Archive

Captain’s Blog, Final Entry

As I wind down in the design office, I will give a quick recap of the Fort Drum UAV underfloor radiant heating design I have (mostly) completed. Having calculated the likely heating needs of the building using modeling software I set about designing the radiant system. From the total heating load required it is necessary to work out how much this load is per hour per square foot. In my case this was 96 BTU/h/ft2 which is double the recommended capacity of radiant floor heating which is limited to 50 BTU/h/ft2. In real terms this means the floor can provide half the heating needed and an alternate source, gas powered radiant heaters in the roof in this case, is needed. From this the floor temperature and supply water temperatures fall out from the manufacturers design parameters based on flow rate. If the full heating demand is used the concrete would have a surface temperature of 117F (48C) and would need a supply water temp of 180F (81C). In the International Building Code this is too hot for concrete which could undergo thermal shock if these temperatures are used. Instead the optimum is 90F(31C) floor temperature with 120F (48C) supply water with a ΔT of 20F (6C). The next stage is placing the pipework on the design. Without knowing the lengths of pipe you need in each run, you cannot see how the runs will fit, what lengths of the individual loops are (700ft is a rough maximum but it depends on several factors) or how many manifolds are needed. With 4 zones to heat I thought I would get by using one manifold for 10x 700ft loops per zone but the total flow of 50gpm in the system was too much for one manifold which could only take 45gpm. Having split each zone in 2, I was able to size the pipes for the system, from the under floor to the supply pipes, in Crosslinked Polyethylene (Pex) which prevents oxygen from dissolving in to the system and causing rust in boilers. With all the pipes sized and laid I calculated the pump size based on the static pressure (with a dual pump, lead/lag system to allow for failures and maintenance and the use of 40% glycol (for the extremely cold winter should the heating system fail)), the size of the expansion vessel needed and the heat loss from the distribution pipe work to ensure that the boilers are correctly sized. And that is it really. For interest, here is my finished design (ignore the duct work):

There are still some issues to resolve. Sometime this week the orientation of the trench drains in the centre of each zone was rotated by 90 degrees which has meant a last minute redesign. Originally my pipes were perpendicular and able to go under the drains. Now they are parallel they have to go round. The main hot water system is still not complete so I have not integrated that yet but that should just be a case of connecting to the header when it is designed. I am also completing the controls which are very simple. Essential the thermostats in each zone dictate the temperature that heating is necessary at whilst there are alarms to indicate pump failure, low flow rate and low temperature. The original brief called for a door switch so that the system would stop if the hangar doors opened but this only really applies to forced air heating systems where the energy could be blown out of the building. As radiant heating heats the object not the air, this is unnecessary.

A little bit more of a technical post but not a bad place to finish.

And in other news:

The gun debate continues after yet more school shootings, the East Coast is currently under several flood watches because of the unseasonable rain (8 inches due today) but at least it is warm and a soldier has been freed from teh Taliban but did he desert in the first place? I now have a week to sell the cars and electrical goods, reduce my possesions down to 11.5m3 (sorry kids the toys are going) and make the furniture look like new before the Embassy takes possession of it again. See y’all in Phase 4 if not before!

And now for my next project……

Like my colleagues, the blog has been on hold whilst I finish my thesis. Since then it has been hi tempo in the office too, as we complete (mostly) the Marine Terminal HVAC design and start on a UAV hangar design in upstate New York. As rather a lot has happened in the last few weeks I shall try and make this bite size.

Quantico: My invitation from the USMC meant I was able to sit in on a 1 star R&D briefing on the latest energy saving measures to be implemented. This included not only changes in policy but a whole host of kit that can either harvest or generate energy to supplement current needs. This includes boots that can charge your radio batteries as well using waste generator heat to wam up shower water. A very ineresting experience particularly as the USMC seems to have less money than we do and is getting industry to do the research for them rather than doing it themselves for the sake of those lucrative government contracts. Needless to say some of this experience ended up in my thesis.

Caven Point: As with all design project coming to an end, this has been a period of mind changing and total redesign. This including swapping ouot VRF for VAV systems, totally removing VRF from workshop areas and changing all the asociated air handlers, make up air units, louvres, fans etc accordingly. Then at the 90% we received requests for additional items including, extra partition walls in large office areas (total recalculation for the room(s) and equipment resizing), changing A/C to just ventilation in three warehouse rooms (more equipment redesign), Air Curtains over all roller doors (to stop flies and heat loss – a ‘helpful suggestion’ to the end user from one of my team) and all this with a week to do just after the thesis deadline. The lack of communication between the design team has beenthe biggest frustration in this period. It still happened that every day I log on and there is a change on the drawing that affects me considerably or the user has realised that something is not quite as they remember asking for and needs changing. Part of the game I know but the inability to stick to the design requirements set out at the beginning of the project has added delays. The whole process is so rushed that any Contractor taking this on stands to make a fortune in changes due to design issues. At least I won’t be around when that happens……..

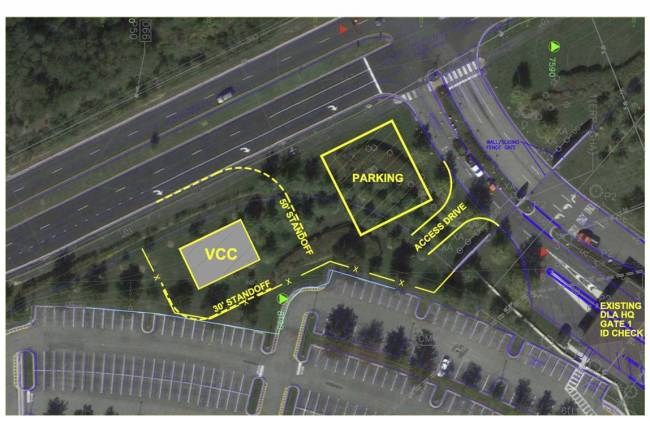

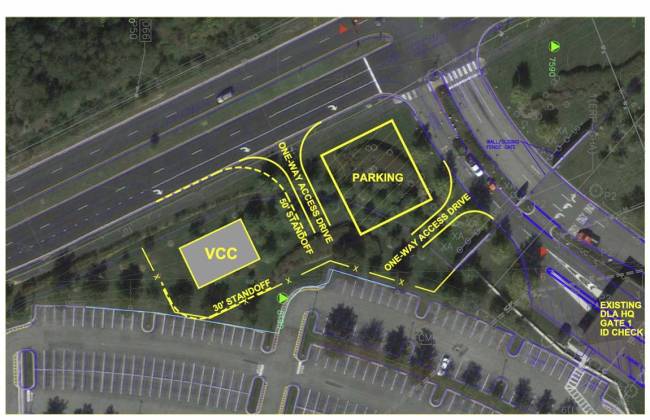

Fort Belvoir VCC: I attended the project kick off meeting in early April which turned out to be a classic case of ‘You can lead a horse to water…’ with some of the shareholders. To recap, this is a visitors control centre which processes people attending mostly retirement functions who are not DoD employees. A glorified guard room in short. However this facility must also be a 24hr facility, blast protected and strategically placed, just in case the worst ahppens. Located after the turn in to base but before the main gate, it is still a design that needs refining hence the meeting. What started off as formality eventually ended in a 3 hour contradictory argument. But to explain this I need pictures:

