Archive

The Waiting Game

Right now we should be on the verge of commissioning the mechanical and electrical services but there are quite a few issues to resolve before that can happen. The weeks are filled with meetings where we discuss at length what needs to be done but nothing ever seems to get done. The disagreements are getting few thanks to the system of referring them up the chain of command but the results are no quicker, as predicted! Part of the problem in commissioning is down to the people trying to reinvent the wheel. USACE employ a contractor to produce the specifications for successful commissioning. They also require the contractor to employ an independent Commissioning Contractor who is under the Contractor’s pay (so not that independent), so that all testing is impartial. However the Contractor can also have a say in how the Commissioning is carried out and can over rule their own Commissioning Contractor. They can in turn be over ruled by our Commissioning Contractor thus leading to multiple conflicts of interest. The main issue revolves around the check list for the various stages of testing. Initially you must have a Start Up when the equipment is turned on for the first time, then a Pre Functinal Check (PFC) which gets the system running then a Functional Performance Test (FPT) to show that the system works as per the specification before having an Interactive System Functional Performance Test to show that all the systems are working in harmony and not in isolation. Our commissioning contractor has written very detailed lists that need to be used but the Contractor’s Commissioning Contractor does not want to deviate from their own standard lists which often get rewritten by the Contractor when they are submitted to try and speed up progress by removing any “unnecessary” tests. A perfect recipe for a hold up! Of course the Contractor is cutting its own detail by carrying out its own PFCs without notifying the Corps to try and get round us and speed up which as quite annoying form our point of view because we are meant to sign off that the tests met our standards which we are being asked to do without seeing the tests. Apparently it is illegal for our commissioning contractor to carry out the commissioning testing themselves which is crazy. It is not as if they installed all the equipment themselves!

Further more there are still on site issues.

We finally had the electrical testers out to look at the pump motors that keep tripping the circuit breakers. I took it upon myself to look at the co-ordination study which identifies how the circuit breakers and fuses are rated to avoid discrimination. This study (which had been approved!) had a lot of conflicts! When I challenged the Contractor they said this one was out of date, but we didn’t know that. When the tester arrived he brought the wrong tester which could not test for trips at less than a second. The next day the correct tester was used and we established the following:

1. All motors are drawing far too much in rush current on start up. For a 220A motor 1300A in rush was expected (6x running current). The regular motors were drawing 2200A probably because they are oversized for the job.

2. The faulty motor is drawing 3600A in one phase, 3450A in another and 3300A in the third. This probably due to damage in the windings where the insulation is susceptible to degradation by the ingress of water.We are still waiting on the results to be confirmed but it looks like this motor will be getting swapped out.

The Mechanical Contractor has also failed to establish why the drain over the BAS server leaks. They are going to cut it out to work out why.

A new project is happening next to the Lab. The office will be expanding by 40% to accommodate the in rush of Medical Corps personnel (mostly civvies) who will be needed. However the contract has just been stamped Ready To Advertise (put out to tender) and the Contract Officer’s Representative has noticed that there is no design for the upgrade. As the drawings have been stamped 100% any changes now will be expensive. I have been tasked with designing the new trailer. Not sure to what level of detail yet but it is very similar to one of course projects except that civvies take 2 weeks to give you an answer, not 2 minutes. There is no budget to work to either. When I pointed out that the longest side of this office was going to be south facing which would mean higher energy bills because the HVAC will be working hard the response was “And?”. Should keep me busy for a couple of days…..

This week I also took part in the Officer Professional Development day where all the military guys in the District get together and swap war stories whilst doing some work with the local community. This got off to an exciting start with an RV at 0600hrs next to the National Security Agency gate (think GCHQ) heavily sign posted with Keep Out signs (not mentioned in the instructions), where going to the gate by accident can result in a full body cavity search and vehicle strip down even for the US soldiers. After a few near misses we set off for the project. In this instance we installed nets to prevent the Canada Geese from eating the plant life in a designated Wet Land area of the Anacostia River just east of DC. This land was created by dumping dredge material in an underused river to create new wetlands and encourage the growth of wildlife. When the plants are eaten they fail to hold the dredged material in place and it washes away. We were given waders then had to go across a waist deep stagnant river to hammer in pickets and zip tie on the netting.

Unfortunately the civvie in charge had not banked on us being very efficient and we ran out of zip ties in 30 minutes. We did manage to carry material over to the site and put all the pickets in place (daily trivia – they call a monkey a pounder over here) before heading off to remove invasive weeds from the municipal golf course adjacent to the river. This was followed by a presentation on how civil works projects in the Corps are funded. This was interesting because Civil Projects (such as our wetland creation) must have a civilian organisation as a financial partner before they are approved. This is quite hard to achieve because these projects can take 20 years to come to fruition so finding somebody who is financially strong enough to last that long is quite hard. This project was part funded by Walmart, fitting really considering the banks of the river were covered in plastic bottles and other supermarket trash. The day concluded with lunch at a micro brewery and a fun day was has by all.

