Archive

A change of scenery

It is not quite a tropical heaven but it is a change of scenery.

The declining oil price has had a detrimental impact on the Projects and Modifications (P&M) budget. Unfortunately, one of my major projects has been suspended until the cash flow problems improve and the other projects are starting to culminate. As such, I decided that I fancied a change of scenery where I would be able to get the most out of my remaining two and a half months. Consequently, I am now sitting in the discipline engineer (DE) team, as a mechanical engineer.

The way I see it is that P&M is the interface with approved engineering design contractors and ensures that the contractors deliver what it is the client is after. The role of the DE team is when a project flies close to the limit of the Engineering Technical Practices (BP equivalent of BS), and the contractor’s won’t touch it, then the DE team can conduct detailed calculations and assess the risk and make a judgement call.

I have been sat here for a little under a week and I am already getting stuck into some calculations; Mark would bloody love this place. I’ve used Bernoulli’s equation, D’Arcy Weisbach, I’ve downloaded some pressure vessel calculation software (yes downloaded only because I’m still scarred from Hevacomp I daren’t attempt it yet). I might need a crate of Stella Artois before I attempt to wrestle with a software programme. Obviously for those of you who know my drinking ability, by crate of Stella I mean a can. I am looking at materials failure of a particular weldless joint offshore and I will probably write a method statement for checking other existing clamps. There are some other bits and pieces to going on and I expect to receive a steady stream of work until I leave.

I am writing this post for two reasons; the first is to illustrate how versatile the BP PLC placement is. Even though a PET officer has been on attachment here for the last four years there are still a lot of people who don’t know we are here and what we can offer. The current attachment works very well and I don’t think I needed to make the move to DE but BP were more than happy to accommodate my request. Future incumbents may be able to explore options for trying to work in different parts of BP although bear in mind that 16 months is not that long to get settled and stuck in. I have discussed this with Brendan and we will continue the info ops campaign prior to leaving to ensure the profile of PET officers is lifted once again. (This is doubly important during a time of redundancies in the North Sea because there will be a large turnover of personnel in key appointments).

The second is to highlight that I expect to be able to add to my A and B competencies prior to taking CPR.

MPDS and Interview Prep

Brendan and I attended an IMechE industry contacts seminar in Aberdeen yesterday and it was predominantly about the Monitored Professional Development Scheme (MPDS) but it finished with a presentation from one of the interviewers for CPR in Aberdeen.

The bottom line is it has made me feel much more confident about going for CPR later this year.

This is most useful to those going for CPR with the IMechE and also PEW as an organisation. However, I hope that there are a few useful snippets for everyone.

I will describe the key agenda points and the important points as I see them.

Agenda

Introduction – no synopsis required and the only key point is that the IMechE website now has an ‘on demand’ facility that allows access to lots of online videos of conferences and seminars from around the world.

Tips for preparing for an MPDS accreditation visit – The title is self-explanatory so I will just go into some of the key points:

- PEW is not suited to the MPDS at all. It takes a minimum of four years to complete the scheme and it is aimed at new engineers joining a company. It is absolutely the right thing to continue with the standard application form approach and students on PEW should not be completing MPDS online.

- Over inflated scores of competencies is not helpful – to have a 3/3 across the board when you clearly haven’t reached that level is a red flag. Should the candidate then fail CPR it is difficult to re-rate and develop. Mentors should scrutinise competency ratings and pick them up prior to exposing to the IMechE.

- Media attention. There should be more of a big deal made of those successful at CPR, both for the applicant and the mentor. Many companies employ a financial incentive but this would not work for PEW. However, increased media coverage may be helpful and is something that could be developed. The key part is that there needs to be more of a celebration of achievement.

- A good thing to put in your E competency on the application is that you are a volunteer to be a mentor. The IMechE are short of mentors and the panel look favourably upon this.

Running and MPDS scheme – This was from the perspective of the Royal Dutch Shell MPDS scheme administrator. Most of his points were not relevant to PEW but it was clear how much effort these other companies invest in CPD for their employees. He suggested that mentors should not have the same background as the candidate so it forces the candidate to explain things properly and it is also beneficial for the mentor to read about different subject matter. I appreciate that this would be difficult for PEW.