Option 1 the Garrison Teams favourite optioin

Option 2 Everyone elses favourite

From the start the Garrison maintenance team said option 1 was the only choice. We questioned this because it clearly interferes with traffic going in to the main gate, causing a potential bottleneck which stop entry to the post or could easily be missed in which case the only way to get back to it is to go on to camp, turn around and go back on the highway. We were politely told this would not happen because the only people using this facility were going to be going to retirement parties normally held mid morning, coming infrequently and that people turning around behind the gate is just what happens (I should add that this is the most heavily guarded gate I have seen in the US!). When we pointed out option 2 offered a far less likely chance of causing obstruction because it could be accessed off the main highway and if we made this road 2 way and no one would ever need to go through the gate in order to turn round, thus improving security. We were told that this choice would obstruct the rush hour traffic on the highway because up to 100 people could need passes all at the same time, any time of day (probably rush hour) and that the gate guards were quite happy waving people through to turn round! There was still no resolution after 3 hours so it was left to an admiral to make the call. I think he diplomatically chose a design that was a compromise. From the mechanical point of view, one of the staff was keen to get renewable energy in to the building. They wanted solar water heating and a geothermal heat pump. We presented the case that solar water heating was not financially viable for a single toilet sink and that a geothermal heat pump would be $40,000 more than air source heat pump and would take over 30 years to pay back. The customer went away unconvinced that money should be a barrier to green technology!

Fort Drum UAV hangar: Because the VCC was so small I was given the chance to put my radiant floor heating research to the test with my next project. This is $30 million UAV hangar in Northern New York State where the minimum temperature is around -30 degrees and 35 degrees in the summer. Most of the building is a standard design but the loads for the location need to be recalculated. However the hangar floor (25,000 sq ft) is going to require full underfloor radiant heating and no one in my department has any experience so I get first go! We have no design software for this so it is back to hand calcs to work out all the losses etc for sizing. Still no idea how I will draw this system either. And a 65% design is due in 2 weeks!

A UAV hangar

OPD: In the USACE Officer Professional Development course we are given the chance to get an insight in to the responsibilites of the District from the eyes of the Commander which means seeing some pretty interesting stuff in the local area. We started with an American PFT complete with 2 mile run, which we all passed, before heading off to the debris vessels. These are used to keep the water ways clear of logs and other debris as well s scooping the bodies out when aircraft land in the Potomac. Next was the Springfield site where a specialist team was clearing mustard gas and UXO from a former university house basement using equipment that would not look aout of place at USAMRICD. This required great tact from the team in dealing with the public who are understandably twitchy about having UXO in theback yard! We visited the Washington Aquaduct to see how USACE produces most of the water for the DC area before a visit to the new Intelligence Community Campus Building. The current buildings are being ripped out, including the fascade, then are being rebuilt as lecture facilites to meet modern code as they were nearly all built in the 50’s and 60’s. This propject had encountered numerous problems with the public, who did not want to see any new building and were against all construction (even if it is in the National interest). This resulted in delays and a reduction in height of the multi storey carpark so that it is below tree top height. Our next day started with a VIP trip to the Pentagon. This building is absolutely enormous (2.4 times the floor space of the Empire State Building) and was modernised recently to be a little town with every single type of shop so no one ever needs to leave. We were given a brief on the role USACE plays in the DoD and then saw the site of the 9/11 impact where a Chapel of Reflection commemorating those who died, is located. After a hasty lunch we tool the metro to the Capitol Building where were given a guided tour which included showing us the few areas the British did not burn down in the War of 1812. We are able to see the Senate debating but this was not that exciting with only 2 senators in the chamber. The final part of the experience was a trip to Arlington National Cemetary which is managed by USACE too and is still Army property. The plot size is enormous and they are having to expand to meet the projected demand until 2050 (barring no more major wars obviously). The most impressive part was seeing the guard change at the Tomb of the Unknown soldier. If you think you can do rifle drill, google this and find out how it should be done!

And in other news:

The weather has been a little unpredictable recently, with a retaining wall collapsing that took half a street with it in central Baltimore. The rivers rose 6ft in 12 hours and we are getting the same again tonight. Wildfire season has started in California which only mention because the USMC base I was invited to in order to see the demo of the equipment mentioned at the briefing has just been evacuated!

I was able to volunteer for a STEM evening at a local Elementary school where the kids learned how to build bridges using toothpicks and marshmallows. This was optional for the kids but amazingly we had 3 full classes and a merry time was had by all.

And on the home front Warrick is really enjoying baseball and develping a good swing, Ava has now turned 4 and we are making the most of the last few months by day tripping to New York, Philadelphia and Amish country with a break in Ocean City due in 2 weeks. So much to do so little time……

Great (Unrealistic) Expectations

Tomorrow is the deadline for our 90% design submission for the Marine Terminal to end all Marine Terminals. In the past 3 weeks there has been a major design change every few days each of which invariably affects the team progress. Firstly the electrician needed another 6 inches per floor for his cable trays. Then the architect and structural guys decided that the maintenance area and warehouse needed to be storm proof which meant upping the walls from steel skin with 6 inches of insulation to steel skin with 32 inches of concrete up to 11.5 feet high then steel and insulation. Forgot flood proof this is now a bunker ready for the zombie apocalypse, apparently essential for a small boat workshop with a bit of welding and a battery store! Finally we had to request an extra 2 feet per floor when we finally calculated the loads and realised we only had 3 feet of ceiling space to put in the HVAC system when the standard over here is 5 feet. Hence this week the section has been working under conditions I have not experienced since Phase 1 design exercises.

It has not been all bad. I have managed to crack Revit, design software, with only minimal instruction proving it is user friendly and intuitive. No problems drawing pipe connections between floors with this one and it is also a BIM program so I can avoid all the other services and structural components. However we are only actually going to provide a 50% solution. We will complete the duct work design but there are still the gas connections, condensate drains, electrical connections, technical specifications, controls details etc which need to go in the full design. Fortunately we are not the only ones in this position as the intention to design a building form 35% to 90% was a tad unrealistic in 10 weeks with all the changes. My Section chief bought us another 2 months to get this done.

My next project is also about to kick off. We have had the preliminary meeting and met all the stakeholders to discuss some early concept ideas. The building is a simple guard house with a standard design that needs to be updated for the delightful Maryland weather. The biggest challenge is actually for the civil guys who have to squeeze a car park in to what is currently a flower bed who are already considering a drive thru option so as not to cause traffic build up on the 3 lane highway beside it. The building is looking to cost around $4 million but that will be based on what design we come up with. The building owner would love to have Geothermal heating, solar heated water and PV cells galore however this is a little excessive for a guard hut with one sink and a cctv screen stuck in a flower bed. Sadly. The requirement has come about because of the number of retirement parties on site to which the public get invited and we have been warned up to 100 people can be in this guard hut! The customer is the Defense Logistic Agency, whose security on this site is second only to the NSA. This was a “No Photos or you will get shot” zone but hopefully this google earth image helps put some flesh on the bones.