Harrisburg is still progressing well. The new roof insulation being installed will take the R value from 12 to 30m2K/W which should make a difference to the bills. We have finally managed to get the world’s worst Site Safety and Health Officer sacked for not performing up to the standards expected. Apart from his inability to submit useful paperwork and carry out relevant tool box talks (he actually did the same talk 3 weeks in row) he considered the best place to inspect his site was from the safety of his truck which would have been fine if the truck was on the roof not 40 feet below it.

A roof replacement in progress.

And in other news:

I have won a 3 day holiday courtesy of the Maryland State Fair we went to 2 weeks ago. All I have to do is pay $75 and attend a timeshare brief for 90 mins and I get a 3 day holiday in North Virginia. I am also going to the opening home match for the Ravens football team courtesy of a work colleague with a spare ticket. These are like rocking horse stuff and generally cost $300 so this is an awesome opportunity. We spent Labor Day weekend on the beach with the kids picking up fossilised shark teeth and going to the the State fair which cost $60 to get the kids on 5 rides!

As requested the top 5 things this week that I have discovered in which the US and UK differ:

1. American Army Officers’ Clubs do not hold the same status as a Mess. They are generally avoided and do not have living in members.

2. Smart Casual in the US Army is flip flops, shorts and T Shirt.

3. American Public schools (think UK comprehensives) get by financially by getting parents to sign contracts that “encourage” them to “donate” large amounts of cash to help fund the school. We have already donated $50 and a joined the PTA for $5!

4. In the state of Maryland you do not need a license or background check to own a shotgun, a muzzle loading deer rifle (accurate to 350 yards with a scope and fires a 0.5inch round), crossbow or compound longbow.

5. It is now deer season but only if you are using a bow. In some states crossbows cannot be used because they are deemed too accurate. (As you can tell there are a lot of hunters in my trailer!)

Proof the old Pope is alive and well and living in Baltimore whilst commuting to DC.

Has anyone come across this in the work place?

Caulk is the New Harry Black

The tension has eased in Aberdeen. 2 weeks ago the middle management for USACE and the Contractor got together to discuss the constant clashes that are happening that are resulting in no progress. It was agreed that this was not a good place to be and that a change in attitiude on both sides to a more collaborative approach is needed. Brilliant! How will this be achieved? Well in the land of red tape a new paper form should sort this out. This will only be used when no resolution to the problem is forthcoming at the site level and is basically a one page document stating the issue, the points of view of the Corps and the Contractor with a desired result and then it is passed up to the executive board, a level up, to make the decision. Will it work? Having attended the executive meeting this morning it seems unlikely as there was very little give at this level either. The issue remains in that the contractor is trying to save time by not doing things as per the book, mostly pre commissioning tests, whereas the Corps position is “we have specific requirements, why is it that hard to follow the contract?”. In this instance I think the arbitrator should be the customer. If they are happy with the streamlined commissioning programme over the thorough one they should choose; this project is for them after all! This was actually a relatively productive meeting, most just end in continued disagreement. The Commissioning Contractor has even started to approach the USACE Commissioning inspector so that they get an answer with out the Corps being involved. We have cleared up a lot of issues in other areas but I am handling 2 main ones still. THe tripping motor now appears to be four tripping motors so the contractor is now doing a big regain to get this back on line otherwise there will be no chilled water being pumped at all. Not good when you have said it is ready for commissioning. Secondly we have leaking internal drains. Not that bad ordinarily except these all seem to drip directly on to the Building Automation System rooms where replacement of equipment would cost millions not to mention the disruption of having no voice or data services. Interestingly the main voice communication in this building is by VOIP not telephone, military Skype if you like, although no one can tell me to what level of security this is up to. After a big meeting with all stakeholders the manufacturer confirmed his product had not failed but there were a couple of issues he had identified. Firstly when the drain is installed, it is done so in two parts and flashing is needed between these parts to ensure any water that seeps around the top of the drain and concrete is directed to weep holes that direct the water back in to the drain. There is no flashing installed in these drains. Consequently water gets round the concrete and flows outside the drain. The Sub Contractor has tried using caulk (american for silicon type sealant) to stop the leak but to no avail because of the missing flashing. They have been instructed to find a better solution. A second type of drain is leaking because the seal between the galvanised grating and the porcelain body has no gasket. A bad design I thought, until the manufacturer pointed out this design is generally used for floor drains at grade level so any seepage would just go into the earth. There is a special drain to go between floors but it was not specified correctly and now it is too late to change. How is it going to get sorted? Caulking between the grate and the bowl! In a similar vein we have sound attenuators in the laboratry exhaust systems that are not as per specification. These metal boxes are currently all made of pressed steel bolted together. This is not considered sufficient because there is a chance that gas could escape between the bolted surfaces – not great when you are dealing with Sarin and lots of other nasties. The contractor solution – caulk it! Hence the title for this piece. Having actually caulked the attenuators they proudly showed one of the engineers their handy work whereupon he ripped all the caulking off to show it would not hold up. They are now putting in welded seam attenuators at their own expense. (see below)

In Harrisburg they have finally started replacing the roof. However the same old issues keep rolling on. There is a crunch meeting with the Designer of Records to help sort out who is right. What the Contractor doesn’t know is that he is now losing work at Harrisburg because no one wants to work with this company ever again.

