Archive

The Devil is in the Details

Just thought I would pop you all a quick post in the heat of the moment…

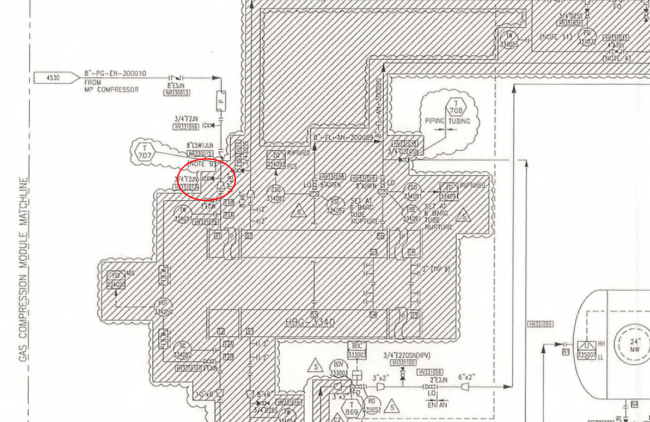

We’ve been slowly grinding through the the last 10% of the project execution and progress has been okay. The focus is firmly on achieving mechanical completion 1 (MC1) so things like re-instating junction boxes, modifying lighting and connecting instruments is a little in the back seat. Pretty much the last piece of the mechanical puzzle was one valve, HV331077, a 3/4″ ball valve rated at 250 bar. Fitting it would effectively seal the system ready for testing and commissioning.

It is missing…

As of yesterday morning I was informed that it wasn’t off shore, so while WGPSN raised the Engineering query I did a little digging.

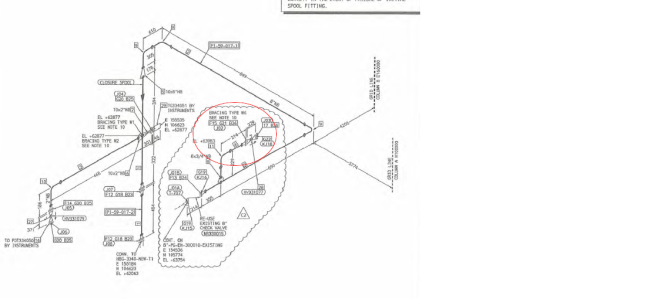

It was on the Destruct P&ID as part of the destruct scope…

It was on the destruct ISO and not identified for retention and re-use…

It is on the construction ISO…

And here’s the little bugger on the construct P&ID, the finished product…

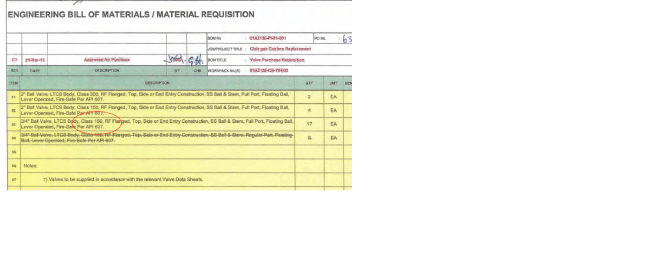

However, we haven’t bought a new one as you can see in this BOM (the pressure class of our valve is 1500):

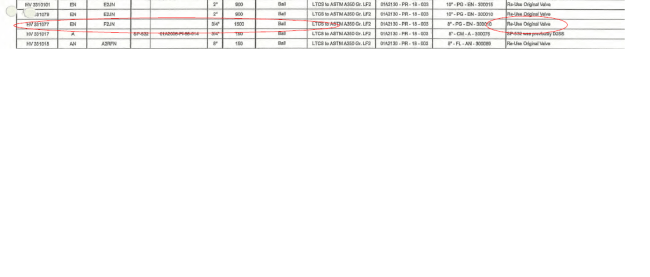

Because someone thought we were keeping the old one and re-using it as per this construction valve schedule:

So what happened?

A lot of attention was paid to the removal and construction of the big heavy coolers, the pipework and all of the supporting steel. All of the big and expensive items were analysed, as they should, to ensure they would operate safely and that they were moved around deck safely. However no-one thought to write a destruct valve schedule, check off the valves for re-conditioning and re-use as and when the lines were destructed. No one thought to check the construct valve schedule against the destruct ISOs and do a sense check. Bottom line is, WGPSN have cocked up and now we are chasing a very real deadline.

Several hours later…

Resolutions

I’ve spent much of the day chasing down options with the WGPSN JRE, Stewart Russell. He was away yesterday and making any kind of progress was like wading through treacle. Everyone I spoke to just seemed to want to stick their heed in the sand and believe that the easiest options would work out. In the end they kind of are, but there is a lot of work required to get them across the finish line. This has been an excellent opportunity to see how the SPA / JRE relationship is supposed to work and I have spent most of the day coordinating BP and placating the TAR team while Stewart has been chivvying WGPSN along to produce their deliverables.

So…

Option 1: We have an untagged valve of mostly the same specification off-shore that is not required for any other i.e. buckshee. The problem is that the valve stem is rolled and not forged which means a deviation is required to get it authorised for service. On top of that, for the deviation to comply with BP technical practices it must be supplied with certification of the mills fabrication techniques to provide QA. However as the valve is untagged it has taken a while to track down the correct certification and this won’t be complete until morning. I have agreement in principle from the BP mechanical TA that this deviation will fly, especially as it is a deviation that has been accepted before as the standard fabrication technique is to roll and not to forge valve stems. Trust BP to do it the hard way. I am confident that with this approach we can have the valve in place by CoP tomorrow.

Option 2: I identified 48 valves currently held in the BP inventory that possibly fit the bill and WGPSN has narrowed this down to 19 hopefuls. By the morning we may actually have a winner, but there is no guarantee that we could get it to Clair before Option 1 could bear fruit. In support of this option would be the fleet of EC225 Superpuma sitting on the airfield at the moment…

Option 3: Buy a new valve of the correct spec. Ironically this is not really an option due to the lead time.

We also considered blanking of the flange where the valve should sit as this valve is a dead leg on the system. However the valve is probably there for a reason and I am waiting to hear back from ops whether this would be a viable solution. And anyway I would still have to do a bunch of paperwork to get a modification like that passed.

So, as it stands the mechanical window which was due to close in about 53 minutes is wide open and my (Projects and Mods) arse is hanging well and truly out of it. Lets see what we can get done tomorrow!

Rolling in the deep.

Quick post this week.

