Archive

Foundations in congested ground

EXP-487-SK002 – In ground services clash review BH responses TS markupI’m looking at the foundations for a new elevated walkway at Wembley Stadium. The ground is pretty congested with services thanks to those pesky M&E critters. Needless to say the SSPs are saying it’s absolutely impossible for them to abandon or move anything so i’ve got to bridge over them. Anyone got any references for good guidance on these issues?

Update following RFs comments:

This is just conceptual considerations however, linked

(randomly inserted at the top of the page) is the latest of the clashes discussions I’ve been having with the services coordinator. My current aim is to work out if the foundations are achievable, meaning identify the types of problems we have (eccentrically loaded pile caps, services under pile caps, services adjacent to piles/caps) and say what the possible solutions might look like.

Any Site Managers on Phase 2?

For anyone that thinks they sound like a dick when they tell someone to move something that’s not stored in the right place:

http://www.bbc.co.uk/news/uk-england-london-39816357

Acoustic barrier

I’ve been working on a project designing a variation of a demountable acoustic barrier for use between the entrance to TFL tube stations and busy roads. It uses a new noise attenuation cassette produced by Echobarrier and potentially geopolymer or wood concrete base units and a titanium dioxide additive to the surface to reduce NOX levels.

The basis of our appointment is initially to act as structural engineers on the design and installation of a prototype. The total budget for design and construction is 300k. The real money will be made through IP rights and by successfully developing the prototype into a system that can be deployed more widely. For this reason the project is relatively confidential so please don’t discuss outside the course (not that anyone is interested anyway).

Due to the low budget, initially, we need to stay close to existing systems to assist with the client risk appetite, ease of installation etc. But we also need to demonstrate options for increasing beauty, function, speed of deployment, improvement to pedestrian safety, longevity, flexibility etc. and to that end i’ve had initial discussions with the architects and a small pre cast company specialising in low cost prototypes, and BRETT Group for delivery of a scaleable solution.

So far i’ve looked at design actions and produced the structural basis of design. All relatively simple stuff. Future work will look at the options for the concrete bases, and detailing for the connections between the posts and base (likely to include a cost comparison of bespoke cast in channels, and off the shelf resin anchor systems.

The snag is that funding has been put on hold currently, but we should get news later this week from the Client on when it might be re-initiated.

Pipes and shit

Whilst I’m pleased to see the Phase 2s on here so the Phase 3s can now wind down the blog contributions, I think RF is under the impression I may be hiding under a rock again, so below is a brief summary of some of the work i’ve done recently using a calculator and felt tip pens. They’re all work in progress so feel free to comment with any suggestions, advice or queries.

Selfridges Drainage Management Plan

Below is the latest of 4 technical notes i’ve produced as part of the Selfridges Drainage Management Plan. They’ve let their drainage get in a bit of a mess and there are literally places where shit has hit various fans (or more importantly some expensive handbags). Expedition were initially engaged to summarise the issues. They reviewed the drainage systems and produced 20 recommendations thinking that Selfridges would say thanks but no thanks. Un/Fortunately depending on your perspective they turned around and tasked Expedition to enact every one of them. There started 2 years of work for the civils team charged out at 15k per month. What a terrible example of poor asset maintenance I hear you cry! But is it really? £15k is probably two of their mid range handbags….retail space is worth a hell of a lot more to them when it’s operating than when a contractor has some hoarding up so they can do maintenance. In retail, as in construction, decisions are made on a commercial basis, and sometimes this trumps engineering factors. If you can’t understand a seemingly ludicrous engineering decision, make sure you’re considering all the wider factors.

That said their latest idea to put a new toilet block on a part of the system that’s potentially already overworked (the exact drainage routes still aren’t known) seems truly crazy, and the work below (still in progress) is me trying to work out exactly how crazy it might be, and how to politely tell them.

EXP 326-4 Outfall 2 Assessment[2015]

Taipei Airport Drainage

Expedition are completing the concept design for the drainage masterplan for a new terminal at Taipei airport. The detailed design is being done by Arup.