The VCC flower bed guard house (40ft by 60ft)

Having read about the experience of all my colleagues it occured to me that I have not fully explained how life as a US Government engineer actually is. Starting at the bottom, all interns start a two year program where they get between 2 weeks and 6 months in all the departments in the District. The longest time is spent in the design section of their college major and in a field office, both 6 month attachments. In this time they are assessed on where there skills best lie so that after the 2 years they will go to the department that they will work best in. They are given plenty of opportunity to get involved at an early stage and are considered ready to go after the 2 years. Typically on a site they are project engineers where the responsibility is to ensure that the contractor does as he is meant to, that the budget is not exceeded (too much) and sort out the inevitable contractual “disagreements”. They have the authority to write changes and approve RFIs and sumittals which can require technical analysis. They will also have a few Contractor Representatives (Conreps) under them (depending on the size and complexity of the project) who are responsible responsible for QA and report the on site issues and who the engineer manages. The project engineers are also the USACE representatives at all meetings with the client and contractor and on the smaller projects are responsible for all engineering issues regardless of degree. This load is shared on the bigger projects with several engineers types to cover all eventualities but with a good level of communication across the office. Promotions are slow taking 10 years for the good ones to become the senior engineer / Contracting Officer’s Representative (think sqn 2 i/c) and another 10 to become the resident engineer (OC) heading up an area office. Careers can span 40 years easily. The pressure to ensure that budgets are met are not as great as the Contractor’s need to make profit, on time, to an acceptable quality, because money can always be found from Congress, but the professional pride in not letting the Contractor rob you blind whilst still being diplomatic and ensuring that the quality is met and the time frame not exceeded has its own pressures. The Resident Engineer and Contracting Officer’s Representative are kept in the frame at all times and do the career reviews, budget management and higher level planning. Most become Professional Engineers (CEng) and there is at least one CPD course a year paid for.

The Design Section seems very similar to other design teams. Lots of very technical people doing number crunching to produce the designs and the only person with a managerial role is the section chief for each discipline. They are actively encouraged to explore new design concepts particularly if this will lead to savings in energy and efficiency in which case the love is shared and everyone learns about the new kit. Yes it is a bit quieter than the cut and thrust of the area office but these are not social inadequates, but professional, motivated individuals who don’t much of an excuse for an after work shandy or two. Career progression is in line with the guys on site with the section chief taking 15 years or so. The Section Chief does the managerial side of the business but is also involved in the technical side. Although not directly producing the designs they will be familiar with the intricacies of all the projects on the books. They also manage the design budgets, plan the project schedule and attend the pre project meetings.

With USACE the clients are always other Government agencies. This can be anybody from the NSA (who account for about two thirds of the District’s Portfolio) the medical services, DLA and federally managed civilian infrastructure, mainly levies and dams. USACE are normally the ginger step children in the construction process, being the subject of frustration rants from the client, designer and the contractor when things are not going according to (the often optimistic) plan. As the clients representative they have built their reputation on producing high quality government projects, but they expect to get sued after every project for liquidated damages (and lose) even if the contractor is solely to blame. However after all that the guys and gals are all very happy particularly as retirement seems to be the only way people leave the organisation. There Navy also have their own civilian construction engineers (NavFac – Naval Facilities) as do the Air Force (no funky acronym weirdly). All civilians are able to volunteer for operational tours as well, with the average tour lasting six months and worth 2.5x their regular pay check.

With impending cuts due the future is uncertain. The Army is to reduce from 550,000 to 450,000 and the process is only just starting. A number of planning exercises are likely to be run where less needed jobs are removed and the person involved is notionally demoted to a lower grade but still employed, some times in another district, and given a warning that their job is not likely to be around so that they can look at the options. With 33,000 in USACE it is certain that cuts will be made but being a busy organisation who supports overseas operations it is hoped they will not be severe.

And in other news

We had spring for a whole weekend then after 50 mph winds winter is back for a bit longer with more snow due Monday. The baseball season has started again and the Orioles are currently second in the Grapefruit League. Not sure what that means but it sounds impressive. Warrick is signed up for the local team which starts softball in April with 2 games a week. My engineering skills are being tested to the full with his home work, having had to devise a Leprechaun trap as well as producing a set of experiments for his STEM fair. Sadly my thesis proved too technical so I have had to come up with a whole new idea. Ahhhh the pressure! I have finally got the invitation to Quantico. Although not the FOB demonstration exercise which is California in May, i should still prove to be an interesting experience.

“Everything is Awesome!”

I am actually enjoying being in the design office. Not because of the hours of never ending spreadsheets which mushroom in to new ones every time you think one is done. Not because the architect changes the size of the building every time I log on which really mucks up your heat and cooling load calculations and means I have to recalculate everything daily. It is because sometimes I get the chance to be part of something unique and world famous.

2 weeks ago I was in West Point as part of the mechanical consultancy team from Baltimore. My line manager and I were invited to attend a Quality Assurance review for the new barrack block which New York District are taking the lead on. West Point is enormous. Granted it runs 4 year college degree schemes and is not just a military finishing school. This place is built to last and actually has Ivy League Status (3rd in the ranking after Harvard and Princeton). Started by the Corps of the Engineers in 1802 following the Revolutionary War with Britain, it has been a seat of learning since the Sausage Factory was merely a prep school and is expanding. They need more accommodation

Some Renderings to show how the new barracks will look.

The new building philosophy is to make buildings as green as possible (ideally to 0% emissions) by reducing energy loss and increasing efficiency (hence lots of glass and big open spaces to circulate air more freely). Sadly PV installations have been rejected (the generals over the river Hudson didn’t like the idea of seeing the stony fortress with sparkly roofs) and geothermal not practical (there is surprisingly little space for the extra outhouses and the place is built on sheer granite cliffs) so efficiency and use of natural cooling and heating are the key. So how do I fit in? The new buildings are all to have radiant flooring for cooling and heating which is very bold. A system of pipes set in the concrete floor laid in a topping slab 8 inches thick through which hot or chilled water is pumped to provide the necessary comfort conditions. So in heating season the floor provides radiant heat and in cooling the ceiling absorbs away the heat and cools the air. This system still requires a boiler and chiller but as the energy transfer is through water they are smaller and losses transferring the water to the rooms are considerably less. A Dedicated Outdoor Air Supply (DOAS) is necessary to prevent condensation build up but this is a fraction of the size of a standard ducted air system. The problem is the designer nominated has never designed this system before. So we were there as technical experts to asses the the viability of the system because if it is successful this system will be used in the refurbishment of all the living accommodation. Granted, everything my Line Manager and I knew was from 5 papers we read before arriving but it was enough. The main concern was raised by the Head of Maintenance who, until now, has only ever managed buildings with big air handling units using fan coil units to heat and cool the rooms. Big ducts and inefficient fans with big chillers and boilers make this an inefficient system but as the the building maint teams are full of guys nearing 60, Head of Maintenance is worried about training them up on a new system.

