Archive

Post CPR debrief and thoughts for the next batch

DB suggested that I might like to record my thoughts post CPR, so this blog is an amalgamation of Steve Dollimore’s email to me immediately after his CPR and my thoughts and views post my CPR (both written before results).

I understand that it is quite early for the current course but it is really worthwhile thinking about this now, as the groundrush at the end of Phase 3 and Phase 4 can be pretty full on!

Reports

I spent quite a while on the reports (2k (Experience Report) & 4k (Project Report)) to try and get them just right, working on the assumption that if it was covered in the required detail the interview would be easier. In reality, I probably agonized over these a little too much and left far too many ‘hooks’ as it is not possible to cover everything in enough detail.

I found the reports to be good revision of my time on attachment, but highlighted just how little useful information I had gathered to support my attribute claims. I know this will probably go unheeded, but it is well worth thinking about your CPR docs now and gathering the required info as you go so that you have relevant photos, calcs, or standards to refer to when compiling your reports. As a rough guide, if you are using something as an example for your DO’s it is probably worth building a decent pack of evidence in prep for your report.

If you can get the reports final drafted prior to leaving your Phase 3 attachment, you should get a civilian perspective on what you have written.

Preparation

The CPR rehearsals with the lecturers/mentors are really worthwhile. Be prepared by re-reading past AER/TMR’s and most importantly ER and PR. Prepare your presentation well in advance and have a good couple of run throughs prior to the event. (I left this late and only managed a couple of practices before the mock – I think I could have gained more from the experience if I was more prepared.

It is worth doing a second/third mock with somebody willing, to gain a second perspective (I borrowed Steve Dollimore’s recent knowledge and a civilian mate who had just been through CPR). As a result there were very few tough questions that had not considered). I think using a non-military mate worthwhile as they will have a more similar perspective to the reviewers (i.e. not tainted by green).

Presentation

The CPR presentation should tell an interesting story, not just be a list of attributes. I found that writing a script then leaving bullet points on the back of the presentation slides was most useful (avoided the temptation to read it).

Scripting is good to ensure you contain the correct information but be careful not to come across too wooden. It should be an informal style presentation that is interesting.

Don’t get sidetracked when you notice them writing during the presentation, at the range you are it is obvious you are looking!

Buy a presentation flipchart early – not many places sell them. A3/A4 is a personal choice, but I would argue that at the range of about 1m across the table from your reviewers, an A4 flipper is perfect (and cheaper).

Keep slides clear. A few photos, or one big one without wording I would say is best.

Interview

The interview runs for about 60mins, and I would say is broken down into 15mins fro presentation Q’s, 30mins PR Q’s, and 15mins ER Q’s, with a few randoms thrown in for good measure. By randoms I mean unrelated questions about the ICE, and your views on Civ Eng in general. For example “What can you offer the ICE?”

You can largely guess what the presentation questions will be based on your preparation. This is a good chance to demonstrate sketching ability, either built into the presentation, or to elaborate on something in it after. Don’t sketch in the middle of the presentation – it kills time and looks too planned and therefore suspicious.

In honesty, I don’t really remember much of the interview; it really was over in a blur. I remember being highly attuned to the reviewers reactions to my answers though (At one point one said “Oh dear, that’s not good!” but I was unsure whether it was my answer of the situation I was describing that merited the reaction).

I think all of the reviewers had conducted CPR’s at the RSME before. I was hoping for a couple of newy’s who would be interested in Afghanistan, but that wasn’t to be. That said there were several questions on the military, “How does the Army approach E&D?” “Describe how you did something in AFG?”

I found it interesting that there appeared to be no outright technical questions. Whether there were but I didn’t think they were that technical, or there just were not any I cannot fully remember. The interview was more like an informal chat about my experience that was genuinely quite relaxed. I am not sure if I actually relaxed, but at one point I even strayed onto who the greatest Briton was! (My view that IKB should have come top over Winston C in the UK documentary (Backed up by Jeremy Clarkson) a while back was enthusiastically agreed with).

Written Test

Everyone seemed to be pretty happy with their written questions, ranging from views on military future to management strategy.

You are looking at an intro, 6 paragraphs of narrative, and a conclusion – about 1000-1200 words.

I handwrote, as I think that you can easily waste time by re-writing on a computer, and it also shows you can work without IT. I think only 1 of 4 used a laptop.

The time goes very quickly, but do not skimp on the essay plan, it will keep you focused.

Aftershocks

Good to be done, but a 2 month wait for the results is a little too much. Obviously we all spoke to each other afterwards to dissect the interviews and share with each other how we probably f@*ked it up, but retrospectively looking at it I think we all tend to focus on the bad bits and take for granted the level of knowledge that we portray without thinking about it.

Ultimately, there is nothing that we can do now, but I am not burning my notes just yet!

Overall

The reviewers will most probably stay in the mess overnight. Therefore time breakfast right to chat in the morning. It is important to show you are normal, even if you are not.

I think we all spent a lot of time the week before review chatting with JM and RF. In my case, probably worrying too much about the trivia. Without blowing too much smoke up their proverbials, they know their stuff having worked in industry, and offer sage advice that makes you think a little more. Just chatting about engineering puts you in the mindset and helps hone your vocabulary prior to interview.

It is not worth researching your reviewers. I don’t think anybody did from our course, but purely from the work addresses we could work out the rough bent of each of them. It made no impact on the questions asked.

Its not as bad as you think it will be – the reviewers are old pros and they went beyond the call of duty to calm you down.

Hope that helps. I don’t know the result yet, but will happy to chat through the process and prep with anybody either way nearer the time.

Enjoy the rest of your attachments. Take lots of photos!

Westie

Drainage Basins

My fear with sustainability goals is that they are often the first casualty of cost saving exercises. It is very easy for a consultant to suggest all manner of intricate sustainability measures that if made a reality would no doubt be groundbreaking and win lots of awards, but when the client is paying for it, it is a different story.