I was looking at the structural support for the downpipes. There were a number of constraints. The design requires twin stainless steel downpipes (circa 500mm diameter) to be supported from the roof truss and at berm level, but unsupported between so they resemble steel columns. Large thrust forces will be developed at the pipe bends, high wind loads are expected, differential movement is expected between the roof and the ground (+/-45mm horiz. and 15mm vert.), seismic effects must be considered.

I initially looked at cantilevering the pipe 8m from the ground to alleviate the differential movement issue, which required me to assess the dynamic response of the pipe to the expected wind load, and the thrust of the water hitting the top of the hopper. However the lead engineer wasn’t entirely uncomfortable with this, with too many variables for us to mitigate the risk without unwarranted analysis at concept level, so I then had to look at options for supporting at truss and berm level.

The latest (although potentially not final concept) using WGS 77 Victaulic couplings as a “flexible” (the meaning of the word here is relative as their flexibility is limited 9mm per m length) is shown below. Although we calculated the forces and specified the couplings we omitted this from the concept document. We’re not paid to develop detail so why take on the liability. I also got slapped on the wrist for writing “WGS77 or similar”. Despite seeing this approach numerous times on site it’s avoided in the design office as it opens up all kinds of legal issues if a “similar” product fails.

Open Doors

Just been told about this. Might be an interesting visit if anyone wants to wander around a few construction sites. You could potentially argue that it’s CPD at a push or steal a good idea from one of these sites, apply it on your own, and look like a hero!

IStructE guidance

Writing AER 5 has prompted me to signpost some guidance for the Phase 1s as they move to their site attachments. It would also be useful for the next batch of phase 1s but I doubt they’ll see it unless one of the lecturers can pass it on.

Join the IStructE as a student member. I don’t think it was covered except for some structures ninjas attempt to charter with IStructE. Maybe I slept through that advice in Phase 1 (my fault) or maybe it wasn’t covered (it should be).

It’s free, you get access to their online library, learning resources, student groups and talks, essential knowledge series, “Brohn” online modules, “The Structural Engineer” (online only), you can join their working groups (good CPR evidence)…….and most importantly it’s actually a navigable website unlike the ICE one. I feel they support learning in the way that the ICE should be doing (clearly not a point i’ll be making at CPR).

Join here:

Specifically:

The essential knowledge series is really simple introductory reading.

The level 1 technical guidance notes would be useful pre-reading before the corresponding lectures on phase 1 and as a refresher when you come back to that topic on phase 2.

The level 2 technical guidance notes are a good starting point for any phase 2 or 3 design you need to do in that subject area and they all highlight recommended further reading, generally easily understood IStructE design guidance. These are still being written.

Level 3 notes looking at complex design issues will follow during 2018.

I plan on coming back to them as a handrail after i’ve finished the course as well.

Grease build up in Non Return Valves

BLUF: Can any of you geeks point me towards any discussions or case studies on the effect that fat, oil and grease (FOG) has on (NRVs?). I’m guessing it’s not going to be good but I need to know how bad it could be, maintenance periods, dosing options.

Background:

I’m working on the adaptation of the drainage for an existing department store in London. Over the years the store has developed a maze of drainage, both foul and rainwater, no-one really knows how it works and there is a history of FOG build ups causing blockages, and being London concern regarding rat ingress.

There are around 20 proposals to fix all the issues. Two of these are flap type NRVs to prevent rat ingress, and grease traps with a wider grease management process. However, there are areas where in the short term (2-10years) we will not be putting in grease traps for commercial reasons and so there is concern over whether fitting the NRVs to this section would make grease problems worse. The store doesn’t have a great record of maintaining the system so “just check regularly to prevent blockage” probably won’t be successful.

Optimistically I’m hoping that the pressure required to operate the valve may be enough to clear any FOG build up but I guess this would depend on what volume and the frequency of flow, and what type of valve we specify.

Innovation. The conclusion of the trilogy.