The rest of the team was their to review the project management plan, the general management processes and the commissioning process (which New York District want to do themselves). This internal review takes members of other districts to check the process, providing the sanity check that the whole project is going to work. This is an interesting concept because they have the manpower to achieve this, especially as New York is a tiny District with only a handful of projects going on. So after a foot of snow trapped us in the hotel we blitzed through the design and came up with the following recommendations for the radiant floor system:

The rooms should not have switches on the windows to turn off the system. The rooms could still be heated/cooled with out significant energy waste (the windows are the size of cat flaps anyway!) but a dew point sensor needs to be installed so that the system does cut if the room reaches dew point to prevent condensation from building up.

The current floor design calls for a layer of insulation between the topping slab and the structural slab. We think that putting the pipe system in the structural slab will make the cooling ability of the system more efficient because there is less thermal mass for the cooling effect to pass through. The current design anticipates the floor will cool the rising hot air when most cooling takes place in the ceiling. In the top floor an extra cooling slab is needed in the ceiling to ensure that these rooms benefit from the cooling.

The design needs to be reviewed by someone with technical experience – ASHRAE have been carrying out studies recently on the system to establish the best way of achieving the effect but there is not a lot of experience in this country in design.

The recommendations were accepted and we even managed to convince the Head of Maintenance to talk to Dartmouth College (New Hampshire) who installed this in 2006 where their head of maintenance was equally dubious but now loves it particularly because there are no fan coil unit filters to be changed from the top of a step ladder! Construction has started on site and they are having to blast away 70,000 tons of granite cliff to make room for it.

The site today. Note the big bundles used to tamp the explosions and the explosive drilling rig on the right.

Meanwhile back in Baltimore the Marina is still plodding along. Despite a few deadlines passing we are all getting extra time especially because the architect changes the design everyday. My solar wall has been canned because the architect doesn’t think the external wall will take the weight which he could have factored in if we had been involved for the start of the process and not at the 30% point. We have now sized the VRF system but still have to work through all the spaces that don’t need VRF, work out the exhaust rates, calculate make up air rates, add gas radiant heaters to work areas etc. My mentor is getting obsessive about some really trivial details which is also slowing me down. Currently he is planning to upgrade the current portable dust collector with an industrial grade wood mill sawdust extraction system for the saw bench because his only reference book on the subject is the Guide to Industrial Ventilation. He also asked the user if they would like the new ferrari system which they are now keen to install. In reality the current portable system more than meets the needs of the new users who only use the saw once a week max. We have had 2 snow days which is another reason we got more time particularly as New York had more snow days. This was even after the Project manager in New York called the head of design in Baltimore to question our ability to complete the job but then went straight to the head of engineering (the equivalent of a captain going to a full Col because Troopy might be late). Needless to say the PM is now back in his box.

I have been deemed ready for my next project in March which will now be a Visitors Control Center (think large guardroom with conference rooms) and if there is time another barrack block renovation in Aberdeen complete with “Collabratorium” meeting rooms. Lots to do.

And in other news:

Today here was a stabbing in the 7/11 over the road from the office which was a little out of the ordinary even in Baltimore just like the tornado that touched down 50 miles south of us. Puxsatawny Phil predicted 6 more weeks of winter on Feb 2nd and despite a 39% success rate the little bugger was right this time. The polar vortex is back next week. We managed to get a long weekend at Disneyworld Florida and stayed in the Shades of Green resort specifically reserved for serving and retired members of the US armed forces for next to nothing and a discounted park ticket. I am still the best Dad ever especially after selflessly taking my daughter to meet all the princesses. And the title of this piece is the theme tune to the new Lego movie which I took the kids to see and can’t get out of my head, but it seems quite apt.

The Impact of the Arctic Vortex in a Design Office

Since the end of the holidays the weather has been a touch on the chilly side. In early January there was even a frostbite warning for people venturing on to the streets and the public transport literally froze. So since the New Year there have been 5 snow days, a bank holiday and then my mentor took 3 days sick leave. Combine this with a week long delay to get the energy modeling software and the knock on effect is a delay in productivity. Not always a bad thing except I was hoping to write my TMR using my project as a basis. Now that is in, the tempo is picking up, naturally. The modeling is nearly complete and I am now working on equipment selection and looking at incorporating energy saving technology in to the design. The first is to use a variable refrigerant flow system as the primary heating system. This is an old Asian 50’s technology which is starting to become very popular over here because of its efficiency. The principle is instead of pumping heated air round a building in large inefficient ducts, you simply pump the refrigerant directly to the room it is needed in where a fan coil unit then blows over the expansion vessel producing cold air at the right condition. What is even more impressive is that the expansion vessel can be switched from cooling to heating with an automatic valve change. Even cleverer still as that all the fan coil units (up to 50 odd) can be linked and can become heat recovery units too so if a room is too cold, the refrigerant in a room that is too hot can be directed to the cold room without going through the compressor. The Compressor/condensor unit is kept out side, so no mechanical room needed, and is about the size of a large fridge. As the building is aiming to get big points for green technology this is looking like a good system. The second design is for a Solarwall heating system. Placed on the SE/SW wall of the building this is free heating for relatively little investment ($20,000 for 2000 square feet) provides nearly free heating. A semi permeable polycarbonate shell heats the air, through solar energy, against the black wall which rises up the wall and is accumulated at the top where it is then pumped in to the space through a fabric duct with holes, like an ITC aircon duct. This will be great in the large warehouse area which VRF struggles to heat and often has the large loading door open. I have not worked out the energy produced but this was used in Harrisburg heat my warehouse too (see Matt Fry’s blog) where it has proved very effective.

I took the opportunity to visit my possible next project, Hale Hall. This former 1920’s barrack block was retro fitted with HVAC over the years before catching fire in 2006. Going round the building meant getting dressed in protective suits because of the presence of mould and bird poo. What was strange was that the fire damage was limited to the roof of one side but the whole building was water damaged and trashed. It was like walking through a time tunnel because the place simply had all the top secret stuff ripped out and was left. Not even desks had been cleared. Below are some of the odd HVAC designs I discovered.

As you can see all the HVAC will come out and be replaced! There are a few more weird designs but alas my camera lasted 11 shots at -8. The current budget is for $20 million to do the revamp complete. However the current estimate is $18 million to carry out the demolition alone which includes clearing out the debris and old office equipment. If this had been done at the time in 2006 instead that would have saved a packet. Now a specialist contractor is needed in full 4 Romeo to clear the building because of the biological (and asbestos) hazard. This project is likely to get paused whilst the budget is reviewed.

