Archive

Peaks and Troughs

This week has been particularly variable in the level of activity. The project has very definitely been split into 3 separate blocks now with 3 distinct teams, I have found myself on Block B which is the largest at 17 storeys. Being the highest pretty much puts my block on the critical path, and rather critically we are running about 4 – 5 weeks behind depending on who you talk to, the high level of liquidated damages on this job £500 000 per week brings the delay into sharp focus, the week commenced with my project manager under considerable pressure, I think I was one of the few people who started this week with a guarantee of employment by Friday.

- Last Friday the sub-contractor stated that the first slab pour on my block would happen on Wed 20 Mar 13, even my inexperienced eyes knew this to be a complete work of fiction from the outset, hitting that timeline required the laying of all the drainage on the basement level, pouring of a further 4 pile caps, installation (once receipt of the finalised design and materials) of a pump chamber that will raised the foul water into the main sewer on the road outside, the steel fixing of the slab (thank God for the industrious Eastern Europeans, although not when I’m the one locking up as they always leave last) and the fixing of the internal walls and slab step up. Funnily enough the slab pour didn’t happen until today (Fri 22 Mar 13). The problems encountered along the way have been interesting, some of which I’m kicking myself as I feel I should have seen them coming.

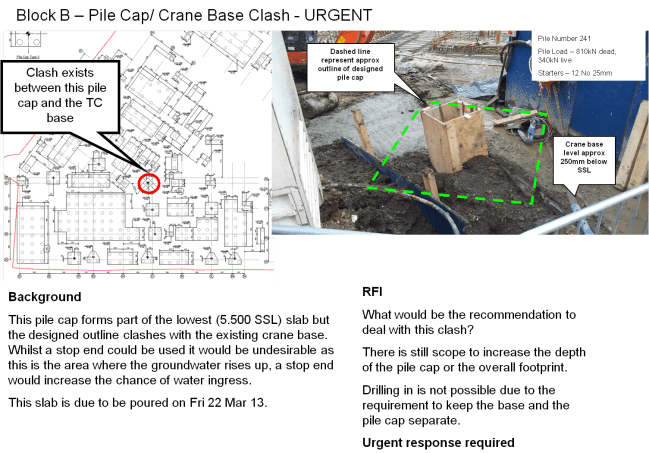

- Crane Base and Pile Cap. The crane base for my block sits just below the finished slab level of the basement, inside the basement itself but outside of the final structural walls. Somewhere along the line, either in design or tolerances during construction the base was constructed very close to one of the structural piles and overlapped quite severely with the pile cap as designed. Due to the artesian water conditions on the site we wish to minimise the number of joints in the concrete and therefore wished to include the pile cap in question. I was brought to my attention by the sub-contractor’s foreman. The design engineers have been somewhat overwhelmed with RFIs on this job and as such a response is not guaranteed in a timely fashion, I decided on a new approach. The world of construction doesn’t seem to have seen a quad slide before, it works. The response was received in good time to implement the solution although in the end time simply got the better of the pour and that particular slab pour didn’t include that pile cap.

- Mistaken Pile Cut Off. Those of you that know me know that diplomacy isn’t a strength of mine and it took all my effort to remain as neutral as possible during this incident. In the rush to get the slab poured on my block, the sub-contractors normal MO of banging in RFIs constantly about the most minor of items fell by the wayside, they assumed that a pile cap drawing was wrong, not just a bit wrong but wrong by 3 metres. They believed that a pile cap with a top of concrete level of 8.000m was wrongly detailed and so have read 5.500m and commenced pile trimming, right up to the point where there was no reinforcement left in the pile and so on the final pile crunch they lifted a 1.5m lump of concrete out of the ground. The problems that this has brought to light are:

- What to do with the broken pile? How to tie any remedial work to the pile as there is no steel left in it.

- Who pays for the solution to be implemented? A couple of issues here as it seems the steel should still be present in the pile at the break off level which raise QA concerns about the piling contractor, we are now looking at the possibility of having to try to use a cover-meter on piles that are exposed to check the length of reinforcing.