Everything has pretty much fallen by the wayside for two of my Clair scopes. The first is the Clair coolers replacement project which, as you know, is about 90% complete offshore and is on the TAR critical path. The mechanical window for the TAR is 27 Sept (3 days later that originally planned due to delays) at which point all process and safety systems are required to be buttoned up and ready for pre-commissioning testing such as low pressure nitrogen leak testing. The last two of my closing spools were sitting on the quayside as of COP last Friday and their boat should be leaving today. This leaves a very tight window for their installation and I have all of my fingers and toes crossed that they are going to fit first time. Should they be out then I have 2 spools sitting at the fabricators partly made up, but the lead time to have them off-shore would still be about a week. So, if the final closing spools don’t fit I will still be delaying the TAR completion at a cost of around £3.5M a day. I am really hoping this doesn’t happen, as you might imagine.

Further to this, I have fusible loop modifications which need to be installed by 20 Sept in preparation for testing by my contractor. With 4 days to go I am not confident that we are going to be ready although the off-shore team have been aware that this needs completing for over a week. Then there is the corrosion coupon being fitted to one of the process lines which again I am awaiting a progress report on. It seems that Stuart jumped ship at the right time and my days are generally filled with trouble shooting the issues that remain with this project.

By far and away the most pressing is the fact that the TAR plan has not incorporated any of the E&I scope (about 600hrs in total). I discovered this early last week, basically the WGPSN plan over estimated the job card hours and quite early on the TAR team mugged off the WGPSN plan in favor of their own baselined plan with more accurate job duration forecast. The fallout from this is that they have only concentrated on the jobs directly under their noses, removing the old coolers and pipework and fitting the new, as is their wont. It seems most people were aware that there existed a discrepancy between the plans and that the TAR team were riding on a wave of false security, but nobody thought to action it until early last week. With the TAR plan re-baselined to include the new E&I scope the project went from 5 points ahead of schedule to 5 points behind. I am hoping that with off-shore input to include what in the E&I scope has actually been completed we will come a little closer to the ‘S’ curve, but I am confident that we are going to remain behind it until the close now. It just goes to show how important accurate planning is and how damaging having two plans can be.

The other scope featuring on my plate at the moment is the installation of additional bracing to the Clair production manifold. I am inside the 12w gate now and following some fancy footwork I have managed to narrowly avoid being red-flagged. However I still don’t have a workable plan to get this executed off shore. My issue is that to install the new steel I need to replace 8 temperature transmitters with longer assemblies. To this the instruments must be removed and the pipework can’t be flowed while this is done. The project does not have the clout to warrant an outage and so I have to fit it in to a planned outage. There is one planned for December and I am making progress, but I have a feeling it is going to be a messy execute which is not ideal. The wells are taken down based on the requirement dictated by the controls team off-shore and the process engineers offshore, so there is no defined plan of which well will be down and when. My feeling is that I am going to have a team off-shore who will be sitting around waiting for the right well to be off-line to do their work over a period of 2 or 3 weeks. If this is the case then my justification for running the project is weakened I might get bumped out of my slot. At this stage, the more robust I can make the plan, the more likely it will get through the next gate. What would be hand would be a JRE to handle the material and workforce coordination, but I am still waiting for confirmation on who this is.

In other news…

I ran the Great North Run on Sunday and was narrowly beaten by Mo Farah finishing with a time of 2 hrs 3 mins (me not him). Not the fastest time in the world, but then I’ve never been the fastest runner in the world. I was just chuffed to finish so close to the 2hr mark considering how sporadic my training has been.

Scotlands’ summer is well and truly over and we have had the heating on every morning in the last week. It’s going to be a long cold winter methinks.

The Pressure

It has been some time since my last post, so I thought I had better clear a space and get some info into you all.

I had a good trip off shore.

My conclusion is that working off-shore is very similar to working in a patrol base devoted entirely to engineering although with far better facilities and food. Not convinced about the helicopters they use to get there though…

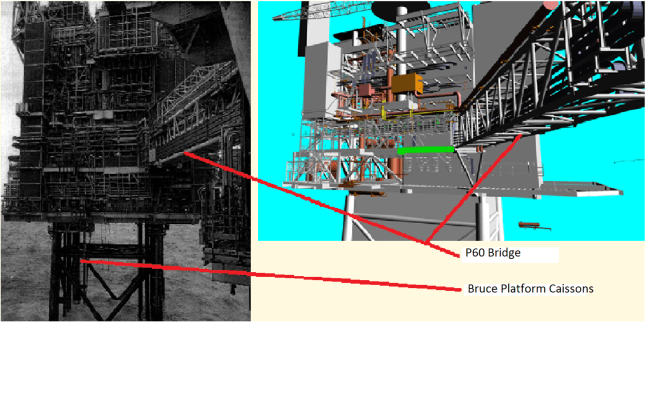

Bruce P60 Bridge

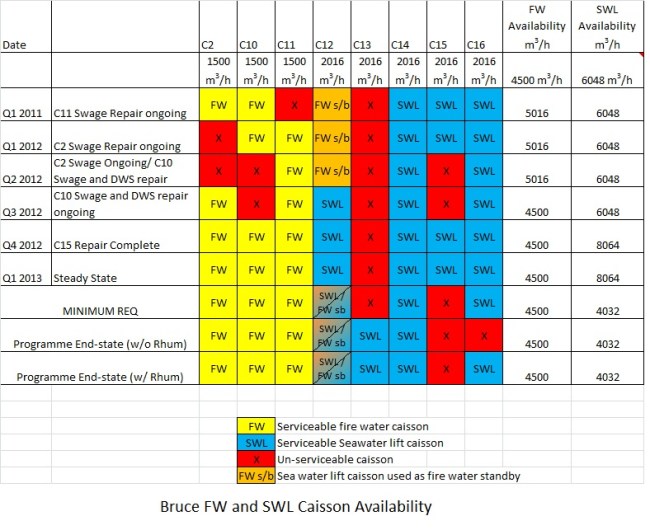

The reason for the visit to Bruce was to mainly have a nose around on the pretext of assisting with a design survey on the landing points of the P60 bridge. I took the opportunity to see the Bruce sea water lift caissons, both from a distance, but also at the point at which they come on board at the cellar deck of the PUQ platform. I am currently awaiting the delivery of the workscopes for this project so that I can write up the DSP for end of Define. I am aware that the project is likely to be killed following the DSP, but there are so many people who believe that this project should be carried into execute I will try and get some buy in. I have hopes that a phased execution will be more palatable to the powers that be, affording schedule flexibility to work around larger, more important projects.

