Archive

Quailty Inspection

Things have been manic here. We are still recovering from the H&S incident last week and now we are preparing for the Quality inspection.

AS part of CRL’s checks, they carry out a ‘Performance Assurance Evaluation’. Each contractor within the CRL project is rated in a number of areas from environmental, Quality, Community liaison etc. The contractor is given a score of 0-3

0 – Non Compliance

1 – Basic Compliance

2 – Value added compliance

3 – World Class

In round 1 BFK came at the bottom of the ratings, round 2 we came middle of the pack. Now they are aiming to lead the pack. What does this mean to the LSW gunner on the ground…. well let me tell you.

I have been going through concrete delivery tickets, recording the time of batching, time on site, time of spraying, flow rate and temperature. Each delivery ticket has its own ref number, which must be associated to where it was sprayed in the Shaft lining ie ‘Advance 4 Quadrant 2’. From this spreadsheet I have then calculated the concrete usage, both theoretical and actual, to predict the next concrete test.

The number of quality tests associated with the sprayed concrete lining (SCL) is incredible. Just keeping track of it has been a job in itself. KT20, the Workmanship Specification for SCL, sets out the concrete tests and frequency.

Each one of these test requires several cores or beams to be taken. Each one of the cores needs to be recorded; the name of the individual who did the sampling, the time it was taken, the location it was stored and the location of where the sample was taken. When the core strength results arrive (the 1 day strength, 28 day strength and 90 day strengths) all need to be recorded and associated with the correct core. AS you could imagine I have been up to my nuts in work recently preparing for the inspection.

Additionally I have been getting all the testing equipment calibrated and a complices certificate produced. This has included the Hilti pull out gauge, Hilti gun, pentromenter, flow cone, digital thermometer and the flow table. I now know BS 12350 inside-out. I’ve had to purchase a curing tank that will store the cores between 15 – 20 degrees and AC for the basement to ensure the air curing is below 25 degrees.

Anyway it seems that we have finally got all our ducks in a row. The inspection will take place on Tuesday next week. I will await the outcome.

The good news is that because I volunteered to be the environmental Champion as well as the Quality Champion for our site, I will have the same ordeal with the environmental audit in 3 weeks time.

Who said Civies don’t work hard, this is a ball buster.

Shaft progress

This week has been an up hill struggle against the Sub-contractors.

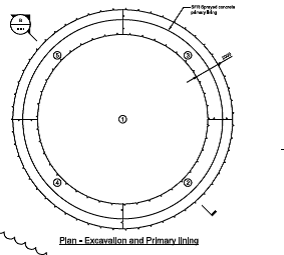

It seems you must have eyes in the back of your head if you are to stand any chance of catching their numerous ‘cutting corners’ approach to construction. After completing the Ring beam last week the proper job of SCL works has commenced. The shaft has been excavated 1 meter at a time, in quadrants ensuring that the 400mm lining is in place before the next quadrant is excavated. However their method of ensuring the correct profile and thickness of the layers has been sub standard. After watching them use depth pins to ensure the correct thickness I asked the question if there would be an issue with water ingress.

THe issue is that although the sub-contractors have applied with the Material Specification (KT20) by providing 50mm of cover, they have not thought about the water ingress from the clay. understandably there will be very little from the clay be the life span of the shaft is 120 years and the 400mm SCL is now reduced to 50mm in certain areas. AS a result we have instructed them to stop using the depth pins and use an automated monitoring system.

The second issue relates to quality control. In order to prove to CRL that the SCL lining is adequate, we must provide samples. THe testing forecast is stipulated by KT20. KT20 also stipulates that:

‘All on-site and off-site testing shall be carried out by laboratories accredited by UKAS or similar, acceptable national body or by persons accredited to a similar standard. ‘

However when I asked for their UKAS certification it transpired they were not accredited. This has resulted in us raising an NCR (Non Compliance Record) for each one of the tests they have taken. Additionally they forgot to carry out the tests that are required once a month. I was fortunate to realise this had not happened and they are conducting them now, only 2 days overdue (although still not accredited to undertake the tests).

