Archive

Reduce your Embodied Carbon!

In my previous blog, I mentioned I would be involved in an Embodied Carbon (kgCO2e) study to be completed retrospectively on Gatwick’s newly finished Pier 1. Here are four generic recommendations for embodied carbon (and cost) reduction that could be applied to any construction project.

Useful to those currently in design offices writing design specifications and those going into phase 2 who might influence materials specs – some of these are a great way to save your client money, helping them to meet embodied carbon reduction targets, whilst providing perfect evidence of achieving UK SPEC competency E3 – ‘Engineering in a way contributing towards sustainable development’.

They may demand a broadening of the mind of clients / design colleagues to gain agreement!

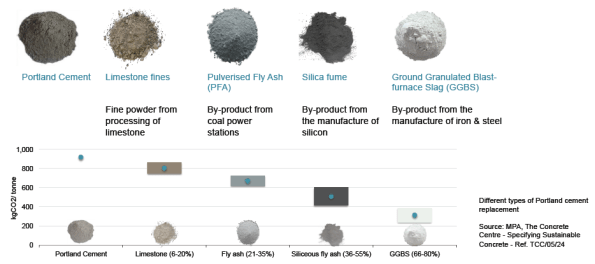

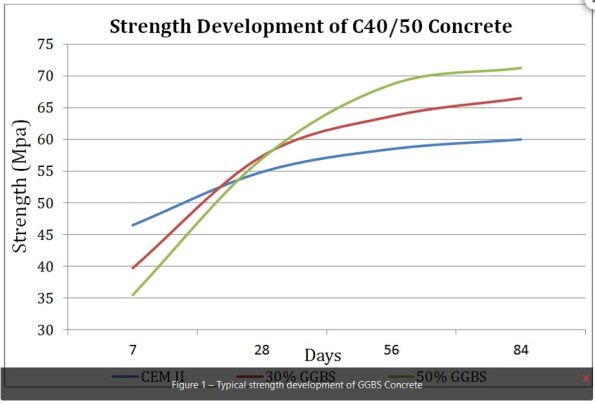

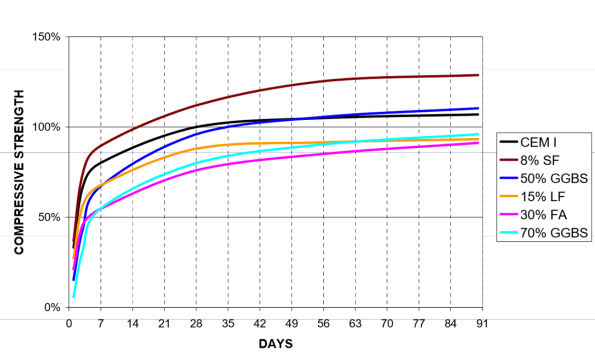

- Replace up to 50% of cement content of concrete with Ground Granulated Blast furnace Slag (GGBS): (the civils will know more about strength implications and codes for this but BS 8500 gives the guidance on tolerances).

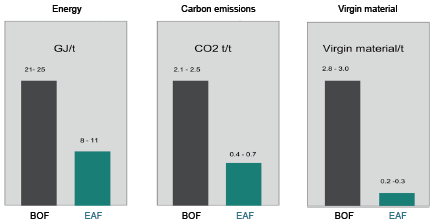

- Specify Electric Arc Furnace (EAF) steel (up to 100% recycled steel) over Blast Oxygen Furnace (BOF) steel (up to 30% recycled steel).

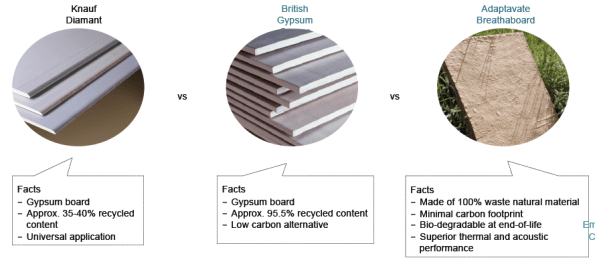

- Consider natural materials for internal building fabric. Caveat to this is that the ‘adaptavate Brethaboard’ below will require thicker plaster finish skim than the other two. Other alternatives products exist using natural clay which can absorb and release moisture into internal space, thereby passively regulating humidity.