Alas the road kill round up is being killed off because there is very little other than racoons to report on. Instead I am going to pick my favourite incidents from the Corps “Safety – A Week in Review” bulletin. It is amazing what people will do to get off work! LWD = Lost Working Days

1. Employee was walking into the restroom and fell. In catching their fall, the employee received a fracture in their wrist. LWD – 3

2. Employee was returning from lunch, stepped on a rock and twisted their ankle. LWD – 3

3. Ctr. Employee was posting reservation cards on campsite posts using a golf cart. As cart was traveling downhill, the brakes failed on the cart. The cart crashed into a concrete base, occupant thrown, shattered his kneecap. LWD – 15 (is that all!!!)

4. Contr. Employee was digging mud from a duct bank and strained his back while conducting this activity. LWD – 2

5. Contr. Employee was climbing a ladder to check water level inside concrete wall placement. Leaned to far to the right side and fell off the ladder. LWD – 1

These notices are always followed by the deaths of civilians in Corps run areas, mostly lakes. They invariably involve alcohol, deep water, no life jacket and a coroner from any age 1 to 80. The only funny happened last month when a guy dived off his house boat and landed on a corpse. What are the chances…….

In Other News

We have had a very nice week off in Virginia Beach. Apparently it has been one of the wettest summers there on record but was a lot better than most of the summer holidays I spent in Cornwall. The kids have started school and Warrick now goes on the big yellow school bus, just like the Simpsons. And running training has resumed for the Army Ten Miler now that evenings are below 30 degrees and 100% humidity.

Fun and Games

On arriving at the Aberdeen I was given the chance to attend an Electrical Quality Verification Course. Given the chance to get some CPD in I leaped at the chance. The 2 hour commute to Fort Belvoir seemed a small price to pay for this course which is all about using the National Electrical Code to ensure that the work the contractor is carrying out is with in guidelines. The first day started slowly with the biggest problem being translating the various terms being used delivered a thick Mississippi drawl. A receptacle is a plug socket, a raceway is a conduit run, ground is earth, a bell end is HV cable gland, and wires come in standard sizes not cross sectional areas etc. but eventually it all started making sense. We looked at all aspects of electrical installation from contractual, to motors to mass notification systems. Some aspects are different due to the use of 110v and 208v but this proved a very useful way to understand how the US system works. There were even a few jokes (e.g. Completion Date – the point at which liquidated damages start being paid). I now have certificate saying I am qualified to inspect electrical work for the Corps!

Back in Aberdeen the tension is building. With 90% most of the work is complete but we are now coming up to commissioning. However the Contractor is still over budget and desperate to save money. Most RFI’s we are receiving basically ask if they really need to do a complex finishing procedure when a 80% solution is working. With furloughs well and truly in action the office is empty Monday and Friday so we effectively only work a 3 day week which is slowing down responses and frustrating the Contractor. I have been getting stuck in to the RFIs to help clear the back log. My first issue was a chilled water pump motor that trips the breaker every time it tries to start automatically. The other 3 identical motors in the setup are not doing this so it is highly likely that the motor is damaged (probably in the factory) and should be replaced under warranty. This was identified 2 years ago but the Sub Contractor says the problem is resolved because if you manually turn on the motor a couple of times it stays on! This is the typical mind set of what we are dealing with. I have been checking the specifications (deficiency notifications are nearly always challenged by the phrase “show me in the spec where it says that”) and the electrical code to justify why we want a working motor! The meetings this week have been quite passionate and there is now a definite “them against us” feeling. More interesting times ahead as I get further involved.

In Harrisburg work is progressing. We have nearly come to a compromise on the drainage expansion joint issue. A guideline has been quoted from the PVC Pipe Design Guide stating that an expansion loop or an offset (a 90 degree Z type arrangement) is the answer. Although this does not feature in the spec or any of the design guides used it seems the offset solution might be the one we all agree on! There are now 40 odd skylights installed but only 16 left to go in as the manufacturer is behind. Only 1254 to go. The roof reinforcing may start soon and the roof drain outlets are being installed. Some of the Big Ass fans are nearly ready except that there is an issue with some of the fans being too close to existing lights and diffusers. Apparently this was missed by the designer but spotted by the contractor. There may be something for me to inspect next week.

Road Kill Round Up

2x Racoons (anything on the interstate is obliterated in 5 minutes so it is too hard to identify much more)

And in other news:

With my parents over we have taken the opportunity to do some of the things we have not yet got round to such as a Baseball Game (Oriels beat the Red Sox 6-0 and you get a free cap for being in the military), a visit to the Naval Academy at Annapolis, eating soft shell crap (claws, legs and all) and a tea party for the neighbours to celebrate the birth of Prince George. Hurrah!