At the Perth children’s hospital the Environmental and Sustainability plan (ESP) listed many methods of achieving a Greenstar rating (which I later found out was not a mandatory element of the government contract so was shelved). These included:

- Stormwater harvesting,

- Rooftop gardens,

- Animal bridges from the adjacent park to the rooftop gardens

- Automatic shading devices on window

- Automatic airflow management systems to take advantage of daily temperature ranges

- Solar panels

- Cement replacement materials

- Post Tensioning

- Etc

Of these the majority have been left by the wayside (especially the animal footbridge (or pawbridge) which somebody was obviously smoking crack when they wrote it), with reasons cited as too expensive to implement. It appears that sustainability, if not mandatory must as a minimum be cost neutral and PR positive to have any chance of coming to fruition.

The same can be said of the Perth Gateway project. The project is a AS$1bn national priority scheme to construct a landmark road structure around Perth airport and road and rail freight terminals to make the region an efficient industrial hub. In summary, for BG&E it is a big road project to design 5 major highway interchanges to improve the traffic flow in the area.

I became aware of the issue today when eavesdropping on an engineer ranting about how he was annoyed that the client (Airport) was not listening to him. Though not completely related to the gateway project it is linked. I investigated a little further and intend to get on a site visit to see what is going on. Essentially during a 1 year storm, the airport receives a flood flow of about 8m3/s (from upstream and its own drainage) but only releases 4m3/s which is good as it is attenuating the flow and reducing the impact downstream. It is also bad for the airport however as now that they own the land (it was recently privatized) they want to develop areas of it for commercial property, the bulk of the water flow that is supposed to go under the runway through 1x1200mm culvert barrel, doesn’t, it floods the potential commercial area, a lot.

One option was to increase the size of the culvert but disruption to air traffic, issues downstream meant this was a non-starter. Another was to re-route the waterway around the bottom of the runway through a swamp (imaginatively known as runway swamp and formed back in the day when they didn’t care for sustainability and were happily excavating peat). It turns out that the swamp because it is so old (1960’s) is now heritage listed an cannot be disturbed so that option is out. Another option was to re-route the flow an make a living stream to the nearest existing water course. This option was picked up on by BG&E and the plan was the extend the living stream another 4km to 6km to tie in with the interchange drainage and no doubt boost the sustainability rating. The airport saw this as additional cost and decided to attenuate the flow in an up-steam basin away from the commercial property and do away with the living stream.

The engineers issue was that although the flow difference between the 1 year storm and 100 year storm was only likely to be 2m3/s (not huge) it was still possible to design the drainage to incorporate the features of a ‘living stream,’ but the client wanted the design changed to be more efficient and hence act as a drainage ditch. The point of a living stream is to slow the passage of water by implementing a more natural channel shape with more gentle channel profile and meanders to inspire vegetation growth that will slow the passage of water by increasing the mannings number and energy losses. This creates a more hospitable environment for wildlife.

The second drainage sustainability aspect of the gateway project is the attenuation of the stormflows around the interchanges. The main interchange has been designed with 7 basins which can hold a capacity of approximately 30,000m3 which is approximately the 100year storm. At low flows the water runs through the basins to a channel that terminates below the outlet in order to allow low levels of water to be absorbed into the ground. At higher flows the channels outflow to fill the other basins before backing up. The maximum outflow of the system is only 200l/s which if operating at capacity would only take about 40hours to clear. I am told that through modelling and a reducing water head this figure is actually over a week. As Perth is effectively a sand based city the water can leach into the ground, but with a relatively high water-table there is not much opportunity for this, so it was not factored into the design.

To prevent water-flow sedimenting the soil channels the basins are grassed, and are planted at 130% the required density to ensure that there will be enough to stabilize the soil after inevitable losses to heat and wash out. It feels a little ironic but entirely necessary that they have to install a reticulation system to the basins to ensure the vegetation doesn’t die in the summer months.

In other news I went East to the Wheatbelt region to conduct a few site investigations of bridges that require a waterway analysis. We stayed in the town Quairading in the arse-end of nowhere, in the only hotel which I can confirm without shadow as the worst hotel I have ever stayed in. I don’t want to go into detail (I’m still having flashbacks), but suffice it to say, I have stayed in Blackpool before. As an added incentive, the ex-trucker female bar manager, with bingo wings that would rival Harry Potters wizard sleeves for looseness, took a shine to me. We started work early, finished work late and funnily enough the week long recce took 2.5days. I have now seen rural Australia and no longer feel the need to see it again.

The weather has turned. It was 25 today and biting cold. Coming back to the UK is going to be a shock!

Old Bridges, New Bridges, Socks

Since last blog, things have not progressed massively with the work I am doing. I have completed the culvert sizing a preliminary draft reports for the 9 small bridges in South WA, and BG&E have just be given the contract to assess 14 more. It is not difficult work, just time consuming. BG&E are happy to take it currently as there is little on the plate for the waterways department and it keeps a regular client happy.

I have recently picked up a feasibility study on a Bridge up North in a town call Three Springs. It is a simple 2 span flat slab structure over a seasonal drainage channel that has been assessed by Main Roads WA (MRWA) as reaching its capacity. The reason for this is a recent revision of the standard vehicle loads. From the previous T44 classic truck load, it is now a fictional vehicle based on a 3 trailer road train with an additional UDL along its length. This puts the bridge in the critical basket.

The plan is to check the capacity of the existing bridge then apply several methods to ascertain the effect, and price all against the cost of replacement. The bridge has been assessed as having a strength of 30m/mm2, and the steel a strength of 247N/mm2. Half the battle is working with awkward numbers from converting to metric after calculation in imperial units in 1960. I am using a grillage analysis programme called ACES with though better than QSE is still pretty cumbersome and crashes frequently.

The methods will be: (1) A concrete overlay slab. (2) Carbon Fibre Reinforce Polymer (CFRP) strips on the soffit/surface.

