600-2009 the latest version of the code is now 2018 so check and see which version is being used on your site/project and find the 2018 version if you need to.

For the civil students, it is a combination of Concise Eurocode 2, Economic Concrete Frame Elements to Eurocode 2 and the concrete equivalent of the blue book. It also contains detailed guidance on how concrete and reinforcement drawings are drawn to Australian standards (generally not different to UK standards but helps plug the gaps left by Phase 1).

For any E&M students, it’s a ‘concrete cheat-sheet on steriods’. Worth a check if you need to know the requirements or principles behind the reinforcement or concrete in reinforced concrete. The book also contains lots of look-up tables so you don’t have to calculate minimum lengths from the code clauses and explains what all the drawing symbols mean.

A question for the PEW staff – does the wing have a list of useful design references? If not, it could be a useful reference for the students in Phase 2 and 3 (and beyond) particularly if the list maps the UK standards to the Australian and American equivalents. Any thoughts?

Next year’s PCM exam?…

In Melbourne there is currently a situation straight out of Greg Tripp’s PCM exam…

Project Setting:

The West Gate Tunnel Project is an A$6.7 Bn portfolio of projects to improve East-West journeys through Melbourne with a target completion date of 2022. The project is funded by the Victorian Government who has employed a private company (Transurban) to deliver the project. In the project setting Transurban is acting as the Client. The designers are an Aurecon Jacobs JV (AJJV) and the contractor is a CPB and John Holland JV (CPBJH). AECOM and SMEC have formed a JV (ASJV) to fulfill the Proof Engineering role.

The problem:

The tunnel alignment runs through a site that was previously used as the Country Fire Authority’s Fiskville training college. The site was known to contain soil contaminated by PFAS (Per/Poly-Fluoroalkyl Substances) which was used in legacy firefighting foam. The college closed in 2015 partly due to the PFAS contamination risk.

I understand at the time of signing the contract, the Client and Contractor JV were aware of the presence of the PFAS. However, since signing the contract, the Australian Environment Protection (EPA) Agency has classified soil containing PFAS as contaminated material. Despite determining PFAS as contaminated waste, the EPA has not issued a classification for the waste which means it cannot be transported off-site for disposal. Consequently, the TBMs have sat at the bottom of their entry shafts for 6 months and not moved an inch and over 130 staff have been laid-off.

Although I have not seen the contract, the media is reporting that the Victorian Government’s contract with Transurban transfers the risk of soil contamination onto Transurban. As the issue has not been resolved after 6 months CPBJH has notified Transurban they wish to terminate the contract arguing a ‘Force Majeure Termination Event’ (an event beyond the control of both parties has occurred preventing a party from fulfilling their obligations). Despite the commercial dispute works continue on-site and in the design offices.

The Stand-Off:

CPBJH’s intention is to negotiate a new contract for the completion of the remaining works.

Transurban disputes CPBJH’s notification and is arguing the contract remains valid.

The government is arguing that Transurban and CPBJH must resolve the dispute and the project must still be delivered on schedule.

The workers union is putting a lot of pressure on the Victorian Labour Government due to the number of workers affected by the delayed works.

What do you think?

- Who owns the contamination risk?

- Was the contamination foreseeable to the Contractors?

- Does CPBJH have a right to claim a Force Majeure Termination Event?

- Who should bear the cost of building a new contaminated waste disposal facility for the PFAS contaminated waste material?

- Should the EPA bear more responsibility for the impact on-site?

- How involved in the resolution should the Victorian Government be in the resolution?

- Where do the AJJV and ASJV stand if they conduct design and review work after CPBJH has notified Transurban of their intent to terminate the contract?

- Dan you worked on this project. Any inside thoughts?

Government Warned 6 Months Ago

West Gate Tunnel Builders Seek to Terminate

Eurocode Simplified?

A quick one for the civils (and maybe even the E&M’s if you ever get asked to look at a future civil problem…).

When working on my thesis I stumbled across this website: EurocodeApplied. Basically, it provides free online calculation tools for structural design to Eurocode. You select the relevant check, enter your input data and select any relevant National Annex limitations. It also summarises key data from the code without having to find every table or figure.