Bruce C13 Caisson Reinstatement

I have been involved in this project for a while now having originally secured the deferment of the scope by 12 months and by providing input to the re-development of the Caisson renewal programme. With the deferment now taking place, I have been asked to take on the C13 scope through to completion of on-shore execute i.e. delivery of Rev C workpacks. Other than that I will have to ensure that certain equipment is ordered next year, but little else. I have put forward the idea to the Programme lead that this project remain with the RE secondment so that I will be able to hand it over to my replacement who would take it all the way through on-shore trials (Sept 14) and into off-shore execute (Apr 2015). The following replacement would then be in a position to close out the project, but also possibly be involved in the next part of the programme. My idea is that this programme has suffered mainly because it has no continuity as people move in and out of the organisation. We may be able to offer some continuity and this idea already has some traction with Kerry Scott and if we have a candidate to replace me, I will keep pushing it.

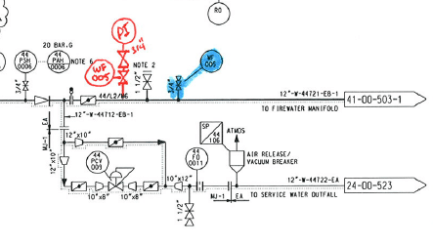

Magnus Firewater Main Overpressure Protection DSP

I am currently at the end of drafting the DSP for this ~£3m project. The project itself is already deep in on-shore execute with the original off-shore execute planned for Oct 2013. at present we have little chance of making the 12W gate criteria, not in the least because the project has no official BP sanction to be in execute. The problem is that the project SPA recently got a new job and left leaving myself and the new SPA to pick up the pieces. There are overdue milestones, unforeseen deviations and a critical scheduling issue confronting the project at present and I am in the process of trouble shooting them. My key concern is that the asset is only permitted 1600hrs downtime in every 365 day period for each of the firewater pumps. This project modifies the overflow route to the outfall and requires each pump to be taken offline sequentially for a period of up to 29 days. At present there is no buy in from maintenance as to the effect of this scope on their schedule. Ultimately an ORA (Operational Risk Assessment) could cover any breach of the Fire water performance standard, but only in extremis.

Clair Coolers Replacement

The SPA for this scope has also gotten himself a new job and so I have been tasked with bringing this project home. The back of it is well and truly broken and the TAR focus has moved on to the Clair Ridge tie back, but there is still plenty to do with a number of issue left to resolve to ensure that the project finishes as per the ‘s’ curve. Thankfully the issues with SeaFab have been concluded, with all of their scope complete. The 7 closing spools have been contracted out to a diferent piping firm (Isleburn) and they are coming along nicely. This will tie in nicely with my thesis as I will now be involved in the commissioning process of the whole scope including a trip to Germany to close out the aspects with the cooler supplier. Further to the current off shore execute I have been assigned the execute of the HP cooler installation which is scheduled for the 2015 TAR, another workscope that I will be able to hand over to my successor if things go well.

Clair Manifold Piping Supports

Having identified that this workscope required a production shutdown, I am trying to find a slot in the plan with a planned shutdown in which to fit this job. I have a couple of meetings next week that should move this one forward.

Competencies

Having had a good look at my competencies earlier in the month I can see that I fall short in section B, much as Chris did before me. I have brought this up with my mentor as pretty much of the work I am involved with is great for A and C, I need to get myself in the ‘2’s for B. With that in mind, I will be looking at getting involved in some work on the new ETAP flowlines, which may offer me the opportunity to exert design influence rather than where I am at the moment which seems to be more design mitigation. I am pretty much at the limit of my capability in terms of projects and so I have started to turn down opportunities. If I get some work on the ETAP then I will be busy right up to Christmas.

In Other News

Went on a sea safari out of Banff a couple of weeks ago where we saw a Basking Shark. I had no idea you could see these in Scottish waters and the 10m long monster actuall swam under out little Rib. I haven’t gotten around to formatting the pictures, but when I do I will post one up here. Other than that things have been pretty busy with visitors almost every weekend for the last two months. I finally caved this weekend and bought myself a Raspberry Pi, so I will be spending the long Scotish winter learning how to programme in Linux, the main reason for this is to anlyse the suitability of my garage for a home brew set up and then as a temperature monitor once I am ready to brew. Thinly veiled excuse to tie together to of my passions, beer and technology. Beats a home made 2d milling machine. Speaking of Mr Hill, here’s a photo to get your motor running…

Ticket to Ride

Funny how when you are waiting for a project, 4 come along at once.

While the work all seems quite bitty, there is a common theme running through everything and all of the systems that I have worked on are interconnected in some way. I’ve found that while I am developing my understanding of how the assets work I am simultaneously trouble shooting issues and developing my ability to use the BP project management systems. I’ve built up a good network of contacts in my previous project work and am starting see the fruit of this as I now know who to go to when I need to discuss a particular issue with a project.

All in all it has been a challenging few weeks and I am really looking forward to my site visit and intend to get a lot out of it. Not least 5 clear days for phys and TMR work!

Clair Coolers

As I mentioned in my last post, this TAR job is now on the critical path thanks to the ineptitude of the piping fabricator (SeaFab). Despite now being directly managed by both WGPSN and BP, with the BP North Sea head of Procurement making weekly visits, Seafab are still falling futher behind schedule! They are running a truly farcical operation with spools being sent for NDT with the wrong documentation, the office being too disorganised for the 3rd part verifier to be able to sign off on the release of apparently completed spools. Unfortunately I have had to take a step back from the daily management meetings due to other work, but I still get the feedback when the project engineer returns each day.

I am still chasing up the IVB process with Lloyds Register, but this really doesn’t account for much of my time.

Clair Manifold Piping Support Bracing

This is part of a project that was executed last year. The main thrust was to standardise the pipe supports on the gas production manifold skid. As a platform develops new wells, it also develops new production lines and for some reason there is no set method for arranging the supports for near identical piping configurations. This project set about to standardise the supports on the 8 production flow lines. I have been given the final part of the project to execute which is to add lateral bracing to the new pipework to eliminate vibrational effects. Everything is fabricated and the work packs are complete, the project just requires organising to take off shore. The show stopper I have found is that because of the of the new bracing, 8 temperature sensors need to be removed and replaced with slightly longer ones. The asset can’t flow these lines while the sensors are removed and this will result in a 3.5 days lost production. The project won’t go ahead with this metric, so I need to find a solution whereby the instruments can be replaced one by one, this would effectively reduce the outage to 0.5 days. I have 10 days to find this solution or the project hits the 12w gate and stalls. Such fun.

Bruce Caissons

This is still chuntering on in the background, but I am still awaiting input from a couple of sources. On a far more interesting note, I may be taking on this whole scope as SPA (i.e. the £26m programme). It wouldn’t mean much for me as the C13 project goes cold at the end of this year (seeing as I made the case for the deferment), but it means that the next two secondees might well be in a position to pick it up when it comes back on line. I need to discuss this with BP, but the Caissons SPA seems to see a lot of possibility in the idea. It would provide some real continuity to a programme that sorely needs it.