- Pour Day Panic. This is the one that I absolutely know I should have picked up sooner, I had been doing the checks to ensure the drainage was in place under the slab, but I had been guilty of assuming the sub-contractors knew what they were doing and of not thinking it all through. With the concrete deliveries 45mins off I realised that the drainage that was in wasn’t as it had been previously the soil and vent pipes for the foul system and therefore a pipe that continues up throughout the floors but in fact an open top gully that needed to sit flush with the top of slab. Thinking I must be wrong I asked the question about the absence of the gully pots and saw a foreman’s face drop. So disc cutters out, panic ensures and ground workers installing gullies as the concrete is poured no more than 5 or 6 metres away. Rich earns himself a breakfast.

A Building Is A By-Product

|

“The easiest and quickest path into the esteem of traditional military authorities is by the appeal to the eye, rather than to the mind. The `polish and pipeclay’ school is not yet extinct, and it is easier for the mediocre intelligence to become an authority on buttons, than on tactics”. |

|

| Captain Sir Basil Liddel Hart Thoughts on War 1944 | |

After a number of visits to our site this week I’m starting to feel that this quote applies equally to construction, it is far easier to attempt to win a Considerate Constructors award to make your bosses happy than it is to understand what exactly is going on on your site. I’ve said it to a couple of you over the phone, but for the wider audience; I am beginning to truly understand why construction isn’t really profitable.

We poured our first slab and put up the final tower crane this week, which has really changed the face of the site, the first of the core walls has been poured also. The remainder has been much the same as the previous few weeks, pile cap after pile cap, I estimate that we have poured about 25 pile caps so far, approximately 30% of the total.

The main core pile cap on the highest (17 storey) block was due to be poured on Friday however this was postponed due to in complete detailing by the structure designers. What I haven’t managed to find out yet is why we got to 18 hours from pouring before the issue became obvious to the site team of the main contractor. In short the groundwork and RC sub-contractor had done the take off for the core, found that some walls hadn’t been detailed and raised an RFI, this was transmitted via a complicated info management system that doesn’t seem to keep the site staff informed. An incomplete answer was received from the consultants, at this point I believe a notebook, a to-do list and a willingness to be engaged in actual engineering would have been useful. In short the sub-contractor was unwilling (and rightly so) to proceed with incomplete details and when we (I) managed to get the structural engineer who happened to be visiting that day to commit his answer to paper with a signature it was too late and the steel required wasn’t on site. My knee jerk reaction to this is that communication is the key problem I’m witnessing currently, there are plenty of meetings that go on but getting the information out of those meetings if you weren’t there originally is very difficult.

AER 1 is coming along and I think I have an option for TMR 1 but thoughts on a thesis are non-existent.

New Boy on the Blog

Pretending to be a real person is pretty easy, bluffing your case on a building site isn’t that hard (it helps if you’ve done it before) understanding an Irish Foreman who is as unintelligible as a Ghurka on a radio isn’t quite so easy.

I have been installed as an Assist Site Manager on the Mayflower Halls Site for Osborne in Southampton. As facebook followers will know I have discovered that this title is a little over-inflated; as such on a site that currently only has about 33 people on it there are 2 Assistant Managers (including me), a Site Manager, a Senior Site Manager, a Senior Project Manager, a Design Manager and a Construction Manager. So as an Assist Site Manager I started with less power than 2Lt ETS Officer. However, armed with nothing more sophisticated than a notebook, pencil and a 7 month crash course into how to pretend you know what you’re talking about I have already managed to avoid the other Assistant site Manager shedding the plant ticket checking folder onto my to do list and stopped a pile cap pour that was missing not only the drainage runs but the ground beams that tied into it. Being a real person isn’t that hard.

Things I have learned so far:

· Shaving is optional, even for quite senior managers.

· Civvies measure work in time not output.

· Bullshit still baffles brains. Signs, signs and more signs!

· Reinforcement drawings are nowhere near as simple as the ones they showed you in the lessons.

· Civvies find your use of ‘Roger’ quaint, look at you blankly when you say ‘Diffy’ and call you on the radio more than is really necessary because they like to laugh at your voice procedure.

· Contractors will wilfully do something that is wrong just so that they can be doing something.

· A ground worker who has done his SMSTS course suddenly becomes and expert on everything and the civilian equivalent of a barrack room lawyer.

Joking aside, there are a good many things that I just don’t ‘get’ yet, there has been a number of times I have found myself actually knowing more about stuff than those around me and fearing that I had a bit too much of the classroom about me. Osborne have so far been brilliant and very welcoming.