Archive

Forward Planning Optional

I find myself surrounded by buffoons, I can’t think of any other way to describe these people, specifically people that call themselves senior project managers. So far as I can see that ‘project management’ in Osborne consists of getting as much stuff and many trades on site in one go into the same bit of real estate and then try to fix the f*** up after it has happened instead of thinking about sequencing. I can’t write anymore on this subject because I’m still very angry about it.

And for my next trick I shall make this wall disappear

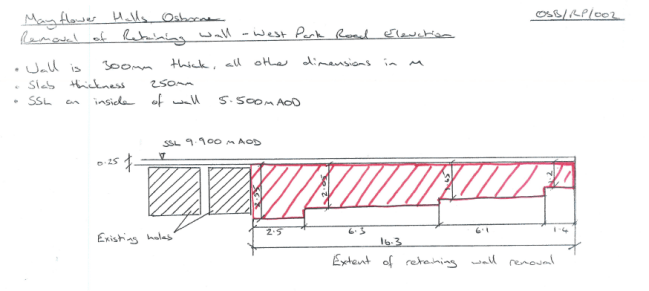

I have been given the responsibility for the demolition of a retaining wall in my block, including gathering the quotes, ensuring the structural engineer is agrees with the method statement, coord of the other stuff in support and ultimately supervision. The sketch shows how much wall needs to come out, approximately 31 m^2 of 300mm thick wall, this will then be replaced by block walls which will probably never be removed.

The saga begins like this…The client specified that the project will use the Southampton City district heating scheme, however if the scheme became too expensive in the future the project should be capable of converting to local boilers in the plant room on my block. If future boilers were installed more louvres would be required, the client would be willing to remove block walls but not RC walls. The last point was completely missed by the structural engineer who designed it in RC anyway, so now it has to come down to be replaced by blockwork. I have called it a retaining wall which is probably slightly misleading as the part hatched in red isn’t actually retaining anymore than about 200mm of ground. The quote from the concrete cutting has come in at £9000, there are of course other costs involved, Osborne staff time, provision of access, power etc etc which I haven’t worked out how all that gets billed yet, I need to go and talk to the boring blokes upstairs (one of which believes that having done some ‘outward bound courses’ and reading Andy McNabb entitles him to pull up and sandbag and spin some dits, buffoons!). When placed against the structural engineers overall fee of £900K means that 1% of their fee will go on fixing a simple mistake.

Is the grass greener?

In other news the new bricklayer project manager spent 5 years in the Foreign Legion and has a healthy collection of crap tats. Another overly tattooed individual that doesn’t work on my block revealed himself to have spent 3 years in the QRH, every troop and platoon commander in the Army needs a photo of this bloke:

Sapper “Boss, I want to sign off”

Troopy “Why?”

Sapper “‘Coz it’s shit innit”

Troopy “OK, have you considered the following things that the Army offers that you won’t get in civi street? Pension, paying for work clothes, paying for gym membership, paying for dental treatment?”

Sapper “Yeah, still want to sign off”

Troopy “What are you intending to do for work?”

Sapper “Well my mate’s Dad’s Brother’s Cousin has got a job earning sixty grand driving lorries and says he can get me a job”

Troopy “Have you actually listened to yourself? Do you realise what you’ll actually end up like is this [brings out photo of fat, useless, former QRH bloke with ink up to his jaw bone in his ripped tracksuit bottoms, sweating himself senseless sweeping up a dusty concrete slab in the midday sun] There’s no G10 to mince around in out there you know, turning up for work hung over isn’t considered good fun”

Retention sorted.

I’m sorry I couldn’t bring myself to rant about what I actually sat down to do so but hopefully this will have made you smile.

For Richard, the surface of the moon can be recreated by pouring concrete in the rain

And now for something…. vaguely useful?

