Archive

Mr. Blue Sky

It is official, summer has arrived in Scotland. You can tell because the fog is slightly less wet, the rain falls at 45 degrees to the vertical (rather than 80) and it is no longer dark all of them time. It also means that my cycle commute can take some of the more scenic routes…

The last few months have been quite intense, hence the lack of blog posts, but finally Edith has arrived, thesis is submitted and I can actually get back to some kind of a semblance of life.

It turns out that the normal returning to work chills were unwarranted (as usual) and things have progressed well in my absense. Not in the least with thanks to one of my BP colleagues who babysat my portfolio over the four weeks. I no have a confirmed date for the final Minox commissioning, my HP cooler funding has come through and my Caissons DSP have been endorsed by the business.

Minox

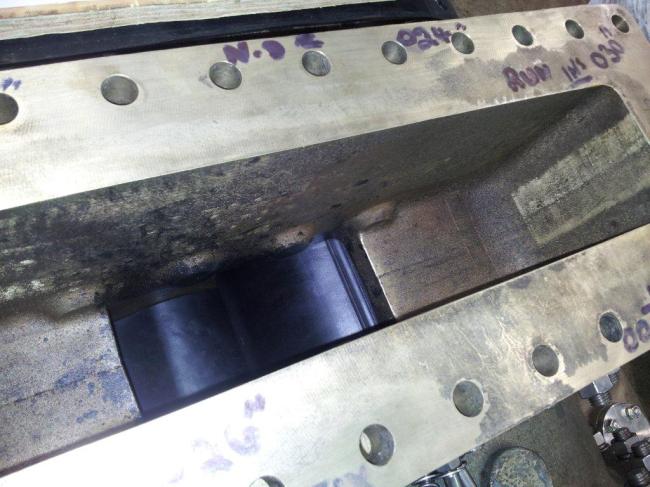

Just before I went on leave, this project stalled right at the end of offshore execute due to a missing suction strainer. This stainless steel witches hat strainer sits pointing into the flow to catch debris left in the pipes during construction. The tolerances on the B blower that we have installed are <1mm and commissioning without it would have been high risk.

The piece was found to be missing during the pre-commissioning line walks, it had been missed at every stage of the project, including my review of the project as I took it on. Added to that all we have to go on are the mark ups on the P&ID and Isos, not design data actually exists for the kit. This has resulted in a project change to the tune of £75. £32k for the re-mob of the commissioning team, £43k for the design of the new strainer and about £200 for the strainer fabrication itself…

An example of a typical witches hat strainer

The amount of detail the team had to go on.

The were a few small issues to quell on my return to work, but I now have confirmed dates to complete this project and it will be one of the last things that I do before I leave here.

HP Cooler

My funding bid for this project has now come in and my final budget has been increased from £6.2m to £8.5m. Of that £2.3m I have alread spent around £400k and the rest will be for Nick to spend as he takes this project through to the offshore execute in the 2015 TAR. It is shaping up to be a corker with a 5m sq cantilever lay down area needing constructing off the East side of the platform,