Bruce P60 Bridge

Not much to say here other than I will be flying out to the Bruce on Monday for the construction survey. I am very much looking forward to getting off shore for a week, especially as the Bruce is the subject of my next TMR! Winner!

Bruce LPBC Exhaust Mods

You may recognise this project from other well known SPAs such as Capts. Adrian Ishwaria and Warner…

…’you’ll just need to read through the files and close out the project’ he said as he walked out of the office. To be fair it is not much more than that, but the electrical workpack was missing, unbeknownst to everybody involved it seems. However, after some searching Woodgroup have found it and so I will review and sign it off if everything is in order.

Magnus Fire Main Overpressure Protection Mod

I have spent most of the last two weeks writing the Decision Support Package (DSP) for this projects. Despite it already being in Execute, the DSP needed producing to retrospectively prove that it has been sanctioned. You really can’t make this up. I’ve reviewed the project information and submitted my first draft of this document. I look forward to getting some feedback.

In short, the project aims to replace some manual butterfly valves with automated ones that will open when the fire main is brought up to design pressure from its normal operating pressure. The new valves need to open in such a way as to negate about 7 bar of overpressure caused by the pump start up. The DSP breaks down the financial, technical and safety aspects of the project so that the budget holder can sanction it. It feels a little nugatory to be writing a DSP after the decision has effectively been made, but at the end of the day it needs doing and I am hoping that it will raise my profile with this particular Asset Program Lead.

Magnus Cold Boot Relief Upgrade

This is a brand new scope to me and so I will be reading up on it whilst I am off shore. Again this is a project in execute with no DSP, but this time I really have to work the DSP up from scratch. There is certainly more opportunity to get involved in the project engineering too as quite early in the execute phase.

In Other News…

I gave a presentation to Engineering Services today outlining who I am and why I am working at BP. I got some nice feedback and I quite enjoyed getting into barracks dress and wandering around BP.

Oh Danny Boy (the pipes, the pipes are calling).

So the Clair Coolers project is in off-shore execute, 27% complete which is actually slightly ahead of schedule and this is good because the TAR itself was running about 2% off schedule up until this week. My role is mostly finished and I just need to ensure that final sign off is completed and a few post implementation actions are carried out before the project closes out further down the line.

Other than a couple of new project scopes I have picked up (more on them in due course), I have been following another issue in the Clair Coolers Saga. You may remember that this was supposed to be a like-for-like change out, with all pre-existing pipework being re-used. Due to various issues the pipework had to be redesigned, doubling the length and creating a whole new pipe route. This pipe work came to a total of 73 spools which were due for delivery from the sub-contractor, SeaFab, about 2 months ago. I’ve been sitting in on meetings with WGPSN (prime contractor), BP and SeaFab because the pipes are not finished. Not even close. Piping construct is set to start early next week and only 43% of the spools have been released and none have been shipped as yet.

The main issue is that there are only 4 companies in Aberdeen who carry out piping NDT, a pre-requisite in the production process. One of these companies is not an approved BP vendor and two of the others are over worked. It appears that everybody uses Euro NDT and it has been taking a minimum of 3 days to get spools through NDT. Added to this Sea Fab have a weld failure rate of around 5.6% and each spool has at least 2 welds, you can start to see the problem.

What has been most striking in these meetings is how unbothered SeaFab appear to be by the fact that they could be in a position where they are delaying a critical path project on the Clair TAR. This would be equivalent to hundreds of thousands of pounds liquidated damages per day….if the contract had any clause to impose financial penalty on SeaFab for late delivery. It doesn’t.

Now I have not seen the contract, I haven’t even had the chance to talk through the subject with the contract manager, but my understanding is that liquidated damages are generally not used in the oil and gas industry. The value of lost production is so high that to impose that on a sub contractor would quickly ruin many of them. Milestone payments are used on larger projects, but the Clair coolers project is only worth £5.6M OPEX, although the NPV would be an order of magnitude higher as the asset cannot produce gas without them.

Other than the issues with NDT, the site contractor cited work force problems as being the main reason for the production delay. His exact phrase was ‘prima donna fabricators’, which makes a little sense to me. Piping, in this industry, is where the real money is. If you see an Aston Martin in the car park, it probably belongs to a pipey (although the one I am working with has an Orange VW Transporter with custom tartan seats). There are only 4 or 5 BP approved piping vendors, of which SeaFab is one and so SeaFab know they have a captive market. It stands to reason that the fabricators know this too and I got the impression that the SeaFab management are currently at the mercy of their workforce. It is no secret that there is a dearth of skilled workforce in Aberdeen and I get the impression that SeaFab can’t afford to have its workforce walk out.

That said, I was shocked by the working practices on the shop floor.

Now you tell me that this is how a shop floor ought to look and I will be happy to call you a liar. WGPSN have issued SeaFab with a priority list, it is clear which spools should be fabricated first to feed the project should the schedule be this close, but at the end of the day, only two of the pipes in that pile are for the Clair coolers project and this visit left me with no confidence that the guys on the shop floor had any idea of the importance of getting this project pushed through.

Yes SeaFab has several other projects on the go, but most of that piping is destined to supply other BP projects and BP has set the Clair Coolers as the number one priority. As much as the WGPSN piping rep wanted to hang around the shop floor to motivate the fabricators, it really is not worth the contractual angst it would cause. That is not to say he has not done his bit to get SeaFab organised, but at the end of the day it is going to be touch and go as to whether the project is delayed because of an inept subby.

I look forward to sitting down with the BP contracts manager so that I can better understand how BP has gotten in to a position where a tiny piping firm has them completely and utterly by the balls. I think I may already know the answer.

Question?

Jim asked an interesting question the other day. Has anyone done any work to quantify the likelihood that (the oil and gas) platforms will exceed their currently expected lifespans?

At the end of the day, risk is managed on a continual basis and the likelihood of a platform being required to exceed it’s original design life is probably around 100%. However the original design, and any later changes, is required to be constantly being reviewed against the asset Safety Case. The asset Safety Case is the legal document that must identify and manage all hazards relating to the asset. As a starting point the “Integrity of physical resources is assured through design, construction and procurement in accordance with recognised codes, standards and practices.” As time goes on potential hazards in new and existing plant are identified systematically, risks evaluated and reduced to ALARP levels by appropriate engineering and managerial methods. The continuing integrity of plant and equipment is controlled through inspection and maintenance managements.

