Archive

Free Software – Phase 2 its out there.

After completing my last TMR which was based on the performance of solar thermal systems and the comparison of land cost. Before I started this TMR solar power to me was simply Photovoltaic (PV) cells, but after a lot of research it was evident that this was probably the worst type of harvesting of solar energy. The main problem I had with my TMR was the systems themselves are extremely complex, for example a Parabolic trough which heats liquified nitrile salts, to a working temperature of around 1500 deg C and running a Rankine cycle steam turbine combined system is rather complex. To compare these systems would be far too much work to be able to fit within one TMR.

This is where free software is the key, I personally have found getting enough raw analysis within a TMR has been hard at times, some times due to the complexity of the subject which I have chosen to discuss and sometimes lack of knowledge and capability. However using free software this can be alleviated, you can complete great research and using such a tool as the American Government package called System Advisor Model (SAM) which the National Renewable Energy Laboratory (NREL) have developed (https://sam.nrel.gov/content/sam-publications) you can use such packages to do the raw theoretical analysis which is required and this leaves you to draw the key information and complete true analysis of the data.

There is tons of free software out there and in terms of renewable stuff the NREL is great and if you need any other help with this subject Mark Hill is the man. I hope this helps Phase 2 a little as I know I was stuck a couple of time of how I can do a real comparison of different systems.

Heat Loads

I have had some technical issues with my work lap top which has stopped linking to the internet and the work internet protocols not allowing me to get on the word press portal. After a couple of packets of biscuits to the NDY IT guru he has solved the issue and put me on a different internet to everyone else!!

Frederick Irwin Anglican School New Chapel, Mandurah.

The NDY experience, the first project which I have been working on is a heat load calculation for a chapel in Mandurah which is an hour south of Perth, so very similar dry and wet bulb conditions to Perth.

The Chapel is a very modern design as can be seen from the images below. The volume of air within the space is extremely large due to the high ceilings, which architecturally most chapels have the same features, however the building fabric of the UK chapel is very different to here due to the potential of thermal energy being built up during the day and stored over night because the temperature differential is not sufficient enough for it to be rejected. The resultant is lighter building fabric which heat up quicker but can also reject heat at a fast rate also.

The Chapel is a very modern design as can be seen from the images below. The volume of air within the space is extremely large due to the high ceilings, which architecturally most chapels have the same features, however the building fabric of the UK chapel is very different to here due to the potential of thermal energy being built up during the day and stored over night because the temperature differential is not sufficient enough for it to be rejected. The resultant is lighter building fabric which heat up quicker but can also reject heat at a fast rate also.

The heat load calculation was completed using a stratification methodology therefore only cooling from floor level to 3m and the remaining airspace heat being exhaust at the zenith. This was fairly straight forward however the program which NDY use TRACE does not have any modelling capability so its quite difficult to see if you have all the geometry correct. The next challenge was dealing with an architect which did not understand for a building to be functional it requires some mechanical cooling and the space which was allocated was vastly too small, so after doing 10 different designs demonstrating that the space was too small we finally came to an agreement. I believe architects here are still 10 years behind and drawing pretty pictures and have no idea of safety in design or engineers working in conjunction with architects!

The heat load calculation was completed using a stratification methodology therefore only cooling from floor level to 3m and the remaining airspace heat being exhaust at the zenith. This was fairly straight forward however the program which NDY use TRACE does not have any modelling capability so its quite difficult to see if you have all the geometry correct. The next challenge was dealing with an architect which did not understand for a building to be functional it requires some mechanical cooling and the space which was allocated was vastly too small, so after doing 10 different designs demonstrating that the space was too small we finally came to an agreement. I believe architects here are still 10 years behind and drawing pretty pictures and have no idea of safety in design or engineers working in conjunction with architects!

Karratha Quarter, Karratha.