All change. Next stop Aberdeen.

I have now moved on to a new project. Progress is so slow that it has taken over a month for the Contractor to give us a revised on how he is going to catch up the 6 months worth of work we reckon he is behind. Having worked out all the work that still needs to be done, only half the paperwork has been completed, most of it was late getting to us and anything health and safety orientated has had several rewrites including the full documentation for a crane lift that was only a page long (apparently as long as everyone wears a hard hat and use a straight back when lifting the operation will run like clockwork on its own!). I think the final straw for me came last week when a RFI was submitted saying that the site plan the contractor had did not match the actually site and that a variation order for 150 new drain pipes was needed especially as part of the building did not seem to exist. When we looked at the drawing submitted it was dated 1985 and did not include the contested “new area” in which the contractor currently has workman in installing a Big Ass Fan!

My visit to Aberdeen proved far more successful. In fact I was offered a position and had a cubicle before I had been on site.

This is $270 million laboratory and training facility for the US Army Medical Institute for Chemical Defense. It is 90% on the construction phase but they are now starting to prep for commissioning. However it is not all plain sailing. The Contractor is desperately trying to make a profit out of this project. When it was put out to tender in 2008 the financial bubble had burst. The original estimate was for $450 million but Clark, the contractor, said it could be done for $250 million and got the award. They do have a good reputation but in this instance things have not gone well with any number of issues and they are now looking at every loop hole to draw more money out of the Government.

Although not as strict as Ben’s USAMRIID project (that was level 4 and needed special suits – this is level 3 like a hi tech university lab) it has some unique features that set it apart from regular construction. One such system is the enormous Air Handling Units which have filters the size of iso containers and charcoal filtration system in the exhaust to scrub chemical which require huge fans to move the air. This means all the exhaust duct work is heavily reinforced (or it would collapse in on itself the moment it is turned on) and the system has to be commissioned carefully. In the adjacent FBI lab a smaller system was installed and when it was switched on it sucked the roofs out of all the labs because the exhaust was too powerful. This lab is still being rebuilt.

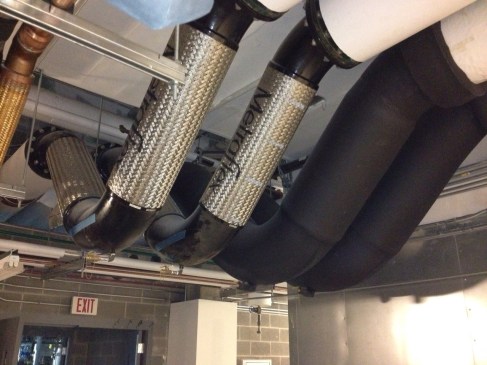

Beefed up duct work

Rat cage sterilisers

Expansion loops for seismic events (the largest are 12inch pipes)

A small AHU.

I will be taking on a direct electrical/mechanical engineer role. There are any number of issues including valves in the exhaust system that leak (not great if they are using Sarin that day), a cooling tower that has bacteria growing in it (type TBC but we requested all workers wear masks in case of legionella. Chinese whispers then turned this in to a site wide outbreak of legionnaire’s disease which was understandably disruptive) and a boiler that appears to be rusting away internally. We have noted that in all the issue resolution meetings, issues that have been resolved are being kept in the minutes. It would appear this is a tactic by the contractor to show that the Government is holding up the progress on site. Interestingly if the Contractor is late it costs him $11,000 a day liquidated damages. If the Government delays we owe $40,000 hence the “record” of Government enforced delays.

Next week I am attending an Electrical Quality Verification Course south of DC to prepare me for the electrical commissioning coming up. This is a real bonus as it is quite expensive and a place came up at the last minute which needed using.

Road Kill Round Up

1x possum

1x ginger cat

5x racoons

1x deer

And in other news:

We had a very pleasant 4th of July where we hosted to a barbecue by my work colleagues and Warrick caught his first fish, we have been to the beach and everyone got stung by jellyfish and furloughs have started. This is unpaid leave for all government employees so now my office is dead Monday and Friday as everyone has enforced long weekends.

I also found this on my travels. Nescafe viagra?

Progressing like an asthmatic tortoise……

Since my last report the project has not really advanced. In 2 weeks we have had enough conduit installed that we can now think about putting in the first Big Ass Fan. The Contractor is still claiming that we are slowing him down by actually reviewing the submittals he sends us and rejecting them. However he has finally admitted that he would like my team to review the submissions prior to official submission or in other words can we do his job for him! He has employed a new Safety Officer and the quality of submissions has improved 10 fold and yet we are only just in a position to let work go ahead.

