Archive

Supply vs Demand – how severe is the current material shortage?

With nearly half a million cases reported globally in the last 24 hours, coronavirus continues to present a direct health risk to many people across the world. Despite this, some countries including the UK are fortunate enough to be confident that they have seen the worst of the pandemic within their borders. As a result, much discussion in recent months has been focussed on recovery and getting life back to “normal”.

Across the world, many countries including China, The USA, France, Australia and The UK have announced significant infrastructure investment as we go forward into a “post-pandemic” world. This will lead to a rise in demand for basic construction materials such as steel, cement, timber and some plastics.

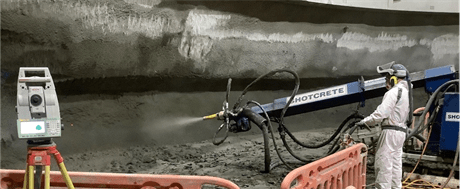

Supply chains have been stressed significantly over the past two years not only by restrictions to movement but by reduced outputs, political events such as Brexit and incidents like the blockage of the Suez Canal. Scarcity of construction materials is already beginning to take hold. For instance, on my site attachment, concerns over a shortage of steel fibre reinforcement (SFR) for sprayed concrete lining of a tunnel shaft are beginning to materialise.

Fortunately, we are able to revert to using steel mesh in lieu of the SFR for the most part but this is more time consuming to construct and leads to increased safety risks from additional working at height, more heavy crane lifts and hot works. What’s more is that a neighbouring team constructing a diaphragm wall on the same site is beginning to see shortage in availability of mesh which could scupper the contingency plan for the shaft.

If SFR and mesh stocks dry up, this situation has the potential to halt progress risking significant delays across the programme. One way of mitigating this might be to call upon the designers to revise specifications and offer alternatives to keep works going without too much increase in cost but the options are no doubt limited for a project that is already well under construction.

Time will tell if design change will be made necessary on my site, but it led me to wonder if anyone else had experienced materials shortages on their attachments (phase 2 or 3 – contractor or design house) and what might have been done to overcome the issue. Can anyone share some of their experience on this matter?

Modern Methods of Construction: manufactured meaning or assembled context?

Since starting on the PET course last year my general awareness of the construction industry has steadily increased and, like many who visit this blog, I have been exposed to new language and terminology. Much of this has resulted from interactions with PEW teaching staff, attachment experiences, and wider exposure to industry through professional development activities. Just like in the military, words and phrases develop meaning based on their context.

One such term that I have stumbled across multiple times is “modern methods of construction” (MMC). On the face of it, MMC is a relatively baggage-free phrase that could be used to describe any recently developed solution to contemporary construction challenges. This interpretation suggests no underlying connotation which is why I have never sought to understand any specific meaning until now.

Recently in my latest attempt at catching up with UK civil engineering news (albeit several months behind), I took some time to read the National Infrastructure Strategy (NIS) which was presented to Parliament in November 2020. In the document, MMC is used generically to lay emphasis on the idea that, to achieve the government’s production, sustainability, and development goals, we must use innovative construction solutions to combat modern-day infrastructure challenges. Late on in the document, MMC is identified as a means by which the government will encourage transformation in the construction industry defining it as “off-site manufacturing by standardising components, designs and interfaces”. This brief and fairly narrow definition provides a clue as to where the term MMC came into use within construction.

After some brief searching it became apparent to me that MMC saw a rise in use shortly after the turn of the millennium. This was a result of a 2005 National Audit Office report entitled “Using modern methods of construction to build homes more quickly and efficiently”. This early report defines MMC in terms of its products including the use of panels or volumetric modules produced in a controlled factory setting and assembled on site for the production of residential housing. In this context, MMC was proposed specifically as a way of meeting increasing housing demands against a backdrop of a stretched workforce. Effectively, it restyled existing methods (such as post-WW2 prefabrication) with an emphasis on volume and standardisation.

Going forward from 2005, the term continued to be used within this context but its meaning gradually broadened in the following decade as it was adopted across the construction industry and by policy makers. In the government’s Construction Playbook (Dec 2020), MMC is described as:

“a wide term, covering a range of offsite manufacturing and onsite techniques. MMC provides alternatives to traditional methods and has the potential to deliver significant improvements in productivity, efficiency and quality for both the construction industry and public sector.”

This suggests that MMC is a catch-all term for innovative construction methods that create a tangible difference across the Time-Cost-Quality triangle. Although this definition provides no explicit reference to the three pillars of sustainability, the accompanying description within the Playbook equates efficiency to delivering quality solutions with reduced greenhouse gas emission – a minor nod to global warming.

The Playbook’s requirement for MMC to benefit the construction industry (contractors, designers and suppliers) as well as the public sector (the client) makes it clear that the benefits shouldn’t just be for government. Despite this appearance of shared gain, the end-user, a critical stakeholder t be considered for project success, is at worst omitted and at best implied within the public sector.

Modern Methods of Construction as a term, therefore, does have a background and hidden meaning within our industry. Some will assume MMC relates specifically to off-site manufacture and on-site assembly of domestic housing however this interpretation is becoming dated. The term has been adopted more widely such that its meaning depends on the context and, as in the example of the Construction Playbook, is less specific in recent use.

Where then, does this lead us? It highlights the need to scratch beneath the surface, to broaden our contextual understanding and to be aware that phrases we use can be unexpectedly misinterpreted depending on our audience’s context. Furthermore, being able to identify short-comings in established definitions, such as the omission of end-users as beneficiaries of MMC in the Playbook definition, means that we are more likely to implement methods that contribute to outputs that suit their need.