Archive

Please tell me this is a worldwide phenomenon!

Has anyone else noticed a tendancy for the entire office to get up to go to the toilet between 1650 and 1657? It seems that everyone is so bored all day long they don’t even want to urinate on their own time for fear that it will delay their exit from the office. Please tell me it happens everywhere.

Sense of humour in light pres for the next 6 months

Since my last update I feel a little more sane. There hasn’t been an outbreak of personality in the office but at least I’m kind of getting it a bit more now.

Parson Street Bridge

What has amazed me on this job has been the amount of preliminary work that goes into a tender submission, I have designed most of the abutment, retaining walls and wing wall at this stage. Initially I thought this would be unpaid but potentially fee winning work however it seems that this is actually paid work, I’m told that civil work is usually paid tender work as opposed to building structures which sounds like tender work is unpaid. Where the money for this comes from I can only guess at the contractor who presumably doesn’t get paid for his effort but must spend money on us in order to get a detailed design, in this case Graham. This is a D&B contract to based on initial design by Atkins with Network Rail as the client. The Atkins design is pretty much just a drawing with few dimensions on it which makes putting any real numbers to calculations difficult.

Things that have surprised me in this process:

- The volume of publications that are out there relating to all the stuff that I’m working on, for example the CIRIA doc on Mercia Mudstone, PD6694 dealing with traffic loads on bridges and modelling how they act on retaining walls. This is just 2 of the documents outside of the Eurocodes of which I’ve consulted about 4 different sections so far. The bits that we practised on Phase 1 i.e. putting numbers to this stuff is the bit that the computer does the art here seems to understand where to look for guidance on parameters and conditions, interpreting the ground investigation and knowing what’s possible on site.

- The lack of clear direction, I think I mentioned last week that there seems to be a huge amount of stuff that just isn’t communicated, so happily I carried on doing the models I was asked to do. I went into a meeting late last week with 2 associate level designers from Ramboll who didn’t have a clear picture of how it would actually be built, the tender process seems to drag a little because there hasn’t been a multidiscipline meeting to start off the process. Such a meeting would have removed the need for me to design so much sheet piling because the contractor is unwilling to risk sheet pile refusal in the mercia mudstone during a possession.

- The point above is illustrated by me trying to work out the construction sequence and putting together sketches to show the stages. I was quite surprise by how much was left down to the GEO dept and primarily me. Ignoring John Moran’s repeated instructions to improve my sketching came back to haunt me slightly yesterday, at least the section technician is putting them onto CAD before they leave the office.

- STR checks on sheet piles. So far I’ve been instructed to let the structures guys check the BM and SF capacity of sheet piles, which means in reality I’ve only designed the embedment depth. I thought the Orator would be really ashamed of me at this point so read through some old notes and put together a quick section checker excel sheet. Whilst this isn’t too thorough at least it gives me a chance to not make a foolish mistake.

- I’ve not seen a real check on my work so far, I’ve just been allowed to get on with it and have been expected to come back if I encounter problems. An example of this is that at one point I had to assume the deck acted as a prop for the sheet piles, putting an axial load of about 1200kN into it, I’ve highlighted it because I figure it’s probably important to the blokes designing it but nobody seems worried right now.

In other news: Riding to work this morning was interesting, I fell off about a mile from my house, it happened so fast I ended up in a perfect cycling pose just lying horizontally on the ground.

A fish out of water

Wow, this is like pulling teeth. Apparently nobody in the office got a personality for Christmas so it remains as silent as ever, social interaction is a sin.