Professional review interview – This is where the real gems were. It was a presentation from David Baker who is a panel interviewer for those taking CPR in Aberdeen.

- The application. It is competence based so do not just list a career history but describe how you have achieved the competence.

- During the interview he expected the applicant to do 75% of the talking.

- Interview lasts 45 minutes:

Introduction 2 minutes

A, B, C and D competencies 20 – 25 minutes

E competency 8 minutes

DAP 5 minutes

Closing comments 2 minutes

- He went into more detail for competence E. You should cover the following:

Code of conduct. Read it and equate it to your organisations code of conduct.

Examples of continuous improvement. For example, this could be new technology that you have implemented or a new maintenance regime you’ve instigated.

Environmental responsibilities. This could be considering HSE aspects.

Continuous CPD. Annual appraisals, courses you’ve been on etc

Promote engineering. Primary engineer for example.

Ethical manner. You won’t need to provide evidence of this competency until 1 Jan 16 but it could be useful to do so. Mark Hill (hobbit108) posted a useful piece on this in an earlier blog.

- Talk about things as “I did this” not “We did this”

- The sponsor is key to scrutinising paperwork, we get this after AER6.

- There should be mock interviews. I know the civils have this but I’m not sure how formal it is for the E&M students. I know that Imran very kindly offered to come back and run them for our course before he left and I will be chasing him to make good on that promise.

- Take in photos or calculations that you can talk about, especially if you’re the type to get nervous in interviews.

- You need to have three out of the five competencies graded at 3/3, with the other two at 2/3.

Key challenges to passing CPR:

Not providing evidence of A + B competence

Not being able to talk about the detail of what was in the application.

Another thing that I took from this is that PET students are different to the normal CPR candidate. They tend to be more discipline based with much less management experience.

From a personal perspective, I feel that my previous military experience plus phase 1 and my experience at BP has certainly given me 3/3 in C, D and E. I think I am on my way to a 3/3 with the A competency and I will be okay reaching a 2/3 with the B.

I also think that the role of mentor is very important. For those of us going to Staff College it could be a useful way of maintaining the CEng flame. I for one would be willing to look over someone’s application, their competency record as they build it up and if I’m available I would help run a mock interview next year.

Engineering Management

The management of civilian engineers is really quite different from that of managing Royal Engineers. In twelve months as a project engineer, I have managed teams not only on diverse engineering projects but the people who make up the teams are potentially even more diverse. As a result, I have had to hone my soft skills to get the job done.

Military Culture. When I was a brand new troop commander I heard the term FIDO. I’d be surprised if anyone reading this blog hasn’t heard the term but for clarity I will explain the acronym. It means f**k it, drive on. It succinctly encapsulates the military ethos where the mission always takes precedence and the will to succeed despite shortfalls of manpower, time or resources means the job usually gets done. And credit to the Royal Engineers, in my experience the final job is usually more than fit for purpose. However, this inculcated culture could lead to a potentially one dimensional leadership philosophy where the commanders just shout louder and get angrier until they drive their subordinates to complete the job. I’d like to think I wasn’t one dimensional but I have certainly had to adapt and develop whilst on attachment. A single leadership approach can work in the Army because of the hierarchical structure, the discipline instilled in basic training and the excellent NCOs that enforce it. It also works because the people in the Army are generally different and more robust than their civilian counterparts.

The Army attracts a certain kind of individual, one who is comfortable with straight talking and potentially being told off if they’ve messed up. Also, the average age of a British Army soldier is 20 years old. There is a natural tendency for these younger soldiers to follow the instructions of older and therefore more knowledgeable soldiers. This discipline, understanding of straight talking and hierarchical structure means that when an order is given, even if not completely agreed with, it is usually followed. This means that things tend to move on a bit quicker.

Oil and Gas Culture Differences. I imagine that some of this will resonate with those in design offices in different industries but I have kept it to my own experience. The oil and gas industry has a very risk aware culture and in particular BP PLC’s top priority is safety first. Their mantra is “No accidents, no harm to people, no harm to the environment”. The average age of the oil and gas sector is between 46 and 49 years old. In the design office, they are nearly all qualified engineers, most will be at graduate level as a minimum. And, at age 46 to 49 there is a tendency to think they know best. Sometimes they do and sometimes they don’t. These engineers are often members of engineering institutions with clear codes of conduct regarding making decisions within the realms of one’s ability, they tend to seek a higher degree of assurance and as such they take their time.