On top of all of this one of the operatives has chopped off two of his fingers. Whilst unloading the kettle skip of concrete washout, the skip rotated back to the vertical position and chopped them off.Personally I have always said ‘dont put your fingers where you wouldn’t put you d**k’ so I have no sympathy for him. However RIDDOR has been notified and the incident investigated. It soon found that the kettle skip wasn’t on the Lift Plan and the lifting operations on site were stopped. All the lift plans had to be revisited and inspected before we could start again. It acted as a good test to see if our record keeping was correct. We had to provide his site induction date and signature, CSCS card, slinger/signaler qualification, daily brief signature, Method Statement signature, the list goes on. The final result is that all kettle skips on the CRL sites have been banned, deemed to dangerous.

Army chief visits Crossrail

A few photos of me chilling with an ex Squadron airborne brother under London.

It was ‘Uniform to Work Day’ yesterday and as a result I was instructed to show the CGS around some of the tunnels under London. I managed to get some good ‘facetime’ under my belt and even mentioned in the CRL news letter ‘working at Crossrail is full time Army officer Capt Mike Burton, currently on a nine month secondment to Bam Nuttall as part of his Professional Engineer Training and based at Fisher Street.’ Well done me!!!!

Thats right SQUADRON!!!!!!!!!

The Ring Beam Trilogy

Ok, so the last post took us to the point of trials taking place, in order to ascertain the correct construction method. As a result the number of reinforcement bars, from the piles into the ringbeam reinforcement, was reduced. THe designers conceded that there was only a requirement for 3 x bars/male pile to protrude into the ringbeam. These 3 bars would provide sufficient shear reinforcement and bond length (in order for the next phase of excavation, where the ring beam will be temporarily suspended). The designers did specify that 2 of the bars had to be on the near face and the other on the far face of the shaft.

With the reduced amount of bars requiring coupling, the 200mm SCL profile was easily achieved and the time required to couple the bars greatly reduced (from 8 per pile to 3 per pile). The ring beam reinforcement cage was put in place and the shuttering positioned ready for the concrete pour.

However, before the concrete pour can be started I had to do a pre pour check. This includes checking the reinforcement of the ring beam, ensuring the connections between the piles and ringbeam, checking the shuttering is as per the shuttering design etc. After reading Rich Farmers comment about the couplers on my last post, I had done some investigation and found that the Lenton Lock couplers ‘bolt heads will shear off when proper installation tightness has been reached, which allows for completely visual inspection’. AS you can see from the photo below, they had not!!!

In fact the sub contractors, nor the CRL supervisors had realised the huge oversight. I then checked the bolts and not only had they not been tightened sufficiently to shear off the bolt heads, they weren’t even finger tight. The result was the concrete pour was cancelled, the shuttering taken down and the couplers all tightened untill the bolt heads sheared off. I was as popular as a pork chop in a synagogue. However the cancelled concrete pour was a fraction of the price it would have been to rip out the concrete ring beam and start again, as there was no way of proving to CRL that the couplers would have held.

You would like to think the fun stopped there but it didn’t. The next saga was the concrete mix. The idea was to spray the concrete (C32/40) in behind the shuttering using the SCL machinery all ready in place. This apparatus had already sprayed the shaft piles with a regulating layer of 75mm and would be used later to do the 400mm layer once we got below the ring beam. However SCL concrete mix is very much different to the C32/40 mix that the ring beam is constructed from. THe first batch arrived, loaded into the pump and sent down the steel tube and then into the flexible rubber hose. However within 30 sec the dryer C32/40 mix had blocked the hose and steel tubes. THey then tried dropping the mix in behind the shuttering with the skip, it didn’t work. Because the concrete had by now been on site for so long we took another slump test and it failed so the entire load had to be dumped. THis then lead onto the next issue, because Barhale had cancelled two concrete deliveries and then dumped the third the concrete supplier couldn’t deliver another batch till the morning. THis meant that the small amount of concrete that had got in behind the shuttering would have been curing to long before the next batch arrived. This would have led to a cold joint forming, as a result bthe shuttering had to come down for a second time. The small amount of concrete removed and the ring beam reinforcement cleaned.