I continue to learn more about sheet piles on a daily basis and have been working on a new rail bridge somewhere in the West Country. It is currently at tender stage and as seems to be par for the course design information is scant, nothing on the proposed drawings has dimensions some every sketch I’ve done has assumed or approx in brackets after numbers. Basically I’ve been guessing at it. I’ve also had to guess at the likely construction sequence too. The bridge is going to be constructed in an area where Mercia Mudstone is about 2 metres below the surface, consequently the sheet piles won’t drive down into so the sheet pile wall has the structural characteristics of a wind break on a stone beach. In order to make this thing work it needs to be propped under the finished road surface (the rail currently runs on an embankment and a new road crosses underneath) with RC axial members, the bridge deck itself I think will end up of as a prop too but I haven’t been pointed in the direction of any of the structures team so I’m not sure how much axial load I can put on it yet, I guess they haven’t designed the beams or deck yet. It would all work fine if you could ‘wish it in place’ as the Orator would say but it’s going to need a serious amount of temporary propping in order to get to the finished product. This is exacerbated by the fact it’s under a live railway and so work needs to work in a series of possessions. I’ve done a John Moran favourite and drawn out lots of little sketches of what I guess the construction sequence is going to be. Each of these stages is then accompanied by a separate file in WALLAP to prove that it works and thanks to Eurocode 7 each one of those is duplicated for both design combinations. This interesting part thinking about actually doing stuff was this afternoon, the other 10 hours of work so far this week have been horrendous, I still haven’t worked out if these people are actually busy or just very good at looking busy, I can confirm that they are actually quite dull not just pretending to be dull. Looking down the barrel of another 6 months of this I can safely say I’d rather be going on tour, you don’t need to do AERs on tour.

Sorry I’ve been a little unfair. One of the principal engineers is just back from 2 months working in the Falklands watching a jack up rig drilling in rock for a new port facility. He’s spent 2 months in transit accommodation down there and has spent at least an hour of his time whinging about it to anyone who will listen despite being on 20% more money than he would have been on in the UK. Civvies can be amusing.

Oh dear!

Many of you will already have seen this photo on facebook but for the benefit of those who aren’t regularly bored by photos of my wife and children here’s your opportunity to laugh at my expense.

So Day 1 Ramboll UK geotechnics team: ‘We’ve got a couple of projects lined up for you to work on; one is the foundations for this bridge the concept that we’ve been given is pretty much unbuildable so I want to look at a sheet pile retaining wall option and the other one is a small domestic extension that requires a retaining wall design because the garden is on a slope. So here’s how to get into the road bridge file, here’s a programme called Wallap that we use for this, why don’t you see how you get on?’

Whilst that sounds rather flippant, this is exactly how it felt. Tonight I have been reading the Great Orator’s lesson notes in the vain hope of at least knowing the difference between drained and undrained parameters. I’m going to the sloping garden tomorrow with a ‘panda probe’ which is an electronic stick to hit the ground with, apparently one of the team did an entire MSc thesis on correlating hitting this thing and SPT values, I haven’t met him yet but I’m sure he’s hilarious.

That’s all for now, I needed to share my despair, this time I really will get found out.

Growing Frustration

I am exceptionally pleased that I only have 6 weeks left on site, the last 3 weeks have proved to be incredibly frustrating for me and keeping my opinions to myself is proving difficult. Those of you that I have talked to in person will be aware of how annoyed I have been at various points during my attachment but here are some of the highlights from the recent past:

- Yesterday I witnessed an incident with 2 of the tower cranes which could only have been described as dangerous. On bringing it to the attention of the project managers I was told to go and get the sub contractor to fill out the near miss report and after some discussion instruct them to remove the crane driver at fault; a message I duly delivered. This decision was reversed by the PMs after shortly thereafter, doing nothing for the company credibility nor mine.

- Last week I have having serious issues with the council highways dept and couldn’t get the desired answer back, so I asked the PM for his help in dealing with it, request ignored, Monday morning we receive instructions from an irate highways supervisor to return the road closure to 2 way traffic immediately 4 days earlier than planned, at the point at which they looked for someone to blame, I walked out.

- I chair the sub-contractors coord meeting on a weekly basis, which means I receive the sub-cons concerns and plans for the next week do my best to deconflict at the meeting and take the points that can’t be fixed then and there to people who can work on them in slow time. Often I have requests for more storage space on site, which doesn’t really exist but that is a story for another time, AER 3 probably. There had been some safety concerns raised over the over head working where we have formwork being struck above mast climbers or people working below, there was a suggestion of a daily briefing that would deconflict space and time for overhead activities. I included in the minutes and put it to the PMs who seemed underwhelmed and at that time more interested in patresses (a subject which has dominated conversation over the last 2 weeks at the highest level of the project) nobody else seemed that bothered, I tried again, ignored again. Last Thursday we had a RIDDOR reportable accident when some plywood being struck from a slab fell on a cladder in a mast climber and broke his shoulder blade, suddenly interest appeared in deconflicting people woking overhead.