Two smaller projects are coming my way potentially. One is a new hangar at Ft Drum in up state New York. Based on a current design it will be my first chance on my own to design the HVAC. The second is a small Visitor Control Centre office block of about 5000 square feet which also requires HVAC. I have also been asked to go to West Point next week to look at a barrack block HVAC design. It is to have a new heating/cooling system which consists of underfloor heating in the winter which is then switched to a chilled roof arrangement in the summer. The Department for Public Works is the customer but is concerned that the set up will lead to condensation and mould growth even though it is ventilated. I will be going with the section chief as a technical expert. Best do some reading up!

And in other news…..

The cold weather is set to continue and the deep south is now in chaos after 3 inches of snow fell because they don’t ever get snow and had no ploughs! The Superbowl is this weekend but no Ravens this time as they actually got dropped from the wild card slot after a terrible end to the season. And the gun debate continues after a shooting in a Mall 30 minutes away. Luckily I have a thesis to distract me.

A New Year A New Challenge

Now back after leave, it is time for an update on Phase 3. I am now working in the USACE Baltimore District Head Quarters Mechanical Design Section and have managed to get my own office complete with window, a perk normally only given to section Chiefs, like my line manager. So with this excellent start in mind I found out which projects I will be working on.

Caven Point Marine Terminal

This is the USACE New York District hub for their Operations Division to run research on the rivers and sea areas around New York. On a nice point of land opposite a car recycling plant and the Manhatton skyline (complete with Statue of Liberty) it has a unique position with in the Army Corps. In Nov 12 it was hit by a 10ft high tidal surge produced by Hurricane Sandy. Although the building withstood the surge all the documentation and equipment in the building was destroyed. Now a shell with some tools and computers in it, $29 million has been set aside to create a new building to replace the current set up. This project has a few unusual characteristics. Firstly USACE is the customer, design authority and project manager and as such there is no contract. This means that many of the normal contractual issues can be simplified ie last minute changes to designs by the user completed by group consensus, but does also leave scope for issuses like last minute user changes! The money is coming from a Federal fund set up to repair government buildings damaged by the Sandy specifically. So far $6 million has been spent from the awarded $35 million hence our budget of $29 million. However while we are designing to this budget if another government agency finds they could do with money from this fund the New York District must give it to them. Consequently there is now pressure to get the money allocated to this project before someone else spends it! New York District Military Design Branch has requested that Baltimore Mechanical Design Section help out because their own section is over stretched. We will be providing the HVAC and Fire Protection designs for this building which is currently designed to 35%. This means the building envelope design is nearly complete but no subsystems have been designed in terms of Mechanical, Electrical and Plumbing. Normal procedure would see us comleting a 65%, with most Mechanical design complete, in 6 months and 95% ready to advertise publicly by this time next year. However the Project Manager now needs a 95% design by mid Feb 14 in order to secure the funding. This works out well for me as I should get to go through the whole design process (and complete my outstanding UK SPEC competencies) by mid Feb 14. At the moment we have a blank canvas on the design. We carried out a recce just before leave, met the design team and the end users who are actually fromthree departments: Support Staff who mend boats and look after the building, the Survey Staff who do the scientific research, and Construction Division who have admin offices there for the civil works programs they run in the area. The new building must therefore incorporate a maintenance workshop, research labs (basic nothing hi tech) and office space. The Office and Lab space is now to be raised 10ft above grade so that future events do not cause any damage, with all fittings in the workshop, which will be at grade to get boats in and out, at either 6ft or suspended on retractable mounts. The building must also meet Leadership in Energy and Environment Design (LEED) and prove to be not only more efficient than the current building but with minimal or positive impact on the environment. So plenty to think about!

View of Manhattan through the unseasonable weather

The Marine Terminal. Note the rust line on the walls which shows how high the surge was.

The ugliest building I have seen in New York. It is a 1920’s design and is an office block!

Nathan Hale Hall, Building 4554, Ft Meade

Hale Hall was a building belonging to Army Intelligence when it caught fire in Oct 2006.

The top floor was largely gutted and since then the building has been open to the elements.

Hale Hall Today.

Money is now available to get the building renovated and back in use as an administration building. A number of structural repairs will be needed as it still has no roof. It will also require a new HVAC system too. This will be my next project although there is no indication yet of the size of the budget. The initial meetings have only just started on this project so I look forward to site visits in full 4R because of the biological contaminants associated with exposure to the elements (racoon and bird poo!).

And in other news:

The transition to Baltimore has been painless although the commute on the light rail is interesting as Matt Fry alluded too in his blogs. The conversations can be very random! The District Christmas party was a unique affair. Not only was it a dry event, it was held at 1100-1500hrs! The food was a very good buffet Christmas lunch Caroline and I we were honoured to be on the top table next to the District Commander. Here I noticed another difference between the US and UK – the knife as part of your cutlery is very much ceremonial! After food there was reindeer racing, a raffle drawn by Santa (the District Commander) and some party games including one where I was the best dressed Christmas Tree thanks to the military guys in the District.

The weather has been pretty unseasonable with snow prior to and over Christmas and more since New Year. The Polar Vortex is coming tonight with temperatures expected to drop to -16. That might be another snow day!

End of the Chapter

I have just returned from my leaving breakfast having received a presentation piece from the whole office, a piece of a welded attenuator to help remind me of my experience!

In the last few weeks I have been winding down and handing over and have the following to report:

Commissioning – Pressure Integrity Testing – The animal holding rooms were checked for air tightness. These rooms are used to hold animals prior to and post testing so they need to be sealed inorder to prevent the ingress of contaminents or anything that may affect results. The testing is done by sealing the door with a vacuum pump so that the pressure becomes negative (pressure differential of 0.25 inches of water) then soapy water is sprayed on areas a leak is suspected of occuring. If there is a leak bubbles develop (see below).

Considering this was a retest it was disappointing that all 5 rooms failed. Most corners leaked, all the air tight plug sockets leaked and all the data points leaked. It has taken them 3 weeks to caulk these up so far…

Filter Installation – The sub attempted to install the pre filter (particulate), HEPA (High Efficiency Particulate Absorption) and HEGA (High Efficiency Gas Absorption – charcoal) in to all the lab filters. In the initial installation meeting the manufacturer stated silicon grease is need on the filter edges to stop them adhering to the housing. If not the filters stick and tear open releasing allsorts of nasties and creating a big clean up problem. This was agreed by all as essential until the actual event when the sub decided he could save money and get the job done quicker by not greasing. On investigation we found this was a recommendation and not specified in the contract so $14,000 later the sub is now greasing, on the grounds that this is a safety issue and should have been in the contract.

Sound Attenuators – I have now visited all 572 sound attenuators in the building and established all the parts of the change have been carried out – that one crew of 3 was used to change over 372 of them to the welded standard, that the bolted flanges with butyl gaskets above and below the floor (as opposed to the clamped sleeve fit originally installed) are installed and the rooms are all sealed between floors. This took 240 days which the Contractor is claiming as an extension to the contract time. Although I will miss the argument on why only one crew was used (a welder and 2 workers, not really technical) the time will be given because there is no physical way the project will be complete by Feb 14. This will take them over the current finish date of Jun 14 which I still think is optimistic. There is a reluctance to call for liquidated damages because the subs on this project are nearly all going bust (bad for the Government to be seen destroying business) and the project is too big to fail. However the cost is still negotiable as $12,000,000 seems excessive! This due to a number of overheads and the fact that relate to the change occuring in 8 parts. However our estimate is currently $3,000,000 for 100 days.