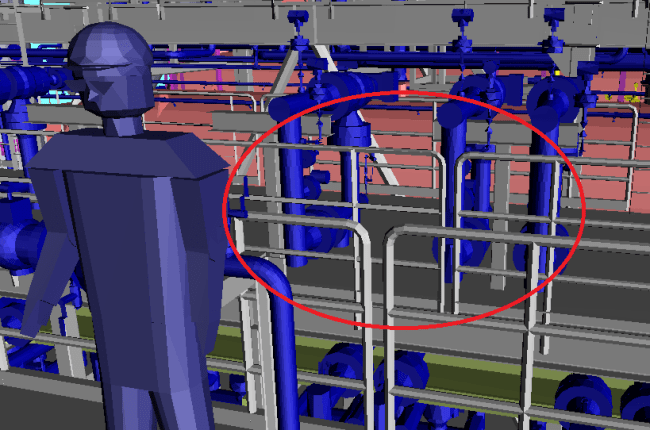

In the picture, the blue element is the new laydown that need constructing, the green is the new cooler and the yellow is the flare boom. Incidentally the silver tubes are the coolers that I helped put in last year. The project itself is nearing the end of the Define phase, but I am finding progress of the structural design team disappointing. Due to a lack of resource in this structural is way behind, process, piping and electrical, which has resulted in some friction. Not in the least that structural identified that the final cooler position needed moving around 500mm; the new cooler is more than double the dry weight of the old and needs to be positioned closer to the main module spars. This has had repercussions on the design work carried out by piping and process which has needed to be modified. I was looking forward to challenging any PCN for this work, but WGPSN has captured it within project growth. At the moment the Define is costing around £100k over the original estimate and I can account for this as due to the fact that the project did not go through Appraise and Select. However, this should put the project in a much better position for Execute.

Caissons

My work on the indefinite postponement of the Bruce caisson programme has come to fruition and my DSP has been endorsed at all levels. This represents around a £20m saving for the business over the next 5 years and potentially more if the risks that I identified are not realised. I still have some work to do in mothballing the C13 project and in reality this will be concluded by one of my BP colleagues on the Bruce team.

In other news

The kids are getting on well, with Hugo just starting to come to terms with the fact that he is no longer the centre of everyones attention. Sleep is still broken and no sign of that letting up in the near future. It is a very good feeling being on this side of the thesis, and for anyone thinking about it completing a thesis and having a sprog at the same time is not advisable.

My last batch of Aberdeen beer is in the fermenter as we speak. It has been going for almost two weeks and has another two weeks to go before it gets bottled. It should be nicely conditioned by 14 July. This is my first attempt at replicating the brew that I made in December and a good test of whether my theory that close control of the fermentation environment will provide consistency in the final product. Unfortunately I have not gotten the fridge rigged up to be controlled by my Raspberry Pi as the SSR arrived to late, but I have programmed a control programme that allows for a low temperature period of fermentation followed by a ramp up in the last 2 weeks. The next iteration of the programme will require some PID control to de-conflict the fridge with the heater and to increase the overall efficiency.

I feel like I have reached the limit of procedural programming and have started to read up on Object Oriented Programming (OOP). This is a more modular approach that will improve my ability to develop the software. It will also allow me to start developing GUI and move towards web and mobile apps. The goal for this would be realtime indication of fermentation temperatures and control of the heater/chiller via a mobile device. It probably seems like over kill for brewing beer (not to me), but then imagine applying the same technology to your house.

Its the root of all evil in my book.

It seems like the last few weeks have been dominated by finance. Despite the fact that the Minox B Blower is now in offshore execute, my attention has been largely drawn into money matters surrounding my other projects. Minox is going well incidentally and, despite the work site being almost 300 miles away, I feel like I know what is going on…touch wood.

My money matters all seem to have come to a head at the same time, which is handy in a way, but is also a pain in the bum to a degree. My largest scope of work is a DSP that I have been writing over the last few months that argues for the reduction of a £25m engineering programme down to the size of a £5m engineering project. I have traction with all of the stakeholders and am on the verge of releasing the DSP into the wild, after that I will run a gate meeting with the stakeholders to confirm their buy in and then get them to sign on the dotted line. This has been a fairly epic piece of work that I picked up in the summer last year, pretty much the first job I worked on, so it will be great to see it come to fruition. The DSP is around 5000 words all told and with appendices is about 120 pages…not that word counts are important or anything “ahem”.

The biggest issue I have had is the continuation of the Clair Coolers project which, for one reason or another (maybe another time for this explanation), has blown through the agreed budget of £6.7m but only completed three quarters of the original scope. I hasten to add that I am not responsible for any of this overspend, but I am responsible for securing the £1.8m required to get the project back on track. Work continues, but we are on dicy ground until my new funding comes in. I am now at the stage where my Financial Memoranda has been reviewed and is pending release to the VP operations and the the big dog Trevor Garlick.