The long awaited concluding part to the innovation trilogy. Spoiler alert – RF was right. It’s about risk appetite and opportunity. Feel free to stop reading now if you can shout that at the reviewers with enough confidence to convince them you know what you’re talking about. If you want a bit more information up your sleeve then see below. Alternatively wait until Disney buy the rights to make the Innovation Trilogy and then watch the film.

Most of this is based on discussions with the authors of “Innovation in Structural Engineering – the art of the possible” published in The Structural Engineer Jan 2017. I won’t cover the report in detail as i’m sure you’re all keen to read it. I also sit on the Expedition Sustainability Group (SG) with two of the authors, and we’ve discussed some of the wider issues in our meetings.

To quote the US Administration and Tom Clancy….”there is a clear and present danger [from innovation*]”. (*also drug cartels but that’s for another day). Therefore Clients are wary of it and there must be a demonstrable benefit (potentially T, Q or C). The sustainability group believe that to implement innovative solutions they need to contribute to both innovation (pushing the boundaries) and sustainability. I think they missed out the key requirement and that it also needs to be functional. If the proposal falls within all 3 of the circles below and has monetary saving it will be difficult to argue against.

![20170211_132843[830].jpg](https://pewpetblog.com/wp-content/uploads/2017/02/20170211_1328438301.jpg?w=595)

One of the authors (Jones) presented his research to the SG. He thinks whether innovation can be realised or not can be expressed as below:

Initiator + Enablers = adoption

Requirement, constraints, Resources, skills

aspirations

The article cites earlier research suggesting that likelihoood of adoption primarily depends on five factors:

- Compatibility – how well does the innovation work with what already exists.

- Complexity – how easy is it to understand the innovation.

- Observability – can the success of the innovation be visually demonstrated. (In the case of SNFCC literally jumping up and down on one of the prototypes was one of the most effective demonstrations – despite being completely unscientific)