For those of you that are reading this in the back of the classroom room whilst pretending to listen to a lecturer you won’t have had the joy of concrete yet. For those of you that are out in the real world but aren’t playing with concrete in the same way that I am I thought it would be useful to see a few things that might make design in the future a little easier. These are the concrete accessories that have appeared on site that didn’t fall into the category of either steel bar or concrete.

Shear Rails

Funnily enough I didn’t have to ask what these did, however I have to admit that I don’t fully understand how you would design for them. These rails are placed in the slab with the ‘mushroom’ end down and the flat bar uppermost. They are placed in a radial pattern around the base of some columns, I can only assume that it is to deal with punching shear in the flat slab (if John Moran answers this first I’ll be berated about my lack of an engineering model and if Richard Farmer gets this first he’ll enjoy dispensing his knowledge). The rails appear to be shorter now we’re starting to get into the post-tensioned slab.

‘Conny/connor bar’ or Anchor Strip depending on who you talk to

This off the shelf product is used in to provide starters without the need to make timber formwork. The steel loops that you can see are tied into the reinforcement cage with the green side flat against the shutter, the wall is cast and when the formwork is struck the green plastic is peeled away to reveal starter bars that can be pulled into position, these are perfect for casting the landings for stair cases. Be careful if you get asked whether you can use these instead of the scheduled starter bars, they ask to make life easier for them but don’t appreciate that slab starters are designed to be 32mm bars for a reason and can’t see why they can’t use the conny bar with 16mm starters.

Baseball Bat

This socket gets cast into the top of columns and serves 2 purposes. Firstly it is used for placing a fall arrest system inside, the red post sits firmly in place and then has an arrester wheel dangled from the end, this allows safe working at height for individual building the decking for the slabs. The second use allows the yellow post to be placed in the socket and provides a firm base to attach an instrument to for setting out, setting out from a tripod on the decking isn’t used because there is too much movement and vibration.

Dream Beam

The final installation of the transfer beam was absolutely perfectly. The use of the steel angle to set out the bolts was the right choice and the beam sits within 3mm of where it was designed to be. Below is the article I have written for the Company update, Osmosis, much like Blackadder’s ‘King and Country’ and our very own Soldier it’s pretty much propaganda but they seem to like it.

Steel plates and 40mm bars that were tied into the columns, note steel angle fixing the 30mm diameter bolts in place.

100 tonne mobile crane lifting one of the beam sections into place.

Dream Beam

An out of hours road closure and crane lift on Monday, 1st July saw a critical element of the Mayflower Halls project completed smoothly and in half the time allowed.

A large transfer beam was required on Block B, the tallest of the blocks on the project at 17 stories, due to a change in the column lines on Level 02, with so many floors above the beam the actions involved necessitated an enormous beam. Originally a specially made plate girder was designed, however in order to reduce procurement time a standard Universal Column section was used with additional plates welded to key areas. The main beam was delivered in 3 sections that when spliced together totalled over 23 metres long and weighed in excess of 15 tonnes.

In preparation for the beam eight steel plates with four bolts welded on were tied into RC columns using a steel angle as a template, once the columns were cast the steel angle was removed ready for the installation of the main beam. Rigorous setting out and checking by Senior Site Engineer Phil Dowling ensured the holding down bolts had been positioned with the precision needed.

Careful planning and liaison with Southampton City Council secured a partial road closure on one of the City’s busiest bus routes for four hours on both Monday and Tuesday evening. A 100 tonne mobile crane was used to place the sections of beam on the columns. The beam located perfectly over the holding down bolts and was in place within a single evening avoiding the second road closure and extra crane time. Site Manager John Wild said, “It was great to see so many different people working together to ensure success.”

Something that won’t be appearing in the next newsletter is the 4.5m high 7m long, 300mm thick retaining wall that sits directly below the transfer beam that will be removed in the near future due to a design error putting it 75mm too far in the footway and forgetting to include the louvres that were required.

Witnessed: Civilian Equivalent of Cowardice!

Wait all this time then 2 posts come along at the same time.