On a much smaller scale, the issue I was having last month with temperature transmitters is still ongoing. This debacle has identified that the purchase order covering the work has been closed, so I have had to work with WGPSN to deliver a new estimate for the remaining work in the project and get a new purchase order set up. These are just delays which take me closer to the 12w gate without having a rock solid work scope. I am not convinced that this project will stay in the plan at this point.

Away from the financial stuff, last week I got off to Germany to visit the fabricator Hans Leffer. These guys fabricate pressure vessels and proprietary drilling and piling technology amongst other things. It was a fantastic trip, the workshop is the size of three football pitches with a huge variety of equipment for rolling, forming, welding etc a similarly large variety of materials. While I was not allowed to actually do any welding, apparantly it is really highly skilled work and 6″ thick titanium block is really expensive, I had a good nose around. Sadly due to the comercial nature of the work, I’ve only got stock photos at this stage, but it gives a good idea.

Pressure vessels at the Leffer works

Tube sheet welding on an STHX (not me!)

Some really big bits of titanium

The inside of a medium sized separator vessel

The trip built into my thesis work well as I am analysing the performance of the heat exchangers they supplied to BP last year. It also showed me how the other half live, fancy hotel and hosted the whole time by Hans Leffer himself. I am not looking forward to a return to the frugalities of JPA!

The thesis is going well at the moment, but these posts are likely to be few and far between for the forseeable future. There just isn’t enough time in the day and something has to give!

In other news:

Corine is getting really big now with only about 6 weeks to go. The race is on to complete the thesis before trouble arrives! The Scottish weather is lovely at the moment, wall to wall rain and sleet. I tell a lie, we did have one sunny day last wee and we got out of the house for a bit, but it really is quite dreech at the moment. On the plus side it is now light in the mornings again!

And some Dilbert!

It’s Getting Hot In Here…

Things have really gone up a gear in the last month and as the Minox B Blower installation date draws closer I feel more and more like the BP SPA and less like the Royal Engineer on Secondment. This can only be a good thing given the circumstances.

Minox B Blower

The Minox materials left the beach on Monday, over a week after the planned departure date due to this wonderful weather restricting shipping in the North Sea. The materials were due to arrive on the Clair today, however the weather again has me at its mercy. I have high hopes that the material will be unloaded on Friday, but it really is in the lap on the gods on that front. My first vendor mobilises early next week and while they don’t require any of the materials, 6 Feb is my redline after which things are going to start to get interesting.

The project has skirted closely around failure over the last 2 months, with the closest being the HVAC vendor feeding back on their own (2 year old) designs, 6 weeks before offshore execute, that they were not fit for purpose. The crux of the matter was that in a previous incarnation of this project, the vendor had planned to upgrade the condenser, evaporator and compressor on an HVAC system (6kW to 12kW), without upgrading the coolant lines. A suitably chastised vendor went away over Christmas and came back with an up-reved workpack for the 4th of January concluding that a two day extension to their mobilization would allow them to upgrade all of the existing lines (about 50 m worth). It doesn’t sound much here, but it was a minefield of stakeholder management at the time. In the end, the asset had no issue with swallowing the extra days and the requirement for hotworks to braze the lines. The original plan to use a weldless connection technique was deemed not ideal given the number of connections that would have to be made with the new scope.

Following that was the news that one of the nitrogen lines on the current blower had sprung a leak leaving the area out of bounds to all personnel. Again, I spent time understanding the scope of the issue and discussing it with the appropriate stakeholders and due to the leak being more of a seep, the restrictions within the area have been lifted from my team. Part of this is due to the fact that the installation of the Minox B Blower addresses one of the platforms key vulnerabilities. At present the A blower is on 100% duty with no standby to deoxygenate seawater for injection into the reservoir. Without it production falls off a cliff. With this in mind, the asset is willing to take a little risk on getting the B Blower installed, and anyway, whats a little nitrogen going to do…

So thats Minox in a nutshell.