There are pages for EC1 – Actions (including wind actions), EC 2 – Concrete (creep, shrinkage, durability, axial and bending checks, shear design and detailing), EC3 Steel (steel properties like the blue book and section capacity checks) and EC8 Seismic (actions, fundamental periods, reductions of earthquake actions during construction and foundations/retaining structures).

Sadly I’m not doing any design to EC over here so I’ve not been able to validate their accuracy. If any of the Civil crew are doing wind loading or simple checks and want to try them out I’d love to know if they are a good source. If validated, it could be a really useful tool for future PET or Clk Wks students depending on how kind the PEW lecturing staff are feeling!

An unexpected risk?

Has anyone’s consultant issued guidance following the Covid-19 (Coronavirus) outbreak?

My consultant is owned by a Singaporean holding company. Their business stragtegy is to create a consultancy powerhouse in Asia so the outbreak is ‘bad for business’. Already, they are reporting that the virus will have a significant impact on this years profit figures. (The financial year runs Jan-Dec over here).

What I have been most surprised and impressed by is the direction all employees of the holding company have been directed to take. It was almost like military orders! A range of measures have been implemented to protect employee welfare/health and safety and to mitigate further business impacts including:

- Cancellation of all non-essential travel to China, Hong Kong, Singapore etc.

- Authority to travel to these countries is required by company CEOs.

- 14-days self-imposed quarantine (working from home) for all employees who travel through or have close contact with people travelling through the countries above.

- Doctors note required before returning back to work.

- Workers in affected countries are all working from home to minimise further spread of the virus.

Interestingly there was due to be a large formal dinner planned next week for all elements of the Singapore business and the senior management of companies outside of Singapore. This was postponed (prior to Singaporean guidance to avoid large gatherings) because the cancellation fee was considered a small price to forefit compared to the risk and cost to the business if the entire senior management became incapacitated. All staff were informed of this decision in a direct email from the CEO explaining why the decision was being made.

I know John Holland have long had a policy of senior management travelling to meetings via different flights so an accident would not wipe out the entire senior management and to maintain avaliability of business leaders at all times. This us a very similar concept to not having the Commander and 2IC permanently co-located on the battlefield.

Our office was also due to benefit from a surge of structural engineers for a couple of weeks from a JV partner. The extra engineers were due to arrive from Hong Kong but with the 14 day quarantine requirements this is now up in the air. Wider project impacts are yet to be determined.

Aware this topic is probably ‘closer-to-home’ for the Australian crew but I’m wondering if any of the UK companies have implemented business continuity plans or if it’s not on the radar. Any thoughts?

Planning for future sustainability?

I often think of sustainability as the design decisions made to balance the social, environmental and economic cost if construction. Often engineers look to reduce material consumption through design but how often do we design for disposal.

Linked to the theme of building being material banks is this BBC article on the disposal of wind turbine blades. The turbines built in the 90s are now over their 25 year design life but the materials selected for their mechanical properties are proving difficult to recycle. You can read more at the link below.

Food for thought perhaps?

BBC News – What happens to all the old wind turbines?

https://www.bbc.co.uk/news/business-51325101

Phase 3

I am working for a multidisciplinary consultant called SMEC. Most of you won’t have heard of them because they don’t operate in Europe but SMEC’s Signgaporian parent company also owns Robert Bird Group so may move into Europe before too long.

SMEC was formed from the team that delivered the Snowy Mountains Hydroelectric Scheme 70 years ago for the Australian government. The scale of the project was insane (more details can be found here http://www.smec.com/70years/).

I am working as a structural engineer within the transport division which mainly focus on bridge design, retaining walls and gantries. Since December I’ve been involved in Proof Engineering for the Westgate Tunnel Project (WGTP) – effectively independent checking JV produced designs for code and project compliance. (Basically resolving all Dan’s phase 2 RFIs). So far I’ve looked at the structural impact of out of tolerance construction, pile and pile cap redesign, amendments to RC detailing and temporary works packages.

Away from the WGTP I’ve also assisted with load assessments of new cranes on existing structures. As the client required an answer in a short time-frame, we used existing models to conduct a comparative analysis between the maximum loading from existing load cases and the new vehicles loads to determine if the new vehicles could be trafficked. Initially the loads exceeded the capacity but manipulation of dynamic and combination lane use factors by more experienced engineers reduced the loading to under 80% of the maximum competitive load. Has anyone else come across any ‘tricks-of-the-trade’ that would be useful to military engineers?

