Archive

4/5th PWRI Flowline Update

So…… it’s been a while since my last blog, for two main reasons. First, priorities and second, any blog would be a cut a paste of my last blog, since the same issues with material and ops support have been a recurring theme. That being said, I thought it was time for an update;

Situation

The 4th & 5th PWRI flowline is coming towards the commissioning phase but there are still issues cropping up. The materials are all sorted, although Ops Sp issues remain, and will always be an issue. I have summarised further problems below;

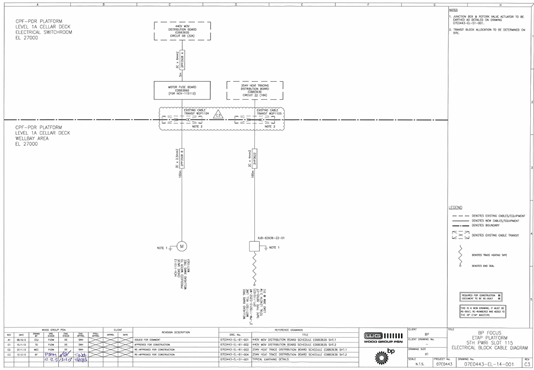

Power Tie in

The diagram below shows the extent of the electrical work that has been carried out.

As you can see a fairly simple scope, with just trace heating and the choke Motor Operated Valve (MOV) to be tied into their respective DBs. Unfortunately when the elec techs went to tie these into the DBs, it was identified by the platform that the cabinet could not be isolated as it removed the ability to remote operate the rest of the choke valves. The following options were considered for the MOV tie in;

- Isolate the DB and have an inst tech with a radio standing next to the choke valves in order to manually operate as required. A risky option as control would be minimal and delayed. This was not considered further.

- Tie into alternative DB. Nearest DB is some distance away and it is unsure what it currently powers. More material would be required, a workpack change would be required and an investigation would be required to understand what it powers. Not considered further.

- Do nothing and wait for the next outage. This would have significant cost implications, since the rate of PWRI is limiting hydrocarbon production and is relying on the 4th and 5th in order to increase. Not considered further.

- Do nothing, but run flowlines in manual, and trim using PWRI flowlines 1,2 & 3. MLCOA.

Decision. Option 4 was chosen as the MLCOA, but requires buy in from everyone involved. It will be necessary to carry an A(Qualified) ‘punch list’ item through System Handover (SH-1), which is not really the norm and makes people twitchy, as it has been known for punch list items to be forgotten about. It also required a growth request to be submitted to get the extra work into the outage in Apr, which is already over booked.

The same issue exists with the trace heating, but an alternative DB has been identified as a temporary solution, until permanent tie in during the outage.

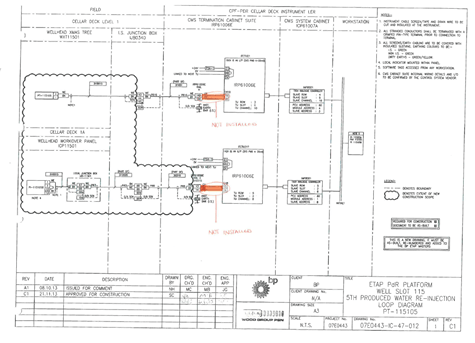

Instrumentation wiring modifications.

18 months ago, ABB carried out modifications for this project, specifically software upgrades and patch wiring modifications in order to get the instrumentation signals from the transmitters to the control room. Two weeks ago, we went into the cabinets to terminate the instrument wiring to find that the modifications had not been completed. See below.

As you can imagine, there were a few phone calls and finger pointing from both sides, but essentially they hadn’t completed all what there were supposed to have done. That then turned into 2 weeks of us trying to get them to commit to dates and availability, but them not doing anything until a PO had been raised to pay them, which takes time to generate and required ABB input, which they were also dragging their heels about. Of course the discussion about why we are paying them again to do something they should have done is a different discussion. We now have someone offshore to complete the mods.

Literally as I type, I have just received an email which states that the mods required would have to be done in a shut down due to the other wiring in the cabinet. This is significant, as the chances of commissioning and putting into service the flowlines now is almost certainly impossible and will have a financial cost of c. $100k a day in deferred production.

Of course there will have to be an investigation as to why the work wasn’t carried out in the first place, I’ll let you know the outcome.