Also, there is a functional structure to the organisation which means that the balance of power is held in different places. For example, and in military speak, the discipline engineers are OPCOM to their principal discipline leads but they are TACOM to the project engineers. (For those of you who don’t know OPCOM and TACOM you should be ashamed of yourselves. OPCOM means they get given the mission statement and can be broken down or asked to do anything – essentially the highest level of command. TACOM is what RE CS squadrons are to the BG. They are given tasks and priorities and can’t be broken down further). This confused split of power exacerbates the situation because with two bosses if an engineer doesn’t like a decision they can trade one boss off against the other.

Consequences

Consequently, if you ask someone to do something in the Army they will generally get it done. This is providing you don’t ask the bottom third LCpl or Sapper who’s been in for 20 years and passed over quite some time ago. It doesn’t even matter how you ask, it can be the politest “I’d like groundworks for the LSB complete by COP Friday, please” because this actually translates as “the groundworks will be complete by Friday unless you know of a good reason why they won’t be then let me know right now”.

In BP it seems that unless you get something it writing it is a bit hit and miss whether it will happen or not. The amount of people in the design office who are happy to agree with something to your face and then not do what was asked of them caught me out at first. For example, I might ask a vendor “I’d like all long lead materials ordered by Friday, please”. And what they seemed to hear is “if you can find the time and as long as it’s not too much trouble try and order the materials by Friday. However, this is very much a target and not a deadline”. This actually happened to me and the materials had a 20 week lead time and if they weren’t ordered soon then the job was unlikely to go ahead. Everyone was aware but the materials hadn’t been ordered because it was not the next step in their process. Don’t assume common sense will prevail, even with bright people, they like to follow a process. In my early days, I would naively believe that people would do as they say; nowadays I follow everything up with a desk visit and then an email. Just sending emails is too easy to ignore.

Continue to be polite and friendly (even if you don’t feel like it). It is important to be polite for two reasons. The first is that the people in the office tend to be nice individuals and they respond better to being spoken to nicely. The second is that as a project engineer I am not directly empowered to get them to do everything I am asking. Being polite and friendly gives the impression that you’re friends and it’s harder for them to refuse a ‘friend’.

Finally, be ready for the confrontation. Officers tend to be quite good at confrontation and you should be ready to use this line of action if required. Be prepared to stand your ground but have the technical, financial or project detail handy to back you up. You can usually tell when a conflict is coming, try and work round it with a smile but make movements early to have all you ducks in a row. A confrontation without evidence is at best unhelpful and at worst undermining. I successfully, and publically, argued with a process engineer about the sizing of a shell and tube heat exchanger. He was trying to throw a spanner in the works and was being particularly obstructive. So in a meeting I produced evidence from the design report from a process engineer stating that the STHE was fit for purpose. He was promptly told to get on with his job. Without the evidence to hand, he’d have tied my in knots and would have shouted me down.

It goes without saying that you need to be firm and as a leader you need to be strong willed. As any kind of successful leader clear and concise communication is important as well. These are skills that come more naturally to us. However, working in BP has definitely honed my soft skills when it comes to leadership and management. Some top tips are:

- When you say deadline they hear target.

- Use explicit language and ask for exactly what it is you want and don’t think you’re being patronising.

- Follow up any agreement with desk visits and emails.

- Be polite and give them no excuse to put your request to the bottom of their to-do list. Also, get round and ask people’s names, know their interests and ask about their weekend. It is hard to refuse a friend.

- Continue to use common sense. Understand the project lie cycle and when the engineers would normally complete steps. If required, intervene and make sure the overarching aims are borne in mind. As military leaders, we tend to be quite good at this anyway.

- Be ready for a confrontation with evidence. Do not think you can argue your way out of something with platitudes. Only use as a last resort.

On your last day at work you can tell people what you really think of them if you so desire but I would’t advise it.