Anyway Enough about what I’m up to. From recent blog posts the list below is where I think we’re spending Phase 3. Please feel free to fill in the blanks, I’d be interested to hear about what you’re working ok and how your finding Phase 2 compared to Phase 3.

- Dave – Arup Oz

- Gareth & Ali – USACE

- Rob – electrical design linked to EDF and Scottish windfarms?

- Jambo – Plymouth bases building services design

- Alex – ?

- Ben – BP?

- Gary – WSP?

- Jon – Arup uk?

- Al – SRM Temp Works

- Dan – Aurecon

- Ash – Bam Nuttal

- Tom – Wentworth House temp works design

- Colin – ?

Technical Information Management

Having left my Phase 2 site last month I reflected on the number of IT systems used and wonder what the military should learn from rather than copy. I observed the following:

- Drawing Management. A single repository for all technical drawings that can be accessed by all stakeholders (Designers, T1 contractor, Client, Project Verifier and Sub-contractors) is an efficient way of ensuring all parties have access to the latest drawing versions. The project used a web-based IT system called ACONEX which can be accessed from any internet-connected device (including mobile telephones and tablets on-site). It has a good search feature that displays all drawing revisions so changes are easily identified. Updates to drawings are notified as transmittals with all parties informed as automatically part of a mailing list. The disadvantage of the system is that not all stakeholders are willing to use ACONEX to share information (external stakeholders often revert to email) which increased the burden on the on-site team to update the drawings stored within ACONEX to prevent information becoming outdated. As the transmittals are not individually targeted or area-specific, it was easy to miss key information due to information-overload and the requirement to manage multiple IT system inboxes. Overall, I believe ACONEX fulfilled the drawing management role well for large scale projects when it is used correctly by all stakeholders and appropriately resourced with a dedicated document controller. For military projects, the same effect can be achieved via SharePoint and email.

- Formal Messaging. ACONEX also has an email/messaging capability but unlike email, every message is serialised, cannot be deleted and is viewable to all project users. These features are both advantageous and disadvantageous across a range of safety, legal, quality and commercial issues. The system enables collaborative working as all staff have access to all information which is handy when individuals are on leave or out of the office. For these reasons ACONEX messaging was accepted as the formal notification system within the project contract and is used for all formal correspondence, Requests for Information (RFIs) and recording key decisions. Another disadvantage of the system is the requirement for individuals to manage an additional system to their email. ACONEX is a good system for formal messaging on large scale projects however for military projects the same effect could be achieved via a formalised written letters/memos emailed to parties with pdf copies uploaded to SharePoint.

- Collaborative Working. Every organisation involved within the project has their own data repository where information confidential to the organisation can be stored and accessed only by members of the organisation. Examples of this include commercially sensitive information, interim programmes, work in progress (WIP) and interim quality records. The project used SharePoint to enable collaborative working across the Alliance Partners as this avoided server access issues. The software is fit for this role but the effectiveness of information access on-site was limited by the different companies’ technology hardware and individual user software licences. SharePoint is already used by the military for in-barracks data storage. Unfortunately, some deployable IT systems are dated and do not have this capability or lack internet access. Where this is the case, files are shared via local network storage devices or transferred between individual computer storage. In these instances, version control is essential; significant time and resourcing must be devoted to data management practices. The user is responsible for the archiving of data beneficial to future business output but this vital step is easily missed; as highlighted by the 2018 TICRE data amnesty at 170 Engineer Group, which identified significant gaps between the data held by TICRE and the individual Works Groups.