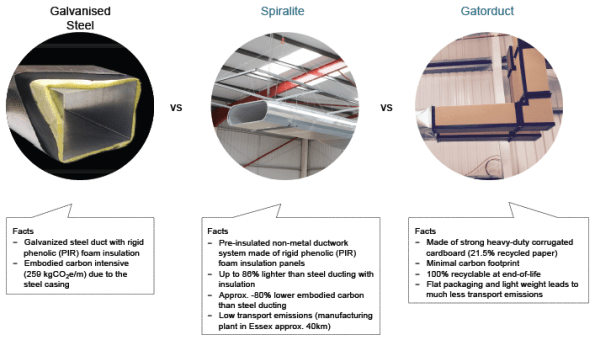

- Replace traditional steel ductwork with alternatives. To me, this might be the most difficult to get agreement from a client familiar with steel design going in and indeed steel ductwork is the generic requirement for all of Gatwick’s HVAC systems. However, in certain situations, such as relatively short lifespan / high turnover retail installations, the Gatorduct might be an better option.

I’d be interested if these types of products are commonplace on other sites indicating that perhaps Gatwick’s construction department remains too traditional / slow to catch up? Or maybe just meeting programme drives designers / contractors to stick to what they know?

Slides to go with Tom’s reply:

Sustainable Engineering and Midnight Lux Levels

Happy new year to all! An update from Gatwick…

Sustainable Engineering

In order to bolster my E3 UK Spec competency of proving sustainable engineering, I’ve managed to get involved with the in-house Environment and Sustainability team. I’ve now got responsibility for an embodied carbon survey to be conducted on the newly finished Pier 1 (see http://www.dailymail.co.uk/travel/travel_news/article-3640991/Gatwick-unveils-186m-state-art-terminal-link-fascinating-time-lapse-video-showing-construction-hi-tech-new-baggage-system.html for a rather good time lapse video – particularly of the baggage system!).

The survey is aimed at quantifying the amount of carbon emitted to atmosphere during the manufacture, transport and construction of the building and it’s materials per m2. This will give a measured baseline of Gatwick’s current sustainable construction performance and try to fill the void between strategic aims of ‘constructing more sustainably’ and the on the ground reality of how well projects are delivering to this.

Broadly, materials such as steel tend to have much higher embodied carbon due to energy intensive manufacturing process. Materials such as timber have much lower embodied carbon as less energy is required to produce it.

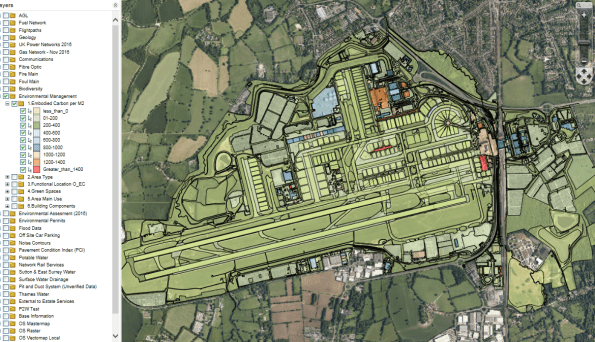

The aerial shot below gives an overview of the existing understanding of the Gatwick site’s embodied Carbon, which is currently quite rudimentary and not much more than a wet finger estimate. Green indicates low embodied Carbon, red indicates high. Pier 1 is the red block to the right hand side of the site view.

Once the detailed Pier 1 survey is complete, I aim to suggest suitable recommendations into Gatwick construction material standards to reduce embodied carbon where possible.

Night time lighting testing.

The first project of the baggage programme is now in the testing and commissioning phase (see progress photo below). For my electrical package, this involved dead and live testing of final circuits, testing of the lighting controls and testing that the specified lighting lux levels have been met.

Emergency lighting testing must be conducted outside of working hours to allow the bag hall regular lighting to be switched off, thus I joined the contractor to conduct the lighting and emergency lighting test in a window between 2330hrs and 0230hrs with lux meter in hand to conduct the tests. In the photo below (yes, that is my hairy arm) we are testing that the electrical distribution board receives the minimum of 300lux on vertical plane under normal lighting conditions prior to testing that it meets 15 lux under emergency lighting conditions (and after 3hrs drain of the battery).

Who needs a second runway anyway..!

Well actually, Gatwick desperately does to facilitate its passenger throughput expansion plans. But realistically it will just be a matter of time before another is built here anyway. In any case, I thought an update from a rather subdued Gatwick was in order. The first major project of the baggage Programme is within a couple of months of completion. With no requirement for foundation or ground works and using a steel frame structure and pre-fabricated sections of baggage conveyor systems, the visual transformation on the new makeup positions site was rapid (see title picture).