Pipe support clash with Line of Sight gas detector

A few weeks ago it was identified that there was a clash between a pipe support spring can and existing pipework which is part of the deluge system. This required a re-design of the pipe support and was moved 90mm to avoid the clash. Shortly after, it was identified that it now clashes with a LoS detector system which picks up gas leaks in the well bay, which is quite important.

It has been painful, but there is now a way forward by moving very slightly the LoS detector. This took a week to resolve and discussions with a whole host of people to get acceptance which didn’t require a separate Management of Change (MOC) procedure.

Summary

This project continues to throw up issues, which take a significant amount of time to resolve. There are of course a few questions that need to be asked;

– Why was the ABB work not completed as thought?

– Why has it only been identified now that the DB and cabinets can only be worked on during an outage

– How was a piping clash not identified in the design phase?

I will keep you posted, as the significant cost implication will cause a fair bit of noise.

Offshore at last

Introduction

As you may have guessed, my ‘site phase’ of the course is actually based in an office many miles from any site. Last week I finally got offshore and I was able to assist with the survey of the helideck in readiness for the lighting upgrade project due in feb, assist with the lifeboat survey in readiness for the padeye replacement project in May and ‘get all over’ the 4th and 5th PWRI flowline projects. Below are a few of my thoughts;

Movement and Arrival

Heli is the only way to get to the platform and takes about an hour. I have had to do 3 courses and a medical (including drugs test – I passed) to get this far and familiarisation videos and site inductions are required on arrival, which takes up the rest of the day. Lesson learnt – Don’t assume when crew are mobilised that they are going to achieve anything on the first day. Factor in at least a day or even two before any work can commence.

Understanding of the job

Getting out on site allowed me to fully understand the scope of each project rather than relying on drawings and pictures. Of course this is obvious, but you will be surprised when the last time any of the SPAs actually went offshore. One of the JREs I’m working with has never deployed. This is sometimes obvious in meetings when issues are raised. They will know about the problem and what they have been told, but sometimes don’t understand what that means or asks the ‘so what’ question. Lesson learnt – Mobilise during the design phase to fully understand the scope and also mobilise during construction so you can get hands on. Sam – I will arrange a visit as soon as I can after your arrival (once you’ve done the required courses).

SafeCal

Due to the Life Extension Project I mentioned in the last blog, there are more people required offshore than they have beds for, so there is a need to use Safe Caledonia, a floating hotel. See pic below. This is tethered to the sea bed and connects to the platform via a moving bridge. The platform doesn’t move (much), but the SafeCal does as it floats. This week the movement was so much that the bridge had to be lifted, stranding quite a few on the platform. Lesson learnt – There are many things which can cause delays to a project, this is just one of them.

SafeCal – Flotel. Note the bridge connected to the platform.

Heights

This is not a place to be if you are uncomfortable with heights

.

Level 1 looking down

Barriers, Barriers, Barriers

Very hot topic at the moment. As it happed I had two issues with barriers. I was working around the well bay minding my own business. When I went to leave, I came across a barrier that had been erected whilst I was working. I went to find an alternative route but couldn’t because of existing barriers all around; so I was barrier’d in. The second issue was when I went back to the same area 2 hours later, the barrier was still in place even though it was obvious that the reason for the barrier in the first place was now redundant, but meant I couldn’t get into the working area. Pic below – bit of a concern when you don’t know you’re in a working area! Lesson Learnt – Barrier control need work. I completed a couple of BOSS cards. (Behavioural Observation Safety System – used as a method for reporting incidences and encourages discussion at the point of issue)

Something just doesn’t feel right

Weather

A platform is very exposed and a combination of wind and rain can make life very unpleasant and stop work altogether if conditions exceed limits. As well as affecting the work on site directly it can also affect the delivery of material from boats, therefore indirectly affecting work on site. Lessons Learnt – Factor in Non Productive Time and make realistic. NPT of up to 45% is sometimes expected.

One of the better days. Carrying out recce on helideck.

SIMOPS

The platform is very busy at the moment, as noted by all the barriers!) There is a high risk of delays due to SIMOPS and needs to be managed properly. Even within a single project we had issues. Our original schedule showed electrical work happening at the same time as piping work which involved breaking containment. This was not allowed due to the risk of spark from the elec scope and the potential release of hydrocarbon from the piping work. Lesson learnt – Ensure no SIMOPS clash or deconflict and scrutinise schedules for internal clash.