A complete whinge today, sorry, but my only real sounding board on site was an agency site manager who they’ve got rid of in order to bring in their own websters blokes.

Hot salty fluids

As previously mentioned I have been supervising bringing the utilities onto site, so far it has gone fairly well I had to decide to abort the BT ducting as there simply wasn’t going to be enough space for the work to go on, this will be revisited in the future as the disruption will only impact on site activities rather than the public. I had to deal with a complaint from the Southern BBC Engineering and Operations Manager which was quite an uncomfortable phonecall, it felt a little like OPTAG where the SIMPRESS are sticking a camera in your face and trying to trip you up with questions.

The geothermal element of the installation is quite interesting, what I didn’t realise is that the Southampton geothermal borehole is the only functioning one in the UK. The original project was started as part of a Dept of Energy experiment in the late 70s, the DoE decided that it wasn’t a viable option but Southampton City Council decided to pursue it and went into partnership with private enterprise and started the Southampton Geothermal Heating Company, there are some other complex company arrangements that involve Cofely GDF Suez that I still don’t truly understand but it’s just minor details. Because the City Council are still involved in the scheme it seems that connection to the scheme is often a planning condition, bribery by another name.

Anyway the scheme works something along these lines (see Rich aged 5 sketch).

The borehole is 1700m deep and taps into a geothermal aquifer containing ‘ancient’ brine at 76 degrees Celsius (the bit I can’t quite get is why it needs to be ancient and if it is it must take a while to recharge) a pump at 600m deep draws the water to the surface it arrives at about 70 ish degrees. At this point it goes through a heat exchanger to with fresh water and the cooler brine is discharged into Southampton Water. The fresh water temperature is now topped up to 80 degrees using some combination of Combined Heating and Power plants (CHPs) conventional boilers and biomass boilers. Once the desired temperature is reached it is them pumped around the distribution network that runs under Southampton. In key buildings such as the Civic Centre there are additional boilers that maintain the temperature of the network.

A building that is using the system has a flow and return pipe plumbed into a metering rig. Crucially the metering rig allows the provider to measure energy used, by monitoring temp in, flow through and temp out the clever computer works out how many MWh of energy have been used, I guess this has something to do with specific heat capacity and other such stuff that GCSE physics mentioned. The demand is controlled by the BMS which decides to raise or lower flow as required. There is a limit on the return temp and the contract specifically states that it must be around the 55 degree mark.

The flow pipe can flow in both directions (not simultaneously for the confused Civils amongst us, I stopped short of asking the stupid question of how that works, instead choosing to nod sagely) depending on demand. So if a sudden demand occurs near the civic centre CHP and pump it will be fed from there and the CHPs and pumps are the other extremes of the network pump water inwards to fill the ‘gap’.

Once inside the building I think ( though need to check) I think it goes through a big heat exchanger in the plant room which pumps it around what I suppose could be described as a ring main and then on everything third floor smaller heat exchangers steal heat away for the DHW and heating systems.

All the connection has been made onto a live system in what they refer to as a ‘hot tap’ the provider have been banging on about it for weeks now and made it sound really exciting. It wasn’t, just a couple of blokes all the way from Scunthorpe with a drill, no steam, no blowback nothing.

What a big shaft. Note all the services running through the same small area of road way, at least half of the ones seen behind the guying drilling shouldn’t have been there.

M’s I prepare for the questions I can’t answer.

Mark, in all seriousness if you’re excited by this they’d be more than happy to have you come and look at all the engines and other stuff that moves.