We are going to be installing a large transfer beam at the beginning of next week, this thing is going to be a 20 tonne beast, with next to no tolerance for line and level. In order to try and give us the best chance of success we are using lengths of steel angle to act as a template for the holding down bolts (don’t ask me why, this was a decision that was reached between the fabricator and the consultant) the steel erecting team from the fabricators arrived on site today. The project manager decided that his total involvement consisted of introducing the foreman to the steel erectors and then quietly slipping away so that once the general name exchanging and such had finished everyone just turned around and looked at me. The setting out engineer had no idea what was going on and so apparently I became the one in charge, not a single person more senior that me visited that part of site for the rest of the day, after the fabricators had left. However in my one trip back to the office to get some lunch I was asked an irrelevant question about brickwork, where do these people come from?

It’s Been A Long Time

TMR 1, some leave, Lizzie not well, the CI’s visit and healthy dose of laziness have all conspired to prevent me from completing a blog for sometime.

Update Artesian Water – The 2 dodgy men that turned up with big drills and a few bags of cement did manage to stem the flow of the water. It took a while and wet feet (not mine) but eventually a chemical grout managed to stop the water. I have to admit I was skeptical right up to the point where the water stopped, it seemed like a very amateurish outfit but it made me laugh to see a Celtic supporting Glaswegian and Rangers supporting N Irishman step out of the same van. The death of water problems combined with a couple of other long awaited solutions have finally opened up the last part of Block B for construction and by the middle of next week I expect to have a water tight plant room.

The project continues to be plagued with design issues a constant stream of RFIs come in from the concrete contractor, I’m trying my best to get ahead and stay there of the construction process but with more trades on site now I can’t dedicate all my time to structural stuff. The M&E types are slowly dribbling on to site and dangling a few things from the soffit in my plant room.

I have been conducting all the inductions on site at the moment and because of that handle a lot of CSCS cards and one didn’t look quite right this morning, apparently the line in fake cards didn’t extend to a fake phone number on the back and eventually it was confirmed that it was a fake card. Free breakfast care of the contracts manager for Rich!

Break Radio Silence

It’s been a while, mainly because I’ve been furiously tippy tapping away on TMR 1 and Friday (blog day) is usually the day small people decide that cool kids don’t sleep.

Now, I’m conscious of the fact that groundwater problems have been a consistent theme of this blog for sometime now and you’re probably bored of it by now…oh well nevermind. The saga continues and this week we have had some grout injection contractors in to attempt to seal the holes. They’ve only managed to drill and grout 1 hole today, and the water still runs, so look out for the next update. On the plus side this comedy of errors made a decent TMR subject.

We’ve got a first floor slab poured on my block now but because of all the delays it looks like the building has had a massive bite taken out of it. All the old hands have repeatedly said that it will start going fast once we’re out of the ground, we’re not fully out of the ground yet but it’s still moving quite fast, mostly because we have a really good foreman and gang on my block. My new challenge is getting motivated over finishes and brickwork, it’s becoming clear that the people around me think like builders rather than engineers.

This week I have been mostly….procrastinating

This has been a glorious week to be on site here in Southampton, only I haven’t found myself on site much this week. I can’t really put my finger on exactly why that’s the case but it seems to be mainly because I’ve been doing paperwork.

After inheriting the Site Waste Management Plan from the other assistant site manager who left the company a little while ago I was told it was all fine, after who knows how many HOTOs you would have thought if anyone said that it should ring alarm bells in my head, clearly I haven’t learned my lesson. So digging into the SWMP allowed me to discover that all was not well and being that it’s a legal requirement it probably shouldn’t be the work of fiction that it was. That took up Monday.

I had yet more students on site this week as the ones that I spoke to last week had obviously said there was some old bloke who still thinks he’s down with the kids that is willing to give out answers freely.