PWRI Flowline

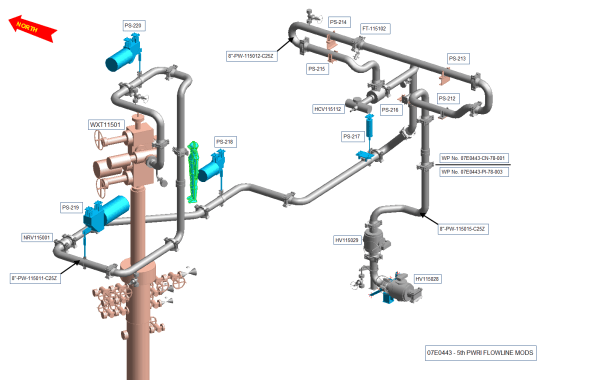

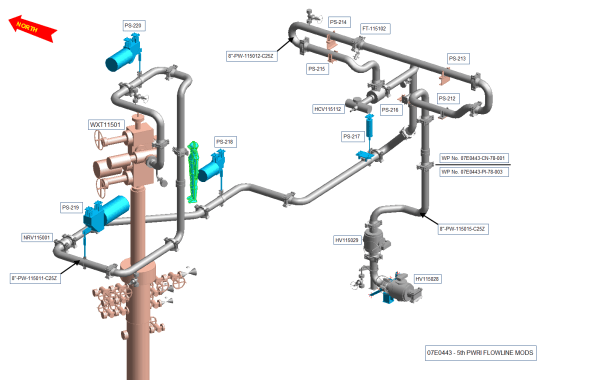

Below are a few pics to put the flowline in perspective. In an attempt to keep word count in this blog down, see if you can ID where on the schematic the pics refer to. Questions are more than welcome. (subtle differences may be noticed between pics and schematic – ignore)

Schematic showing 5th PWRI Flowline

Picture 1

Picture 2

Picture 3

Picture 4

Picture 5

Picture 6

Picture 7

Picture 8

Material, Material, Material

Introduction

This blog is an update to a couple of flowline projects currently under construction. Both flowlines transport Produced Water from a manifold to two different re-injection wells and is required due to the calculated increase in produced water over the coming years. (this has been detailed in previous blog)

The diagram below shows the 5th flowline and starts at the manifold (bottom right) follows the shown route which penetrates different decks and supported where shown (PS) It includes a number of valves, pressure and flow transmitters & indicators and is made of a number of pre-fabricated sections (spools) which are clamped together and arrives at the xmas tree on the left (the red thing). The gummy bear represents an average height person and gives a good indication of size. In addition to what you see below, there is also a small amount of trace heating and power connection to the choke valve; hydraulic connection to two actuators and the associated limit switch cables as well as an amount of instrumentation.

Schematic showing 5th PWRI Flowline

History

The project first ‘went offshore’ over 12 months ago and has been stopped and started a few times, with different Project Engineers & construction teams throughout. The projects re-started two months ago and there have been a number of issues and testing moments…

The problems

Missing material – During the preparation for the re-start it was identified that quite a lot of material has gone missing and has had to be re-ordered over the last 2 months. It is assumed that most of the material went missing during the august outage when the flowlines were paused. It was requested that all the material were back loaded to avoid this, but that failed to happen in time, so was ‘secured’ on the platform; clearly not well enough. The missing material equipment includes pipe supports, seal rings, bolts and blind flanges. Additional cost of material approx. £50k and a significant amount of man hours required to identify exactly what was missing due to some items being offshore and some onshore.

Incorrect drawings = Missing material 2 – A decision was made back in January to add mono flanges to the A, B & C annuli (the bits that stick out at the bottom of the red thing in pic above) so that the pressure transmitters attached to the ends could be calibrated. Unfortunately the drawings were never updates (although it was requested) however, some of the mono flanges were ordered and are on the platform. Unfortunately the remainder along with the seal rings and bolts are not are and are required to be ordered; more cost and potential delay. See below pic of annuli, the mono flange was meant to be placed before the pressure transmitter.

