Archive

Filling the Royal Docks

I have been tasked with the assessment of the feasibility of infilling part of the Royal Docks with material reclaimed (almost all fines) from the surface of a site adjacent to the site. This is to maximise the available land on the site and reduce the need for offsite disposal. Beckett Rankine have been tasked with working out how this can be done prior to it being tendered as a D&B contract.

Site Overview.

The problem is they want to infill this part of the dock:

The surrounding walls on the north and west of the site are in horrible condition so can’t be relied on for support. We are required to provide a high-level concept design of how this can be done.

The ground conditions are:

- GL is at +5m

- Water level is around 4.2m – 4.8m depending on the dock level.

- Made Ground, Alluvium and dock sediment down to about -3.8mOD

- River Deposits _1.5m to -6m (+7m head on GWT, probably governed by the Thames and more importantly the adjacent dock!).

- Lambeth group -6m to roughly -16m (acts as a cut off between hydro regimes)

- Thanet Sand -16m to -29m

- Chalk -35m to -38m

Currently we have 3 options:

- Double skin sheet piled wall (like they have used on Tideway structures on the Thames), dewater inside, then infill.

Pros:

- Structure will be strong enough to support the large lateral water pressure.

- Will allow access to what the cofferdam so the alluvium at the bottom can be removed

Cons:

- Large costly structure requiring material to be brought on site as the infill.

- Large single wall, either contiguous or sheet pile, dewater, then infill from the bottom up.

Pros:

- Much simpler structure.

- Will allow access for personnel to compact layers and remove alluvium.

Cons:

- Continguous piles are unlikely to keep the water out. Large pumps will be required.

- Sheet piles will have to be large to avoid potential buckling.

- Sheet pile, then don’t dewater, remove the dock sediment by dredging, then just infill and vibro compact and use displacement to get rid of the water.

Pros

- No dewatering

Cons

- Not easy to remove alluvial filth at the bottom of the dock.

- How to effectively dewater the fines and prevent long term settlement

The key issues we are having are:

- Identifying which would be the best structure?

- How to ensure that the fines being used as infill are suitably compacted or stabilized to avoid long term settlement?

Anyone got any words of advice or any other similar projects they have come across?Currently we are investigating what has been used for land reclamation techniques on the Thames Gateway, Dover extension and Tideway.

Anchor Design Software

We have just had a seminar with HILTI and they pointed us towards their cloud based design tool for designing baseplate anchor systems, which would have been ideal for Ex STEEL. The free version will allow you to design the anchors and undertake ULS/SLS design to EC2/3. It is quite similar to TEDDs but gives you specifications of products (albeit Hilti ones), making design just that bit easier. It also will show you the calculations, therefore it is very easy to follow and verify what is going on, it also gives useful references.

The limitation with the software is that it assumes the baseplate is rigid and there is no verification that it is, which has to be checked independently in the free version.

You just have to sign up for an account.

To give a bit of context at London City Airport we used a chemical anchor solution for the a 7m high 240m long noise barrier, therefore it isn’t just for small scale temporary works.

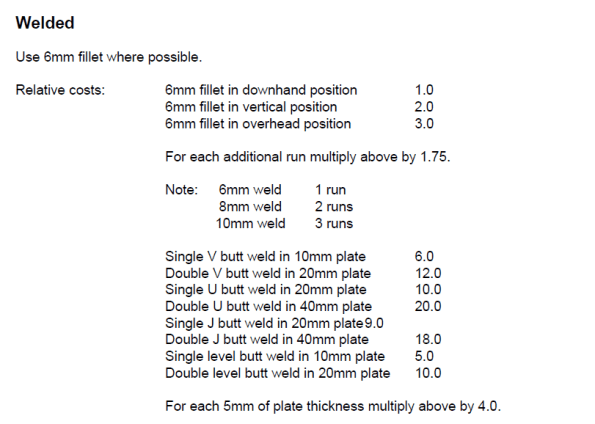

Cost of Over-specification

Ramifications of Past Decisions

This weekend saw the first of 15 consecutive weekend works, caused by a single decision early on in the project.

Early on in the project when the design for the precast elements was not complete, a decision was made to start piling. This was due to high standing costs for the piling barges and instructions from the client to start work. This meant that the first row of pre-cast was not able to be placed.

An aerial view of the deck showing the missing precast between the dock wall and the new deck

The solution was bringing in a 450t crane to lift everything into place. This is achieved during the weekly 24hr airport closure between 1200 on Saturday to 1200 on Sunday.

This 24hr possession enabled the installation of 8 beams…. I question whether the management are ruing their decision many months ago.

It will be interesting to see whether BAM can claim the full costs of this back from the client, stating that this is due to a PMI telling them to do so!

Bye Bye Tolerances

Yesterday on site we had an interesting discussion about an issue which has been in the background for a while, which everyone has been ignoring until it’s actually preventing concrete being laid.