Same old, same old

Everyday and with every new part of construction the same issues keep popping up, no power (or faulty generator), water logged floors or roofs, inadequate storage or working areas, unscheduled deliveries. Occasionally a real problem rears its head but that is usually squirreled away to the designers before we have a chance to really look at it. I’m getting to saturation point on what I feel I can gain from the site, it is becoming very frustrating, I have asked to spend some time at head office with the pre-construction team to see how the bid process can be got so wrong as it has been in Southampton.

I do find myself wondering whether I’m completely missing the point, one of my early posts ‘A Building is a By-Product’ talked about the fixation of winning prizes like Considerate Constructors but what I wonder now is whether cashflow really is more important than product or profit even. This project almost certainly won’t be profitable, it won’t be on time (massive LADs) and has been beset by design and management issues from the outset and yet nobody seems to be getting angry about it, especially the levels above contracts manager who you would expect to be getting nervous. The only solution that I can guess at is that there is some clever back room processes that can get ‘Sad Ken’ across the line ahead of the field in the 1530 at Chepstow and turn a profit by some miracle. People that are clever with contracts any views?

One thing that has kept me interested recently is being given pretty much the entire responsibility for bringing ALL the utilities onto site in the same week on the same road. A planning condition is for a single road closure for service installation (in reality we pushed our luck with the transfer beam and got away with it) and so starting next week in a stretch of road about 80m long I will overseeing the circus that will see geothermal heating, gas, mains water, HV electricity, BT and the foul water system all connected in 5 days. In sorting some of this stuff out I’ve had an interesting blast from the past, it started off a little like this:

PM ‘You need to either speak to Keith Olbury or Frank Dickinson at Lanes for Drains’

Rich’s internal monologue ‘No it can’t be even with that name’

Later on the phone man with distinctive squeaky Yorkshire accent ‘Hi is that Rich’

We talk business and then I say : ‘You’re not a former Royal Engineer are you?

‘Yeah I was’

‘A plant operator?’

‘Yeah, why?’

‘I thought it might be you’

‘Where do you know me from then?’

‘I was your Troop Commander in Tidworth’

‘Really?’

I guess I made a real impression then.

Yes Frank Dickinson was a particularly poor LCpl in my Troop that I was now relying on for a service in the real world, both of us with ‘manager’ in our titles, oh dear.

Embracing Egan

If you can cast your minds back to your original degree courses (PET students amongst us) they probably mentioned something about the Latham and Egan reports. Greg mentioned them during his lectures during Phase 1 from a mainly contractual perspective. But what other areas of this business we are playing at did they touch? If I find myself with enough time I may expand on this blog and look at other areas in the future but here I will focus on the part of the Egan report that talks of standardisation and pre-assembly, if this morphs into an AER or TMR perhaps I may spend time on the stuff that went before but here I’ll look at a few bits on my site that seem to have embraced the message.

My project is a relatively simple group of 3 RC buildings for student accommodation, given our high levels of liquidated damages and the tight timeline speed of construction is more important than quality. If I was building a high end hotel or apartment block I might be looking out the window at a very different scene but here is a snapshot of the stuff that is streaming construction out here:

Structural Insulated Panels (SIPs) – These are being provided by another trading arm of the Osborne Group, Innovare. The function that they are fulfilling here aren’t their primary purpose and the project manager that visits talks of their strength in house building, they have been approved for construction up to 5 stories (which no other structural framework) but in theory will go up to 8 stories. On site they are being used as an infill panel that will form the internal skin of the building. The construction can be seen in the photo below; a high density polystyrene laminated to a timber external skin, plywood on the long edge and timber on short edges. Acting as a composite it is remarkably strong although this strength isn’t utilised in this construction. The SIPs panels are the first things that get installed after the falsework has been struck. They are all pre-designed and manufactured and arrive in loads corresponding to whole floors (each individual panel has a specific home on a floor and is usually identical to the panel directly above and below is) they are then lifted directly from the wagon to the floor where they will be used. Installation required ‘carpenters’ to attach a timber baton to the floor slab to locate the SIPs and then a bracket to secure them to the soffit of the slab above.

Section of a SIPs panel

SIPs panels used as infils (the things wrapped in grey plastic)

Windows – Less ground breaking but each window is designed to go directly into the space left in the SIPs panel, the glazing is then installed and that completes the internal skin of the building.