A, B & C (top-bottom) annuli showing (L-R) well isolation valve, (white) double block and bleed valve, silver flange to pressure transmitter

Incorrect progress reports = missing material 3 – The whole project is broken down into job cards and further broken down into activities and this is how progress is reported on a daily basis. The job cards were not accurate and it transpires that a short section of piping was not completed (the well kill line), and the materials are missing. This is now an issue since the transition spool which connects the well to the pipework has a lead time of 6 weeks and the whole project is expected to be completed by the end of the year.

Long lead items – Some of the missing items are off the shelf but some has lead times of a number of weeks. The schedule has had to be re-arranged so that the individual items are sent offshore as they are received in time for construction, in some cases just days before. This makes a lot of people nervous since logistics in the North Sea isn’t exactly reliable; during my visit last week, I observed a supply vessel sitting 500m away from the platform for 3 days before it turned around and returned to port due to weather issues.

Valves – All valves were delivered back in January and were fully tested and certified prior to delivery. Although there are no specific guidelines for the requirement for re-testing if not installed soon after delivery, the unofficial line to take is that engineering judgement should be used to decide if a re-test is required. Unfortunately were weren’t able to check the condition and storage of the valves since they were offshore and so it was decided they would all be re-tested as a precaution; cost circa £50k, but an absolute nightmare to get them off the platform and a lead time of up to 6 weeks if not damage. It was a good job this was done, since the choke valve had damage shown below.

Damaged face of choke valve

Ops support – The operations team permanently on the platform are required to assist when there is a need for break in containment or electrical isolation, i.e. anything that if it went wrong would have a significant impact on the platform. Although requests were added to the ‘Area’ plan, the guys offshore were just too busy with other higher priority tasks and so could not assist.

As an aside, this worked in our favour since the delays due to material issues would have meant we wouldn’t have been ready for when we asked for ops support, but used their lack of availability as the excuse why we could progress!

So why did all this happen?

There are probably a dozen of more reasons why this has been the project from hell, but can be summarised as poor material control and poor management over the last 12 months.

Material control – Creating Bill of Materials, placing/receiving orders and getting it to the platform is the easy bit. Once the boat arrives it will depend on who is offloading it, where it is placed (there are a number of different lay down areas) and if Woodgroup have anyone aware of the delivery and able to take ownership of the material. It’s also difficult to ‘secure’ material. You could lock it in an ISO, if you had one, but during the TAR, ISO’s were broken into to identify what was inside and anything kept in a corner in a nice neat pile, risked being thrown away into the scrap bin during tidy up, or being used on other projects.

Installed choke valve. Note the pipe of ‘stuff’ behind and that cable tray, bottom right, is just sitting there.

With regards to material checks, they simply weren’t done with enough attention to detail. Confirmation of what was offshore was a nightmare and we couldn’t mobilise someone to check due to bed space. It didn’t help that the drawings didn’t reflect changes that were agreed.

Management – The management of these projects was not good enough. It was not through lack of intent, but the JRE responsible had his focus on a more urgent project and spent a lot of time offshore for that. It was also almost impossible to get the info required from offshore; It didn’t help that he was new to the project or that workloads were increasing due to the manning cuts. I of course must shoulder some of the responsibility since I am the SPA, although taking over the project just before the platform entered the TAR didn’t get me off to a good start.

The way forward

Due to lack of ops support, the projects will only advance as far as it can and will then pause (yet again). The remaining work, primarily instrumentation and electrical will re-commence in January, with full and detailed ops support and then roll into commissioning. All material has been received, less a few bolts and seal rings, and will be available. That being said, I have just been called away to discuss the mono flanges and the fact that we don’t actually have them!! Clearly there is an additional cost associated with the material and delays and will be circa £300k.

In other news……

– Matthew is now teething, has a cold and has just had injections = 3 hrs sleep last night.

– The house renovation is moving forward, with the extension planned to start on 7 Dec. Drawings, planning permission, Thames water approval and Party Wall notices have all taken a significant amount of time (and cash) so my advice is, if you are planning to buy a house – buy one that’s already extended! Or factor 10% of your budget and a lead time of 3 months for the above.

– Managed to get offshore last week – blog to follow

The Oil & Gas Industry

Following an amount of chat on whatsapp regarding shares and in particular oil & gas shares (and following Jim’s comment on my last blog) I thought it might be worth writing a small blog to let you know where the industry is at the moment, as it seems like the construction industry is ‘steady away’ while the oil & gas industry is on its arse!