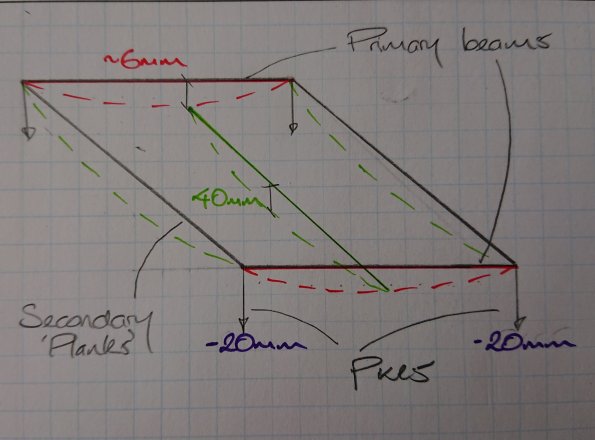

Issue: The pavement thickness of the client has been specified as 150mm + 20mm. The precast secondary elements they are resting on are designed to deflect up to 40mm, the primary beams 6mm and the piles to settle up to 20mm. Whilst we haven’t actually been given FPLs (finished pavement level) by the designer yet, they are coming and we will have to be within +/-6mm to be compliant with the spec.

This is a similar problem to on Joe Murrows site, we can’t however back prop to limit deflection as it is over water!

This has raised the following questions:

- At which point does out liability end? FPL which change over time therefore so long as it’s less than 20mm is that okay?

- We have raised RFIs regarding which is the overriding factor, pavement thickness or FPL. We think it is going to be FPL, but if it is do we risk overloading the planks to get this? Atkins have designed for the concrete to be up to 45mm thicker to account for this, it is likely to be tight at midspan though…. This also doesn’t take into account the as built levels being lower that design.

- How do we monitor this settlement?

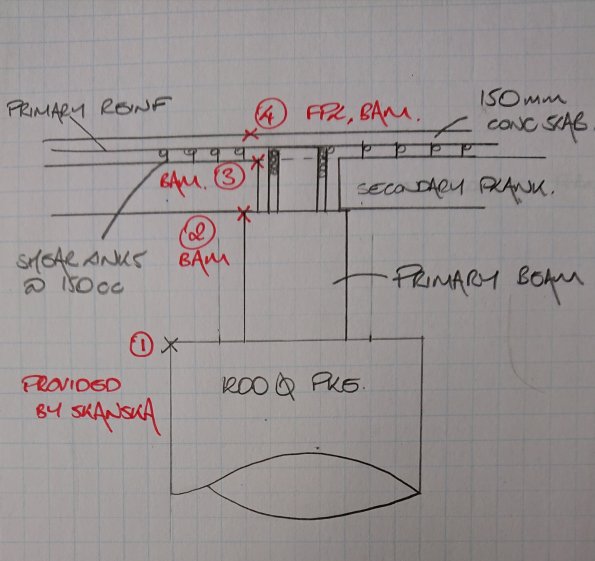

- Currently we are monitoring the levels at the four stages highlighted below. What we have suggested is that monitor selected areas, these include areas under the most loading and where the piles might be bearing on different boundarys to those it was designed for. These are being monitored weekly at top of plank level, point 3.

- At the moment it all comes down to resources, it is isn’t in the spec that we have to monitor it, therefore there is no money for it. A very shortsighted viewpoint I think as the elements listed below are intrinsically linked to knowing how much movement there is!

Areas where we are recording levels

Any ideas on how we could:

1. Cheaply and easily monitor settlement accurately?

2. Accurately measure Deflection?

London City Airport

Having started Phase 2 with BAM at London City Airport (LCY) two weeks ago I have finally worked out enough of what is going to on provide some useful information about the project.

PROJECT OVERVIEW:

The project was tendered at £85m aiming to increase the capacity of LCY by building a new apron and taxiway as well as extending the terminal. Currently planes have to taxi up the main runway if they want to take off from the 27 end, this is

serverly restricting the capacity of the airport. BAMs role is to deliver the piles and deck and for Bechtel to follow on and construct the terminal building.

The plan is to pile into the existing dock and use precast beams and planks with an insitu topping layer to tie it all together. The project is zoned, the original plan was to undertake sectional completion, starting with P1 in Dec 2018, then P2, P3 etc. This has not gone according to plan with the rows of the piles being completed east to west length ways rather than north to south as originally planned.

P1 is basically being run as a different job to P2-5 as it involves land based operations, whereas P2-5 are being undertaken primarily from barges.

P1 Land based pouring and piling.

P2-5 Barge based piling, subcontracted to Skanska Cementation. Note the planks in the foreground, these are sheer links to tie in with the 150mm in-situ concrete deck.

KEY ISSUES:

Logistics. Currently there are over 4500 precast concrete elements that are being manufactured in Ireland, by Shay Murtagh, with only 20% of the total delivered there is massive pressure on them to up production. With this increase in production there is added pressure on BAM to get them placed on site, which is difficult requiring a specially built barge to place them, shown below:

Design Change. The original design was created by TPS, a subsidiary of Carillon, which obviously didn’t end well, therefore the design has been novated over to Atkins who has majorly redesigned it. They drastically increased the number of beams and planks required and the deck reinforcement complexity. This has led to BAM scrambling around trying to plug the gap between the lump sum price they tendered and what they are currently forecasting, circa £150m.

The airport is operational. The airport is open which due to a 6 degree angled safety zone from the Dock wall restricts access for the piling barge to nights only, putting the works behind from the start. It also imposes lots of other silly little constraints which cumulatively gets in the way, putting the project further behind.

Overall the client is not on side and a very adversarial relationship seems to have developed with each side looking to blame each other. Not suprising really when the project is running at least 4 months behind and £65m over budget…..

MY PART:

I have been assigned to the deck team, which is currently planning on how to install 80,000m³ of in-situ concrete onto the precast planks. This is interesting due to the amount of different types of bar layouts, 32 at the last count. This coupled with the constraints of delivery and getting things onto site, often on the night shift, requires a lot of planning.