Vacuum pumps – Finally the designer gave me the calculations for the vacuum pump sizing. The issue boiled down to an error in the specification the designer added to the drawing. The pumps were listed at 104 ACFM at 28″ Hg each and should have been 330 ACFM at 28″Hg each. This meant the expected flow rate for 2 pumps running to support a diversity of 35% is 37.85 Standard Cubic Feet per Minute (SCFM). The filter is rated for 25 SCFM, so really is undersized. The parallel arrangement for the extra 25 SCFM filter was correct. We had a teleconference with the sub, designer and pump manufacturer who all agreed by the end that this would work with no back pressure issues for the extra resistance. Mission complete. The designer admitted fault and will do the revised drawing for free. The filter is still going to cost $5000 each to install, one in both B and C building.

Floor Drains – our cracked floor drain issue never really ended. On review we convinced the contractor that we needed to check the drains again. The first test is to run water in the drains to check they are not cracked too. We then requested that the drains be tested by pouring water into the drain to simulate the flood condition they are designed floor. This is because the drains were all installed in 2 parts. The recommendation is that plastic flashing is incorporated in the joint to so that water going between the drain body and concrete is directed to the weep holes.

The flashing should sit between the base piece and the plate below the strainer

However the spec did not call for flashing so we are now worried that the drains are going to get leaks round them when the concrete shrinks and cracks. As some of these drains are above the labs this could be disastrous. We have agreed to test 20% focusing on the accessible ones to minimise damage. However if over 10% leak we will need to consider remediation which looks like core drilling a hole around the drain an inch deep then filling the void with caulk! Testing starts next week.

Pump 17 – The sub organised a meeting for the designer, contractor team, USACE and the motor manufacturer to discuss the motor performance. As anticipated the manufacturer rep was a sales rep and had not understood the test results sent to him, paniced and promised a new motor! It arrived a week later but has not been fitted yet. We are still waiting to hear what the in rush currents should be. I suspect if this motor runs well enough the whole episode will be forgotten and we will continue with the oversized pumps, throttled to death and wasting money through inefficiency before burning out prematurley.

Whole Building Maintenance – the contractor was unable to produce the revised operation and Maintenance program for the building in time for me to assess it. The recent maintenance report is better but still needs tweaking so I leave the system in a better state with all parties talking amicably and my successor starting dealing with a nearly finished product.

Tomorrow I am giving a presentation on the Corps to my fellow officers before starting phase 3 on Monday.

And in other news:

We had another Staff Ride for the military guys to Gettysburg, this time all day with a lecturer from the War College to further explore leadership. There is always something new to learn here.

The Engineer Memorial at Gettysburg, ironic because there were no engineers at the battle!

The Ravens have won a few games now and are in the playoffs for the SUperbowl but their chances of a double are slim. We were invited by friends of mine in harrisburg to Thanksgiving. We ate turkey and ham until we couldn’t move then had pumpkin pie for dessert, great training for Christmas. The Black Friday sales were not too bad in Hunt Valley so I have done half the Christmas shopping and we took the kids to the Mummies (think egyptian) exhibition in Baltimore, stopping by the German Market on the way for a gluwein. We had back to New York this weekend to see the Christmas sites and neet Santa at Macy’s. Silly Season is well and truly here.

Back in!

A 3 week delay enforced because I have not been in the office much means I have lots to tell! 3 weeks ago was the annual British Army Staff Conference (BASCON) held every year for all UK Army personnel to receive an update on the current Army issues. This was briefed by a number of generals looking at the current challenges and giving us the latest news which we are not able to get over the US intranet. For those coming out this is a great time to make contacts. I have now got a POC at Quantico where the USMC is pioneering research in my thesis field, deployable energy production and integration. I have been invited to come and see how the USMC is tackling the situation which will prove invaluable I am sure. Time of visit is still TBC but hopefully in the next week before the Thanksgiving/Christmas shut down. There is also the Association of US Army Annual (AUSA) meeting where defence manufacturers descend on DC to show off their wares. Attendence is by invitation according to the Embassy so I missed it, but I know others organised their own tickets and got in. Luckily a colleague of mine grabbed a load of literature for my thesis so I was ablt to get some benefit even if I did not get in.

In Aberdeen work is ramping as people leave the Office Engineer realises I only have 3 weeks left in office. Current issues include:

Equipment Maintenance: The customer, contactor and I have been working to ensure that the everyone understands what is expected. Recently we have had design firm representatives on site to brief up the boiloer operators on how to use the kit more efficiently, a tricky problem especially as the boilers have no real load to supply. After my visit to see the automated boiler water quality monitoring system and seeing how the manual method of water quality management is not very effective I have asked the designer and Customer to consider an early upgrade prior to or as part of the service contract. This has met with an encouraging response as everyone is aware of the potential problems and expense of a boiler breaking.

Pump 17: Having asked the design team to review the design for the whole system for the condenser cooler they have agreed that the pump is oversized (to allow for scaling!) and should face remedial action. An impeller reduction is their prefered solution because they are hoping to pin this back on the contractor. The electrical issue with the pump is still not resolved but Pump 19 is now tripping the same way that Pump 17 is. It was agreed that a VFD would be the best solution but the purse is pretty empty and long term cost saving is rarley considered an investment. The motor manufacturer has yet to reply to any questions.

Surge Tank: The blow down seperator to the boiler, which removes debris from the boiler tank currently empties in to a 4inch drain which floods because it is to small. It was thought that a surge tank would alleviate this issue so I was sent to investigate. Initially it seemed the best option although at $30,000 an expensive one. There were a number of issues. Location was a problem because of existing pipe work but more importantly how could the tank actually get in to the building with the only access a standard door. When I reviewed the as builts it did not match the “current plans” we were issued. In fact there was a 6 inch drain 6 feet from the blow down point. So instead I proposed a new floor drain be installed at a cost of $5,000 instead which went down well on all sides. It proved the importance of updating team documents too!

Sound Attenuator: As previously mentioned our exhaust sound attenuators from the NEAT labs (where the nasty experiments go down) were to be replaced with welded ones as the screwed and glued type were not sarin proof. This has had a Request for Equitable Adjustment for $2.3 million and 236 days from the contractor. It is now my job to work out if the work has been done, by how many workers, with what kit and how long it took. Initially I thought there were only 178 to review. However this was on old plans. After review there are actually 573 to review. That will keep me busy until I leave and reinforces the importance of updating documents!

Generator Commissioning: Our 12.5 kW generators have been going through their precommissioning tests involving running them at various levels for long periods on mobile load banks (truck mounted resistors with fans to cool them down). These have been going well once the subcontractor got the load banks working (3 days lost) with all criteria being met which is a relief because most other commissioning tests have been problematic due to failures in the systems.