The oil & Gas Industry – Where are we?

The industry is not in a good place right now and of course it all relates to the price of oil. Demand has decreased whilst supply has increased leading to significant problems for all involved, especially for those who have the highest extraction costs. Different people will have different views as to the cause of the current trough, but can be summarised as follows;

- Increase in production in the USA due to onshore fracking.

- Canada & Iraqi oil production and exports are rising year after year.

- OPEC declined to cut production.

- Decrease in demand from the far east.

- Conspiracy theory that the Saudis & USA want to hurt Russia & Iran.

- Conspiracy theory that OPEC want to drive the new USA fracking market into the ground (excused the pun).

To make matters worse, in order counter the fall, many producers have increased production.

The following is a history of Crude Oil prices since 2000 showing a significant drop in 2008, due to a combination of an oil drilling ban being lifted by the USA, easing of tensions between the US and Iran, a stronger US dollar and the likely decline in European demand. It also shows the most recent drop which is struggling to recover in the same way the 2008 drop did.

So what?

So, unless it costs you less that the price of crude to extract the hydrocarbons, you are making a loss. Let me put it into context. The cost to extract from the North Sea is somewhere between $20 and $60 /bbl depending on the operator, type and location of reservoir etc. Each producer would typically assume an extra amount per bbl of say $10-20/ bbl as an investment cost for future improvements/developments etc. So unless you are at the far left of this scale then you are going to make minimal profit, if at all. Currently BP (North Sea) is in the bottom third.

What is BP North Sea doing?

For the last 12 months or so, BP have been on a big drive to reduce operating costs and try to get out of the ‘bottom third’. BP expect oil prices to remain low for some time to come and are taking quite a pessimistic view on this. In order to make the North Sea more profitable, BP have been looking at the following;

– Cutting staffing costs, circa 200 in the last year (circa 10%)

– Cutting back on OPEX & CAPEX budgets

– Prioritising projects that add the most valve for the business

– Delaying projects or extending projects to share cost with following year’s budget

– Increasing production to lower average cost of production

– Simplification across the business in order to reduce costs

To answer Jim’s question – Yes there is a reduction in our projects, but also a drop in manning, so still busy! The less important projects have been pushed to the right with the big ‘increase in production’ projects still moving forward.

The future

The price of oil is expected to remain low for some time, unless something significant happens that reduces global production. BP is continuing its drive to improve efficiency and simplicity and increase production, and is continuing to invest in existing plant and future developments. It has been working and BP is creeping towards the middle third.

The above information is not a recommendation to buy/sell shares, and is just the view, in part, of the author. The value of investments can go down in value as well as up, so you may get back less than what you invest. I certainly would listen to me since the BP shares I bought in Jun have dropped 30%!!

Gut Feeling

Pre-amble

First I must apologise for not blogging for so long, as I’m sure you’re all on the edge of your seats waiting for my next instalment; I should have listened to those who warned me about parenthood!

This blog is regarding the design of a previously discussed project and conveniently reinforces what both Damo and Guz have just blogged about.

The Project – ETAP Lifeboat Maintenance Padeyes

Each of the 3 lifeboats on ETAP are lowered using a pair of winch cables attached forward and aft. The cable release mechanisms are sufficiently delicate that carrying out maintenance on the lifeboats requires maintenance strops to be used in order to provide a secure fixing to the structure in case of a release mechanism failure (size 10 boot). Due to new lifeboats being installed a couple of years ago, the maintenance padeyes are now considered under sized and out of alignment to the boat fixing locations. See figs 1 & 2.

The original solution

The solution was simple. Cut off the existing padeyes and weld new, uprated padeyes in new locations. See fig 3 & 4.

So what’s the problem?

This project has been ‘hanging around’ for some time and hasn’t really moved forward, not helped by the ever changing personalities (see future blog). Following a couple of meetings back in June, the BP Offshore Execution Lead expressed concern that ‘it just doesn’t feel right’ and although I agreed with him, I just put it down to being new, as well as accepting that circa £100k had already been spent getting this project through the design phase so far, surely it must be right?