The Joule-Thompson Effect

Since arriving at BP I have come across the Joule Thomson (JT) effect a couple of times. I even thought about doing a TMR on it but I couldn’t really find the correct angle. It is where a gas goes through a restriction orifice (RO) and expands. The expansion of the gas results is a reduction in pressure and the gas accelerating. Both the expansion and acceleration lead to a decrease in temperature of the gas. It is worth noting, not all gases lead to a decrease in temperature, and some like helium expand and involve an increase in temperature due to the nature of the chemical changes occurring during an expansion. However, hydrocarbons end up having a drop in temperature following an expansion. The resulting temperature drop can take the minimum temperature outside the minimum permissible temperature of the materials involved.

Consideration of the JT effect is usually incorporated into the design process so you’d think that this should not be a problem. However, my recent experience has proven that this is not always the case.

The problem can come from several different factors. One explanation is that there are some rules of thumb which are not so good and some rules of thumb that are quite good. For example, how much the temperature drops depends on how big the drop in pressure is. Also, a gas that starts at a lower temperature is likely to suffer a larger temperature drop for the same pressure difference than a gas that starts at a higher temperature. The rule of thumb is that a gas will reduce in temperature by 0.5 degrees for every bar. However, in reality it could be between 0.2 and 1 degrees for every bar. This is a poor rule of thumb.

Another, industry rule of thumb is that the temperature creep will not go further than 1m back up stream from the RO. This is a conservative estimate and in reality it is likely that it will not get beyond 0.23m back upstream because of the warmer gas fluid flow upstream of the RO. This is a good rule of thumb but not one that seems to be widely known.

BP have never had a low temperature brittle fracture in the North Sea due to the JT effect. However, since Deep Water Horizon there has been a shift in culture towards checking everything. So much so, that in safety meetings such as HAZOPs, it is often asked whether during a blow down to ambient pressure (ie the greatest pressure drop and therefore the lowest possible temperature), will there be a low temperature brittle fracture. It has become a fashionable question to ask. It is like a junior officer coming up with the implied task of liaison during JOTAC. It is said without any thought for how to do it. This serves in creating work for other people like SPAs. I have spent a considerable amount of time reading on this and discussing the matter with purported experts and have finally got to the bottom of the problem.

For my HP discharge cooler project I inherited a HAZOP action of this nature and I have drawn a simplified schematic of the system in order to explain it. I am replacing the heat exchanger (or cooler) and the question was would the minimum temperature reached during a blow down damage the new cooler. Ultimately, this is an idiotic HAZOP action and I will explain why below. However, it has taken me a long time to realise this was stupid.

During a blow down to ambient temperature the flow of gas would be from the suction vessel through the recycle line to the BDV, as shown by the red arrows in the schematic. It would not go through the HP cooler because the resistance of going through the compressor is significantly higher than going through the recycle line. Also, the recycle valve is a control valve that would be set to fail open. Furthermore, the RO is significantly further away than 1 m from the cooler so there is no chance of low temperature creeping upstream to the cooler. This is according to the rule of thumb.

However, there is sometimes a good reason for why the JT effect has been overlooked and they cannot all be discounted so easily. The North Sea is a mature oil field and the designs were completed up to 40 years ago when the hydrocarbon composition coming out of the ground was different. Initially, it was mainly liquid that was produced. More recently, as the field has matured it tends to be gas. There is no JT effect with liquid so things were not designed as rigorously for the JT effect. Instead the considerations are different, such as a liquid stream will carry much more debris and cause corrosion so they select the materials for what was the situation at the time or the foreseeable future. Furthermore, the operating conditions are different from start-up conditions so the design needs to incorporate the worst case. Prior to start-up of a well, the hydrocarbons in the caisson will settle under high pressure so that less dense gas is on top of liquids. Therefore, when the well starts producing again the build-up of gas in the pipe comes through an RO first and if it is a big build up in can take a long time to clear the RO and hence create a low temperature that the pipe specification was never anticipated to see

There are also other considerations. Mechanical engineers need to be provided with the lowest temperature a line may see to ascertain whether the line will fail or not. If the line is LTCS it is fit to -29 degrees. To say the liquid will be lower than that is unhelpful. How much lower, -100 degrees or -30 degrees and for how long. There are other factors too, such as ambient air temperature and wind speed. Just like in a heat exchanger a forces air flow of a temperature that creates a large temperature gradient will combat a low temperature brittle fracture because it will raise the temperature of the pipe. Therefore, engineers need to start to look at the likelihood of conditions combining to make the worst case scenario. It is a very complicated matter and one that it is unsurprisingly overlooked during design. It also makes things hard to prove are safe because you may be trying to prove the absence of a set of conditions or that worst case scenario is unlikely. The JT effect should not be thrown in as a fashionable buzz word to make people feel like they are contributing to safety meetings. But it does need proper consideration for the full life cycle of a well.