Lab Vacuum Pumps: This started as a previous RFI on the size of filters for a lab vac system. As this has been going round the houses a while I have decided to investigate to close the loop. Having looked at the spec the information is confusing. Apart from the fact vacuum is measured using Standard Cubic Feet per Minute (SCFM) in standard conditions and Actual Cubic Feet Per Minute (ACFM) based on atmosheric pressure, temp and humidity. Installed are 3x vacuum pumps rated at 330 ACFM at 28″ of Hg (more imperial units!) but the spec calls for 2 pumps to provide 104 ACFM, with one in reserve, so it appears the pumps are 6x oversized! I have asked the designer to show me the calcs to confirm that the pumps are sized right and apparently under vacuum the pumps produce 25ACFM. They are however being very cagey about how this was worked out. Even if this is correct the single charcoal filter rated at 25ACFM would be irrelevant if 50ACFM is going through it. THis was my first authorised change for the 2 filters in parallel in July. Now I not sure that even this configuration will work especially asa in the other building wing 2 filters identified for this system but in a different location are actually 350ACFM rated. I have very little data to work this out my self other than the number of outlets and the diversity factor so I will wait until I receive the information before I go further.

Payment Assessments: the monthly investigation into the works of fiction the contractor submits as pay requests. These never match up.

In Harrisburg one of the QA guys has been sacked and escorted off the premesis by security. After being told his contractor was not being renewed the guy went to the contractor and off loaded a whole loaded of information they did not need to know thus putting USACE in an awkward position. Once this was found out he was off the site but there could be issues in the future. The roof is still going well with 35% covered but the Contractor still has no plans to get equipment on to the roof. A submission to cut the 45 ft roof beams in to 3 to make the more managable on the roof is being considered. In 3 weeks they have removed on 15ft Air Handler off the roof in pieces. There is still no plan on how a replacement unit will be installed.

And in Other News:

Halloween was a mental experience. The whole neighbourhood was decked out ghoulishly with most parents sat out giving out candy while the kids and teenagers topped up on sugar and food colouring. It was 20 degrees so great for the kids and finished at 2000hrs on the dot because the heavens opened, but a merry time was had by all. We handed out 6lbs of candy and the kids brought just as much back! A trip to New York with my parents was very enjoyable, with trips to the empire state building (reduced entry for military personnel – not free!) Central Park, Times Square, The Statue of Liberty and Ground Zero. The Ravens are still struggling and temperatures are now freezing which means roof work is stopping soon. Shortly it is Thanksgiving then silly season starts just as I arrive at the district design office. Fun times!

The Drinker from the Poison Chalice

Ironically the office has got a more positive vibe now that our commissioning engineer has been “moved on to Baltimore”. Since I arrived she has been a source of frustration for both the contractor and us, regularly winding the subbies up by telling them they are incompetent (which is true) but not offering any constructive comments. This has caused such bad blood that she is number 3 on the Client’s Representative Top Ten List of Things He Hates (the Contractor is not even on this list!). So after much wrangling the boss has moved her on (which was a mutual decision) before the project goes backwards. On her leaving we sorted through the stuff she had left and found items dating back to February that were months over due which even the contractor had forgotten about.

Over the last months I have taken it upon my self to try and resolve issues that have been dragging on a while because no one else can get a result (the poisoned chalice). For my avid followers this has so far amounted to the floor drain and the faulty pump 17 (more on that later). Now I have picked up another topic which is Temporary Building Maintenance during construction. I gathered together the customer reps and we thrashed out the issues concerning maintenance. Aside from the equipment that is due commissioning there is no record of maintenance on anything else including the fire pumps. There is also concern that what maintenance there is happening is not good enough especially when water from the boiler has 10x too much iron in it and cooling towers have excessive bacterial growth. I took the time to review Operation and Maintenance Manuals for all the big items (boilers, chillers, cooling towers etc) and then tried to check what the non commissioning items only to discover that the submission for theses items has never been sent to us. Armed with some good facts and examples I had a meeting with the contractor who was very receptive (they like dealing with Army guys more) who admitted the document was missing and that they could improve by changing procedures and including more details. As I suspected there was no way they were not doing the maintenance but they were not always including the details because this document had not been written to tie it all in. So months of whinging dealt with in a 2 hour meeting. I have now got to go through the building equipment list and identify every item that needs maintenance. Should take me 6 weeks! We also have over 2000 QA issues to address. So many of these are legacy from guys who have left the project that they are just sitting there with no one taking ownership. I will be sorting them out next week and apportioning responsibility where necessary. Some of these are over 2 years old and have been dealt with but are still not signed off.

I also visited the steam generation plant on site to see how it compared to our boiler setup. This is pretty big facility providing steam for all other buildings on site. Our interest comes form the fact that the plant has a continuous analysis system that checks the water quality constantly and can notify the engineer by phone or wifi if an issue occurs that the machine cannot sort or even order more chemicals. The equipment is all provided free by the vendor (although the installation isn’t) who set this up and enhance boiler lifetime considerably.

Above. Where the magic happens

Below. One of four big boilers

Our current boiler system relies on little old men taking readings every hour for 8 hours, chucking in a coffee can of chemicals when ever he thinks things are out of kilter. This seems very old fashioned and imprecise and the water test result imply it doesn’t work. However this is what the customer wants! I will have to change their minds.

Pump 17 continues to delay the commissioning of the cooling system so I used this as the basis for my TMR to try and get resolution. As mentioned previously the pumps are too big and need better control through VFDs but without analysing the situation it is difficult to get any support. It turns out the motors are nearly 200% oversize even including the need for expansion. We have referred the matter back to the design team in Baltimore because the designer is not conceding on this. Interestingly the Design firm recently acquired the firm that employs all our QA guys…….We still have no answer on whether fire dampers should be tested with the system running. We have gone to the engineer at Ft Dettrick to find out what they did and why. Rain last Friday managed to flood the sump with the fuel return tank in it. This is inside the generator building and is meant to be dry so it was a bit of a shock to see the watering pouring in through the pipe line from the flooded sump in the fuel storage area. Even more of a shock for the King Snake stuck down there! It turns out a bung to block this pipe had been left off because no one thought the other sump would flood but it did because the lid was badly fitted. QA issue 2001…..

In Harrisburg the fun and games continue. The Contractor still has no idea how the steel beams are going to be moved on the roof. The most recent idea has been to cut all the beams in to 3 pieces so that they can fit on the quad bike trailer. This will cost them even more money and slow down the job even more. On that note we have still not received an updated schedule due 1 July. Office engineering are drafting a letter saying that as no schedule has been received it is obvious that the contractor considers the project is running on time so there will be no come back if the project runs over time. This might get there attention especially as they are running 9 months late. That said even after a directed letter was sent, telling them to employ a new Safety and Health Officer in 2 weeks, it has been stiffly ignored for 6 weeks. When challenged the response was that they were having trouble hiring someone. It turns out that they were trying to poach the SHO off the HQ project next door but he would rather eat his own hands than work for these clowns! The High Bay Drain Fiasco continues. There are actually serious discussions as to whether there is a need for the over flows especially as we had 9 inches fall last Friday and there were no problems.