The following were highlighted as being a concern;

- It was understood from handover that the lifeboats would remain in service. The plan requires a significant amount of scaffolding around each lifeboat which by virtue of the restrictions, takes the lifeboat out of service.

- The plan had all 3 lifeboats being worked on at the same time. This just wouldn’t happen due to the obvious sensitive nature of the lifeboats.

- The plan required an amount of hot works (grinding/cutting & welding). Although the lifeboats were not in an area which required additional measures to be taken (use of a habitat, for example), there was still a risk to the lifeboats themselves and layers of protection would be required; reinforcing point 1 above.

- The padeyes would require testing once welded in position. The plan used a jig that wrapped around the davit structure see fig 5, so that the forces would be self-contained and not add to the davit arms themselves. This required both heavy and awkward lifting above a lifeboat and inches from the edge of the platform.

The solution

Following a ‘deep dive’ an alternative idea was suggested which was solely a bolted design, see figs 6 & 7.

This design had the following benefits

1. No hot works are required which means less protection and less scaffolding reqd, which leads to a quicker install and a shorter time to get the lifeboat back into service.

2. Potential to construct using rope access only from the platform above. This would mean no scaffolding reqd and potentially reduce costs.

3. The entire frame could be proof tested onshore using a mock up davit arm/frame, and then re-assembled offshore.

So why wasn’t this option considered in the first place during the Appraise/Select phases?

It was, but as I understand it, was not selected because it did not look aesthetically pleasing!

Now what?

I am expecting a Project Change Notification (PCN) of between £50-100k to get this re-designed and ready for offshore construction, and potentially a delay to the ‘ready for construction’ date.

Conclusion

Even though a significant amount of time and resources had been spent on designing the solution, it does not mean it’s necessarily the right one. If it doesn’t feel right, it’s worth doing a ‘down, test and adjust’ to make sure the direction of travel is the right one, especially if the project has sat idle for some time and/or the entire team had changed.

This project is, technically, as simple as it gets. But from this blog and my previous, you will see that it is not straight forward and often it is the ‘so whats’ surrounding the project which add most of the complexities and frustrations.

In other news

Currently planning for phase 2 of the Grand Design, which incorporates replacing the boiler (expect a separate blog on this), getting drawings done for proposed extension and getting the final 2 rooms ready for move in. Pics to follow.

Back in!

Finally finished paternity leave and spent the week trying to get back up to speed at BP; thought you might all like to see the new Francis, namely Matthew James (I hear you all say awwwwwwwwww). As you can see, he’s got my good looks. Once Ive got TMR2 out of the way, expect a couple of blogs which ive been meaning to write for some time.

Guz in a dress?? for everything else there’s Mastercard. (Other payment methods are available)

Lessons learnt

Introduction

A few years ago a number of lifeboats were upgraded to take into account the increased size of the modern platform worker, which resulted in slightly longer lifeboats. The lifeboats are permanently suspended by the winch lines but require additional pendants and padeyes to temporarily hold the lifeboat when maintenance is carried out on the winching gear. Due to the increased weight and the misalignment of the padeye and maintenance fastening location (due to increased length) it was identified that new padeyes would be required.

Solution

Quite simply, cut and grind existing padeyes off and weld on new padeyes in adjusted locations. A fairly straight forward job? Nothing is ever that straight forward in an offshore industry!

Who’s who

WGPSN – Engineering Service Provider who are contracted to deliver the project

CAPE – Scaffolding contractors

Sparrow – Lifting contractors

Lloyds Register – Independent Verification Body

Issues

Following a constructability review the following key points were identified.

- Confirmation of the test load for each of the padeyes.

Non-destructive Testing (NDT) is carried out on all padeyes to ensure they are fit for purpose, the question is how much do you test them? Going into the meeting the plan was for a test load of 8.5Te on each padeye, which accounts for a lifeboat tare weight of 4685Kg, 10 pax at 98Kg each and a Safety Factor of 1.5. The gentlemen from Lloyds, who act as an independent verification body, questioned how these figure came about and it could be easy to understand why they would ask that. The tare weight is 4685Kg but is held by two anchor points, so why not half? During maintenance you would only expect 3 pax to be involved so why 10? The industry standard for a safety factor is 2.2 or 2.5 depending on the application, so why 1.5? All very good points and the answer was simple. That is what Lloyds agreed to (told us) at the last constructability review. Unfortunately the individual who told us that was not at this meeting due to being on holiday, so nothing could be agreed there and then.