The overlay slab works by increasing the depth of the section thereby increasing the amount and quality of concrete in compression at the outer fibres. This concrete overlay is keyed into the existing slab by steel -reinforcing bars glued in with epoxy resin and bent at 90degrees to the vertical to allow for shear and stop the slab slipping off. This method works fine in practice if the issue is one of sagging capacity. An additional depth of unreinforced concrete above a large hogging moment will have little effect.

The Sika Carbodur CFRP strips are simply epoxied to the underside of the slab at regular spacings and work as an increased tensile member at the extreme fibre of the section. A quick couple of calculations this morning tells me that the moment capacity of the section can be increased by 30kNm by use of 4 strips per m. This method has the reverse issue of the concrete overlay as it does nothing for a hogging moment unless strips can be applied on the top. In this case it would be much easier. Helpfully Sika provide a downloadable design package to assist.

Cost calculations (uber rough at this stage, and including for labour) tell me that the concrete overlay option will be almost 75% cheaper than the CFRP strips. But this detail will be refined when I can establish exact lengths of the CFRP as they will not be required to run the whole length of the bridge and can be curtailed to suit the induced moments.

See attached sketch for a rough idea of what is going on, but my initial thoughts are that a combination of the 2 would be most appropriate as the hogging moments appear large and a relatively small increase in section depth will give an increased factor of safety for sagging.

In other news, the CEO of the Shire of Murchison is back from holiday, and sent me an email to say she has a lot of money to spend on a bridge. Not too sure how commercially savvy she is as she informed me that she has not read my proposal yet and the BG&E fee has not been agreed. That said, I think the pricing is fair and hope that we will be given the contract next week. To the best of my knowledge there are no other tenders and they need the bridge fast so it bodes well. If won, I will take the reins of the project, hopefully getting some decent PM and contractual experience, with the intent to complete design before I leave.

I walking about the office in socks an Ozzie thing or is this common practice in the UK too?

Off to Bali tonight for the weekend, but not taking my board. I don’t want to do a Corby on the way back!

Use of MathCAD

Morning all,

I have just sat through a seminar on MathCAD. Admittedly by a specific MathCAD training company.

The software appears to be able to do all that excell can but with a simpler interface and transparency that allows easy checking.

I struck me that a knowledge of and access the program may have saved many hours of student time during design exercises, and probably lecturer time in marking. I understand that Excel has it place as a readily available and flexible tool that is relatively inexpensive, but wonder if for STRE design work MathCAD may have a place (or whether it is used already?).

I am interested to know what your experience of the program in industry is:

- Have you heard of it?

- Do you use it and to what extent?

- What do you think of it as a design tool?

- Do you think it would be suitable for use on PET course/STRE’s?

Thanks all.

Proposals, Presentations and Thongs

Over the past week I have been working mainly on the proposal for Ballinyoo Bridge referred to in my last post. The issue with the site is that it is just so far away from anything and all quotes for geo, survey, road safety audits, and visits all include the cost of substantial amount of travel and accommodation. I evaluated the 3 Geo quotes and found them all to be fairly similar in content, which made my job easier, but 1 was significantly higher in price. I assumed that they just didn’t want to go up North but was surprised when they called to express their interest and ask if there was anything else that they could do to assist their quote. It was really a 2 horse race between the others who were coming in over $30,000 cheaper for the same service. I had to get the quotes amended to allow for pavement design and a different drilling methodology. This drilling issue that arose whilst talking to the clients Works manager, who stated that the river was in flood due to unexpected rains in North WA and would probably be so for the following 5 months. This meant that the geotechs would not be able to drill a BH at every future pier (as dictated by the Aussie code), and would therefore have to drill from the deck of the existing bridge. It turns out that this would only be a couple of $k so not a huge issue. The bigger issue is that the drilling would effectively close the single lane bridge and hence the road for about 10 days. The shortest detour would be about 600km, so it looks like the geotech investigation will have to wait until the low level (ford/culvert) crossing was trafficable. This will be about 3 months if the rain holds, so even if we progress with design without firm Geo, the construction is not likely to be completed in their dry season unless BG&E pull out all the stops and complete it in a couple of weeks. I was able to reduce all the quotes by a couple of $k by organising with the Shire works manager to provide a water source to cut off the water-boring costs.

My initial experience of the BG&E flat organisation structure was good. The idea being that it allowed everybody to interact with each other and had direct access to senior engineers and directors for building effective project teams. Though this obviously shook my being to the core as I found it impossible to understand how anybody could work without a organisation wire-diagram, it appears on the surface to work. Recently though, the cracks are showing somewhat. Directors employing junior engineers direct and not involving their ‘line managers’ means that the junior engineers are not being managed effectively and often have too much work to deliver at the same time. This could be eliminated by involving line managers to manage workloads, but this is an additional cost to a project. This situation came to head when an error on a project meant that a junior engineer was accused by a director of negligence and the line manager had no ability to protect him because he knew nothing of the situation. I think this may be something Rich Phillips is looking at but it made me appreciate the military management structure somewhat, and thought it would be a good thing for industry to take on.

I have been to 2 presentation over the past 2 weeks. The initial conference was about the new products that Hilti were bringing out. A recap on the use of chemical anchors in design brought back memories of the hospital project where Chemical anchors were seldom designed, but were the “get out of jail free” card that contractors were constantly abusing to save time. The second part was an introduction to a hollow drill bit that is used as part of the system to suck dust out of a hammer-drilled hole in order that it is immediately ready for chemical anchoring. The presentation concerned me so much that the practice at the hospital was so poor, I immediately emailed the engineers to make sure they were in the loop, and even emailed to presentation to the main culprit subcontractor with a summary of why the particular drill bits would save him money.

The second presentation was organised by Engineers Australia (ICE equivalent) and was by a civvy who worked with the Defence Science and Technology Organisation (DSTO), so I decided to go to support the military. Turns out that all that is Science and Technology in defence is not that interesting. 1.5hours on radar waves pretty much killed me, though I did rouse briefly when he spoke about the large civil structures designed for the systems. There was pizza though. For my CPD log I will state in the “What did you learn from this activity” box, “Always read the presentation summary before you attend.”