HP Cooler

Following on from the fun and games I had last year with the Clair Coolers replacement, I am the SPA for replacing the HP cooler. This scope is in Define and I have been responsible for putting together the £1.5m of funding to get it installed. One of the key issues that I have been driving is that of defining the project drivers. The original coolers were replaced due to a vulnerability in the process used to weld the tubes into the tubesheets, essentially the fabricator had skipped a step and failed to add galvanic protection to the shell side of the tube sheet.

Given that the shell sees thousands of litres of hot sea water a day, and the designs allowed for an area of relatively undisturbed flow around the junction between some of the tubes and the tubesheet allowing carbonic acid to form, it was only ever a matter of time before corrosion ate through the HP/LP interface. This issue is a key driver for the installation of the HP cooler as the same fabricator and QA procedures were responsible for its commissioning. However the situation at the HP cooler is subtly different with the shell geometry being different, with far less undisturbed coolant flow and the tube side flow being effectively dry, so little or no risk of H2S drop out and corrosion on the tube side. While the failure of the HP cooler is fairly certain, the difficult question is what the time frame is. If it is less than 5 years, then there is a huge driver for this project to be complete in time for the 2015 Turn Around, a planned shut down of the asset. I am keeping a close handle on this issue, but there are a couple of other stakeholders who I am working closely with to ensure that this issue is brought home sooner rather than later.

The other issue that I am dealing with on this scope is the question of tube rupture. There exists a deficiency in the design of relief systems for HP/LP interfaces across the North Sea, mainly due to the lack of understanding of this issue when most of these systems were designed. I am quite lucky to be right at the forefront of this research with this project, playing a direct part in how the issue gets resolved for the HP cooler scope. A shell and tube heat exchanger typically has a hot medium under high pressure running tube side and colder lower pressure medium running shell side. Should catastrophic failure of a tube occur, computer modelling shows a transient pressure spike based on the interaction between the high and low pressure mediums that reverberates around the shell effectively magnifying the initial effect. This pressure wave then propogates away through whatever route it can find. Because this near instantaneous interaction between the two medium has never been fully understood until now, the relief mechanisms built into these systems are underspecce’d. In the case of the HP cooler, the BP discipline engineer I have been working with has had to take his analysis right to the limit of the ASME codes and the relief line still falls below unity at the elbows.

Effectively, if one of these events occurs, the pressure wave would take pretty much every part of the system, for a radius of several meters, up to the limit of its test pressure, with the exception of the relief elbows which would be taken just beyond. This potentially gives me a specification for the redesign of these elbows within the HP cooler scope, but it is a huge judgement call on the part of BP with the only real mitigation being that the chances of it happening are very remote. Sadly most of this information has come to a head in the last week or so, a missed TMR for sure unless Bren or Nick want to give it a bash.