For example, the Bruce was originally composed of two jackets, the Process Utilities and Quarters (PUQ) and Drilling (D). A third was added 8 years after commissioning to receive and compress gas from the Rhum oil field tie back. Export risers, compression equipment and all manner of controls will have been updated and re-validated to conform to the new operating conditions, changing their design life. These changes are captured through various risk assessment procedures/studies, such as Layers of Protection Analysis (LOPA), Hazard ID (HAZID), Hazard and Operability (HAZOP), throughout every stage of the project. The higher the risk, the higher the sign off required of the risk mitigation within the organisation. I have found that individuals are generally very diligent with respect to their responsibilities when signing off as a technical authority.

Of course this kind of development results in different parts of the asset being designed for different (relative) design lives. Another consideration is that the design process conditions may not ultimately reflect the operational process conditions. The Bruce test well must have showed no indication of H2S in the formation and so the installation was designed with the minimal capacity for sour service. However, there is every chance that the well could have gone sour over time as different areas of the formation were accessed. In the case of Clair, H2S levels have increased consistently, with 500ppm expected over the next few years. This type of change has a significant effect on the life span of pipes, heat exchangers, valves etc. At the end of the day, the design life of the installation is something that is constantly changing and being reviewed on a regular basis.

I do find it worrying that in my 3 months here I have come across several instances of under design despite conformance to the appropriate code.

Bruce P 60 Bridge bearings – aggregate travel of the bearings was many times what was predicted.

Bruce Caissons – Premature structural failure due to under design of the caisson walls. It turns out that secondary forces around the sub and above sea guides were not modelled.

Clair Coolers – Under design of Coolers resulting in shell side weld corrosion.

Clair Coolers – Over stressed piping runs due to apparent lack of consideration of cyclic process conditions. FEA has shown that on start up and shut down the pipe stress exceeds tolerance and the speculation is that the pipes were designed for steady state operation only.

One issue I am currently dealing with revolves around conformance with a BP general practice which recommends that impact tested Low Temperature Carbon Steel is used on all new pipework. By ensuring that impact Tested LTCS is used throughout, the risk of using non-impact tested LTCS in the wrong place is mitigated and Procurement and Supply Chain Management (PSCM) is easier for projects. However the Clair piping specs state that non-impact tested LTCS be used (ASTM A106 Gr B), so I have had to raise and approve a deviation for an approved practice so that we can use a pipe which has a higher specification (ASTM A333 Gr6). A333 has slightly lower % manganese, sulphur, phos and carbon content, but tensile and yeild strengths are identical. The only differences are in the testing regime, with impact testing specified for A333 and not for A106. Here’s the kicker, for A106 to have been used on the cooler project it would have needed impact testing to conform to BP standard practices. The problem lies in the asset piping specs and they are clearly overdue for updating.

Asset longevity is, therefore, a delicate balance of mitigated risk against productivity. The items listed above are all managed with inspection regimes, intervention repairs and replacement programmes. Unfortunately it appears to me that there is potentially a significant amount of un-identified risk within the industry which can only increase as time goes on. In the case of the over stressed pipe work on the Clair, a project is being initiated to survey all of the pipework on the installation that might be at risk from this same issue.

I would be interested to know if the Army uses/has instances where it would need a change management system. The only thing that I have been able to come up with is the seven questions, sort of a management of change on the battlefield. Ideas?

Sittin’ On The Dock Of The Bay (or the hard at Peterhead).

I’ve been trying to get this post up for the last 2 weeks, but after a slow start, things are really motoring along in the North. Summer has arrived, which means the heating is now only on in the evenings and it only rains every other day.

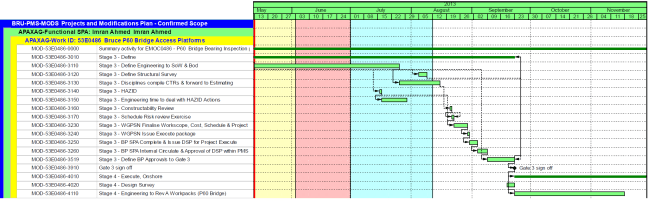

P 60 Bridge inspection platforms

This project is starting to see a little more life now. At about 51% completion I am on target for close out of Define by the beginning of September, although with no funding in FY 14/15 all the work will get kicked into the long grass. With Cessation of Production for Bruce sitting around the 2017 mark, there is no appetite for this work, the asset is more interested in squeezing the field for all it is worth.

At 51% most of the design work is now complete and the engineering is about to take over. My input has been limited to ensuring off-shore involvement and digging up answers to design team queries i.e. what are the standard railing panels used on the installation, will the current design allow sufficient access, are we too close to the process lines….with the general low profile of this project, getting answers to these questions has been like getting blood out of a stone.

The picture about is the layout of the inspection platform (inside the black circle) beneath the PUQ side of the P60 bridge. The query has been around the proximity of process flow lines (in yellow) and whether the jacking procedure can be conducted within the constrained space. My answer is yes, mainly as this is where the original scaffold would have sat anyhow, but getting confirmation from the inspection team is not going well at the moment. At the end of the day the design will go through a constructability review and the HAZID where an representative from the asset will be able to comment on these issues, but it would be preferable to put them to bed earlier.

All in all, it’s a fairly easy going project and it has been mostly running in the back ground. 16 July will see the HAZID (Hazard ID) meeting take place although I am yet to see any forward movement from WGPSN Tech Safety who are contractually obliged to run this process. Chris has warned me that if the Tech Safety rep is a dud, I will probably need to chair the HAZID, but I am fairly happy with that as my recent experiences with the Clair Coolers project have set me up well to step in should the need arise.

Bruce Caissons

Due to the project below, this one dropped off my radar the last couple of weeks until it appeared on the weekly Engineering Services update where specific projects and task are highlighted as a specific priority. Getting the decision to defer the re-instatement of the C13 Caisson has now become a high priority and so I am re-applying myself. I originally put together the document and analysis that brought together structural and operational reasons for deferring this project until 2015. While the decision to defer was taken verbally, nothing was documented leaving the collective Project and Mods arse flying in the wind. However, over the last couple of days I’ve re-invigorated the issue and look to be on track to get the decision signed off over the next few weeks.