In other news, Nicky and I went down to Cottesloe beach and joined the world record attempt for the ‘largest number of people connected on the sea on inflatable thongs.’ Before you get too excited, a thong is actually a flip-flop over here; but when paddling out to the line-up, there were plenty of thongs on thongs so I am not complaining.

Ballinyoo Bridge Replacement

It has been a long Christmas break. Partly because BG&E extended their close-down period to 3 weeks, but mainly because we had both sets of parents over. It has been like trying to herd deaf, incontinent cats for 2 weeks. I have been at my wits end, and I have actually been glad to get back to work.

The start of the new year has brought with it a few new projects for BG&E, not many but the year is still young. It is still quite evident that the company is scratching around for work in order to fill time until something more substantial comes along. At present I have continued to work on culvert sizing reports for the Main Roads WA panel contract, I am still waiting on a response to a proposal to upgrade a culvert crossing in the Perth Hills (though this may be shelved by the Department of Parks and Wildlife whilst the deal with the fallout of the recent bushfires), and I have recently been handed management of a bridge replacement proposal in the middle of nowhere.

The Shire of Murchison strangely prides itself on being the only Shire in Australia to have no Township. With a land mass of 50,000 square km and a population of 117. The Ballinyoo bridge replacement project was initiated by MRWA in 2006 but now in 2012 on it’s 4th iteration it looks like the planets have aligned and it’s a goer!

Only 9 hours from mine

The main reason for now replacing the bridge (aside from it’s amazing state of disrepair) is ironically due to the Shires isolation. The government will be starting the Square Kilometre Array (SKA) project to place loads of satellite telescopes in the area where there is limited ambient light interference. They expect that the construction traffic alone will increase the roads daily vehicle use to a whoping 15 from a mere 3. Couple to that the fact that it is only serviceable for 8 months of the year when not inundated by the massive 700m3/s flows it regularly expects in the wet season, and you wonder why they are bothering. The bridge was the first precast concrete bridge in WA, and though it is 85years old, the initial quality was pretty poor standard and it has required significant maintenance just to keep it open over the years.

My main effort this week has been baselining where the project sits with BG&E. One of the main issues has been what the client actually wants. A 20year dry serviceable structure has been requested, though not formally. It would be easy to provide a simple design to achieve a 20 year dry bridge but due to a total of a 2400m floodway along the sides of the structure with a dry serviceable return period of 7 years, it hardly seems worth it. I organised a kick start meeting with anybody who had corporate knowledge of the project which was useful to keep all informed and for me to establish a route forward. Following the meeting I have been in comms with the client to backbrief them my recommended scope and to confirm the findings of my previous work review, in the hope that once confirmed, I can produce an accurate proposal for completing the work.

The project comprises 3 BG&E elements:

- Waterways – Design flows and stage heights to set bridge soffit height and culvert sizes

- Civil – Approaches, road alignment, culvert

- Structural – Substructure and Superstructure

Waterways

The catchment area is pretty huge at approx 82,300 km2. It’s flood flow at 20 year return period is approx. 750m3/s at a height of 246.7m AOD. When the deck height is currently 245.9m AOD this is a problem as the 5 year period is actually higher. The issue with raising the bridge to meet the 20 year period is that to raise the bridge means to raise the road, which will increase the headwater upstream of the bridge and therefore mean that the deck will need to be higher still. An option to reduce this is to install culverts into the approach rises to lower the stage height. By placing a culvert through it attenuates the storage somewhat and allows a lower road/bridge. It is an iterative process that can only really be obtained accurately using computer software. That said, design is based on historical flood measurements, estimations of flow, surveyed levels and guessed manning’s numbers so ‘accurate’ is a pretty vague word! The question remains whether it is financially viable to raise the road height along the whole 2.4km alignment.

Civil

Civil

Once the bridge height is set and the intent for the alignment is established (floodway/culvert/nothing), the design of the approach embankments and road can be completed. Nothing much has been done on this yet, as they originally worked up 2 alternative alignments in the 3rd iteration when the existing alignment was off the table. The client now wants it on the original alignment. This is difficult for BG&E as the project is currently in the proposal phase and therefore not billed. This deficit will be made up in the fee if won.

Structural

The design at present will be a 72m proprietary Rocla bridge system (so not much in the way of superstructure design) with a piled/rock socketed foundation that will be connected to the newly raised road by 2 earth bund approaches with an additional culvert to maximise the dry serviceability period.

The original plan was to use the Rocla precast spun concrete piles, but due to them cracking on a previous build, standard circular concrete piles or H piles will be driven. These piles form the piers that join with the headstock – this is something I need to look into this week.

Still a long way to go on this one. Not entirely looking forward to the site visit, but at least I will get a bit of red dust on my boots. Finding it particularly hard to pin anyone down on anything, so I have started a decision register that I can roll out at meetings to track past and current decisions made.

Last week of JHG, First Week of BG&E

It happened again!

It has been a ridiculously busy end to Phase 2. The main reason has been another formwork incident in the South Block. During the pour of the last slab on level 1 the deck dropped by about 200mm. I wasn’t looking at the time but heard what sounded like a baking tray warping in the oven (Nicky still baking like a good wife should!), and immediately realised that it was the metal formwork buckling. I ordered all those still dopey enough to be standing on the deck to get off the slab, called the site manager and H&S officer. I then paused the concrete supply in line with the QA procedure implemented after the last settlement. What followed was the usual excitement involving the unions and subcontractors making the incident out to be bigger than it actually was (The ABC news channel quoted one of the concreters who had “seen his life pass before his eyes”).