We are now in the position to pour the concrete again. The spraying of the C32/40 mix has been scrapped and they are using a skip with a tremi on it. This should result in the first quarter of the ring beam being poured within the next few hours. In reality it is about an 8th because either end of the ring beam reinforcement cage can not have concrete poured onto it., as it must be left open in order to tie in the next quater of the ring beam reinforcement cage.

Ring Beam update

My last post got us to the point of reaching the excavation depth of the Ring Beam. THis post will go into a little more detail.

Due to the amount of reinforcement of the piles, the construction sequence of the Ring Beam had to be modified. As you can see from the sequence below, the reinforcement in the piles needed to be cut.

However in order to decide how much-needed to be cut a quick calculation was required to see what bond length was required in order to hold the Ring Beam up.

Once the reinforcement requirements for the Ring Beam were calculated, the decision to cut the reinforcement could be made. However although the calculations demonstrated that all the reinforcement was not necessary, the decision was still made that all the reinforcement bars had to be coupled back together, once the SCL had been completed. I am in the process of trying to find out why this decision was made.

The next issue is trying to obtain the 200mm SCL required in the cavity below the piles, where the Ring Beam will sit. There has been several modifications, but it now seems that with design #4 (as seen below) we are managing to get the correct SCL profile.

Trials are taking place as I write, we will see if this construction method works

Very slow progress!!!! (Nothing to do with me)

There has been some slow progress on site. Last week came to a grinding stop, as a conflict between the four parties (client, designer, contractor and subcontractor) forced all excavation to cease.

The access shaft is broken down into a number of components. The Secant piles have been designed under the contract C123, by Jacobs. The remainder of the shaft has been designed under the contract C121 by Mott Macdonald. This has caused several issues as there appears to have been very limited communication between the two designers.

Jacobs insisted that once the Secant piles had been driven into place, propping would be necessary during the excavation phase. Additionally they insisted that the shaft was excavated in quadrants, sprayed with a regulating layer before moving onto the next quadrant.

However Mott Macdonald, who is the designers for the Sprayed Concrete Lining (which covers the Secant piles), insisted that the shaft did not require propping. BFK, who have the construction contract (C300) to build the shaft, decided to excavate the shaft without propping. This was agreed by CRL and Mott Macdonald. However after 8m of excavation the project was stopped as Jacobs had not agreed with the decision not to prop the shaft. The site subsequently fell silent for a week until CRL finalised an agreement between both its designers.

As a result BFK have been able to continue the further 2m to the required Ring-beam depth. However this has forced Barhale (sub-contractor) and BFK (contractor) to issue a compensation notice.

The ordeal has not stopped there. We have now got to the Ring-beam depth of 10m and the next phase is to pour the concrete Ring-beam. This process involves excavating the shingle away from the bottom of the piles and behind the piles in order to create a cavity for the Ring-beam to be poured. Again the sub-contractors were under the impression they could construct the Ring-beam in one go. However the reinforcement bars from the piles does not allow for excavation of the shingle, as they protrude into the shingle. They had planned to cut the reinforcement bars away however the bars are required to provide shear reinforcement between the Secant Piles and the Ring-beam. Additionally the reinforcement bars that protrude from the piles and eventually into the Ring-beam are required to suspend the Ring-beam when the next phase of excavation takes place (Stage 6 in the sketch).