In other news

I have just been on holiday to Brazil, and it was really nice to get some sun in what has been a genuinely long winter. It was a bit of a shock going from a humid 40 degree paradise back to a -5 degree freezing cold Aberdeen. Although given the fact that I was sunburned on the first day and looked like a crab stick for the majority of the holiday I need to accept that I am more suited to cold weather rather than the sun. Check out the tan lines, it looks like I’m still wearing a white t-shirt.

As you can see from the picture, my kids have inherited my propensity for tanning.

When Mark grows up he should become a valve doctor

I went to a very interesting seminar on valves used in the oil and gas industry for high severity operations.

It concentrated on compressor recycle lines and flow line choke valves.

The subject matter covered included material selection, how to control flow rate, pressure differential, corrosion and erosion resistance, analysis of modes of failure and of course developing technologies. They use DRAG technology, which is essentially using a tungsten carbide filter to surround the valve plug on a globe valve in liquid stream to protect the plug from damage, excessive pressure drops and to remove any chance of cavitation. A picture of one of the discs that together with lots of other discs stacked together form the filter. The flow being from outside to in.

Surprisingly, it was not delivered as a sales pitch despite coming from a private company. I think that they know what they produce speaks for itself. I for one learned a huge amount and will be applying some of the lessons learned to my projects. It will be a way of ticking the new technology competency.

Mark, if PEW doesn’t work out you should consider it…

A lack of commitment

I am coming to a crunch period in my time on attachment with BP. There seem to be a number of things coming to a head all at the same time, both from a BP perspective and a PEW point of view.

I want to complete a design phase attachment with WGPSN as a mechanical engineer for about two months, in the same way Chris Warner did, so that I can satisfy the DO where I feel I may be weak. It will also undoubtedly make me a better engineer, which is the whole point of this attachment. The problem is that my role as SPA demands all my time and focus and my line manager is keen for me to do the attachement at a time when there will be no advsere affect on my projects, which is fair enough. In true military style I forecast out what the key activities were that I needed to have in the bag so that I could genuinely feel comfortable just monitoring my projects for afar for two months. Sadly, my plans are falling to pieces because the key activities are predicated on receiving work from other people in good time and trying to get anybody to make a decision before we are right up against a deadline is proving problematic. As an example, I inherited a Hazard Operability (HAZOP) study report containing a number of actions relating to process engineering. Unfortunately, the report records the actions as an SPA responsibility (cheers Imran) and not a process engineer responsibility. So it appears that I am culpable for the action even though it is impossible for me to close it out because I know I am not competent to do so. Depsite badgering the process engineers, the best I have got is an emailed response expalining in great and complicated detail why there shoudln’t be any actions on me but also still refusing to formally close out the action. Thus, the situation is not resolved and I will have to keep escalating until someone finally gets told to piss or get off the pot. This takes time and effort that I would prefer to be using elsewhere.

That said, this proactive approach has been beneficial. I feel as though I have a good grip on the key project risks as a result of forecasting ahead and trying to anticipate what is likely to trip me up at Xmas time.

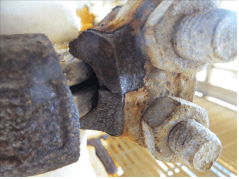

As another example of people trying to become human teflon, there is a distinct aversion to taking responsibility for pretty much anything. On another one of Imran’s projects that I inherited, the Minox Blower, there has been an issue with handing over a piece of kit that has a defect. This one was not Imran’s fault at all I must add. However, there is a cracked weld on a motor jacking point that is used to align the motor after a period of maintenance, therefore it is not requird for routine operations.