One stumbling block has been how the contractor is going to install the roof drain in the 85ft high bay storage area. The design contractor stated a hydraulic platform “must” be used to install the pipes but gave the wrong dimensions for the storage shelves in the building on one diagram (although it was caveated approximate dimensions). There is no platform small enough to fit between the shelves so the contractor is claiming a change in site conditions because he based his estimate on this drawing. In reality the contractor only discovered his mistake in May as he could not be bothered to do a site recce to confirm his requirements and now he looks foolish. This change means the Government will owe him money and no one here wants to give this guy any more because of his appalling attitude. As the contract managers were discussing how to deal with this I was given the chance to find a solution with in the contract (thus saving money!). These shelves go up to the ceiling and access to the shelves cannot be denied for longer that 8 hours so a permanent scaffold is out of the question. In half of the building there are horizontal beams in the shelves 6ft from the roof on which scaffolding planks could be placed to create a walkway down the aisle (325ft long). In the other half of the building the beams are not present. The Contractor has spent weeks trying to find the manufacturer to get custom made beams fabricated so he can use the scaffold boards in this half of the building but nothing could be found. Having looked at the problem it was simple: use the “required” platform (as per the contract) to get up and install the planks in the area with the beams, starting from one end and working out because of the limited access, then use the same platform to install wooden beams in the other half of the building, again working from the accessible end out, so that the planks could be laid on these when required. I took the news back to the office, ran it past the project engineer who saw it was viable and would actually be a solution at cost to the Contractor with in the contract and not us. However the managers decided to give the Contractor the money for the modification ($30,000 so far for the planks ) especially as he has now found the original shelf manufacturer and is having custom made beams produced (bill to follow) as a goodwill gesture and show that we really are partnering. They will be using the scaffold plank concept.

However this week I have been going through the contract, working on ways to deny the contractor any further chance to blame us for his delays. This has taken the form of an enormous spread sheet which details when all submittals were handed in, when they were meant to be handed in, how long we took to review and the knock on effect any delays had on the project. A great piece of work which has taken me all week and has lots of hi lighting to illustrate points. Most importantly it shows that despite some of our delays the contractor is still taking months to action any of the returns. A further letter is being drafted that now states the Contractor is solely responsible for all delays and will be getting an interim project report of “Unsatisfactory” unless there is a radical change in attitude and a revised schedule showing how they are going to make up 8 months of in activity. This is actually a big deal because if they overall project report is an “Unsatisfactory” then the Contractor is banned from bidding on any Government contracts for 5 years and the grade is published in Engineering circles. Nuff said.

I was invited to attend a Solicitation Site Visit too. This is when Contractors are invited to a potential site to access the ground prior to putting in their tenders. A fairly unremarkable experience as it is just lots of people looking at a waste water treatment facility (that was interesting) that needs up grading with very few questions allowed. It did get really interesting when one guy stepped in to a ground hog trap (think a smaller version of a bear trap) and could not escape. It took two guys to get his shoe back whilst the rest gingerly crept out of the long grass.

As work is drying up here I am investigating Aberdeen Proving Grounds next week. This is a huge project that is similar to Ben’s Biological Research Facility in that it is a Chemical Agent Research facility of equal, if not greater, complexity and with a shed load of E & M stuff going on. And they have already asked if I can help!

Road Kill Round Up

2 deer

1 Racoon

(It is 35 degrees with thunder storms everyday – I don’t go out in that!)

And in other news..

We have had quite a few parties including Warrick’s Pre Kindergarten Graduation the Baltimore District Picnic, numerous leaving function for Matt, Ulli, Ben and Sarah as well as Warrick’s 5th Birthday party. We have gone to the beach at an old quarry and the timing belt in my car went which cost me $2600 and a new cylinder head.

And it is set to get hotter. Time to plan a summer vacation.

A journey of a thousand miles starts with a single step.

After 2 months of pushing and frustration we finally have a project that is under way. Not bad considering the the Contractor was given notice to proceed in Oct 12. The past few weeks have given me yet more insight in to the world of contract management and the ways in which contractors can try to extort money from seemingly watertight documents.

3 weeks ago during the Contrator’s biweekly (fortnightly) meeting it was announced that the Government (us) was sitting on over 53 late submittals (30 days old or over). This seemed a little high so on returning to the office we all checked the register and the Contractor was right. My mentor was on course, so taking the initiative I started tracking down the outstanding submittals with the design contractor. They had not received any of these documents and some were now key to the project ever getting of the ground and I am not just talking about the scaffolding proposal. On going to my mentor’s cubicle I discovered 95% of the documents under his desk where he had not finished sending them on. The situation sounds a lot simpler than the reality. Although some were actually just very late in being processed (from December!) there had actually been a change in the procedure in early Mar 13. The contractor had been instructed to change all submittals to electronic formats to be sent to USACE and the design contractors simultaneously to help save time and money rather than send us the big bundles of paper and documents sent previously. Parts of these documents were sent electronically but the drawings had not because it was assumed by the contractor they had already been sent on by USACE as hard copies. In an afternoon I was able to identify all the missing documents and FEDEXed them on to the design contractor for comment. It was typical that the District Engineer had flown up from South Carolina that day and had to see all this but he was reassured that there was more to the slow progress than just the late submittals so we got away with that one. The quality of the Risk Assessments from the Contractor continues to be poor and there is still a big question on how the drainage in the 90ft High Bay area is ever going to get installed as there is no room for any form of elevating platform. Going through the roof would actually be good option!