So it is now back with the designers, because if the sub-contractors have to cut each reinforcement bar in each pile, then attach them again it will take 3 weeks instead of 1 to construct the Ring-beam. The governing factor in my opinion will be how many bars will be required for the Shear reinforcement between the Secant Piles and the Ring-beam. The issue of suspending the Ring-beam in ‘stage 6’ of the excavation can be done by increasing the embedment depth or increasing the strength of the concrete (currently designed at 35N at 3 days), A decision needs to be made today or the project will go on hold again!!!!!

On another theme, I will be meeting Chris Sexton (Ex-RE, now Tech director of CRL) and the CGS on the 26th June. I’m sure to have a great time.

Quality issues!!

The excavation of the shaft is well under way. The Sub contractors (Barhale) have continued to fall behind schedule for a number of reasons, mostly falling foul of the detail within the contract. According to their project program, they were supposed to have excavated to the lower ring beam at 10m below the capping beam by Friday. However, as of Friday, they had only achieved 7m depth. Firstly, this was due to the shaft piles allowing water to seep in-between the male and female piles. Secondly, it was due to the excavator not having the correct fire suppression systems in place. Thirdly, a Compensation Event Notice (CEN) was issued to them as they were overfilling the Muckaway trucks by up to 3T.

However, we (BFK) have begun to fall foul of the contract detail between Crossrail (CRL) and ourselves. They have issued us with a number of Early Warnings and CEN’s. Most of this has been down to the quality procedures (or lack of) that BFK have been implementing. As such I have now become the ‘Quality Representative’ for the site at Fisher Street. As I have mentioned before in previous blogs, each material used in the project must be approved by CRL and each significant component has an Individual Inspection and Test Plan (ITP). The shaft excavation is using a Sprayed Concrete lining (SCL) method and therefore a lot of the assurances required for CRL are obtained by the continuos testing of the concrete used in the spraying.However, it seems that the testing plan, detailed in the concrete ITP, have been ignored and therefore there is no way of demonstrating the quality of the concrete. Luckily for us this situation has not been replicated at Fisher Street but both Bond street (BOS) and Tottenham Court Road (TCR) sites have fallen foul of the testing.

In order to get a better understanding of the CEN and the Early Warning process, I organised a presentation from one of the contract managers. The presentation was extremely interesting. The NEC option 3 contract, used between us and CRL, has been modified in a number of areas to achieve CRL’s goals. The 900 variation orders that have now been issued by CRL have not had quotations associated to them. So when it has come to increasing the target price of the contract there has been some serious arguments. In order to regain the money that CRL are losing in the increased target costs, they have been issuing large quantities of CEN’s. This has resulted with BFK attempting to use clause 60.1 of the NEC to get out of any compensation payments. This entire field of the project has been really interesting, after a bit more investigation I was invited for drinks with the Company that has been arbitrating between CRL and BFK. It turned into quite a heavy drinking session with the CEO and deputy CEO on Concordia Consultancy, very interesting.

Back on site, there has been some serious progress, however in the office the rifts are growing more than ever. Alejandro, the Spanish Agent, looks like he is about to get the sack. He was moved here from TCR where he was a sub agent and has not really made the transition from one role to the other. The sub agent on site, Lyndoon, appears to be universally hated within the CRL project, and is refusing to work Shift timings. As a consequence the other subagents are having to pick up the slack. I have offered to assist but Im unable to act as a sub-agent, due to the terms of the contract.

Anyway, I am enjoying the work more than ever and I feel I am getting a great deal of benefit from the secondment.

Finally back at work!!!

Its been a relaxing 3 weeks away from work but I’m finally back. The 2 weeks in Italy were great however coming straight back to MA module A was a reality check.

I had expected a lot of progress on site, who was a kidding. There seems to be very little change in the 3 weeks away. However this week has seen it all come together, the simple reason is that the excavation sub contractors start work next Tuesday and it all had to be in place. The temporary works that I have been heading up have all come together at the 11th hour. The steel platform, which has been the thorn in my side since arriving, has finally been erected. Although as predicted there were numerous adjustments that had to be made. Top tip, never get a structure fabricated off site and expect it to go into a complex location without some serious on site alterations.