The most interesting day this week was Thursday. The problem of artesian water continues to be an issue, a meeting was called with the client, the geotechnical consultant and the site team to discuss what has happened in the past and where we might go next. With the best estimate of the borehole location (the log only recorded it to 100mm accuracy) plotted on the ground 4 very well paid men and me stood around looking into a hole next to a pile cap with some dirty water in it. We spent 3 hours discussing what could be done on site and in the meeting room and all the while the geotechnical expert was remarkably quiet on what could be done. Not much of plan came out of the session other than to find out what would be the opinion of the EA in a round about way if we did nothing. The tip that the Great Orator mentioned on one update about the water problems about the UK spec lead me to do a bit of a search on IHS and allowed me to reveal a few choice lines that would indicate to me that the Geo Consultancy haven’t done what they should have done and didn’t inform Osborne of the potential problems. I didn’t wheel this out during the meeting but mentioned it one of the client’s representatives (who is also part of the Osborne Group) afterward who seemed very excited about what I was telling him. This morning (Friday) during a conversation with the same guy I mentioned where I will be doing my consultancy placement and he asked me to initiate contact with them explaining the problems and exploring the possibility of them coming to advise on the situation, they have accepted. In 2 days I’ve managed to make both my current and future employers happy. This is all TMR gold dust so I’m also happy.

Whilst the cat is away, the mice fight and knock off early

The senior project manager has been away this week so the atmosphere has been much more relaxed, fewer signs have been printed and more decisions made.

A significant portion of the car park slab in my block was poured last Friday. We take it in turns to stay late and lock up the site and the more experienced members of the team saw me off, the slab was brush finished which apparently requires the concrete to be just right and means that the new boy gets to stay on site until 1930!

Politics have been interesting this week, relations with the sub-contractor are somewhat strained and the delays in the build are growing and it has all become a bit odd. I’m trying to avoid getting involved if I’m perfectly honest, I’m quite interested in seeing how civilians resolve conflict. The activity that has brought this to a head has been the standard of the gas membrane that is being placed under each of the blocks. An extensive ground investigation and gas monitoring survey found that they is no gas on site, the building inspectors decided that the inclusion of a gas membrane is the minimum they expect and rather than spend the time and money in trying to convince them that there is no need Osborne decided that it was easier to just get on with it rather than fight public sector bureaucracy (I’m sure we all agree it was probably the right decision). Now this means that we have to fit the membrane correctly as it is inspected before each slab pour, unfortunately the sub-contractor is trying to pay it the least amount of attention possible. The slab pour that went ahead last week had membrane workmanship that was pretty poor, the inspector came to look at it and only just passed it; because of this we have been rigid on standards this time around and this has caused arguments between the one of the site managers (who does need lessons in diplomacy from time to time) and the sub-contractor’s foreman.

This week I’ve been acting as student liaison, on Tue I had a graphic design student to take around site to take photos (including yours truly) for a project on construction, the process of getting all of these photos approved by the companies who have an interest has been slightly painful as the on site computers can’t deal with the size of the photos and I’ve had to bring them all home to resize and send on. On Wed I had about 12 students from the University to come and ask questions for their Construction Management assignment, their question set was identical to the one that I completed 11 years ago for the same lecturer and slightly more recently for you Mike. A lot of the questions looked similar to AER 1 and so I provided them with a copy of that (but didn’t tell them that I’d also sent it to the lecturer to stop them copying) and a few other bits and pieces. All of this is so we can grab a few more points for considerate constructors.

Wanted: Dutch boy for permanent position under a ground floor slab

This week has seen a number of changes, specifically with the sub-contractor, a number of new black hats have been handed out (the mark of a supervisor on our site), civilians don’t seem to get the phrase ‘You’ve changed!’