The bulk of the remaining works includes the controls and electrical installations, as well as general road layouts, markings and safety barriers. I’ve picked out two hiccups that others will be able to identify across other sites.

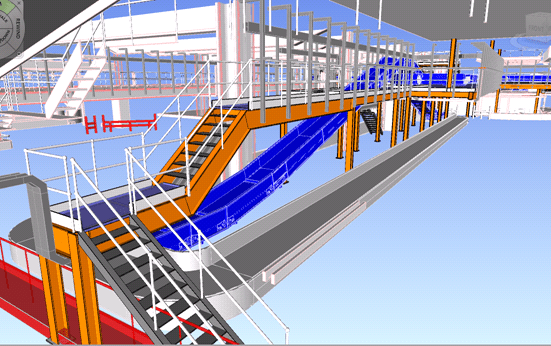

Firstly, designing in a 3D model with inadequate detail. In Revitt, the walkway below had sufficient width (750mm) to serve as an emergency escape route. In reality, the motors from the conveyor systems (which had not been modeled in sufficient detail) encroached into the walkway. The outcome is that the walkway below needs new steel work in order to widen it by approximately 200mm. Whilst the amended steel work isn’t part of my works package, the electrical and controls containment and cabling that will run along its perimeter is, thus will incur minor delay.

Secondly, excessive lighting glare. The proposed flood light style system for illuminating the area where operators make up baggage containers has now gone up. Not considered as an issue during design due to the requirement to meet Gatwick standard requirements for illumination and glare, now that it is in situ, the glare from the lights may well cause a problem to the comfort of the baggage handlers. To try to head this off prior to hand over, I intend to firstly, ensure the contractor proves adherence to the required glare standards and secondly, bring the stakeholders together prior to completion and confirm acceptability, and if not, a suitable improvement.

Whilst the project is due to finish just about on time, the most significant delays to the project were due to Gatwick Airport process issues (such as the change control systems) rather than any technical or unforeseen engineering issues.

This will be one of my biggest takeaways from working in a live operating environment – factoring in time for the project team (most of whom are new to Gatwick) and contractors’ project teams to understand and meet the clearance process requirements of the numerous stakeholders during any engineering works. This could be for the simplest of electrical isolations, to fire systems deactivations, to emergency light testing.

Outside of baggage projects, I’ll be playing the role of dummy passenger supporting one if the other big programmes being delivered here – the Airline Moves project. This project consolidates all EasyJet flights in the North Terminal as from end of January, and moves all BA flights to South Terminal (plus a load more moving parts). My role will be to prove the route and identify faults from check in to boarding prior to the project going live.

Farmyard Acceptance Test

Aiming to broaden my attachment experiences, I volunteered to be the client’s representative for witnessing a Factory Acceptance Test of a Medium / Low Temp Hot Water plate heat exchanger set being installed as part of another project.

Perhaps naively, for a piece of equipment coming in approx. £80-100k I expected the factory to have a roof, floor, some walls and a clean(ish) environment. Instead, I met the fabricators on a dusty farm outside Basildon in Essex. I half expected Del boy and Rodney to come around the corner to take me through it.

It turned out that, despite first impressions, they had done a reasonable job spatially, improving what were very cluttered design drawings into a much better arrangement from a maintenance point of view. Valves and key items such as the distribution pumps and dirt / air separators were much easier to access and remove if required than in the original design. Having said that, all the equipment was stored in the open air (in a working farmyard), almost every pipe viewed was surface corroded inside, and the minimum design separation distance of feed and return pipework connections in the header had not been met.

Welding workshop:

Internal corrosion:

I registered all issues into a report for review by the Contractor and the wider GAL project team and requested confirmation of remediation plan for the internal corrosion of the pipework and protection of the equipment from further weather damage.

I’d be very interested if anyone else has done a FAT on a similar system and what the construction environment was like? Also, any views on the significance of rust inside nearly all the pipes – I haven’t dug into the design calculations of the system but I imagine the pumps were designed to meet certain frictional losses which would have been increased from the corrosion to some extent? Could a decent cleaning flush when installed with subsequent inhibitor application during installation be sufficient to smooth / protect the internal surface?