- Serviceability of the Lifeboat during the offshore execute phase.

Removing the lifeboat from service would impact the number of pax allowed on the installation and would therefore affect a whole host of other activities planned at the same time, so it was important that the lifeboat remains in service throughout where ever possible. Going into the meeting, it was understood that it would be ok; difficult but doable in terms of scaffolding arrangement, protective screens for welding etc. A concern was raised by the construction team in that the job could not be executed without taking the lifeboat out of service, so why had we assumed it would be ok? Again a simple answer; because that was the opinion of the construction representative who attended the previous meeting; that individual has since moved on.

Lessons Learnt

- Continuity is key. Where at all possible maintain key personalities throughout a project in order to help understand decisions made earlier on in the project. Given the recent and still ongoing job losses and efficiency drives in both BP and WGPSN I’m not surprised this has happened. I know I’m not the first person to mention this, and believe it was Angela who made a comment that after 6 months, she was the only person on a project who had been there at the beginning.

- Clear and accurate record of decisions. Whenever key decisions are made make sure it is clearly and correctly documented with any supporting information. The only evidence I had of the test load was in typed handover notes from the previous SPA. If continuity cannot be achieved then this becomes even more vital.

Looking Forward

These issues will cause a delay. Not to the execution offshore phase, as that is in Q2 2016, but certainly to the issue of key deliverables required for offshore execution. Not a concern but if the time lines were shorter then it well could have been. More work now needs to be done to clarify these points and of course man hours means increased costs. It might surprise some of you (or maybe not) that the current budget for this (one might say simple) project is (currently) circa £180k.

Grand Designs Part 1

Although it has been a relatively sedate pace at BP it has certainly not been slow at home. Having moved into the new house 3 weeks ago I have already stripped 3 rooms back to plaster and floor boards ready for windows, plastering, electrics and plumbing.

Being a 1930s semi built with solid walls and suspended flooring, it doesn’t lend its self to being thermally efficient, so with my new found knowledge (thanks Mark) I aim to change that.

A quick lesson

For those not in the know, the U value, or thermal transmittance, represents the amount of heat lost (in watts) through a square metre of the considered fabric per degree of temperature difference between the inside and outside temperatures. So if the temperature difference is 20OC, U value is 1.4 and the surface area covers 2m2 then heat loss would be U x A x (Ti-To) = 1.4 x 2 x 20 = 56 watts.

When there is a combination of materials through which heat is lost, i.e. insulation, air gap and brick, then the overall U value can be determined by calculating the reciprocal of the sum of the thermal resistance, R values. In the case of 25mm insulation, 10mm air gap and 225mm brick the relative R values are 1.19, 0.15 and 0.3 m2K/W respectively and additional thermal resistance of 0.04 and 0.13m2K/W are also considered for the outside and inside surface resistances. Therefore giving a total U value of 1/(1.19+0.15+0.3+0.04+0.13) = 0.55W/m2K. Simples!

Windows

Current windows are approx. 15 years old and in some places, much older. Solution: Upgrade with new uPVC double glazing filled with argon with a U Value of 1.4 w/m2K. The value of 1.4 is below building regs part L1a value of 2.0 for new dwellings.

Walls

Current walls are 225mm solid brick with a U value typically of between 2 and 3 W/m2K. Ouch. Solution: apply 25mm rigid polyisocyanurate (PIR) insulation to the inside of external walls to reduce overall U value to 0.55. This does not reach the part L1a value of 0.3W/m2K but in order to reach that value then an insulation thickness of approx. 60mm would be required and a compromise had to be made.

Ground floor

Currently the flooring consists of 18mm floor boards and carpet giving a U value of approx. 2W/m2K. Solution: addition of 50mm PIR insulation will reduce the U value to 0.35W/m2K which is higher than 0.25 required in new buildings but a compromise had to be made with the increased cost and depth of floor joists.

(current state above. You will notice a whole host of cat6, coax and HDMI cables running under the floor)

So what?