As part of our CPD, Ben, Matt and me were taken by the head of Baltimore Construction Department to the Washington Aqueduct. During the Civil war a project to divert some of the Potomac in to DC to provide a pressurised water source to down own areas was devised. An aqueduct was created that sent water right in to town with pressure high enough to power the 60ft fountain outside the Capitol building. The design has been refined over the years and now provides the potable water supply for DC, Arlington and two counties in Virginia. We visited the purification plant that was designed in the early 1900’s. The process is the same as those we learned about but now the site is fully automated and larger than the original concept. It was interesting to see how the far the automation had gone – the whole system was monitored by two technicians – and there are extensive on site labs for checking water purity and biological contamination.

Holding ponds – 4 of them (with geese)

Main plant pumps

We have also had the Chief Instructor and Senior Instructor over for their visit. This was another good opportunity for us all to see Ben’s site in Fort Detrick, my site and Baltimore HQ as well as present to the PEW staff on our experiences and reaffirm that the US option is a great opportunity for future PET courses.

Meanwhile back on site work has finally started. As of last Thursday two men are installing the conduit necessary to install the 24ft Big Ass Fans TM (That is the brand name not the nick name).

A Big Ass Fan TM

This is a huge psychological break through as up to now we were convinced this project might never start. In a meeting with the client on the same day I put forward my value engineering proposal to the Client that the contractor should be able to use a roof lift that allows access to all the roof levels in the building without interfering with operations, as opposed to installing scaffolding stairs that will go 100ft up to the top level and be in place for 2 years. As expected I met resistance because of “legal reasons” but when pressed on what these were the answers were not convincing. “What if they damage it or break it – we become liable” was the main argument so I suggested a waiver or on site agreement could over ride this concern. Although not convinced the Client is prepared to let me investigate as he can see there is cost saving to be made. I am in consultation with the legal department as we speak. I also suggested we look at siphonic roof drainage for future projects. This was the basis of my TMR and is able to reduce the cost of roof drainage (and the size of pipes etc) by over 40%. The Client was very interested in this and is keen to get this looked at on the new warehouse buildings going up on site. He suggested this system should also be introduced to the whole of USACE! And to cap off a good week the Contractor was served a Letter of Concern stating that the progress is unsatisfactory and that they are due an interim grade of unsatisfactory for their progress to date. As expected the reply was trying to blame us for all the issues but we have enough paperwork to prove otherwise.

And in other news:

We have just survived our first near tornado. The Government alerts all went off telling us to get in the basement (typically the kids had just gone to sleep!) and we watched as the radar picture on TV showed a direct path of a potential twister to our district. Fortunately nothing happened but three twisters did touch down nearby. They were only small and apart from scaring some motorists, destroying a house garage and moving a car 6 feet, there was very little damage. Also I have taken Warrick to is first Monster Truck show. An interesting experience, not only for the trucks but also to see a gathering of the Red Neck Clans.

Road Kill Round Up:

3 deer

2.5 Racoons (the hot weather seems to be keeping them off the roads)

101 uses for the phrase “There you go” Pt 1– this is the Swiss Army Knife of East Coast phrases and covers a number of scenarios. It can be used to mean the following:

1. You have arrived at your destination

2. Here is the item you were looking for

3. I see where this conversation is leading

4. Well wasn’t that a fortunate out come

5. Now I understand

6. I think I know what you meant (but with some reservation)

7. This is what I did and look what happened

8. I think you have just answered your own question

9. Just like that

10. The job in hand is complete

11. I can tell that was really satisfying

12. That was the end of that

Until next time.

Progress is not a dirty word……

It has come to the point now where none of my office can talk to the Contractor’s Executive Officer (big cheese on site) without wanting to commit serious injury to him. To say this guy is unhelpful is an understatement. It seems the expansion joint issues are not the only show stoppers he is employing to buy more time and money.

The past weeks have been spent mostly in meetings. After a partnering session last week it was decided there was not enough inter stakeholder communication so to make up for that we had four meetings in a week: a whole site meeting to up date the Client on all projects on camp, a health and safety meeting with the contractor, a partnering session with “all” stakeholders and a site specific update meeting with the client.

The first meeting was very long, had lots of top level squabbling and achieved nothing in my opinion.It did have donuts.