Artesian water continues to flow, sometimes I feel like we’re de-watering Southampton, without the help of a pump. The visit from our geotechnical expert was pretty unsuccessful, in truth he was an environmental expert that was going back to report on what he had seen to his geotechnical experts. The geotechnical experts have said ‘You’re F*$!ed’ clearly I’m paraphrasing, the best solution that has been suggested is to try and over bore, or encapsulate the former borehole location with a hollow casing allowing it to find a level and then backfilling with a tremie pipe using a grout, they are fairly non-committal on the possible success rates of such an undertaking and there will be a significant cost associated with getting something done and getting a specialist to deal with it. This would be all very well and good to try except for a couple of problems:

1. We don’t really have time to experiment, this is now holding up the build, I find this situation pretty frustrating because everyone seems to have ignored it for quite sometime now.

2. The attempt to cap the water with the concrete plug means that to execute this plan would require breaking out of about 6 m^3 of C50 concrete, so we’re going to get hammered for dayworks.

This leaves us with the french drain option, drawing the water off to a point where it can be collected and enter the drain system, the Environment Agency don’t seem too worried about the situation but winning over Southern Water might be a harder sell. A conversation with the Great Orator has helped, but in reality nobody can be sure of what may happen. I’ve done a bit of research and the waterproof joints that have been put in use a product that’s certified for 80m, we’re only talking 3m on my site and therefore it should shrug it off as long as the workmanship is up to scratch.

Such a seemingly simple problem has become quite a big issue, it is made so much worse considering the option to cap the piezo on the first place was offered up for a mere £600 per borehole, I would say we’ve easily spent that in fuel to run the pump. I think next week will see an attempt at the french drain option attempted, perhaps we’ll pull it off.

A Slow Week

No blog last week as I was on leave with nothing significant to report other than an interview for my design placement at Ramboll UK.

It was been a slow week for personal involvement, and therefore a short blog.

With the first slab poured on my block just before I went on Easter leave the transformation in the time I was away was significant, starter bars had become walls, starter bars for columns were still awaiting design details which made things a little awkward, the M&E fairies were still trying to magic holes in walls by the power of though alone. Most of Tue and Wed were spent setting up a significant retaining wall that when poured will mean that we can backfill and progress at a much faster rate; as much of the areas awaiting groundworks are at a higher level posing a problem for formworking and working at height. One thing that has become very clear is, the instant a slab is hard enough to walk on every man on site want a little bit of space on it, either the carpenters, the steel fixers or just for storage. It is impossible to keep a slab clear and no matter what you put in place to try and control the space it won’t control the people, short of being there constantly there is no way to stop it from degrading into a mass of men and materiel.

The most interesting thing that happened this week was to go on a day long crane rescue course. The background to this is about the requirement in both Working at Height Regulations and LOLER to have a rescue plan and competent people to conduct the rescue. The emergency service can’t be relied upon to recover people from tower cranes as in general a standard firefighter lacks the techniques and equipment to do so and the urban search and rescue teams aren’t a continually formed unit and therefore are slow to respond. So it falls down to 3 people who have done a 1 day course to drag a large man from a small cab up a tall tower. The system is quite easy to use and doesn’t require any knowledge of knots or rope systems. Our site has been operating without an evacuation plan for the cranes, one for working at height in general is in place and now it will probably fall to me to write the rescue plan. The one question it has raised in my mind is how we plan for the use of the dems harness or ISHK on exercise, never have I been briefed on a resuce plan for someone that falls from a dems bridge and dangles from a lanyard and as an exercise conducting officer I’ve never used it although I would not have planned for that eventuality, thoughts from the floor?

Our artesian water problems continue and have been exacerbated by attempts to stem the flow whilst I was on leave. The rather unscientific solution of dig down further and chuck a load of concrete on it has failed and now the flow of water has increased. Today will see a visit from RSK (the environmental and ground consultants) who will see what could be done, I don’t believe there is one personally, the nature of the ground gives multiple routes to the surface for the water through the fissured clay that sits below my block. A chance conversation with someone who was involved in the foundations of the BBC Radio Solent building next door has revealed that they had the same problem, an uncapped borehole that continued to flow under artesian conditions, and in the end they resorted to what was in effect a French drain under the slab to the nearest point where the water could be disposed of.

Rich