- Company Developed Software. The project used a JH online application (Project Pack Web) to record and track key project information useful to business output. The application was used for procurement, risk management, environmental monitoring, and quality records. The Client and Project Verifier had limited access to the quality record element for the notification and release of hold and witness points. The system allows JH’s regional business team to monitor key information required for business output in the same way that Brigade and Divisions can view Unit information within ODR and JAMES. Work Lots were used to group all relevant information for a specific work activity into one record for ease of reference. This included Activity Method Statements (AMS), ITPs, checklists, permits, defect lists, hold and witness point approvals, materials, sub-contractors and related works. The Work Lots form the basis of the Client’s handover file at the end of the project. The advantage of this application is that the regional business has visibility of project information, Work Lots are generated as part of day-to-day activity and in-house software can be adapted to meet the needs of the project. The disadvantages are more bugs compared to commercial software and it can be clunky to use. Unfortunately, the system was not used to its full potential and there are some areas that failed to provide adequate functionality resulting in duplication of data. JH is currently involved in a number of JVs and partnerships where different IT systems are used. This reduces JH staff familiarity with in-house software causing skill fade and additional training requirements. For large construction projects, PPW type software has significant utility and if properly resourced and developed. The majority of military infrastructure projects have simpler quality requirements and use existing defence procurement systems. In the military context, it would be more cost-effective to identify appropriate Work Lots at the start of the project and use an electronic file structure to archive quality records. The tracking of other key resources and data can be achieved via spreadsheets on SharePoint or a local area network.

What are your experiences from Phase 2? Has anyone come across any better systems for use in a military context?

High-Rise Concrete Pump Cleaning…How?

Walking around the high-rise construction in Melbourne I’ve been asking myself one question… How do they clean the static boom pumps and concrete lines after a pour? I know significant ALC charges were incurred for not cleaning the ANEMOI Volumetric mixers properly before shipping them back to the UK.

At Batemans Bay we cleaned mobile boom pumps via ‘blowing out’ into skip bins and washed water through the discharge hose but I’m guessing this isn’t practical in vertical construction.

When using a fixed/hardline pump a foam ball was forced along line at the end of the pour to remove all the concrete so the line could be left in place. I’m guessing a similar approach is used in high-rise construction. Does anyone have any experience or insight?

Another question I’ve been pondering is how are the pumps stages increased? Do you have to strip the top section and use a tower crane each time you increase a floor?

Australian Fires

Hopefully this post will keep the E&Ms happy as it has nothing to do with engineering!

Some of you will have seen the Australian Bushfires on the news and just flicked past the articles without too much thought.

A few weeks ago, the fires were particularly bad west of Sydney, causing the air quality in the city to be equivalent to smoking 40 cigarettes a day.

Most of the Australian countryside is like a tinder box with high temperatures and little rain making it perfect conditions for the fires which have continued to spread. Last night strong winds and dry lightening storms added to the number and scale of the fires. (The winds were so strong a volunteer fireman was killed when the wind lifted and overturned his 10t truck).