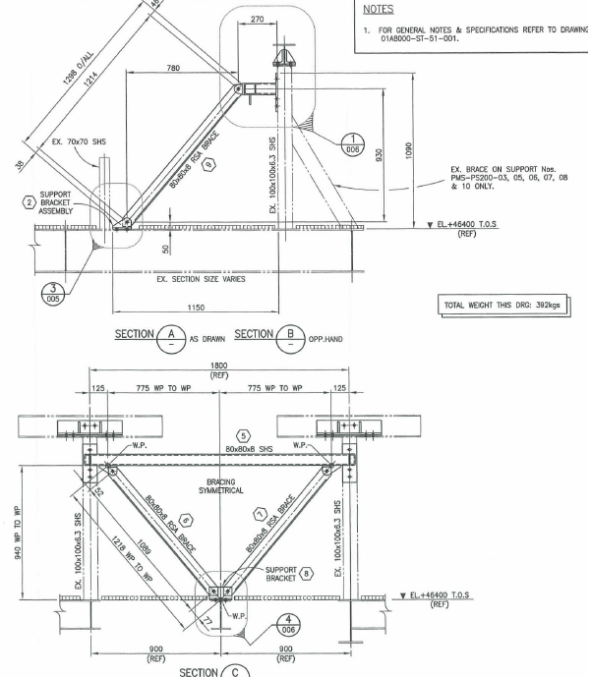

Flowline Bracing

This job just seems insignificant in comparison to the other two, but I am really keen to get it sorted before I leave BP. It is scheduled for a May execute, although the project itself has been in offshore execute for almost 2 years now. I now have a WGPSN engineer assigned to it and so things are moving in the right direction. The thing I am most chuffed about is picking up on a potential flaw in the design. To put the new steel bracing in the project is replacing some temperature transmitter assemblies, the originals have an effective length of 100mm and the new ones 200mm and they support a 1kg transmitter at the end. Basically a 0.5″ threaded tube cantilevered out from a thermowell on the horizontal axis with a 1kg lump at the free end.

The feature directly above the red circle is the situation I have, a metal can on the end of a strut, although in my case the strut is being modified to be double this length.

I put in a query to the instrumentation engineer who specified the new assembly as to what guarantee there was that the new assembly would with stand the doubling of the moment around the thermowell and any vibrational effects from the line to which it is to be attached. The response was not a great one, I have my fingers crossed that this is not a show stopper and while I have a feeling that the assembly is probably good for the increase in moment, I am not so sure about the vibrational effects. I will be disappointed if this project gets kicked into the long grass again.

This is the kind of solution I am expecting, of course rotated though 90 degrees.

In other news

There is more, but I think I will have to save it for the next post as it is late and you are probably bored (well done for getting this far though).

Corine is quite big now (possibly a surprise to you, but number 2 is due in 8 weeks, a girl), but is soldiering on regardless. I have some hard deadlines to hit for my thesis so that it is mostly in the bag by the time she arrives. Mostly for this reason, all extra curricular activities are on hold.

I am concious that I have not included any pictures in this post, mostly because I am writing on my PC and not the work laptop where I keep all of the ‘cool’ stuff. So as a reward for getting this far, here is some more Dilbert for you. He really does keep me going some days…

Things fall apart…

There is a genuine BP post on the way, just as soon as I finish this TMR…until then some comments on the following would be appreciated. I have been providing some engineering advice to my old housing association in Woolwich over the last 3 or 4 years. Over Christmas there was a roof leak in one of the upstairs flats caused by the structural failure of a roof air vent as per the pictures below.

The only thing holding the vent in place was the lead flashing which, under wind loading, has failed quite catastrophically as can been seen above and below.

Below is an example of the stack arrangements on the roof, the third stack in is identical to the failed one and is clearly already starting to buckle.

Below are pictures from the front and side of the development. The stacks are positioned in the valleys of the roof and can’t be seen in the photos, but it gives you an idea of the size and shape of the roof, the elevation in particular.

My first thought would be that stacks at this elevation, on a hill and overlooking the Thames and a lot of flat space, would be subject to near constant wind loading. I would have expected something a little more robust holding them to the vertical than a few mm of lead flashing. However, I am not expert in roofing design and my first assumption is that this would be a standard building practice that, in this case, should have avoided/improved upon by the architect/site engineer. I have advised the Residents Association request that Gallions inspect the remaining flues and vents as I am sure that this is going to be an issue common to most of them (especially going on the jaunty angles in the photos).

There is mounting evidence that the developer has cut numerous corners, which the housing association (Gallions, now Peabody) failed to pick up on when taking over the building on completion. I am interested in your views as to whether this would be another one…

Headache

Clair Manifold Support Bracing

I have been trying to schedule this small piece of work for the last two months. I originally had it in the plan for December to execute during a well head maintenance period. Due to taking on the Clair coolers and the number of issues we saw at the close of that project, this one wasn’t ready for delivery.

Front End Loading

This particular job is the final part of a larger project to standardise the supports on the production manifold on Clair. Development of wells is such that this had been developed somewhat ad hoc, with each flowline or group thereof being a separate project and therefore subject to different design in the supports. In 2011 the standardisation piece was completed but a Project Change saw the development of additional cross bracing to reduce vibration resulting from the modifications. The vibrations are not so severe as to threaten integrity, but it is something that should really be address when considering preserving the long term integrity of the system.