Karratha Quarter is a combination of residential, office space and amenities. Karratha is in the North of Western Australia, as can be seen from the image below and this has a very different envirnoment compared to Perth. The main work which I completed for this was checking tender documents, this was for all disciplines which has given me a broad spectrum of experience. This task was meant to be completed by Christmas and this is something which I have noticed since I have been with NDY is that dead lines are often missed and there seems little structure in the company on who controls which projects. The result generally is people being dragged from one job to another and being very ineffective.

Capital Square Tower 1, Perth.

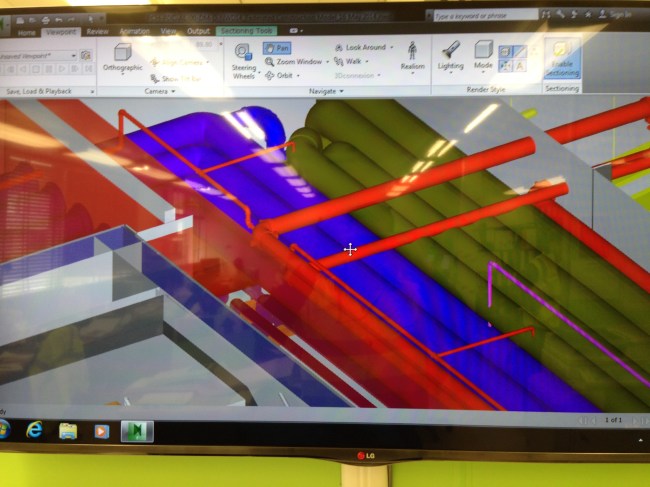

Using my experience from site running BIM model clash detection meetings I have been asked to do the clash detection for all the services for tower 1 of Capital Square a new river side development. This is initially completed with a clash detection run by a program called Navis works, then me looking at all individual clashes and coming up with a solution which I feed back to the Revit 3D modellers. This is done in an iterative process completing all the clashes for Hydraulics initially especially drainage, then Mechanical etc etc. This is a long process but one which I can directly influence design and ensure the model reflects something which can be built which I have experienced first hand from Perth Children’s Hospital.

Life outside of work.

I have last minute been called up to do the Rottenest Swim as part of a team which is a 21km swim from Cottesloe beach to Rottenest Island, which is going to be a serious challenge with limited training, I also have swimming State championships coming up and then Hannah and I are off to Hobart, Tasmania for the swimming National Championships. So keeping fit and wet!

Phase 3 – NDY

Happy New Year

After a most welcome break from (Perth Children’s Hospital) PCH I started Phase 3 with Norman, Disney and Young (NDY) last week after an amazing Christmas and New Year camping in Esperance and Margaret River, finishing with a 7 hour wine tour on New Years eve. It has taken the office a while to start up and I am now starting to be involved with some projects. Due to NDY being the main engineering consultant for PCH I will only be doing back of house work if any work on that project. I am starting a new small packet of work which is a consolidation of a number of Fire Alarm panels into one main panel. This will be interesting and also increase my knowledge of fire control systems and generally Information, Technology and Communications (ICT) systems which are becoming ever more complex and inportant with building services. The last item I wanted to blog about was the NDY beer fridge, its a 3m by 2m fridge full of beer!! This I am told if for retention purposes and of course friday evening drinks starting at 16:00, I have also volunteered to be on the NDY social club commitee as the memeber who orgnises sporting event such as the Corporate Triathalon which is in 6 weeks time. Further news is Hannah was second in the Australian National Pentathlon trials in Melbourne this weekend missing first place by 16 seconds and we are both on the commitee for our local swimming club helping organsie events this year. Hope you all had a good Christmas and New Year.

Wrapping up at PCH

PCH

The last few months have been amazingly busy with the project becoming more intense every week as the time is dramatically running out and a number of items are still not designed. As a whole the basement, the area I look after is quite lucky as it does not get as affected by superficial changes which the Architects seem to change with no consultation with the engineering consultants and most of the user groups are not interested in the back of house areas so all good for us in the basement!

The photo above is a photo of when I first started on the project and its not until you look at the photo below to believe how much work has happened. This does not really show how much the basement has changed considering when I first started in the basement there were no services installed other than a section of Syfonic drainage in the corridor of death.