The second was our first attempt to get the contractor back on schedule. As it stands the Health and Safety Officer for the contractor has yet to produce a piece of work that would constitute a complete H&S assessment so we cannot authorise work to proceed. The Executive Officer swears blind (for a whole hour on send only) that this guy is amazing but this is not supported by the paperwork he submitted. The big issue is that work needs to be done 80ft up in the air and a fall arrester system needs to be employed. A Qualified Person must design a system in accordance with USACE guidelines (they must have an engineering degree and experience in the fall arrester industry). This H&S guy is only Competent at best through a 5 day course run by a manufacturer and a distance learning package done on line 5 years ago. However the Contractor insisted his name is submitted as the Qualified Person but then said he was going to get in Qualified Fall Arrester Engineers to design the system anyway! The H&S guy also submitted a Risk Assessment (Activity Hazard Analysis (AHA) over here) for a cherry picker with only 3 risks identified – People falling, things dropping, the rig moves! This was only the first that I have been checking over, the remainder are equally poor including the Rescue Plan (“fire department will be used if there is an accident” – not a bad idea accept if they had talked to the on site fire department they cannot deal with problems in the building as there are no ladders long enough!) . His response – “Tell me what you want me to say” or “This is the way we have always done it”. He is on his final warning, but I am not sure what constitutes the last straw yet.

Our third meeting between stakeholders was equally frustrating. The Design Contractors and USACE cannot believe the contractor has been on site since Oct 12 and is using phrases such as “I have not had the chance to look at the building so I have no plan on how I am going to proceed” and “I don’t know what order to do things because I don’t want to disrupt anyone”. The contract states work cannot be inhibited but as a change to the contract temporary offices for 105 pax will be set up to house office workers whilst their department is up graded. The Contractor Schedule says it will not be until this time next year that a temporary office will be ready to move in to and they are only setting up portacabins! Another hour was wasted discussing how the contractors proposed plan might affect the office workers. At this point I pointed out that if they had a Rep from the Office building who knew what the impact would be at future meetings then they would have saved themselves a lot of wasted time guessing. I think my accent might have confused them because the look I got from round the table was close to the one I would expect from saying “I am going to cover myself in chocolate and let you lick it off”!

The fourth meeting was a simple catch up on all the week’s meetings where it is was agreed that all the other meetings had been productive!

What I have learned is the following:

1) The Contractor’s Executive Officer cannot delegate down and never approaches the necessary department if he has a question – he has always done that. He must also be a blood relation to the H&S Officer.

2) In the Stakeholder Analysis the occupants of Building 2001 were never identified as important.

3) The Meeting Agenda is rarely a guideline for how the meeting will actually go and recording and publishing minutes (my idea in two of the meetings!) is a good way of confirming what was discussed with everyone involved (except the Executive Officer who disagrees with everything)

4) American meetings are more about donuts and talking loudly then they are for solving problems

We wait in anticipation for the next wave of unhealthy and unsafe submittals to cross our desks with no start to the construction phase in sight…

On the plus side I did get to see a Levy and Pump Station that had been flooded out in North Pennsylvania in 2011. The river had risen over 30ft after heavy rain and had flown over the levy knocking out the pump house and resulting in the area flooding. The on site engineers were asking for $1 million from the Corps to raise the pump station up 10ft so that it would not flood next time . However it only protects some very old houses where everybody escaped unharmed, which the Corps has not seen as essential. At a time of cut backs I would have to agree.

The river is a 100m to the left. The pump station and (now broken) generator hut were completely submerged.

The River today. Note the 30ft trees that were swept away in the flood still in the river. The bridge in the back ground was completely submerged.

This weeks country hits:

Timber! I am falling in love

Truck Wheels in the Moonlight

Roadkill Round Up:

30+ deer (saw a guy parked in the central reservation in rush hour collecting a 2 day old carcass that he could not have hit and he was not the state clean up team either)

15 racoons

6 Ground Hogs

5 piles of red mush (could have been one deer)

And in other news:

Apart from mass shootings on Mother’s Day, tornadoes in the deep south, girls being found in a house after 10 years of being missing, a $580 million lottery winner and IRS scandals, I am pleased to announce Warrick will be graduating from Kindergarten in a months time, complete with certificate presentation and Mortar Board. Only in America……

I am also signed up for the Army Ten Miler in DC where 30,000 people with service connections will run round the Pentagon and back early on a Sunday morning in October. Time for some training…

A bit too quiet…..

With everything on hold until the submittals are answered it has been a quiet week. The big news however is that one submittal is a potential problem. In the roof are a series of pipes that will take the rain water away from the middle and out to the edges. These pipe runs are 500 ft long, 12 inches in diameter and are made of PVC . In last week’s site meeting the contractor asked about expansion joints in the pipes. In these conditions PVC expands over 6 inches for every 100ft and the design has no mention of expansion joints. After some research the contractor has come up with a price of $750,000 to incorporate the design change (each joint is $1000). One school of thought is that the contractor should have thought about this even though it is not mentioned in the drawings or specifications as it is common sense the pipe work will expand and not our problem. However to further complicate matters the current design doesn’t actually have any expansion joints in it and has never leaked in the the past 25 years! Mike, my mentor thinks this is more of a bluff on the behalf of the Contractor who has under priced the scaffolding he needs to work above the high bay storage area. This has therefore gone back to the designer to make a decision. I think they will risk it for $750,000 and not bother. I would like to see where the liability lies with that. And apart from a 5 hour Safe Driving computer package, interviewing my department and learning everything I can about the project I did go on a site visit to Mechanicsburg. This is an Army Reserve project for a new Drill Hall and Servicing bay that is a year behind. When the design was done the designer missed a large rock pinnacle just below the surface that just so happened to have every underground service running through it. This meant a huge variation to the contract was required to dig out this hard limestone. From the geological data I saw it seemed obvious there was rock there but the site was going well now the warm weather is here.