The solution seems clear, re-weld it. However, as a project engineer based on shore I cannot weld it and it is not in my budget to get a vendor to do this. Nor am I empowered to get the repair or maintenace team to do the job. Hence, we are stuck again and I cannot clse the job out because this needs to be fixed. The reapir and maintenace team leaders have agreed they can do it but will not take it on. I have had to raise it several levels to try and get it as a directed task. This consumes so much more time that is necessary to complete realtively simple jobs. This does however tick the B3 Do, which is effectively make sure that what is installed works.

Finally, the PEW deadlines are a bit rubbish overe the next two months. We have had over 4 months between AER2 and AER3 and then we get between 20 and 25 working days between AER3 and AER4. There is also a TMR and probably thesis form C to complete by the end of January. I think for next year’s students this is worth some debate at PEW as to whether this has yielded the best work or just work that would suffice. I am trying to feedback into the embryonic modular thesis process and see what peope think. I can see a positive note though and that is that by about March time we will be able to slow down a bit and take stock of what we have achieved prior to going for CPR.

North Sea Update

Firstly, I apologise that it has been quite some time since my last blog so instead of going into detail on any one subject I will try and write a bullet point list of the things that have been occupying my time and some points of engineering interest:

1) Financial. I technically approved an estimate for £2.5 million and some change. This was for the replacement of the high pressure discharge cooler. This covers the detailed engineering and offshore construction costs for the project and I had to go through and scrutinise each line of the 35 page estimate because there was only £1.8 million left in the budget.

2) Flushing skid Issue One. I had to prove to the process engineer that the formula used by the vendor would work. The vendor had stated in an email the formula they had used to calculate flowrate but the process engineer was unconvinced. Although the query went back to the vendor I thought it was quicker to try and prove it myself. See the attached picture for details and hopefully I’m not wrong because the flushing has now occurred.

3) Offshore. I managed to get offshore again and I did some line walking, which involves trying to decipher process and instrumentation diagrams and then trying to see if what is on the diagram matches what is actually on the asset. I was also involved in an isolation for potable water prior to the issue of a permit.

4) Flushing Skid Issue Two. When there was a problem with the powering the flushing skid it was suggested that the existing hydraulic pressure unit (HPU) may be suitable to flush the system. I did a quick calculation to prove that this wasn’t possible (below):

5) Apart from that, I have been doing all the project engineer stuff for my other projects, which is keeping me busy. Hopefully, my next blog won’t take as long.

More Electrical Issues

A combination of Imran leaving and some of the other SPAs being on holiday have contrived to make my life considerably busier, but in a good way. I have now taken over all of Imran’s tasks, the HP Cooler Replacement, the Minox Blower, Flowline Supports and the closeout of LP and MP Cooler Replacement from 2013. On top of this, I am still responsible for the Retrofit of Cabins and I’m intrinsically involved in the Lifeboat Modifications. I’m not going to touch on all of these areas, just the closest crocodile, which is a problem with a flushing skid for the lifeboats. I would appreciate any good ideas that may be out there.

The Detail

This job has not gone smoothly, it has had problem after problem and nearly all of them could have been avoided. The latest issue involves a flushing skid, which is a piece of equipment used on hydraulic equipment to clean the components and test the system. For the lifeboats job we are recertifying the davit A frame, which is used to recover the free fall lifeboat from the water if necessary but on Clair the davit and A frame have not been used in 9 years. Anyway, the flushing skid required has to meet certain criteria in order to adequately flush the system, in this case it needs to produce a Reynolds number in excess of 4000 and NAS of 6/7 but not to exceed 7. The job is due to start on 7 Jul, with the skid required in early Aug and a skid has been procured and been shipped offshore. The flushing skid that has been procured has a motor with the following ratings; 37kW/400V/50Hz and 43kW/460V/60Hz.

The platform conditions are 440V and 60Hz so a fair assumption is that the power output is closer to 43kW than 37kW. Depending on power factor and efficiency of the motor, it could draw up to 78A. I do not have a data sheet for the motor so I have assumed 0.85 for both. I have approached the manufacturer and vendor and requested the data sheet.