Since getting the steel platform in this week other components have begun to arrive and get put in place. As you can see, the generator, receiver, compressor, MDU and finally the Siltbuster HD unit (which will neutralise the PH level of the water before discharge) have all been put in place. The water treatment system will be in place by the end of next week, consisting of a concrete washout, settlement tank and the Sitltbuster HD unit. Fingers crossed that this system will work, as other sites around London have had some serious issues with the water treatment systems they have in place.

The Muckbin has also been completed this week, including the propping of the sub basements in both our building and the adjacent buildings. The only issue now is some debris netting to be put in place in order to protect the public footpath and our building, as it’s a listed building. The Muckbin will be accommodating the 200m3 of soil that will be obtained from each 1m depth of shaft excavation. My only concern now is that the Muck skip or the excavator will knock into the building and stop works for a considerable amount of time. I have had a designer produce a scaffolding barrier that would protect the building, however the powers to be have decided against it. We shall see who is right in the weeks to come.

The equipment platform has been completed with my first large concrete pour. Inspection cubes were taken and the whole procedure went fine. This was the final temporary works structure to be completed before Barehale (sub contractors) began to take over the site. On the whole the three temporary work structures have gone pretty well and I’m pretty chuffed.

The 80T heavy-duty crane arrived today, hence me being in on a Saturday. What a beast. One of the smaller cranes is being used to assemble the 80T crane. We are lucky to have even got the crane in the first place. There are only two cranes capable of fitting onto our crane platform, due to the restricted nature of the site, which were also capable of the lifts. Additionally Crossrail have insisted all plant are fitted with specific exhaust filters, you guessed correctly, neither of these two models were. However we applied for dispensation and hope that Crossrail will agree. We await their response, however we have taken a gamble and installed it any way.

The site looks like we are ready to start the excavation works now. As you can see from the photo below, once the settlement tank and siltbuster are moved out of the shaft and the 80T crane is built the excavation work can begin.

As I have mentioned in other posts, the paperwork involved in the project has been obscene. To obtain the authority to begin the excavation phase we have had to demonstrate to Crossrail that all our paperwork is up-to-date. This has involved Material Compliance Records (MCR) for every component used in the setup of the site and for the excavation phase itself. Each component we use from; Hilti bolts, paint, concrete, steel, reinforcement etc has to have a document produced with proof that the product meets the required standard. The document then has to be approved by Crossrail, you can imagine the implications of this. On top of the MCR’s an Inspection and Testing Plan (ITP) has to be produced for each phase of construction. This has involved obtaining welders qualification certificates, steel mill certificates, concrete batching plant certificates, the list goes on. However I think we have finally got there.

My final bitch concerns jack blokes. When I started on site there were only two Engineers, myself and Gemma. Now that the site is properly under way, they have surged more manpower to us. This has come in the form of a new boss, Aleandro from Spain, who speaks limited English, arrives late on a Monday and leaves early on a Friday to go back to the failing Eurozone. The term ‘useful as a chocolate fire guard’ comes to mind. Additionally another sub-Agent has arrived, who spends all his time on Linkd In, looking for his next job. I have been watching him, he has produced 4 documents in over a month. I wish he would move to Spain as well. As you could imagine the atmosphere in the office could be cut with a knife most of the time. I predict it is only a matter of time untill Gemma explodes with one of these two individuals, I can’t wait!!!

Who is watching the Watchmen….?

Well it’s been one more week closer to the Cross rail Mile stone of excavating the shaft by 2 May, and we have got no closer.

Temporary Works

1. The Temporary Works design for the steel platform has finally been produced and after a few alterations we have sent the final design to the fabricators.