(Above – T support on the production manifold)

(Below – Proposed new bracing to these T supports)

The bracing itself is not the issue, it does not breach containment and is affixed to the primary bracing. It is all drilled and bolted and therefore can be installed during normal production. However, the bracing results in a clash with the existing temperature sensors which requires for them to be removed and replaced with longer stems. The manifold cannot be flowed while these transmitters are removed. A simple probably £20-50k project is stalled because to run it in isolation would cost around a days production, 30,000 barrels at $100….

This part of the wider project was developed as a project change when it was identified that the new supports would not mitigate against vibration effects sufficiently. So the initial Define was not completed properly, that much is clear. This has been compounded because the project change has been developed with no thought to the schedule implications of replacing the transmitters. It is clear from the Workpacks and the WGPSN plan for the work, that an assumption was made that the transmitters could simply be replaced prior to installing the new bracing. I can find no evidence that any other solution was looked at for this problem. I would have thought that connecting the horizontal part of the T supports and diagonals down to the floor from there would avoid any clash and if can’t schedule this project into a planned outage, then I will be recommending that the project goes back into Define to better understand and develop a solution.

Time is Money

The hardest part of this process has been finding the right person to discuss the problem with to identify a way forward. The only planned outages generally fall into the category of TAR (Turn Around) or Wellhead Maintenance. There is no way that this work would get into a TAR, and if it did it would be the first to get thrown out again. The well head maint period is my best bet and they happen about twice a year with individual wells taken off-line for various workscopes to get completed. Clearly, no engineering manager is overly enamoured of the idea that I parachute some extra work into their plan and getting traction with the Wells team has been tricky. I now have the ear of the Wells team lead and I am hoping to get to a definite yes or no (expecting a no).

Bottom Line

This is probably the least important piece of work I have going on at the moment, but it is causing a disproportionately large headache. As an engineer, design should never take place in isolation, even if an SOR or other such mandate imposes project limitations, surely we must be professional enough to look beyond these boundaries for complications that the original author may not have foreseen?

Round Up

This is the post that was going to be written on Friday, basically a round up of my portfolio, since I haven’t done that in a while…

Clair Coolers

Leak testing completed last Wednesday which means that commissioning is pretty much there and with start up scheduled for Thursday, all fingers are crossed that the new coolers and pipework do what they are supposed to. It has been a manic month and a half getting this project finished, but worth it. We are just over £1m over budget and about 5 days late, but the TAR is off by 2 weeks and none of that is our fault, so we are looking good. The budget bust was probably a given based on the emergent nature of the work, but I have secured the necessary expansion to the financial note and at the end of the day the partners did not really have a choice.

The next 90 days will be spent completing the technical and financial close out and I am intent that this is completed on time. We shall see.

Clair Minox B Blower

This is my next biggy with off shore execute scheduled for Feb 2014. This is a scope that has been engineered and is awaiting the slot to execute. It probably deserves a post in its own right to explain the ins and outs (of which there are several), but it is offering me a couple of interesting opportunities. Not in the least the issue of a safety critical interlock arrangement on the modification which has been identified as not being necessary. I think that it has potential to satisfy my B competencies as I am planning on writing a draft technical note to cover the issue and support a decision to proceed without it being implemented. Time is tight, so this is high on my to do list.

There is a fair amount of schedule and planning work to be done on the project as a whole to make sure it goes off without a hitch. This Thursday I will be flying down to Stroud to visit the firm who are reconditioning the blower of my post from last week.

Clair HP Cooler

I’ve still got to find the time to write the SOR for this project. It is halfway there and I am getting increasing pressure to get it over the line to support the design estimate that is just beginning. Yes, I know, how can the estimate go ahead when the SOR is not written. Well, this is the fourth leg of the Clair coolers saga that was dropped from the 2013 TAR due to increasing complexity threatening the execution schedule of the other three coolers. It has been estimated before so this is really just a revision to include the cost that were not picked up in the original estimate, the SOR is more of an update that a brand new document. This is due for 2015 execution and therefore almost certainly going to fall one of the two new secondees.