Bathroom pods – Because each room is en-suite you can imagine the amount of time fitting 1104 showers and toilets would take. Each of the rooms will be equipped with a pre-manufactured bathroom pods, it is made of fibreglass and inside is a fully fitted an functional system, all that is required is for it to be lifted onto the correct floor and then positioned next to the riser, the pod is then wired up, plumbed in and fitted with the duct for the extractor fan and it is ready to go, finally they are surrounded by the dry liners to build them into the room.

Twin Wall – I expected to see the usual pre-cast stuff on site (stairs, drain rings etc) but had not heard of this before, whilst it doesn’t necessarily make the job go faster it certainly helps. The main thing this achieves is a saving of hook time on the tower cranes. If you imagine constructing the walls around a stair core using traditional methods you get something like this:

- Lift large bundles of steel to a place where the reinforcing cage can be pre-fabricated (2 lifts)

- Lift pre-fabricated cage into position on the starter bars in the slab (3 lifts)

- Lift formwork panels into position in sections on the inside of the core (perhaps 4 lifts in total)

- Lift formwork panels into position in sections to the outside of the core (another 4 lifts)

- Use crane-liftable concrete skip to place concrete (say 0.675m^3 per metre run say 10 lifts)

- Wait to go off

- Strike formwork using the reverse of the 8 lifts at steps 3 and 4 (8 lifts)

- Total crane lifts approx 31 lifts

Contrast with twinwall

- Lift twin wall sections directly to point of use (4 lifts)

- Place twin wall starters in wall sections (1 lifts of 12mm bars)

- Use crane-liftable concrete skip to deliver concrete to half depth of the twin wall (say 0.125m^3 per metre run say 3 lifts)

- Allow to go off

- Fill remainder of twin wall during slab pour

- Total crane lifts approx 8

Twinwall used to construct stair core.

Twinwall in place with decking (note skinny starter bars, internal structure and that only approximately a third of the wall will be cast in situ concrete hence the reduction in crane lifts in concrete placing)

A huge efficiency saving on crane time which means the columns can be put up at the same time as the walls and reduce the floor to floor turnaround time. The efficiency saving is such that it is obviously economical to get twinwall pre-cast in Ireland (presumably by the proportion of the population who lack the intellect to work on a building site in the UK or OZ) and ship it to Southampton although the carbon emissions are probably questionable. The other benefit is the finish, the walls are all spec’d as Plain Finish which allows for a +/- 3mm local deviation because these are big panels there are fewer joins to finish making for a smoother finish.

Off Topic – Kind of

I’m hoping some of last years gang are still half reading this though I doubt it.

I’m currently responsible for doing the site waste management plan. It involves collecting the mileage travelled by the workforce and deliveries, coupled with water and electricity consumption. All this is used in support of achieving the required BREEAM rating (but extra stuff is required for that bit too). This is a nightmare and requires me to trawl through lots of signing in sheets, delivery record sheets and waste transfer notes. I’m currently thinking about writing a proposal to Osborne Group about commissioning an App for iOs/Android that should take some of the monkey work away from me, I’ve got a quote from a developer for it and will put it to the company in the next couple of weeks.

Out of interest how is all this stuff done on the other UK sites? (hence the reason some other courses are looking at this as Mike is the only other person still here)

Demolition Man – The Plot Thickens

Those of you who care or who are bored enough to flick back through the blogs may remember that there was a requirement to demolish a significant amount of concrete wall on my Block due to the structural engineer not designing the knock out panels for the future louvres.