The new delivery date for the steel platform has moved to the right and SHOULD be delivered by the 29th Apr. My fear is that once it gets delivered it’s not going to fit without some serious alterations on site… we shall see. However once the platform is in place the generator, compressor, receiver, settlement tank, siltbuster and electrical MDU can be placed in position. As you can see the platform is most defiantly on the critical path for this project.

2. The Muck bin saga continues, it looks like the design has been approved by Cross rail, now that Merebrook Consulting have resolved the sub-basement propping issues in the building opposite. This means that the reinforced concrete slab can be poured next week and the retaining wall units put in place later that week.

3. The equipment steel platform on the other side of the shaft has now been designed and should go in later next week. This will allow the Concrete pump, accelerator tanks and the concrete remixer to be put in place.

4. Finally the 80T crane platform has been signed off by Cross rail. The idea is that the Over Site Development Geothermal Piles that have been put in place will be able to take the load of the 80T crane. The majority of the bearing capacities of the piles are through the end bearing capacity and not the soil friction. As the piles are deeper than the shaft there should be limited loading onto the shaft wall.

Who is watching the Watchmen?

As the Cross rail project is funded by the public taxpayer, the client (Cross rail) has employed an entire team that monitors the contractors (BFK). This ensures that we (BFK) comply with the standards that were drawn up in the contract. However it means that every single piece of paperwork has to be authorised by Cross rail. That includes the: Daily Briefs, Work Specific Activity Briefs, Method Statements, Risk assessments, ITP’s (Inspection Testing Programs) and signing off on all the materials that we use. However, we sub contract a vast amount of work, so we have to check that the sub-contractors are applying then Cross rail ensure that we are complying, the whole process is man power intensive and massively inefficient. Who would have thought that a Public funded project would have been so inefficient…?

Anyway, less moaning. I’m off on a two week holiday next week for my Easter break. I will keep you updated with the site photos. AS you can see below, not much change from last week. Hopefully you will see much improvement over the course of the next two weeks.

Who ever knew that starting the construction phase would require so much paper work.

We are now only 2 weeks from starting the shaft excavation. The Section 61 noise consent form has been accepted by the council. The predicted water discharge consent form has been approved by Thames Water even the British Heritage have signed off on the refurbishments to the office building. It looks like we may even hit the Crossrail Milestone of starting the shaft excavation by the 2nd May.

The major issue for this site has been its restricted site. The amount of equipment necessary to excavate an 8m radius shaft 80m deep has been enormous. This has led us to produce extra space in the form of 2 storey steel platforms. Rich Phillips would be proud of my Google sketchup concept sketch that I used in the Temporary Works Design Brief. See below Rich.

After being volunteered … I have now been nominated as the site Temporary Works Co-ordinator after successfully passing the Kier ran Temporary Works course 1 and 2 and a scaffolding course.

This has meant that a number of site issues have been left to me to resolve, the one causing the biggest headache is the muckbin area.

Muckbin Area

Unfortunately, no one joined the dots together and realised that for each 1m of the shaft excavated there would be approx. 370m3 of soil. Where to put it on such a restricted site?

The only place to store the soil is on a road between two existing buildings. However both buildings have basements and sub-basements that would require propping due to the additional loading. Anyway a solution has been found, the sketch below illustrates the concept.

With the addition of a void former the additional load can be carried pass the adjacent buildings basement and sub-basement. The only issue now is deferential settlement on the unknown services that run below the road. However we will resolve that next week.

The Temporary Works Co-ordinator role has been quite an eye opener. In recent weeks we have had to produce briefs and partial designs for: sub-basement propping, muckbin area, 80T crane platform, 2 storey steel platform to house the generator, compressor and receiver and a single storey steel platform to house the concrete remixer and concrete pump.

The next 2 weeks are extremely important. All of the temporary works must be in place before we can start the main excavation. Hopefully between now and the 2nd May you will see some big changes to the site.