The photo above is a photo of when I first started on the project and its not until you look at the photo below to believe how much work has happened. This does not really show how much the basement has changed considering when I first started in the basement there were no services installed other than a section of Syfonic drainage in the corridor of death.

The hospital as it stands at the end of November.

The hospital as it stands at the end of November.

Milestones

The major miles stones which have been achieved in the last two months:

Central Communications Room 2 handover which alone I had substantial tactical, operational and strategic influence and effect, this alone had damages of $180,000 a day and total worth $4 Million and it was delivered 2 hours early!! The amount of information and technical knowledge learnt during the process of building CCR 2 has been amazing, I have learnt about all the aspects of Tier 3 Comms rooms and to my astonishment I caught the professionals out a few times.

The official handover to the State (the chaps in the green hard hats)

Connection of Chilled Water from the Central Energy Plant, this was a major milestone which I personally organised all of the works involved (including all the safety paperwork, works on a Sunday etc) with the Mechanical Subbie and all liaison with our Client the State. This was achieved in a safe and controlled manner and all within the time period which did not have any knock on effect to daily works on the Monday. The only disappointing part of the works was that the work was achieved but due to Strategic level politics between JHG and the State the Chilled water still has still not been turned on.

A subsidiary side of this main work was the connection to the CCR 2 pump room which has its own set of heat exchangers and pumps to ensure a mechanical separation from CCR 2 and the main chilled water system due to one system running at 1500kPA and the other 400kPa. This system incorporated all the BMS side and was fully functional on the delivery date of CCR 2 which included flushing of the system which again I learnt a great deal, chemical endorsement by the water corporation and water treatment for a tier 3 communications room which included a temporary Reverse Osmosis supply.

Hydraulic Plant room which had a milestone deadline of end of November fortunately was in the full control of Christopher Contracting the plumbers who are exceptionally good subcontractor. We had to have a few technical workshops which I managed with them and our engineer consultants NDY. The most impressive part was the modular tank manufactures which came from Malaysia who were exceptionally professional and built all three tanks in three weeks, they could of shown the Aussie some work ethics!!

Plant Room 10 was meant to be completed on the 10th of December 2014 but sadly Fredon is like that Sapper that you are told about before you become a Troop Commander who takes up the 90% of your time and is the worst performing. We achieved the Chilled Water date of 25th November 2014 but the high temperature pipe has all been manufactured but not installed yet because they still have not got sufficient paperwork as per the specification foe the pipework to start to be installed. The quality issue with Fredon is still a major problem and the latest incident is their shell and tube heat exchangers which have poor safety in design and maintenance accessibility.

Life

As mentioned in the last Blog Hannah signed us both up to the Mandurah 70.3 Ironman, fortunately for us it was the hottest day be have had since we have been in Aus at 36 with a recorded temp of 45 off the tarmac. It was a great event overall and I had a great swim and bike but the run was brutal in that heat but completed in 6 hrs so happy enough. Hannah has just got back from National’s in Brisbane for Modern Pentathlon and came 4th so she is chuffed with that and is competing in Melbourne in January so hopefully a top 3 there.

I have had a fantastic experience and learnt such a great deal whilst being part of the basement team and unfortunately got slightly too involved at times and my work/school work balance lapsed and the blogs have been missed at times but with New Year ahead you will be hearing some more from me, have a great Christmas and New Year.

JHG learning from others!!

Information Communications and Technology (ICT)

The Fiona Stanley Hospital which is also a hospital built in Perth was completed in December 2013, it still has not open due to the ICT packages a State deliverable not functioning properly. This has been one of my major focuses for the past 6 to 8 weeks, ensuring we (JHG) deliver the ICT package early enough to the State to enable the State to have sufficient time to make Perth Children’s hospital (PCH) work. My main focus has been on the Central Communications Room 2 (CCR 2) and having it ready for commissioning on the 25th November 2014, which has involved all subcontractors from looking at UPS power, Critical Essential power, in row cooling, leak detection, fibre optics, copper cabling, earthing system and quite interestingly a carbon based anti static flooring. Which is has is a black carbon based primer which is the medium to conduct electrical current through it with a number of specific earthing points.