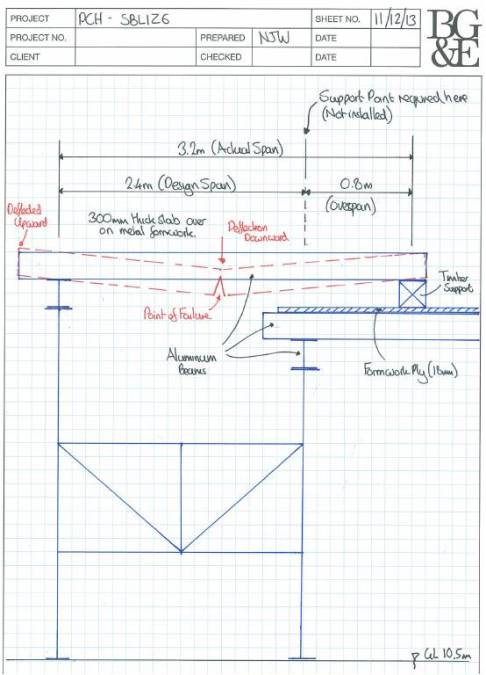

On closer inspection it could be seen that the aluminium beam, on which the deck was bearing, had fractured causing the load to be transferred to the adjacent beams causing them to buckle. My first assessment was that it looked like a combination of over-loading and material failure. See image and calc sheet for sketch. The investigation found that the falsework was not constructed in accordance with design and the beam fractured because it had been overloaded due to an additional 800mm onto its design span. Though the falsework had been inspected by a 3rd party engineer, it would not have been possible for him to see the error in construction due to a ply sheet obscuring the view. The decision is yet to be made on the responsibility for the incident, but I think it is safe to say that the 3rd party engineer’s indemnity insurance and the formworkers are likely to take the hit.

What is interesting about this is the timeline surrounding the pour. The slab was originally planned for the Thursday, but was was delayed to the Friday due to a steel delivery issue, then further delayed to Saturday as the pour clashed with another large pour in the North block. It was then returned to the Thursday at 3pm on the Wednesday, resulting in an incredibly compressed timeline to complete of the slab (Steel was still being fixed in one corner of the pour as the concrete was flowing in the other). In my opinion this should never have happened, once a decision has been made it must be stuck to otherwise confusion reigns. The element being poured should always be ready the night before in order that quality and safety can be preserved (but maybe that is just my military head talking, as it seems to happen quite often here).

Though the incident would probably have occurred even if the pour had been on the extended timeline, it highlighted the lack of resources in the South Block and the pressure to perform to a demanding schedule. The advancing of the slab pour was dismissed as irrelevant in the investigation by the director who ordered it the acceleration – nothing more was said.

We are now left with this……..

Pretty much everything I feared would be the result of the original settled slab (SBUBZ3) is now hapening to SBL1Z6. Jackhammers have been going endlessly in a vain attempt to recover some of the lost time. Ironically to save 2 days we have almost certainly lost a week. The construction director still wants to complete level 2 by Christmas – lets hope Santas little helpers can break concrete out!

I have been a little more involved with the commercial department recently. Mainly running through the monthly claims and assessing their validity before forwarding to the Project Director for authorisation. PCH has not been the best for experience in this element of professional development due to the separation of the commercial teams from the site team. This has got better over the months but it is still a difficult beast to work with. I hope to gain more contractual experience with BG&E in phase 3.

In my time at PCH, I have been responsible for pouring 42% of the concrete in South block (over 5,000m3), this was mainly used in 14 suspended slabs, but also in 290 columns and various other walls and stairs. I am content that I know how to sequence and construct a building but painfully aware just how much detail is involved in just the smallest element of a structure. It is clear that the devil is in the detail and an engineer must know the structure inside out to ensure it is built correctly. This is a learning point that I will take to phase 3 as minimising the different details is key to simplifying construction and hence improving quality.

I have mixed emotions leaving the PCH project. Whilst excited to be starting the design attachment, I do feel that I am leaving the South block team even more under resourced. Though this has been raised at every team meeting, the PM has been unable to secure the hire of a replacement engineer. Whilst not the most effective engineer in the world, I think the reduction of 33% of the engineer coverage, which can only be a cost saving measure, takes no account of the wellbeing and workload of those who remain and is likely to have detrimental impact on the continuity within the team.

After a brief meeting with BG&E last week, I will be moving into the waterways and bridge department initially, but will be a kind of ‘floater’ with the ability to get involved in anything that takes my interest. I hope to get involved in the city’s new underground bus station design, some bridge maintenance/design and try to get up North to work on some of the mining infrastructure.

In other news, this is the first time in my life that I have not been issued clothes for work, Tesco’s, the Army, and JHG all issued me a uniform. Now going into a swanky city office environment I have had to buy new clothes. It was a little like back-to-school shopping with my mum, but I came away with the obligatory office attire of tight trousers, and pointy shoes. I am not sure how long this will last before I break out a couple of polo shirts and the chino’s!

First week in the design office.

The first week has been a gentle break into the design office life. It is clearly evident that consultancies are scratching around for work prior to Christmas, highlighted by 18 consultancies bidding for a potential A$100k upgrade of a culvert in the Perth Hills. If it is deemed that the structure is already adequate after the site investigation, the contract will only be work A$30k. If it is won by BG&E, it is likely that I will take charge of the ‘Bob’s Crossing’ project (I see it as a warmer in the bank). The tender response is due in prior to Christmas, and I will be reviewing it tomorrow. My thought currently is how to make the tender stand out from the others, which for a simple investigation is fairly difficult, however, a little research shows that the area is used by families for picnicking and kayaks for entry to the river, so potentially there may be an option to provide a simple jetty or slipway at minimal cost.