Bruce P60 Bridge

Yes, this is still going on. I now have all of the deliverables for this project in Define and will be writing a project sanction DSP over the next 2 weeks. This one has snuck under the radar a little bit and I need to create a document that presents the engineering challenge vs the financial benefit to the asset so that they can decide to go or no go. With the Rhum field now definitely coming back on line there is potential for a change in atmosphere on this issue what with the extension of life of field by a fair few years. This is my personal mission to get some kind of resolution on the project.

Bruce Caissons

C13 is chuntering along in the background and I won’t really be doing any work on it until the new year. Suffice it to say that bringing Rhum back on line may have a significant effect on this project. When Rhum starts up the asset will have no redundancy in sea water lift unless this caisson comes back on line. We shall see if it changes any, my guess is not in the next 12 months but it is likely to be a priority for 2015 installation.

Clair Flowline Support Mods

Not much to say here. I’ve bumped the execute into May 15 because there is no appetite from the asset to give me information while the TAR is ongoing. I will keep plugging away at it, but I am not overly optimistic.

In other news:

Hugo has started walking so, being Swiss, he should be skiing by Christmas. I have started home brewing, my first batch is homebrew version of St Austells Tribute. It is merrily bubbling away in the spare room and hopefully in a few weeks should be a decent pint. The home made heat exchanger (single pass immersion coil) and aerator (car pump + aeration stone) worked very well. I will post some pics at some point. There is a striking correlation, Hugo finds his legs just a few week before his dad loses his!

Pump It

Just a quick post today, more on friday is the plan…

Now that Clair Coolers is winding down, Clair Minox Blower B is starting to wind up for off shore execute on 2 Feb. That gives me 19 days to the 12 week gate and while we are mostly there, there is a fair bit of work to get us through. The Minox system uses nitrogen to strip oxygen from sea water for use in re-pressurising wells to increase extraction rates. Removing the oxygen presumably reduces the compressibility of the injected water which protects the plant and pipes used to do so (water hammer?), but I have a little more reading to do on that front. Either way we are upgrading the ‘B’ blower on Clair to increase water injection capacity.

The project itself is another fixer that has been attempted previously but not completed. To that end the equipment below has been sitting out in the elements (at a cost of £20k a month) rather than in a covered hanger being regularly inspected and turned over. QA issues with the storage company. It is now down for re-conditioning / testing with the manufacturer, the photos below are proof from them that it is actually in a better condition than I first thought. My question to you is, from the information below, what kind of pump is it? It is a blower and it sends nitrogen around a closed system.

Mark, if you read this, I can send you the photos and GA for one of your pump lessons…

The Devil is in the Detail – Closure

Well, not quite.

When presented to the Technical Authorities, one of them noticed that on the valve plate it stipulates a maximum design temperature of 90 DegC, not ideal on a line that can see 175 DegC. This was missed at every step along the way and set our meeting off to a bad start. Luckily Woodgroup were able to offer up a ringer that was suitable for service up to and beyond 175 DegC. However this new valve had had the valve stem changed out, but there were no certificates to QA the material used. As a work around I got agreement that the valve could be fitted for leak testing, thus allowing MC1 on 28 Sept, but to be used in hydrocarbon service it would need to Positive Material Identification (PMI). PMI would have required for a trained person to be mobilised with the equipment (think speed gun), so I gave the Asset a choice, PMI the in place valve or we fly out a ringer with certs complete. They went for the second option and so this valve is now fitted and I am left with the glamorous business of ensuring the deviation is recorded in the change management system – queue much chasing after people, bullying and coercion.