This system uses small copper strips and a conductive flooring which is a new system, compared to that of the existing systems which involved a full grid matrix of copper foil to interlink all the floor. The next phase is then pour and rolling the carbon based conductive flooring which is roughly 2-3mm thick and then do a physical test which is meant to represent the pressure of a foot and ensure the floor is conductive see photo below.

Quite an amazing product made by Sika the German paint company, I conducted the testing with Tercel the earthing company and it was an interesting experience. Below are a number of photo’s of CCR 2 including blown fibre tubing, copper interconnect cabling and all the electrical works to power the racks.

Quite an amazing product made by Sika the German paint company, I conducted the testing with Tercel the earthing company and it was an interesting experience. Below are a number of photo’s of CCR 2 including blown fibre tubing, copper interconnect cabling and all the electrical works to power the racks.

We have Power!!

On the 15th of September HV power was connected from the Central Energy Plant to the hospital a huge and extremely significant milestone for the project, this was the first piece of work which I worked on when starting the project. It involved a weekly meeting, factory acceptance tests of all LV main switch boards, air freighting equipment in from China and lots of hard work. It was delivered only two days after programme so a huge achievement by all involved. I have learnt a great deal about HV and the switching process and also Australian Standards on safety equipment and earthing.

The first part of the process after everyone was content that everything had been completed, all the inspection and test plans had been signed, was locking out of all the HV switch gear in PCH, then with coordination to ensure all HV rooms where clear of people the switching process began. Photo below show the actual switching on of PCH from CEP.

The first part of the process after everyone was content that everything had been completed, all the inspection and test plans had been signed, was locking out of all the HV switch gear in PCH, then with coordination to ensure all HV rooms where clear of people the switching process began. Photo below show the actual switching on of PCH from CEP.

Mechanical subcontractor troubles

With continued trouble with the mech subbie, with no thought into how the large diameter pipework is being restrained caused a huge amount of problem, when they finally designed there support system and it was entered into the BIM 360 construction model. It meant weeks of modelling to get clash free before installation could proceed. This battle has continued with lack of documentation for welding certificates in line with the specification and the latest item which I have been investigation is all their commissioning sets being dramatically undersized. Looking at BISRA, CIBSE and the manufacturing guides lines valves on occasion where two or three sizes too small. See photo below for an example.

The pipe diameters where dropping from 65mm pipe to a 32mm commissioning set as can be seen above and the location of the commissioning sets and motorised valves are located to close to elbows, pipe reductions or locations which would cause irregular flow which would ultimately effect balancing and commissioning. The mech subbie now sadly takes up a large amount of my time due to the determination to cut corners, not build as per specification and proceed in areas which have not been coordinated correctly.

The pipe diameters where dropping from 65mm pipe to a 32mm commissioning set as can be seen above and the location of the commissioning sets and motorised valves are located to close to elbows, pipe reductions or locations which would cause irregular flow which would ultimately effect balancing and commissioning. The mech subbie now sadly takes up a large amount of my time due to the determination to cut corners, not build as per specification and proceed in areas which have not been coordinated correctly.

Aussie Living

On a positive note I am now swimming for a local club and will be going to the National Masters competition in Hobart Tasmania, Hannah has entered us both into a half Ironman in November great joy!! Hannah is also doing trails with the Australian Modern Pentathlon team. I am also still fishing 4.5kg snapper below and kiting when I can.

Things are going wrong!

The mechanical subcontractor is the worst performing subcontractor on site!! They have today after three months of work have realised they have did not design their expansion of their chilled water pipes correctly. This is causing huge problems as currently the system is a fully Victalic system and now they want to weld every change of direction. Considering a large amount has already been hydraulically tested, signed off and lagged, with cable tray below this is going to be major re-works. Also going through the programme with them a completion date of their plant room which will supply chilled water to the Central Communications Room CCR2 an essential part of the hospital, which has a hand over date of December fully operattional ie it has chilled water running to it, now has a completion date of mid feb……not good.