Plate Heat Exchangers (painted blue):

Separately and in an unfortunately similar vein to Kuki’s death on site blog, one of the baggage handlers lost his legs the other week. He was breaking strict protocol by stepping between baggage dolly’s (trailers), when the tug pulled away and he got dragged under one of the dolly’s. A sad reminder of potential catastrophic result of complacency in the work place.

Conveyors, Controls and Carousels

Confusingly, no-one has taken up my offer of talking airport baggage over a coffee here from my last blog. So, I thought I might give you all an update on one of the Gatwick Baggage projects; it might entice some of you sitting on the fence to come and find out some more first hand.

The first project in the programme has now gone into construction phase, with the final design hopefully appearing something like the model below. This is an £8.1m project and, as an enabling project to the remainder of the £140m programme, must be completed by the end of the year to avoid significant knock on delays to the programme.

This structure is a new ‘Make up Carousel’ and consists of two new conveyors feeding a new carousel. This is the same as the baggage carousels that you will have picked you bags up from when you arrive at an airport, however in this instance, the bags have just been screened for explosive threats and will be loaded onto the aeroplane for departure.

The majority of items in this view will be new works, of which most will have to be completed in the daily window between 2300hrs and 0330hrs when the airport is non-operational.

This is the first project that Gatwick Airport, as a client, have tried their ‘package management’ approach. This involves the client taking main contractor responsibility and contracting directly with discipline sub-contractors (Structural, Civils, M&E, Controls, IT and Baggage Systems). In theory this will allow greater control and reduce project risk, though it is proving a steep learning curve for Gatwick, particularly in terms of mechanism for design collaboration between the discipline contractors. Any thoughts from other sites / design offices on approaches used by other main contractors to this would be appreciated.

Getting everything in writing. Our lead designer unnecessarily reworked an electrical design and claimed I had instructed it. When I queried, it turned out the only reference they had was a supposed telephone conversation that I don’t think took place – nothing in writing so no costs for the work incurred thankfully.

Working outside of permit. I think an honest mistake, but the M&E Contractor I am responsible for managed to complete some electrical works outside of their permit to work – on day three of being on site! Cue stopping works and incident report submissions. Not a great start for the contractor.

And finally, as the summer rush arrives and the number of stag and hen parties in the departure lounge peaks, the baggage handlers seem to be competing to see who can throw passengers’ bags the furthest when packing their baggage trollies. I think the informal record is about 4m – perhaps best not to put the bottle of chablis/ouzo in your hold baggage!

Don’t mention Heathrow!

Ever wondered where your bags go after you drop them off at flight check in? Probably not, however below the glamour of the airport departure lounges, there exist dungeons otherwise known as ‘baggage halls’ where kilometres of conveyors and machines screen and sort your bags to their appropriate flights.

Having spent the past two weeks immersed in the baggage halls of Gatwick Airport, I can say with some confidence that I must be the RSME’s new expert on airport hold baggage systems (unless Jim can still remember from his time here?). This blog very briefly introduces the Programme and my role.

The Programme

Every bag that is loaded into an aeroplane’s hold must be scanned for suspicious substances prior to loading. To meet the latest EU regulations, Gatwick must (barring any Brexit effects) upgrade all 30 of their screening machines prior to 2018 at about £1m a piece. Unfortunately it is not a simple case of swapping the newer ones in for the older ones. Due to increased power and cooling demands, as well as severely restricted access to the machines, a programme of enabling and upgrade works to all the current baggage handling systems is required. The budget of the Programme is £139m and it is split into 9 different projects, all to be delivered with no interruption to daily baggage operations.

Pilot project – 6 tonne Explosive Detection System being lifted into position for trialing.

My role:

As the Mechanical, Electrical and Plumbing Building Services ‘specialist’ within the Programme team, I will support all of the nine Projects by managing a) the MEP designers during design stages and b) managing the MEP sub-contractors during construction stages. Work on the first of the nine projects is due to start in July so I’ll be concentrating on design reviews and contractual work up to then.

![]()

Typical baggage hall conveyor – these bags are in ‘quarantine’ – they have gone through the explosives scanner but await decision if they are safe or not.

Typical sorter – once scanned, bags are individually loaded onto trays that then flip your bag into the bin designated for your flight. All governed by barcode readers and PLCs.

In terms of experience so far, I found that the principle designer has fudged their concept lux lighting level calc’s worse than a Phase 1 PET student, and that Heathrow is referred to only as ‘the other place’.

A genuine offer; if anyone is flying from Gatwick over the next year, please do give me a shout and I can go into more detail over a departure lounge coffee!