I am currently working in the waterways department, investigating the flood flows over 9 small bridges in the South of WA in an area called Denmark. The longest of these bridges is only 8m and barely 1.5m off the channel bed, but the flood index flows need to be calculated to design the crossings. My thoughts at the moment are that culverts would be the best solution for these rarely used tracks through the Jarrah forests. They will be quick and easy to install, have a good bearing capacity for large trucks to pass, and will be cheap to maintain. The contract is part of a panel contract with the Main Roads department of the WA government, so there is no competition for the job. It appears that the investigation is completed to size the crossing/barrels and then handed to the MRWA to do with as they wish. Pretty easy for the consultancy really, but done well and they will keep coming. As I understand there were issues with the last set of reports that BG&E submitted; different formats, different headings, elements missed. Most of this was due to splitting the jobs down to individuals and not checking effectively before issue. It appears that the directors have grasped this error and are leaning heavily on the QA and management of work packages within the teams. It seems like common sense to me but maybe I can bring a little coordination and admin (squaring away) to the party.

As suspected, I feel a little like a BeeGee walking around Perth CBD in pointy shoes and tight trousers, but everybody seems to be doing it, so maybe for once in my life I am in what they call ‘fashion’?

Repetitive Issues

As JM always said the biggest risk in construction is the ground conditions, and hopefully that is firmly behind the South Team now (though the basement team will have to deal with the slab-on-ground down there). The Upper Basement and Ground floor are finally complete, meaning we no longer need to backprop the slabs to the foundation making construction a much cleaner and less risky business. The issues with concrete continue though.

Not only is the level 1 slab a much more intricate beast in profile and finish it also uses a combination of concrete mixes to accommodate external areas that require additional waterproofing. Fig 1 shows the structural drawing detailing what concrete mix is required.

The white background denotes a 32MPa mix, the green hatching denotes that it should have a shrinkage reducing additive included to restrict shrinkage to 450micons/m (Eclipse) and the red hatching that there should be a waterproofing additive included (Xypex). From the figure it is now clear what the shape of the building will be for the subsequent floors. There are several awkward aspects of this:

1. A close control of the concrete entering the pump is required, and also skill in ensuring that the correct mix ends up in the correct location, in short competent concrete placing subcontractors (something we are lacking – see later).

2. The external areas all require falls to drainage points. As I have discussed in previous blogs, JHG design team, against delivery team advice, have decided to pour falls integrally with the slabs. In my opinion this is a money and time saving initiative that due to poor placement skill will ultimately cost more money and take more time to rectify.

The following images are examples of poor concrete placement on the last pour:

Fig 2, shows where the concrete placement subcontractor has placed a height marker to indicate the ridge line of the top of the slab falls – a good idea, as long as you remember to remove it. Fig 3. Shows a cutting disc that has been lovingly placed into the top of the slab and pushed in for good measure. These are just 2 of the many issues I have found with the finish of this slab. The others:

- Surface finish not steel trowel float to allow follow on trades to waterproof

- Set-down levels not adhered to and concrete poured too high resulting in edge gullies in what is meant to be a flat drainage channel.

- Concrete poured above the height required (no excuse as they use a laser height monitor.

- Footprints in set-downs (claimed to be formworkers returning to remove stakes used to hold in set-down forms)

Whatever the issues, whether it be poor concreting or trades walking over a finished slab, it states in the concrete placement subcontractors contract that they are responsible for the concrete finish, and for protecting their work. NCR’s are going to rain, especially a separate concrete contractor has now been contracted for the basement and is producing an incredibly better finish. The client even made a joke in the pre-pour meeting about it.

We have started forming up level 1; it is taking twice as long as expected though for 2 reasons.

- The formwork contractor has run out of competent carpenters to do the intricate angles and curves

- The formwork contractor no has no incentive to perform as he is now on a costs + contract where JHG are paying the invoices + a percentage.

All that said the formwork is looking quite good. It is nice to see some curves after 7months of straight edges. What the image also shows is the cast in Halfen channels that the precast walls lock into. The locations of the channels had to be estimated by the delivery team as the shop drawings from the precast panels had not been produced due to a delay in procurement. This may turn out to be another problem to fix down the line if the channels do not allow enough flexibility to accommodate the panel brackets.

The current issue that I have found with Level 1 is that the structural design has not effectively checked the design of the reinforcement, cast ins, services or PT for clashes. It is causing many issues on site that are not helped by the individual subcontractors inability to liaise with each other. It is actually in their contract to liaise with other trades but none appear capable of doing so and resort to just complaining to any JHG employee who is available. It really is very petty. The issue shown in Fig 5 however is purely the structural engineers issue of not deconflicting PT and reinforcement. The issue is not in the alignment of the ducts or placement of the anchors but in allowing in the design of the reinforcement for the placement of the pans that allow the stressing of the cables to take place. As it stands the pans (400mm wide) do not fit side by side as designed between the vertical links, spaced at 600mm across the beam. My proposal was to stagger the PT ducts to allow them to fit between the links. This is only possible at this point at the PT is effectively being used to create a cantilever over a column to increase the capacity of the adjacent beam (See fig 6). It occurs to me that many of these issues could have been avoided by using a single BIM system and good communication.

Fig 5: Clash between PT pans and Reinforcement. Lack of understanding of how the structure is constructed.

In other news, I went on a site visit to Perth City Link (the project Rob Ridley worked on), which is nearing completion, 6months ahead of schedule and on budget – I am sure it has everything to do with Rob’s input. It was good to spend a bit of time with engineers from other projects to share experiences.

The PCH project has decided not to replace me when I leave in Dec. Not bigging myself up at all, but I think this is a decision based purely on cost and not thinking about the repercussions on the remainder of the team. Even a grad engineer would be a bonus, especially when a Grad engineer costs approx $75k a year and the value of liquidated damages in $180k/day. The maths is simple. The ongoing joke(?) is that i don’t do anything anyway – funny!

It was good to get across to see the Bainger’s in Sydney, if only for a little while. While the girls and little ones took in the sun and café culture, Jon and I went out to his site for a wander around. It was good to see how things are done on the East side of the country, and to be honest a little scary how different some of the procedure are at the PCH. I even caught Jon working when away from playing solitaire at his desk. David, I think this is a contender for the new prospectus!