On a positive note the Power Available programme which has been running since April is nearly complete, we have all three substations ready for commissioning, I have attended all the Factory Acceptance Tests (FAT) for the equipment, we have had some huge logistical problems with some of the larger switch boards. Overall has been a very good experience. We are having large problems with the Client changing its mind and also delaying works by

sitting on very small decisions, it is frustrating how so many people don’t like making decisions and we have been trained to make decisions. We are now getting into the real detailed design of how everything operates and it is clear that the detailed design is truly lacking. There are fundamental parts of systems that have not been thought about correctly, for example the Reverse Osmosis water, chilled water to CCR2 (no mechanical separation) and the whole BMS interface with equipment. this is just to name a few, the great side its keeping me very very busy, with thinking about design, functionability on site and cost.

I have also been responsible for the Northern Green Space as a lad was a way for 5 weeks, this involved all the connections to and from the building for the two fire tanks and two rain water tanks. This brought around a new dimension to works as I had a new set of dead lines set by the infra guys outside, who I was pushing as we wanted to run the Syfonic drainage to the tanks instead of flooding the basement. Overall busy times and the pressure is on as the completion date of 30 June 2015 is dramatically looming and there are some fundamental things going wrong, mainly the mech subbie…

On a positive note spring is here it was a lovely 25 the other day and is warmer at night now, Hannah and I had a great weekend at Shark Bay which is such an incredible place, but a 10 hour drive!!

Corridor of Death – The drama continues

Fredon our Mechanical Sub-contractor have become that Spr which your OC always warns you about that will take up 90% of your time because they are the problem child, Fredon is it!! They have been putting up pipe in the corridor now for over 8 weeks and have achieved about 50 to 60 metres! It has become increasingly contractual and I have spent a lot of my time making a case file against them as they have the audacity to send through delay notices. We now have a workshop with them on a weekly basis, which is micromanaging them and to be honest we would be better off managing them ourselves.

But we have made progress!! We had to coach them through the welding process to ensure that they did sample welds, the welders where qualified, we inspected the welds and ensured they documented all the welds. We then had to ensure they painted the pipe as they were all rusty, now we are lagging the pipe and the Client (State) are not happy which will be todays work. We have completed everything to specification and closely monitored it so we could avoid this.

On a positive note I have been to multiple pump Factory Acceptance Tests (FAT) and Mark thank you the pump knowledge is invaluable, I even sound like I have some idea what I am talking about!! We have also installed our first switch board to the Northern Substation which comes in two parts for shipping which will be bolted together today. I also attended the FAT for that and again John the electrical knowledge was invaluable.

Overall a lot of fire fighting and less of what we should be doing but all great experience learning something new everyday.

Power Available?

The last few weeks have been hectic, subcontractors have been difficult to manage and we have invested a vast amount of time programming every room to give all subcontracts strict deliverable dates. This has included tons of work shops and study groups and now we can see the light as it will soon all be added to the main contractual programme to bring The New Children’s Hospital (NCH) back on target, loosing three months of delay in seven months of work, back on target by Christmas!!

However I have done a lot of work with the Power On Programme which needed to be changed to Power Available as Power On portrayed the wrong message, it basically means power will be available to be used but in matter of fact will only be on the HV side. This process has included inspections of the LV switch boards attached photo below there are six for the three substations and the UPS boards are yet to be built, and we started installing the HV switch gear yesterday.

The different colour are for essential and Non-essential. The front two boards are for the Northern Substation and Plant Substation is at the back, I re-visited yester day and they are a lot further ahead looking at Factory Acceptance Tests on the 6 June and delivery on the 9 June.

The next challenge is the Corridor of Death which is slowly progressing and I am trying to get the subcontractors to utilise the model which they are contractually to do as much as possible. We have had to move one Fire Hydrant Pipe which has been in location since last October as Fredon Mechanical Services Subcontractor modelled there pipe wrong and did not even model the brackets themselves. The corridor is becoming an increasing concern and we called in the director of the main problem child subcontractor yesterday to try and resolve some design and shop floor problems. This meeting will hopefully see change and progress watch this space for an update!