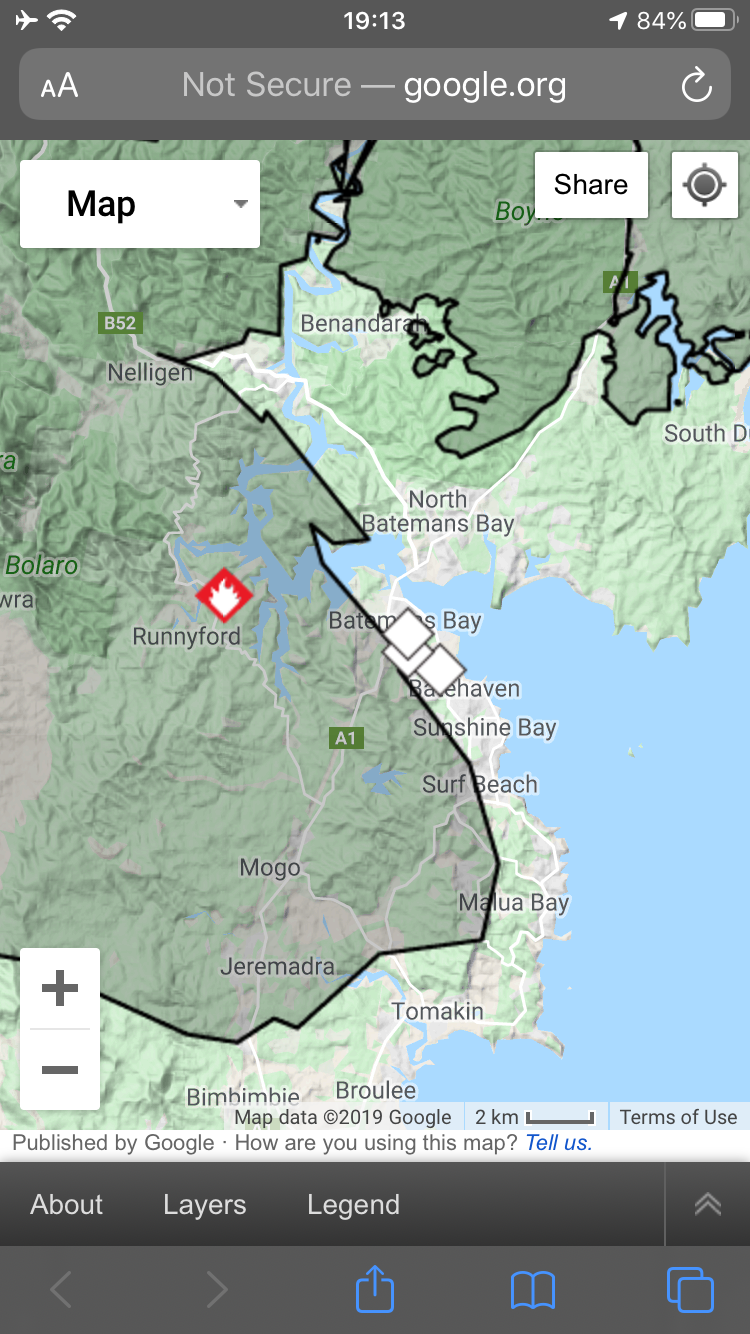

This morning we got a text alert notifying us of an emergency fire situation in Batemans Bay where my site attachment was (we moved down to Melbourne 4 weeks ago). I viewed the online fire tracking website which showed the town is practically cut off by fires. This prompted me to log onto my old project time-lapse cameras to take a look. (Pictures taken one daylight and links below).

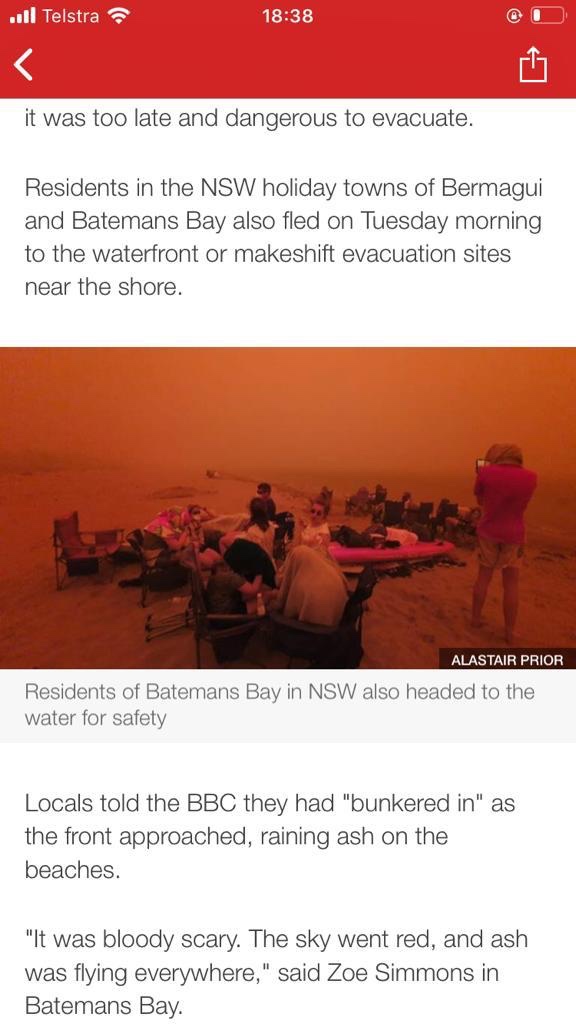

Today a picture from Batemans Bay has made BBC news and is probably one of the headlines you are waking up to this morning. It is difficult to describe the scale and impact of the devastation from the fires.

Currently there is no works on the project site due to the Christmas shut-down. Hopefully the situation will have improved in a weeks time when the site re-opens.

Sadly the fires are like this along most of the coast from the Queensland boarder in the north to parts of East Victoria in the south. All PET students are safe in cities and ready to see in the new year in Australian style.

Wherever you are and however you are celebrating I wish you all a happy new year from Australia.