Clair Coolers

This has had almost all of my attention over the last 3 weeks or so. From being brought into the project, I effectively took on the job of developing the Management of Change strategy in order to close out the project. BP has a relatively robust MOC system, but it is not designed for emergent projects such as this. Originally cited as a ‘like for like plus’ replacement this should not have been an issue, with very limited actual change being brought about. However, various opportunities to add value to the project surfaced and as previously described, the project is like for like no longer. Whereas a normal project would have had an Appraise, Select and Define stage prior to Execute, in this case Appraise and Select were skipped (Appriase – No project=no gas production=no money / Select – ‘Like for like’ = Previous version lasted 10 years, Life of field is about 10 years). Define and execute were essentially compressed into about 9 months with the Prime contractor responsible for the overall project, but with BP mech and process teams designing the coolers themselves. My role has been to manage the output of the most recent risk assessment, drive forward the process of ratification of these risks by the BP technical authorities, develop the strategy for engaging these individuals, examine technical issues surrounding residual risk and compile the evidence supporting the mitigation of said risks.

Picture of the Clair Coolers sitting in a hangar at Peterhead.

Cooler transport frames to get them off-shore safely.

This job has really developed my understanding of how BP do business. More importantly it has increased my understanding of how critical risk appreciation and management are to successfully executing a project. Ideal considering the up-coming HAZID for the Bruce bridge inspection platforms. There is a plan afoot to get off-shore over the next month or so to actually see the coolers getting fitted, but I am not raising my hopes to high as there is unlikely to be a lot of space off shore during the TAR.

In Other News

Hugo had his first birthday party last weekend and it was a great success. Next week he starts nursery as Corines parent will be heading home and she will be working half the week for Grampian housing association. I and Chris attended Kingswells Primary school yesterday for the third leg of our involvement in the Primary Engineer Scheme. This saw the children racing the shoebox cars that they had made over the previous two sessions. The vehicles were rolled down a ramp and measured for distance traveled and deviation from a center-line, with the children doing the launching, measuring and scoring. Chris’ teams put in a valiant effort but at the end of the day were resoundingly defeated, he might be the fastest man in all of Nairnshire but I am the king of the classroom!

Got to Turn Around

After a busy week last week, things have continued to pick up pace. I am now supporting two projects as well as managing my own little one and developing my understanding of how BP conducts off-shore business. It is quite clear to me now how crucial good risk management is from an early point in project life as my involvement in the Clair Coolers project is showing.

P60 Bridge Access Platform

This project has gone quite at the moment, there are no milestones looming (the first one is in July) and the team in Runcorn is on the case. I had a project review meeting planned for last week where I was to discuss with the JRE (Andrew Dickinson) and the senior structural engineer (Ian Hartley) where the design was and identify any sticking points. But due to picking up some last minute work, this has now slid to the right and will take place this week. I’m looking forward to finding out where Ians design work is leading as his initial drawings showed the steelwork being welded in place. The key issue in this design is avoiding hotwork if at all possible so that it can be carried out outside of a TAR (even during a TAR the asset is really not keen on hotwork) and so I am interested to see how he proposes to attach the inspection platform structure to the asset.

Caisson Re-placement programme

My visit to the Bruce ACE turned out to be less exciting than I imagined. It was a completely on-shore meeting, for some reason I thought that the Area Engineering Support Team Lead would work off-shore, but I will put that down to industry naivitiy, I expect everything to be off-shore. In reality, as you would expect, everything that can be done on shore is done on shore to protect the bottom line. In the end the meeting took place between the caissons team from Projects and Mods (Kerry, Craig and Myself), the AESTL (representing the business end of the asset), Colin Wilson (representing Discipline and the caisson integrity case) and one of the Bruce mechanical engineers (representing the asset in terms of process and mechanical engineering). I made the case for the delay of the Caisson 13 until 2015 on account of it being a new scope that would not fit around the 2014 TAR due to the requirement for a good weather window (project team requirement), the reduced water requirement of the asset against the figures cited in the safety case (asset/process requirement) and the fact that while structural failure in one of the other caissons was relatively likely, it did not present a threat to the export/import risers and the repair process was a proven technique that could be worked up in a short period of time . This was essentially the fruition of the stakeholder/technical authority engagement I had conducted in the previous week and (with the support of the stakeholders who were actually there) the result was that the AESTL supported the move to delay the project execution. It was a good meeting but while the decision was made, none of the paper/electronic work that will ultimately provide a coherent background to the decision has so far appeared, so this week I will try and chivvy that along. The hardest part of this industry seems to be getting people to front up and write down their reccomendations after they have verbalised them and therefore take on some of the risk!

Clair Coolers

I got involved in this on Wednesday last week and it has since given me an excellent grounding in the risk analysis procedure used in the eMOC (electronic Management of Change) system. The project is in the process of going off shore, but it is unusual in that it has not followed the BP Capital Value Process and therefore has several substantial residual risks attached to it.

The coolers are shell and tube heat exchangers used for cooling produced hydrocarbon gas as it is compressed to around 250 barA. In October 2012 gas was found to be contaminating the coolant fluid and upon inspection internal corrosion of the coolers was found to be the cause. The coolers were repaired sufficiently to be put back into service and a plan was initiated to install like for like replacements. Simples.

Since then a whole raft of side issues have caused this to be anything but a like for like replacement. As changes have been signed off and deviations agreed the risks have mutated. This was the third eMOC risk assessment designed to capture and treat all of the remaining risk. Present where the contractors representatives, the asset and various disc lines from within Engineering Services. In the end it was a little like herding cats, especially as the chair refused to admit she was chair (even though she clearly was), the SPA remained steadfastly silent and implacable throughout and any argument that could be made circular was. Lesson learned and if I am in that situation again I will have no problem in volunteering to chair. I understood pretty much everything and the areas I didn’t people were happy to explain. What should have taken a day took the better part of two days, but conclude it did with a list of 18 risks requiring action at either pre or post implementation. I’ve got the job of ensuring that these risks are captured in the electronic system and so I’ll spend the next week reviewing the supporting technical documentation, summarising it and, more than likely, chasing it up in the first place.

It is an excellent example of how a project can be forced through a change managment process, but at the penalty of significantly increased cost and complexity. Every day the current coolers are down is a loss of about £500k so it is not surprising the decision was taken. Had this project been Appraised properly at the start many of the problems encountered would have had early solutions, but then the process would have taken 2 years instead on 9 months.

One of the most striking aspects of this project is the sheer complexity of removing and installing the coolers. BP commissioned a construction animation (at a cost of around 25k) from which the pictures were taken as screen shots. As a tool for educating all parties it clearly show the removal and replacement procedures with incredible clarity.

One of the most striking aspects of this project is the sheer complexity of removing and installing the coolers. BP commissioned a construction animation (at a cost of around 25k) from which the pictures were taken as screen shots. As a tool for educating all parties it clearly show the removal and replacement procedures with incredible clarity.

At this point the pre-TAR shutdown on Clair has begun, the original coolers failed last month and the project is now underway. Initial work-scopes have begun with the installation of the new coolers to take place in three weeks and it is all hands on deck to get the project risk conveyed and agreed by the Clair Engineering Support Team Leader so that it can be effectively managed into the future.