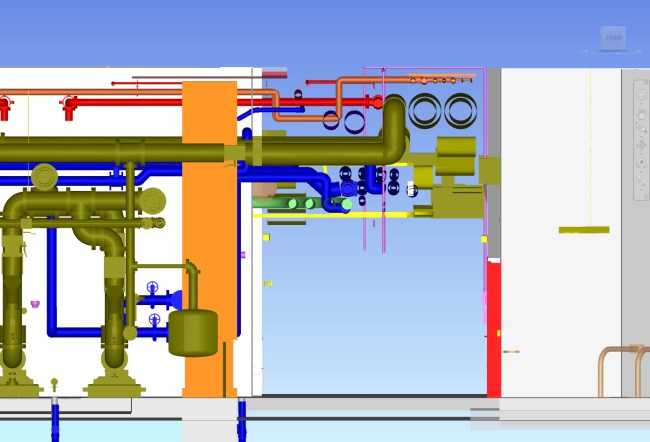

To prove we do use modelling attached is an area I am working on at the moment, the interface between corridor and main service riser.

We have also started to see progress in all the Plant rooms and these should start to progress over the next few weeks……

Metalic insulation in a HV Switch gear room….thoughts?

John,

I thought this might interest you, how do you earth metallic covered insulation in an HV switch gear room?

New Children’s Hospital (NCH) Perth

Western Australia (WA) Wait Awhile!

The Project

The New Children’s Hospital Perth has been in construction since Jan 2012 and is the largest structural project JHG has undertaken at A$1.2Bn. This is the same project as Nik West but I will be looking at the services not concrete, however since Nik left the project it has changed quite a lot. They are still pouring concrete for a project which is due to be finished next summer! However the services are at full steam ahead. I am lucky enough to spend most of my hours in the basement, which the only benefit is its slightly cooler! I work with one other guy and we are responsible for all the services within the basement, we have split the basement in two, I have responsibility for one half which is East and West block which can be seen in the following picture as the blue and red areas.

As you can seen from the pic it includes two substations, LV and HV, one large Hydraulics room including reverse osmosis, grey water treatment room, pneumatic tube room, fire pump room, multiple air handling rooms and all the services which connect them to say the least. My initial challenges are getting a full understanding of everything in each room therefore I can actually ensure everything is done correctly. My role is Services Coordinator which basically means everyone asks us everything about the services!!

So after my chat with my boss he said “Ollie the corridor of death is 6 weeks behind this is your challenge” the following pic is the corridor it will probably be a small focus of most of my blog’s as its the main artery of all the services. This is how it looks now:

At present fairly sparse, with only wet fire (sprinkler system), fire main, Very Early Smoke Detection Alarm (VESDA) and some drainage. The hardest thing is the project is run using a BIM 3D model to ensure clash detection but not everyone one has bought into it, so we use the model but also have to do it by hand having discussion groups with the contractors and de-conflicting. I will go into more detail with the BIM modelling in the future. The following is a cross section of the corridor:

As you can see its busy and a lot to go in.

LIFE IN WA

Say no more…

![IMG_1809[1]](https://pewpetblog.com/wp-content/uploads/2014/12/img_18091.jpg?w=300&h=225)

![IMG_1663[1]](https://pewpetblog.com/wp-content/uploads/2014/12/img_16631.jpg?w=300&h=225)

![IMG_1761[1]](https://pewpetblog.com/wp-content/uploads/2014/12/img_17611.jpg?w=225&h=300)

![IMG_1973[1]](https://pewpetblog.com/wp-content/uploads/2014/12/img_19731.jpg?w=300&h=225)

![IMG_1975[1]](https://pewpetblog.com/wp-content/uploads/2014/12/img_19751.jpg?w=300&h=225)

![IMG_1733[1]](https://pewpetblog.com/wp-content/uploads/2014/12/img_17331.jpg?w=300&h=207)