The flushing skid starts using star delta and as such it requires a 3 phase and neutral supply. The problem is that the platform only has a maximum of a 63A, 3 phase welding point from which to power the skid. Since it is the SPA in charge of this job in on holiday I have been left to try and resolve the issue and I am trying the following three options. If anyone has any better ideas then I’m all ears:

- Install a temporary JB and use a single cable from this to hook up the flushing skid once it is in place. Then, detach the cable, move the flushing skid to its second location and hook the downstream end of the cable back up to the flushing skid again. There is a switchboard that appears to have a spare cubicle, it looks like it has 3 phase and a neutral and is capable of taking 200A. However, there is conflicting information because the platform as built shows no neutral but the ABB as built shows a neutral. I have requested that the REP offshore checks what’s inside the switchboard and get accurate information. I sense this will take a lot of time and effort because it will require workpacks, isolations, method statements, a temporary electronic management of change, cable calculations and the procurement of materials.

- Get a new skid with a motor of a suitable rating to be able to be powered from the 63A welding socket and yet supply enough turbulence. This is my preferred option. It sounds the best on paper but I have no idea whether a suitable unit even exists.

- Source a suitable generator to power the flushing skid. It sounds a bit like overkill to get a generator for one flushing skid, and there may be problems with exhaust fumes and footprint depending on size of generator. That said, I know I’ve got a flushing skid that works already offshore so this is just the other half of the equation.

Since time is tight I have decided to pursue all options with equal measure and try and get a solution asap. I wanted to avoid holding out for option 2 and then find out it’s not viable in a week’s time.

What is frustrating is that this machine was released by OIS, an inspection vendor, as safe to use. This is the second time on this project that an electrical engineering problem has slipped through the net and caused problems further down the line.

In other news…

Brendan and I had to help out at Banchory Beavers Summer Camp. All I can say is that Brendan is bottom of my prospective babysitters list. He was beasting 6 year olds and at what point said “Listen in means you stop talking and listen to me or Nick. Oi chap, do you have a problem?”

Imran’s leaving do was a success. He got so drunk he lost his keys and slept outside.

Offshore Experience

I went offshore this weekend to get a feel for the platform and to complete a detailed recce of all my jobs. I was offshore with another SPA, and we went round the platform and explained things to me. He is a structural engineer by degree so he did his best but he was a bit put of his depth. It was kept to an idiot’s guide level of explanation but it was very useful nonetheless. I managed to steer the conversation away from steel and concrete so we covered all the important issues such as chemical processes, piping arrangements, electrical single line diagrams, safety mechanisms, utilities including use of gas turbines fire water, potable water, storage of fuels and chemicals.

I had a detailed look at the jobs I am likely to encounter such as the Lifeboats, HP Cooler Replacement, Cabin Retrofit, and DC Charger Replacement. I also looked at some of the jobs that Imran is desperately trying to palm off on me. All in all, I feel like things are getting really quite busy and people are ready to trust me with much more responsibility.

The first thing I noticed was how seriously they take H&S, and quite rightly too. They termed it an open environment and it was where every crew member felt it appropriate to approach another person on the platform and point out any issues, or potential issues. They called it a Time Out For Safety (TOFS). It was good to see how the different systems work but I did notice that the permit to work system does slow things t like too many permits open at once so work can end up being stymied.

Jobs for the boys…

There are quite a lot of similarities with working in the military that would make ex-Army a good fit for working offshore:

Travel. Be ready for hurry up and wait, it was like travelling with the RAF. I had numerous delays but without any good reason. I was almost bumped off the flight at the last minute only to be told to turn up on the off chance. What should have been 70 minutes of flight time (50 in a fixed wing plane and 20 by helo) took 6 hours. However, the airhostesses are not overweight men in sandy coloured coveralls.

Workers. The average worker is just like a career sapper but aged 40 – 60. They like doing what they know and no more. You have to double check on them and make sure they’re actually doing as they’re told. The more senior guys on the platform are like the NCOs and WOs. These guys are dynamic and get stuff done and know what to do through heaps of operational experience.

Routine. Work routine was like being on operations. They work long hours and have a bit of down time in the evening. They then have time off to play hard. A typical rotation is two weeks on, two weeks off. The platform was full of workers and not a place you’d want to be without a busy job. A bit like being stuck in Bastion longer than you needed to be.