The reference to my TMR is that this began as a simple like for like replacement that has grown arms and legs. When the design contractor was completing the calculations for re-installing the existing pipework it was found that the pipe routes were under designed to meet the stresses imposed by the process pressures and temperatures. It seems that the original design failed to take into account the change in conditions induced by the recycle line from each compressor at each stage of the three stages. With this included in the calculations the temperature in the flow lines was capable of reaching a maximum some 50degC above what had been designed resulting in potential over stressing of the system. Now it is unclear to me how often the operating conditions achieve the design conditions, but judging by the colour of the assets process engineers’ face after the realisation dawned it was often enough. He was quite clear that had he known this before, the gas train would have been shut off much earlier.

In Other News

I feel really left out in the America stakes, I often see wild animals (deer, rabbits, hairy coos and even an Osprey), but despite riding as quickly as I can they remain steadfastly alive. Hugo will be starting at a creche in about two weeks and Corine will be starting with Grampian shortly after that. Summer has arrived (two days so far) and cycling in to work is very pleasant, especially when I get to detour through the local woodland. Chris has got Dougal with him this week and so I accompanied him for a lunchtime walk. It is amazing at how alike dogs can be to their owners, Dougal was consummately happy crawling through the mud at the bottom of every ditch , although I thought his chat was better than the average Commando Engineer.

Believe in me

It has taken 5 weeks of blindly stumbling along in the dark fug of unknowingness, but finally I feel like I am adding value!

P60 Bridge Access Platform

I made the trip down to Manchester last week and it was good to finally get the ball rolling on this project. In an amusing turn of events, the senior structural engineer assigned to this project is new to Wood Group, so that makes up all of the members of the team essentially new to role and inexperienced in one way or another. In the two hour meeting I successfully bluffed my way through the kick off review and drew up a baselined plan that correlates the job responsible engineers (JRE) plan and my Project Execution Plan.

As you can see, the PEP does not go much beyond September when I have to meet the only milestone and circulate the Decision Support Package for end of Define Gate. I’ve been told in no uncertain terms that this project is unlikely to ever become more than a desktop study and in the knowledge that the scaffolding contractor currently builds the temporary scaffold and leaves it up for a year before destruct and re-build, I tend to agree.

That said, there is still money to be spent and a Basis of Design must be delivered. It is not a complicated design as you can see below, but as ever the devil will be in the detail coming up with a method of attachment that does not require welding due to the process pipelines that the bridge carries between modules and the pre-eminent fear within the industry of something being on fire that shouldn’t be.

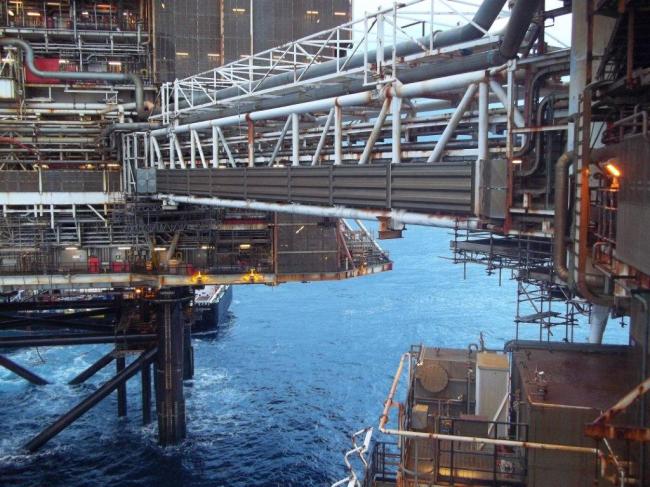

I have an off shore survey planned for early August that, so long as it doesn’t get bumped, will give me and the lead structural engineer an opportunity to see the scaffold in situ, the bridge bearings as well as the sea water/ fire water caissons. On the whole it is a good little project to cut my teeth with very little space to really screw things up.

Temporary scaffold currently installed on the P60 bridge to allow access to and jacking of the bridge for bearing inspections:

Dance floor scaffold beneath D end of the P60 bridge.

View from the D platform landing, the shrouded area is protecting area surrounding the bearings.

Looking from the PUQ platform back toward the D platform.

This bridge is f*****g huge!

Seawater Lift Caissons

The results of my investigation into the business drivers for replacing the Bruce seawaterlift caissons have been very interesting indeed. The original caissons were underdesigned to reduce weight so that they could be lifted into place on the installation during the initial construction. They started to show premature wear about three years after commissioning and have been a source of problems ever since.

The original Capital Value Process for a replacement programme was instigated in 2009/2010 with the Select phase ultimately recommending a full programme to re-instate all but one of the sea water lift caissons. This was based on a series of structural surveys conducted in 2009 that showed that all of the caissons were in danger of total structural failure. The programme has progressed in that C13, the closest to falling off, was removed in 2010, but the challenging plan to replace it has not yet come to fruition. It has been designed and is ob the verge of being fabricated, with an installation planned for summer next year. Next year is a TAR year for Bruce, a process that adds to production in real terms, whereas the caisson only adds to production in secondary ways such as a reduction in PoB for surveys, fewer emergency interventions e.t.c. While replacing all of the caissons makes excellent engineering sense, the business drivers are far less clear and the reinstallation of C13 is highly likely to be delayed until 2015. The scope of this investigation is to:

- Understand the drivers for the caissons programme: integrity concerns, operational availability of seawater and firewater pumps?

- Re-examine the key drivers to determine whether these are still valid ensuring agreement from the appropriate stakeholders

- Propose a forward caissons programme based on revised understanding of the key drivers

In light of this, I’ve spent a lot of time reading the reports of work that has been planned and completed (or not in some cases) and meeting the stakeholders to develop a technical note assessing the importance of the key drivers and a revised programme to deal with the issue. Buy in from all of the key stake holders; the asset (Area Engineering Support Team Leader), the structural engineers in Discipline, the asset mechanical engineer and the Life of Field team who will authorise the budget in the longer term, is fundamental to getting this programme back on some kind of track and I think the original failing may have been lack of commitment from the asset with the plan being devised in isolation. My rationale for this is that the high level plan specified in the Select Decision Support Package makes no account for the impact of TARs on the plan, which is strange considering the complexity of the project and ultimately it was this oversight that has delayed the project thus far.

The bottom line is that Cessation of Production for the Bruce field is forecast for somewhere around 2020, but the installation will still require the caissons for the decomissioning process of some 7-10 years duration. There is added complication in the form of the Rhum oilfield which is tied back to the Bruce installation. One of the partners in the Rhum field happens to be the Iranian government and production has been on hold for about 4 years, the up shot being that if Rhum is turned back on then CoP moves out by another 4 years and more water will be required for process cooling.