The HQ building is coming on well and they are starting to pour the floors. I enclose a photo of this possible project for my successors (C and E&M).

The steel will all be up by next May but there will be plenty going on especially as that is when the Mechanical equipment will start going in.

And in other news….

It is a bad time to be depressed in DC with a shooting and self immolation not to mention furloughs. The furloughs did not impact us because our funds come from last years budget but we had guys from the district drafted in to keep them employed on our budget.

The Orioles finished 3rd in the League so did not qualify for the wild card place in the finals, the Ravens have had a pretty ropey season winning 3 and losing 3 with not much hope of another Super Bowl this year but the State College Terrapins (Terps) Football team is doing well with 4 wins and one spanking by Florida State 63-0. This equals the biggest loss in the history of the college competition but that is what happens when your quarterbacks are all injured in the game.

Halloween is rapidly approaching and the amount people spend over here is staggering. They really go to town and where we are is so popular for trick or treating, people bus in from around the county. We have bough 4kg of stickys already but we have been warned that might not be enough!

We also took part in another great US tradition of going to visit a time share at an outdoor pursuit centre. These places are very well set up for doing nearly everything both winter and summer so we were nearly tempted to stump up $10,000 for 2 weeks a year for life (transferable to resorts all round the world). However when we declined and they asked if $5,000 was OK we decided that was too necky and collected our voucher for a free 3 day holiday and left.

Warrick also found a car for me.

Progress of Sorts

At last some progress is being made although it is not always a smooth ride. We have had some commissioning inspections take place with some passes and some fails. A big issue has been the boilers. We have 4 boilers which run on natural gas and diesel. For the Functional Performance Test in the commissioning process the spec states that only 1 boiler needs to be tested on one fuel type. The Contractor decided to use the only boiler that has been used consistently (more on that later) which was the best of the four and promptly failed the test for NOx emissions. As a result there is now a big concern about the state of the less used boilers especially if the contractor only needs to get this boiler improved to run the test again. Back in July a water sample from the boilers showed excessive iron and bacterial growth in the boiler system which indicated that the cleaning and maintenance of the boiler was not up to scratch. Despite raising this with the Contractor nothing has changed so I have been tasked with checking the monthly maintenance logs for the building, to work out what else is not being maintained correctly. The big concern is that damage is done to big line items (boilers, chillers etc) that will make any warranties on equipment void and will cost a lot of money to put right especially if the service contractors, who will maintain the building, discover this. This has been a huge task made harder by the fact that our hard copies are not in the correct place and the downloadable documents take 20mins to come through and can fail at the last minute. Have looked at the spec the contractor has failed submit a key document on how Temporary Operation and Maintenance is going to be carried out for the building. Instead the focus has been on the temporary conditioning maintenance need to pass commissioning (and that has been dubious so far) and not much else. This week I called a meeting with the future owners to hear their concerns and draw up an action plan to get the concerns addressed. Concerns included the use of pre printed check sheets which only the date changed on, poor record of future maintenance plans and a general lack of information which the client has been asking for.

This week we received the test results back for chiller motor testing. It confirmed that pump 17 has a fault because the in rush current is high even when the load is uncoupled. However the report stated that the issue could be due to valve settings! I emailed to ask how this conclusion could be reached but the independent tester refused to comment. However both the Corps and Contractor agree that the motor is faulty and needs replacing. This does not solve the problem for the system however. The bigger picture is that the pumps are too big for the system and are not running efficiently. The pumps send the chiller water to the cooling towers on the roof. The pumps all feed in to a header and are balanced by butterfly valves. Simple enough except the motors are too powerful (4x 200hp) and so the valves are set at 25% or the roof floods when the cooling towers over flow. The motors are also expensive premium efficiency motors which are not able to perform efficiently if the valves are only 25% open and the power being throttled is going to damage the butterfly valves to the point that they will not be able to completely seal the pipework for maintenance. The designer insists this is as planned but we are all asking if a Variable Frequency Drive can be installed (at a fair cost) so that the pumps can be controlled and allowed to soft start. Another option is to cut down the impeller size in the pumps. This is next weeks battle.

My leaky floor drain has finally been replaced. It was found that there was a fracture in the drain which was allowing water through so a replacement was necessary. However we have also requested that a pan directing water away from the server in the room below should the drain leak again, be installed as an extra safety measure. This was met with a bit of resistance because the drain is now mended. However after a bit of encouragement I have got the agreement to install one after the Corps has been trying for a year. It helps that the Contractor QC head is an old Navy Construction Brigade RSM (think Navy sapper) who dislikes my civilian counterparts and will only deal with me and my US Army counter part on now on tricky issues.

The final issue this week has been dynamic fire dampers in the air handling system. This are spring loaded dampers that activate when the fusible link holding them open melts. Commissioning requires that these be tested with the air handlers running but the manufacturer advises against this (the air flow may break a closed damper designed to activate when the air handler should have been shut down) as does the designer who thinks that despite the installed pressure relief valves in the system the pressure changes may end up pulling down ceilings. However the spec states that the air handlers must be running but no one can say why. We suspect it is to check that the system will cope in case a link fails prematurely but no one as yet can confirm this. The test is on hold.

Yesterday we had a departmental breakfast at Denny’s (the national greasy spoon chain) which was a really good way of seeing everyone out of work and doing a bit of bonding. It was scary to see how much my co workers actually eat – even the smallest guy ate double what I did and I was filled to capacity!

In Harrisburg it has been very productive. The roof replacement is going well and a surprise test of the recovery procedure for someone activating the fall arrest system worked well. We have also identified a cherry picker that the contractor can use to install the over flow drains in the 80ft high Bay Area. These can go through a 35″ door at 123ft but cannot be rented so at $200,000 a pop it will be a big expenditure for our struggling contractor. The QA guys have also noted “inaccurate” claims for materials. A claim for $150,000 of electrical kit was submitted but on inspection there was only $20,000 of kit found. The project engineer let this one go because relations are better but is keeping an eye out for future claims. The customer has also asked that all conduit for fire detection systems be painted red in accordance with site standing orders, not mentioned until most of the electrical conduit had been installed! Fun and games…

And in other news…..

The Navy Yard shooting sent a bit of a shockwave through the sites because it was so close to home. A guy I flew over with was in the compound that day but was in the adjacent building and managed to get away unscathed. There is also another chance for sequestration because the Government here has yet to approve the new budget for the next financial year which starts October 1st. This will affect all non essential civil servants which amounts to most of my office. Could be quiet Tuesday. The Raven’s Game was a fantastic experience. It was one of the best sporting experiences I have ever had as the show is not just about the sport. With Cheerleaders, bands and fireworks they sure know how to throw a good party and football is actually a very exciting sport now that i understand the rules! Fall has started so we are making plans to head to NYC in before it gets crazy expensive for Thanksgiving and Christmas. So much to do and so little time.