If you are interested, here is what the most expensive valve in the world (gram for gram) looks like…

The real drama didn’t start until close of play last week and luckily I’ve not had to get too involved. On Thursday the ACE Engineer responsible for developing the commissioning plan highlighted the fact that the test pressure stated on the piping isometrics was some 30 bar lower than that required by the piping specifications. Following some calculations by BP it appeared that the incorrect temperature factor had been applied to the design pressure to calculate the test pressure (1.5 instead of 1.75) resulting in this discrepancy. This quickly blew up into quite a large issue between BP and WGPSN, with WGPSN spending the weekend checking all of the pipe work in the Coolers project, then all of the pipework in the Clair TAR and then all of the Pipework in the Magnus TAR. A considerable expenditure on Wood Groups part to ensure that, while the pipe work did indeed fall short of the required standard, it was more than suitable for service. Part of the issue lies in the way that BP specifies pipework on assets which is flawed in that it is a massive over estimation in most cases. Ultimately the situation has been justified and there will be no requirement to replace the pipework, which is a massive relief, and the hullabaloo that it caused nicely distracted everyone from the valve issue and I have managed to get it sorted in the back ground.

In hindsight, I should have spent more time when the valve issue was flagged up restraining WGPSN to ensure that we had the right solution. I allowed us to go forward and present a completely inappropriate valve to the TAs and it was only luck that we had a second, more suitable, option to present to them. I am now in the process of trying to implement these tactics to the new issue, Independent verification.

OSCR Regulation 19 mandates that IVB is carried out as a check calc for the project to ensure that disasters like Piper Alpha and Deepwater Horizon don’t happen in the North Sea. There are 20 days until the system is due to go live and I just got handed 23 pages of comments that require response from WGPSN. The clock is ticking once again.

In the background I have also re-written the project Approval For Expenditure to make sure that I don’t run over budget. I like the philosophy of moving the goal posts and in this case it was agreed. My request was for a cool million and it should be approved shortly, unfortunately they BP won’t be giving me the 10% commission I requested.

All in all, good stuff for CPR methinks.

The Devil is in the Detail – Addendum 1

MC 1 is now predicted for some point tomorrow. Luckily it isn’t just the Coolers project holding this up, but we are probably the higher profile due to the nature of the issue. We are much closer to having a valve in place, but as ever the last few steps are the hardest.

Option 1 : At about 8 this morning I was informed that the valve would have had a serial number heat printed onto the body. This would allow the identification of the specific valve so the Mill certs could be acquired. A body was duly despatched to sand of the paint from the valve body to discover this magic serial number.

This is what was found:

If it wasn’t for first hand knowledge of the searches that take place when you fly off-shore I would be convinced that somebody out there had been smoking crack. Un-tagged valve my arse. One of the issue with having a couple of hundred miles of water between the site and site office is that you can’t guarantee that the right idiot is giving you the right information. Having that photo would have saved about half a day of effort.

The deviation request is due to be release to me imminently although the review team (Engineering Tech Authorities) that I have had queued up all day have pretty much all gone home. It turns out that even civvies can have REMFs. So another unnecessary 12 hour delay to this solution, but this time I have all of the pieces and I have the chessboard, so long as I can steer the issue through the TA’s then the ball is well and truly rolling.

Option 2: The original list of 50 valves has been whittled down to 6 of which one is a ringer, but for the fact that it has the same requirement for a deviation and so the hoop remains.

Option 3: Buying a new one, this one was never really viable due to the lead time.

Option 4: The possibility of blanking of the valve location was looked at, but as this valve is the entry point for the system leak test, it is not an option. The possibility of finding a similar valve elsewhere on the asset that could be cross decked is being investigated, but I really don’t see that one flying at this point. It would still require a significant amount of paperwork to organise so Option 1 is still looking good.

Point of interest…

Since the coolers project is on the radar some bright spark decided to set the cat amongst the pigeons by pointing out that the pipes were only tested to 199 bar vs. the piping spec of 230 bar. This has set minds racing across the TAR and Asset teams although the explanation is quite simple. The new piping is specified for 230 bar by fabrication but it is only tested to 1.5X design pressure. It doesn’t really make any sense to test to specification as this would be tantamount to testing to destruction as far as I can see. I am awaiting a comment from the piping engineers to confirm my view before answering the growing panic, but at this point it is the last thing needed.