I am looking forward to Tuesdays meeting as it will be my first time in the Bruce ACE (Advanced Collaboration Environment – video conference room with the platform) and a great opportunity to understand the situation from the off shore point of view.

I’m getting some good traction with this caisson work and things are looking promising for picking up some work on the Clair caissons. I’ve been complimented on how quickly I have broken down this issue and provided clarification, which is nice.

In other news…

I shall be enjoying not watching Eurovision and instead will be attending the village barbeque (in the rain). Corine has found herself a second job, this time with the Grampian Housing Assoc so we are scrambling to find childcare in the local area. Amusingly, she had a complaint from one of her french students for speaking french during a lesson this week. Apparently in his book this did not constitue a valid technique for teaching french. You just can’t make this stuff up!

Keep on Chooglin’

It has been a busy two weeks, but I have seen some real progress at BP. I have two jobs regarding the Bruce platform, both of which have potential to go off-shore next year which means I would see them through to close out, possibly.

The Bruce platform lies about 175 miles North East of Aberdeen and is composed of three platforms as shown above. Processing, Utilities and Quarters (PUQ), Drilling (D) and Compression Reception (CR). It is, as most in the North Sea are, an old platform having been built in the 90s for a ~30 year life of field. The general currency of projects on these installations is Persons on Board (PoB) and as a result, long lead planning with the client (the Asset i.e. platform) and early buy in is critical to the progression of any project as can be seen in my two concerns. Bruce has flexibility to surge around 20 personnel on board over and above the basic off shore staff at any one time and as I am finding out, these precious spaces are always filled months in advance as per the Assets priorities.

P60 Bridge Access Platform – Between PUQ and D.

The P60 bridge is a 47m long bridge with a loading of around 183 tonnes in storm conditions. It has had a long history of bearing issues as they have consistently failed to achieve their design life. This can be put down to lack of design data on how the platforms move during annual weather patterns and it is a common failing on platforms built post Piper Alpha where bridges are used to link platforms and effectively isolate the more volatile on-board processes from the living quarters and bridge.

The photo on the left shows slight elongation to the piston plates at the PUQ bridge bearing, while the photo on the right shows damage to the stainless steel runner plate. The manufacturers estimated field life for the bearing pad is 20km aggregated travel and this was not expected to be exceeded with the life of field of the installation. Recent estimates have put the actual aggregate travel of one bearing at 3km in a single month of bad weather! As a result of the manufacturers generous estimates, no method for jacking the bridge up to perform regular maintenance was built into the design and so every quarter an over the side scaffold must be built to allow inspection and maintenance to take place. This is costly, but most importantly ties up bed spaces on board on a regular basis. There is a lot of work going on on this old platform and so simply reducing the PoB burden is quite a significant win for the asset.

I have ~£80k to take this project through the Define stage to gate 3, the beginning of the on-shore Execute. This would see the basis of design complete and much of the risk identified prior to the detailed design. This is the BP practice of Front End Loading to ensure that as little time is spent in the On and Off Shore Execute. From what I can see, this is driven by the desire to achieve effective long lead planning rather that simply moving milestones to avoid missing them (which seems to be relatively common at the moment). A project that is effectively Front Loaded is on the 8Q plan (8 quarter) early, PoB are allocated to the project well in advance and once Execute is reached all of the risks are controlled/mitigated in such a way as to allow the project to progress through to closure efficiently. This is the goal.

The original Kick Off for Define took place in February, but seeing as neither I nor my Job Responsible Engineer (JRE) were actually at that meeting, it seemed sensible to run a Kick Off Review to ensure that all parties in the Define were clear on the time-line, scope and deliverable of this phase. So I will be off to Runcorn on Wednesday for this very reason. My plan has the Define finished in about 3 months, although I am not fully clear myself on the deliverables required and so I will be clarifying this with the Programme Lead, Kerry Scott, before I head south.

Seawater Lift Caissons

I have been asked to review the business case for the ongoing programme to replace the Seawater lift caissons on the Bruce Platform and write a recommendation on its continuing validity by 15 May for presentation to the programme stakeholders. The programme is ~£2 million through a £26 million spend and, while being quite complex in execution, presents no serious issues for BP on-shore. The problem comes back to the Assets priorities and for 2014 this is focussed on the Turn Around (TAR) which will see a major development in the existing delivery infrastructure and an increase in production. No firm decision has been made, but it is likely that the TAR is going to steal the best (forecast) weather window for the first phase of the Caissons programme. This review will look to inform the client of the risk they will be taking on running phase 1 during potential bad weather (think delays and increased PoB thus delays to other work) and the assosciated risk with pushing the programme back a year to de-conflict with the TAR.

Caissons on oil rigs are not much more than fancy service conduits and are used to protect equipment from the effect of the North Sea. They are commonly used to bring risers off the sea bed onto the installation and in this case they are used to protect large seawater lift pumps that bring fluid on board to cool various elements of the production process. They are called upon to withstand the corrosive effect of seawater and air, attack from marine life such as barnacles and algae and of course the constant buffeting by the waves. These Caissons are critical to the installations’ Safety Case as they also provide back up to the fire water lift caissons. They are around 1-1.5 m in diameter, 75m long and made from carbon steel. They are typically under designed to reduce the dead weight when lifted into place during the original construction. Caisson failures have occurred on a regular basis in recent years and the HSE is particularly interested in this programme. One of the first things I intend to do is examine how many caisson interventions have been required since the initiation of this programme as it may be a good indication of how many PoB have been squandered by not pushing this project forward fast enough. As it is the programme is a year behind where it is supposed to and I have yet to ascertain exactly why. I am keen on the programme not sliding to the right as at present I could be around to see the off-shore execute next year.

The diagram above shows just how close the caissons lie to the jackets (the legs the platform stands on) and many of the supporting struts, the small red circles being the SWL Caissons. Each caisson weighs in the region of 40 tonnes and presents a very real risk to the integrity of the platform, not in the least regarding potential damage to sub-sea piping if they were to come loose and fall to the sea bed.

All in all I am hoping that this is a lead-in to taking on some aspect of the caisson replacement programme as the lead engineer appears to be quite snowed under. The Asset Lead is also under resourced so I think there is a good chance that I will be able to get more work on this and other related platforms in the future.

On Another Note

Hugo has fully recovered from his Bronchiolitis, but unfortunately Corine is now getting over her bout of Sinusitis. Luckily the Scottish summer has finally arrived and so I intend to make the best use of it, who knows how long it will be around for!