Food. The food was the same as being on operations, Aramark get everywhere. It’s no wonder the Army can’t get a good deal by playing hard ball with Aramark because they must have much bigger contracts to worry about.

Pay. This was a huge difference; the guy I was with was getting £90/day extra for being out there. That would mean he would only need to be out there for 34 days to get the same as our operational bonus for 7 months (not taking into account tax).

Like for like, but not quite…

The pace of life in Aberdeen is picking up and people are actually starting to ask my opinion and give me more responsibility. In the last couple of weeks there are two jobs that have taken up a significant portion of my time; the modification of lifeboats to increase their capacity and the modification of 34 cabins on the Clair asset. Both of these projects combined will go most of the way of increasing the capacity of the platform from 120 to 154, which is the key enabler for the turnaround next summer. The cabin upgrade is going okay so I’ll only cover the lifeboats in this blog.

The Lifeboats

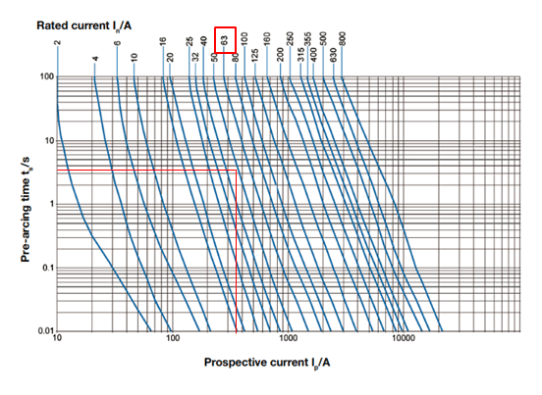

The lifeboats task has been rushed through a little bit and was supposed to be in two phases, with the first phase being like for like. Things have not turned out like that at all. Phase 1 is the recertification of a davit A frame used to lower the freefall boats into the water using a hydraulic pump unit (HPU); it is now definitely not like for like. Despite going through several levels of technical checks it turns out that the original 17kW motor has been changed for a 26.4 kW motor by the vendor and they failed to inform BP. At first it was assumed that the increase was because there must be a bigger pump in the HPU. However, this is not the case and it appears it was just the vendor standardising their HPUs. From their point of view it makes perfect business sense to standardise their units but it is criminal to not inform the client on what was supposed to be a like for like swap. As result of the change in motor there is now a problem with cabling. The current installed cabling is 6mm2 three core cable rated to 36A. Since time is very tight with when the job should go offshore the vendor is saying they cannot swap back to the 17kW motor and that the best solution is to de-rate the motor to 22 kW and change the protection device to accommodate the slightly larger motor. The calculation below is why this won’t work and why we are left with two options: 1) increase the motor and change the cabling or 2) leave the cabling and go back to a 17kW motor. What I have put below will be confirmed (probably more accurately) by WGPSN next week but this is what I think:

The old motor is rated for 17kW, with Ifl = 28 A

The new motor is 26.4 kW

In is the nominal current of the protective device.

The protective device is selected from a time – current characteristic curve where Istart up is 8 x IFL (for a motor) = 8 x 44.5 = 356A

Should the cable need to be replaced then the job may not go offshore because it will involve someone from operations risk assessing the work because there are other live cables in the pillar that feeds the HPUs. The asset may not be happy with this.

Risk Assessment

The other phases of the lifeboats are pretty much on track but there has been a great deal of risk assessment done regarding the construction because there is overboard work, scaffolding, hydraulic fluid and new technology involved. The whole process is very meticulous but occasionally there is a lapse.

When asked what was the mitigation for hydraulic fluid falling into the sea the response was to use big Norwegian thumbs to plug the hole or do it at night so nobody can see!! That sounds more like a Sapper’s approach to risk assessment.

I must stress, this was a not what was captured as the mitigation.

I will keep you up to date with this task because it is due to go offshore for the scaffolding in Jun.

Other news

I have been sampling the delights of Scottish cuisine and have come across a strange soup and a deep fried Mars bar. I’ve not tried the soup, I’ll save that for Joe Wood when he comes to visit, but the Mars bar was actually quite nice.