It was also good to catch up with a few ex-RE’s to take part in the Tough Mudder event. As it turns out the ‘Wrestler’ fancy dress resembled more of a gay 80’s fitness instructor, but it held up well and nobody got broken. This weekend was the Perth Tough Mudder event with chicks, so a slightly fast pace than that with ex-Army lads who have embraced the civvy-spread.

Time for a little break now, so off to NZ next week to gather seismic research for my thesis, and may take some time off to spend with Nicky for our anniversary too.

A Big Week

Progress on site has been fairly significant this week. We have finally completed the Ground Floor! Aside from now being well and truly above ground level, which is excellent for morale, it also means that I no longer have to walk up and down a multitude of steps to access the decks (I have seen my weight increase to my normal fighting weight, so it is either the lack of steps at work, Nicky is baking more, the stress levels have decreased, or a combination of all 3).

The addition of a Project Manager to the South Block team has been a big injection of capacity. The fact that he has come from Leightons, JHG’s parent company may suggest that ‘Mother’ is beginning to take interest in her wayward child, and is reinforcing the project to ensure the success of her investment.

The PM has immediately made an impact at the subbie contractual level. Crown (Concreter) is a notoriously difficult subcontractor to deal with and have point blank refused to pour concrete some days stating that they do not have the manpower. As the concrete pours dates are promulgated daily for 2 days in advance I don’t see this as a valid excuse. It continues to happen though, until after a frustrating day for supervisors and engineers trying to coax Crown to pour some columns that would enable WCF (Formworker) to continue work the following day (Crown and WCF do not get along well), the PM waded in. I’m not entirely sure what he said or promised (I know pizzas were ordered) but not only did they pour the 3 columns we required, they also worked late to 8pm and poured every single column that we had formed, they even brought in an additional mobile pump to get the job done! This was a big win for us as it opened up several additional work fronts and released column forms to prepare for the 1st floor.

A similar issue arose the following day, but this time it was resolved by the issuing of a site instruction to the concreter to pour the upper basement to ground floor ramp regardless of weather conditions. Though the issuing of a site instruction appears to be a caving in to their contractual obligation to pour concrete in all conditions, the site instruction will now be debated at commercial level to decide whether it gets paid or not – I suspect not. Crown’s argument was that the weather (light rain) would not produce the specified finish, correct; but does not alleviate them from poor concrete placement. The contract states “The concrete placement subcontractor is responsible for the finish of the concrete in all conditions, including rain,” and also that the “Concrete subcontractor is obligated to pour concrete regardless of the weather, except in heavy rain,” The latter is a little vague as ‘heavy’ is not quantified but from my objective opinion, and from brief discussion with Richard Farmer back at the Mother-ship, JHG should have no mercy for the subbie in regards to rain – it’s worse in the UK!

In the foreground the drips from the slab above have ruined the surface texture. The remainder of the slab has the (now standard on NCH) golfball effect. You can also see the water runs and to a lesser extent the surface undulations above the grade change.

Core C was my second pour on the job, way back in March, and though all appeared to go well on the day, it was an unmitigated disaster inside the core walls. To add some perspective to this and to put up my own responsibility umbrella, I was handed responsibility of the pour 30minutes before it was due to start. The reinforcement was already installed and checked, the shutters were closed, and the concrete was on the road. The issue was in my opinion one of design. The walls were 400mm thick and heavily reinforced, especially around the header-beams and jack pockets. In some places it was later found that the concrete physically couldn’t get past the reinforcement to the form below creating voids and exposed reinforcement in almost every cell of the core. The structure has now undergone an extensive survey using a mixture of cored samples and scanning costing in excess of $120,000. The rectification work is yet to be completed but will certainly involve the breaking out of large sections of wall (1m squares) to be re-poured.

One of the less significant defects in Core C. This reinforcement has 30mm cover to the surface but due to poor vibration and closely spaced bars, concrete couldn’t get through.

The remediation work has the added issue that it has held up progress on the South floors and subsequent floors that tie into the core will require additional back propping to prevent additional load being transferred to the walls. The JHG solution to the Core C problem was to draft in an engineer with the sole responsibility for ensuring that it didn’t happen again. The next lift of Core C was poured last week, and even with all the additional resources and quality ensuring measures in place, there are still several areas of exposed reinforcement. I think this issue could have been engineered out at the design phase as it should have been fairly clear that the shear volume of steel in the wall was going to make concrete placement difficult. Provision could have been made for either an increased wall thickness or a more sympathetic arrangement of bars in areas of high reinforcement. The concrete is already at a high slump and using a 14mm aggregate to ensure it has the best balance between consistence and strength. This problem will continue for the following lifts unless a preventative solution can be found to minimise the poor flow of concrete around the steel.

I have got myself involved in the procurement package for the concrete precast panel walls. It is a relatively small package at $700,000 but has given me the opportunity to follow the process from initial tender to where it is currently stalled in the commercial department. I was a site representative at the initial interviews with the supplier and the installer and am looking to maintain involvement throughout the process until the phase ends in early December. Time is flying by.

In other project news, and I suppose related to the arrival of a few Leighton managers, is the recent Leighton’s audit of the project that was, I assume, somewhat scathing as it has had the effect or removing the Commercial Director of the project and the General Manager for the Western Australia Region has ‘resigned’. This has also induced a further 2 senior commercial administrators to resign.

Thanks to Mike/Richard for the blog on the shearing of bolts on Reinforcement connectors. I spotted the connectors whilst wandering site and ‘reminded’ them that the heads were supposed to shear off. Luckily they were designed to shear; I had to check when i got back to the office.

ANCON MBT Couplers. This connection was intended to allow the column starters to be replaced at a later date (after the bulk haulage road was finished with). A change in plan meant that it was no longer necessary to do this but we had already gone too far.