Hopefully more to do next week.

And in other news:

A quiet week in the US. A turf war has broken out between rival Ice Cream Vans in New York. Snow Cone Joe has been chasing Mr Dingle Dangle around the streets offering free ice creams to under cut his rival and put him out of business. Joe has now been arrested for threatening behaviour.

Road Kill Round Up:

5x Deer

6x Ground Hogs

2x Possums

2x Racoons (actually from last week still)

1xFire Chief (a DUI ran him over whilst he was marshalling a HLS)

Country Hit Parade:

I am looking for my next Heart Break

How are you doing Country Pumpkin (like the frost on the pumpkin)

She was acting single, I was drinking doubles

And finally a warning for all parents (particularly those who shop in Walmart!)

“Living in America” (cue James Brown…)

Finally after 5 and a half weeks we are nearly settled in the US and actually have working internet!! From turning up at Dulles Airport (of Die Hard 2 fame) on a sunny Friday afternoon in mid March with only a couple of suitcases and 2 hyperactive children, we now have a fancy town house (terraced house in English) with a SUV and convertible parked outside (to blend in), we own smartphones and a smart widescreen LED TV, broadband internet at 20Mbps and today our stuff arrives from the UK. I will not go into the heartache and pain (not to mention the $23,000 we have spent) to get here (most of it actually reimbursable) but needless to say it all takes quite a bit of time. Yes the Colvins have finally joined the 21st Century! We have received a tremendous amount of help from Matt, Ulli and Ben who having been through this already and helped make the process as painless as possible. Barbecue at ours, once I have bought one!

Work started well meeting up with Matt and Ben as well as all the other Army Officers in the district for the OPD week as Matt has described. The Dinner Night should get particular mention (great effort from Matt and Ben) because it is the first one I have had in a floating restaurant on a reservoir at sunset and also it was our introduction to the USACE Dinner Night traditions, in particular the brewing of the of grog. In a nutshell, the junior officer makes a dirty punch for everyone to share but with some poetic significance attached to each of the ingredients to produce a potent but enjoyable brew that is then used to liven up the festivities. A USACE dinner night should be tried at least once in a life time.

Initially I spent 2 weeks in the USACE Baltimore District Office. This was to get my USACE email access applied for (still not got it after 3 weeks!) as well as meeting the various departments who I will be responsible to or might need to contact when out in the field, from the design teams and contract managers to the environmental and legal teams. I was able to go on a field recon of a potential project (a boiler house refit in a barracks block) before going to my field office in Harrisburg, Pennsylvania. The project I will be working on as the only resident E&M engineer is a $53 million roof replacement of a main distribution depot on site. This place is enormous, with a site footprint of 43 acres (1.9 million square feet) which uses an internal Scalextric track of trolleys to move orders around the site. It runs 24 hours a day and cannot be interrupted in its operations during the refit because it supplies operations overseas (photos to follow once I get clearance…). The roof has been redesigned and all mechanical and electrical services are being upgraded to improve efficiency. Currently Matt’s Solar Wall is not linked in with any other environmental condition monitors and each work station (an open area every 2om in every direction) on the shop floor has its own heating/cooling controls for that area making for a very inefficient heating and cooling system. The new system upgrades all heating and cooling machinery and attempts to centrally control the environmental conditions. At present the work has not started as there are RFIs and pre construction issues being ironed out. This a Design Bid Build Contract where an Architectural Engineering company has produced the design for USACE (who only design 15% of their projects) and a contractor has been selected for the construction. Thus there are complications arising from drawing interpretations at all levels!

And in Other News

Aside from terrorist bombings, fertilizer factory explosions, shootings, gun control debate (why should people need checking before buying a gun and ammunition at a gun convention?), live terrorist hunting and a hurricane warning, it has been relatively quiet. However a leading Yoga clothing outfitters company has suffered huge losses on the stock market after it was ‘revealed’ that its leading style of yoga trousers had a faulty batch where the material was see through once worn. Apparently during the “salute to the sun” warm up exercise people at the back of the classes were being treated to a view of the moon and more – (underwear ruins the line………). Customers are being offered a full refund.

Roadkill Count (back by popular demand)

6x Racoons

3x Deer

2x squirrels

8x anonymous piles of dried out fur

1x Owl

1x St Bernard

Country Song Titles

“Come and take a ride on my big green tractor (if you scream we can go faster)”

“I wish I had been a cowboy”

“God is great, beer is good, people are crazy”

“I am old school (and won’t cheat on my wife)”

See y’all!