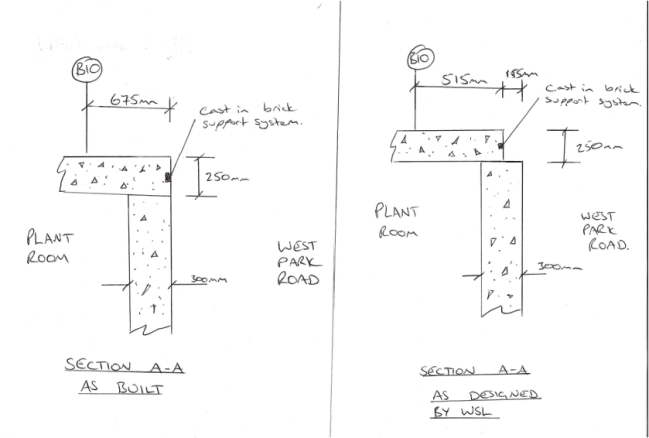

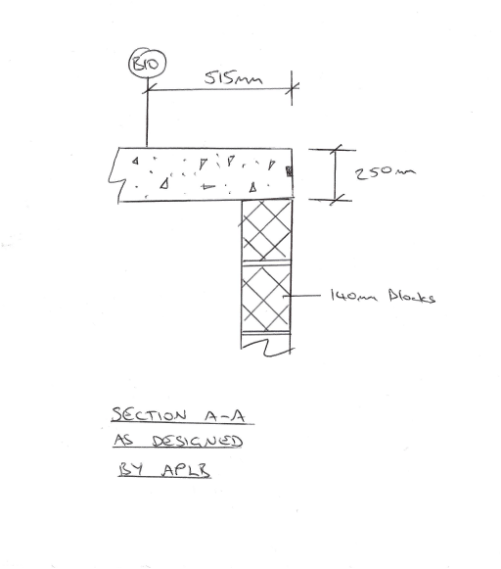

What I didn’t really mention as it was a secondary issue was that the face of that wall was built too far towards the outside of the building by about 155mm. It seems they just read the make up of that section of wall correctly, there is face brickwork here with a cavity behind and consequently just intended to steal some of Southampton on the sly. Once again assumption got the better of me, it seemed it was no secret that the retaining wall was too far forward and the slab edge too but it didn’t seem that much of an issue. When it was only this problem nobody seemed that bothered and figured that something could be done, it was only when the future louvre issue came up that demolition was talked about. My assumption was that because nobody was jumping up and down when the wall was too far forward there must be some kind of clever fix like using a brick slip to save space; so when the wall was removed as previously mentioned on the blog I assumed that they would use the same clever solution to get around the slab edge too far forward problem. How wrong I was. The sketches below show what was built, what was designed by the structural engineer and what was designed by the architect.

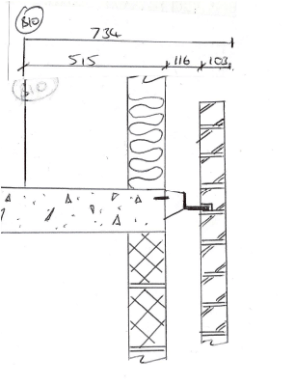

This doesn’t really describe the full story because it’s only when I looked at the slab edge detail that I realised there was no clever fix and very few clever people. Below is my reproduction of the slab edge detail comparing the as built section and this sketch shows that with an overall dimension from B10 to the face of the brickwork of 734mm and an as built slab edge of 675mm we only had 59mm to play with which in order to achieve the cavity and the any form of brick would have been impossible.

So more demolition at the cost to the structural engineer as 150mm of slab is cut back and removed across about 24m of construction. All this against a background of a Project Manager desperately trying to get follow on trades into the area see first paragraph of ‘forward planning optional’ who is slowing up the process by not allowing me to clear the area. The frame contractor has had a lucky escape here as the as built is different from the as design by WSL, the structural engineer, otherwise the slab cut would have been paid for by them but because WSL have made the first mistake it’s all going on their flick. Personally I think the as built/as per WSL would have been an interesting argument anyway was there was no section as I have drawn it instead that rather odd arrangement was supposed to have been worked out from the GA below, note the interesting combination of dotted and solid lines all trying to convey different things.

There are other slab edges out there that have been wrongly designed by the structural engineer and are about to be lopped off too, so it’s not a one off mistake. In another update I’ll try to look at the remediation that follows all this cutting, ends of bars are now exposed to the elements and need fire/water proofing and all the U Bars have been cut off too. I just need to work out what U Bars actually do and why it’s so important they’re replaced.