Reducing the U value of windows from 2.8 to 1.4, reducing the walls from 2 to 0.6 and reducing the floor u value from 2 to 0.37 will ultimately reduce the heat loss by approx. 75% and therefore reduce gas bills. I forecast the total cost of these upgrades across the house will be approx. 16k with windows taking up 12k of that. Average current gas bill, say £100/month, therefore savings £900 a year, therefore a payback period of nearly 18 years!! But at least I have that warm (excuse the pun) fuzzy feeling of doing my bit for the environment.

Next step

Size emitters (radiators) to each room given the surface areas, U values above and internal and external temperatures of 21 and -1OC respectively and size boiler given the emitter sizes and hot water demand calculated.

Final thought.

During a conversation with a sales man from Everest Windows (other window suppliers are available), he said that it is not worth getting triple glazing as the additional money you would save on the gas bill due to the higher U value would be countered by the need for additional lighting due to a reduced level of light because of the additional pane of glass.

General observations

It has been a while since I last blogged and has primarily been down to the relatively sedate pace of life up in Aberdeen. In an attempt to prove I haven’t gone native, I thought I would pen a few points and observations I have made over the last month or so.

Continual Uncertainty

The oil & gas industry is still in a bad place and not likely to recover for a while. Woodgroup (whom provide a lot of engineering services to the BP Projects & Mods team) announced a couple of weeks ago that further job losses will be required and uncertainty exists as to what that exactly means. Last week they also announced that their engineering teams based in Aberdeen will be moving to Glasgow in order to reduce costs and increase productivity; so what? For me, it will almost certainly mean frequent commutes to Glasgow in order to better coordinate projects.

BP itself is continuing its drive to improve efficiency throughout the entire organisation and a ‘town hall’ with Trevor Garlick, the Regional President put it in perspective. When looking at North Sea producers, BP currently sits in the bottom third in terms of cost per barrel to extract at around $37 per barrel, even if that was reduced to say mid-twenties, BP would only rank in the middle third. This is primarily due to the huge overheads BP has because of the size of the organisation; BP cannot compete with the smaller independent oil producers in the North Sea. In order to save money, budgets have been cut and are expected to be reduced further next year including the P&M budget.

Procedures

After initially being impressed with the documented processes and procedures that exist, it now seems that BP staff understands them in the same way we understand AFM, SOHB et al. We know they are there and roughly what they are about but they are not always fully understood, at times don’t support each other and may not be up to date.

When you are both behind schedule and will finish early

There is currently a project being executed offshore to deliver an additional lifeboat so that there can be an increased number of pax working on the platform at any one time. The project started in early Mar and was scheduled to complete in 4 weeks. As you can see from the S-curve below the project is about 7% behind schedule but we have been told that it should be complete in a week; so in a 13 week project the last 23% will be completed in the last week. This is really down to poor forecasting at the beginning of the project by vendors who are completing the installation and final commissioning of the life boat. Arguably it’s not that big a deal as long as it is completed within schedule, but it does raise some eyebrows further up the chain and brings some unwanted questions. So it is not just the army that tries to mould figures to appease higher HQs!!

Timings, Timings, Timings

I know that a few of you have mentioned this in blogs previously, but think it is appropriate to quote Barbossa from Pirates of the Caribbean: Curse of the black pearl when describing contractor deadlines;

“the code [deadlines] is more what you’d call guidelines than actual rules”

In other news

Pregnancy: Still, but I’m the one putting on weight and having food cravings (olives at the moment).

House: moved in, more to follow.

CPD

Brendan and Myself attended a CMI coordinated breakfast, titled ‘Leading in Difficult Times’ which included 3 guest speakers. Lt Col Paul Binnie, Commanding Officer of AUOTC discussed the role of the leader in terms of subordinate development, mission command, clear communication and inspiring your team. Ella Minty, a strategy and change consultant, discussed the concepts of knowing your limits, knowing your boundaries between work and social, seeking results, ambition and real value and fostering challenge, trust and learning, and finished with the line “if you are the smartest person in the room, you are in the wrong room”. The final speaker was Bob Keiller, the CEO of Wood Group who played 7 songs and discussed each one in tern;

Black Sabbath – Paranoid

The Temptations – Get Ready

Animals – Don’t let me be understood

The Matches – Needs and Wants

Paper Lace – Don’t be a hero

Elvis – A little less conversation

Crowded house – don’t think it’s over

I’ll let you decide what he meant by each one.