In other news, Nicky and I have finally booked a holiday to NZ to do the classic campervan tour of the South Island, and hopefully meet up with my cousin from Wellington. We are also doing the largest swing in the world (nothing dodgy) that we saw on the Australian TV show “The biggest loser,” If it can hold the fatties, I’m sure it will be OK for us! We are off to Sydney to catch up with the Bainger’s and take part in the Tough Mudder event.

Contract Acceleration

It is often necessary to accelerate a contract in order to meet a specific contractual or construction milestone. This is done to maintain project programme and in the case of the New Children’s Hospital (NCH) improve cash-flow through payment via milestone achievement.

Acceleration may be requested by either the client or the contractor and the process for implementation should be documented in the contract. It is most usual for a client to accelerate works to bring forward a completion date or maintain programme after a delay or design change.

If acceleration is requested by the client, the contractor should have the opportunity to respond with a decision stating any terms of contract that he considers he will be entitled to; this will usually be financial remuneration. If the acceleration is as a result of activity that is not the fault of the contractor, such as design changes or delays by others, then the contractor is entitled to these additional payments, however if the acceleration is as a result of a delay caused by the contractor, he is not entitled to any additional payments. In this situation, if the contractor cannot fulfil the terms of the acceleration the client can employ others to complete the work at the contractor’s expense or invoke a contractual liquidated damages clause to offset the cost of the delay to project completion. If the contractor requests acceleration, the client has no obligation to accept, but if he does, he will negotiate any additional payment prior to work commencing. Payment is usually on a day-works or schedule of rates basis.

A contractor can accommodate an acceleration by increasing the working hours, increasing the workforce, or both depending on its intensity and duration. For shorter periods it will usually be sufficient to work longer hours and additional days, however this is not sustainable for longer time frames. To increase the workforce at short notice for a small contractor is difficult as to sustain a large workforce is not financially viable and it is not often possible to generate the required labour at short notice. This is a particular issue in Western Australia where the prevalence of the Fly In Fly Out (FIFO) contracts attract the vast quantity of skilled tradesmen with the lure of a wage that is often up to 50% higher that the wage paid in the large cities. This reduction of the pool of tradesmen available for employment at short notice, and the inconsistent nature of accelerated work periods can often result in a contractor being unable to accelerate.

On the NCH project, John Holland Group (JHG) as Managing Contractor has let many smaller subcontracts instead of employing one Main Contractor. This has the effect of reducing costs due to smaller subcontractor overheads, but increasing the demand on organic management. By removing several layers management that a Main Contractor would provide and assuming control of separate subcontracts JHG may save direct costs but increase the indirect costs associated with the friction between trades and the effort required to implement and enforce the contracts.

The transfer of risk associated with acceleration sits largely with the party who requested it though once accepted and documented the subcontractor is obligated to meet the requirement and will be held accountable if it is not met. This may be enforced contractually with a liquidated damages clause or conversely, an early completion bonus.

The Clients contract with JHG transfers much of the risk in the construction to the Managing Contractor. This risk has been conveyed directly to the subcontractors. Although this sounds like an ideal scenario of limited risk to JHG it can actually be detrimental to progress when dealing with smaller subcontractors. A small subcontractor can be significantly affected by a risk being realised to the extent that they may not have the financial backing to support themselves and go bust. This would leave JHG without a trade and hence there is a fine line to be walked between getting value for money and losing a workforce. An astute subcontractor can play this game to his advantage but runs the risk of losing the job if he can be replaced if the game becomes too costly for the managing contractor. At present JHG are already supporting one subcontractor financially and mentoring its management processes, and in dispute with another over payment. Perhaps a more sustainable situation would be a pain/gain contract that would allow a more mutually beneficial working relationship and offer a consistent incentive to perform throughout the project.

It is also possible to accelerate a project by engineering. The use of design changes to increase buildability or re-sequencing of work to cut lags between tasks has the effect on condensing a programme to be more efficient at minimal additional cost. This is clearly preferential to a contractual acceleration but is dependent upon having elements that can be redesigned, and float in the programme that can be removed.

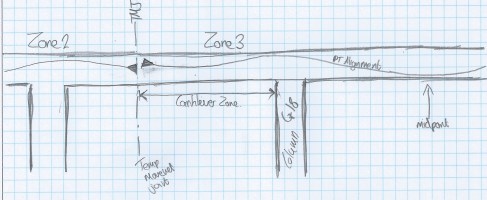

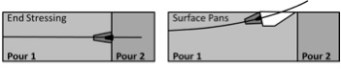

During the push on the NCH project to achieve the milestone payment of pouring Zone 8 suspended slab (see fig. 1), the programme was on the critical path so had zero surplus float but utilising a redesign of post tensioning (PT) and concrete it was possible to cut the duration by 5 days. Both changes were dependent upon the PT. By changing end stressing PT anchors in Zone 1 to surface stressing pans (see fig. 2) it eliminated the requirement to wait 5 days for the minimum concrete strength (for stressing of PT cables) to a 1 day lag before pouring the adjacent Zone 7 slab. Additionally, by increasing the early age strength of the concrete used for the Zone 7 slab allowed an early stressing of the PT cables and hence only a 2 day lag before the pour of the Zone 8 slab. Thus the milestone pour was achieved with 2 days to spare.

Acceleration is a necessary element of construction and is often required to regain control of a programme or to meet a client’s demand. After a formal request to accelerate from either the client or the contractor and an acceptance from the other party it becomes contractually binding and payment may be granted if the reason for acceleration is not as a result of the contractor. The action of accelerating causes several issues for a contractor, not least in WA is the requirement to find additional skilled tradesmen, and the client should take this into account prior to issuing any order. The transfer of risk during acceleration can be re-proportioned but tends after formalisation to replicate that of the original contract. The setup of contracts should look to intelligently allocate risk on a basis of where it can be minimised instead of passing it all on to the one particular party, potentially to the detriment of all. Preferably acceleration can be achieved without the use of contractual obligations, by use of engineering to redesign or re-sequence works to maximise efficiency, reduce costs and minimise delays.