- Trialability – Can you safely test it or is it just a punt

- Relative advantage – How much T,Q,C is improved

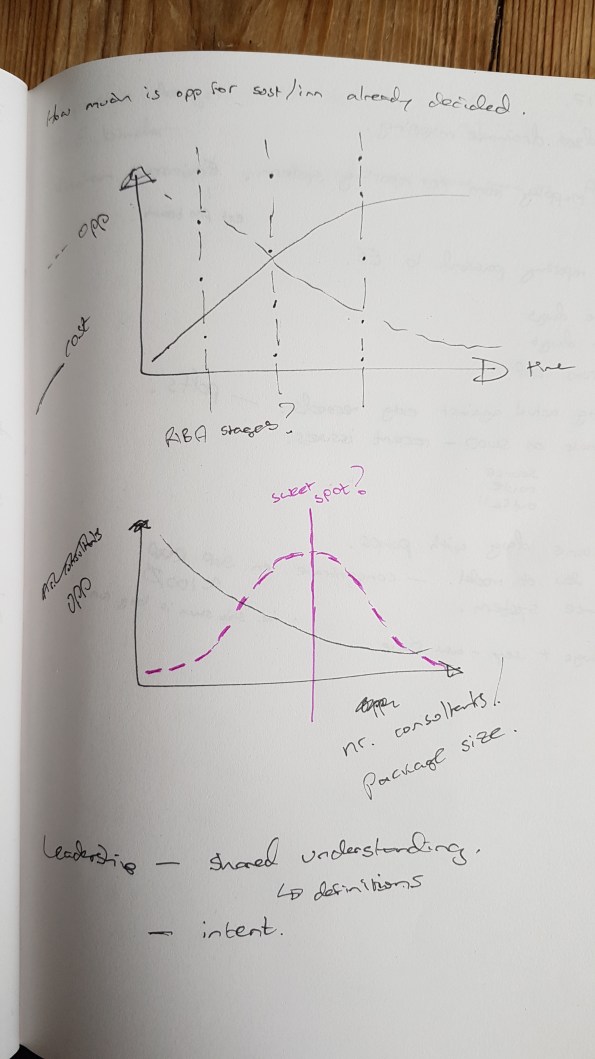

In addition, as I mentioned before, there are unintended contractual barriers. Many innovations may not be realised due to the Client/QS and the way they have tendered the works. We will all be familiar with the opportunity for change versus cost of change graph (top graph below). I think this can be applied to innovation and that right of where the two lines cross, you’re unlikely to see an innovation unless the saving is enormous. Depending on the nature of the contract, the amount of D&B, the size of the packages and when they are tendered, the position of this crossing point, in conjunction with the RIBA stages, will change. The lower graph shows my thoughts on the number of consultants/number of packages. Initially I thought that the more consultants or specialists you have, the smaller their packages of work will be, and the less opportunity there is for innovation. On reading the innovation article, I then revised this to suggest that there might be a sweet spot with enough specialists for a broad range of experience and knowledge, but still maintaining a large enough brief to be able to make savings within each tendered package of work. Put bluntly, why would one designer make a change that would benefit another consultant or contractor’s work package.

Of the 5 factors listed earlier, trialability is the most interesting to me because I had no idea how this would be approached in a military engineering context. It was also one of the biggest challenges on the Stavros Niarchos Foundation Cultural Centre (SNFCC) project., when they wanted to use ferrocement to provide a thin canopy on top of the building.

The team highlighted 3 methods of trialling. The cheapest is to look at other industries or projects that have implemented something similar, proving the material in a different context (or perhaps even the context with a different material? but this is trickier and less likely). This leaves a gap which needs to be bridged with supporting calculations, and is therefore relatively risky. (I think Concrete Canvas have found it difficult to progress from this option to the next option)

The next option is to combine physical models, computer analysis, and prove the innovation from first principles. The level of proof and risk with this option varies massively. Generally the more physical and less conceptual the analysis, the more you can tick off complexity and observability. Providing, that your modelling assumptions are correct.

The final option is to gain certification of compliance through formal testing against specific performance requirements. This is expensive and often outside the scope of an individual project, but can deliver a good level of confidence and consequently a low risk of failure.

The successful SNFCC project used all 3 of these approaches. With the above in mind does anyone know if we used any of these techniques on operations or on PDT?

The SNFCC canopy innovation was ultimately successful because it had the right project team, but this was not an accident. The Client was actively seeking out innovations and had a budget to support this. Expedition understood the intent and set about to secure a team of academic and industry experts to support them in their quest. The project was tendered competitively with the project team demonstrating a viable construction solution to potential contractors. This meant that there were less unknowns, and therefore risk for the contractors to have to price.

The so what for me is that I don’t think i’ll come across many clients actively seeking innovation in the next few years. However, I might be forced to implement innovations to overcome other barriers. If this is the case then i’ll need to decide upon and implement a testing/proving process to demonstrate management of the risk, and a real benefit. I’ll also need to have access to the right team to support me, which means understanding the reachback to 170, academic staff, the wider Corps and the invaluable Engineer Staff Corps.

Expedition is considering forming a technical working group to investigate the potential for reducing the partial safety factor for reinforcement, and safety and material factors in general, following a recent academic paper by Beeby and Jackson. I’m hoping this will allow me to develop a methodology for evaluating some of the safety factors used in military engineering.

Innovation in construction materials

3-2-8-cc-defence-1604 cc-other-sandbag-reinforcement-1604

I attended a presentation before Christmas from a company called concrete canvas.

“Concrete Canvas Ltd. manufacture a ground breaking material technology called Concrete Canvas that allows concrete to be used in a completely new way. Concrete Canvas was originally developed for the award winning Concrete Canvas Shelters, a building in a bag that requires only water and air for construction.

Concrete Canvas is a flexible concrete impregnated fabric that hardens on hydration to form a thin, durable water proof and fire-resistant concrete layer. Essentially, it’s concrete on a roll.

Concrete Canvas Shelters are rapidly deployable hardened shelters that require only water and air for construction. A CCS25 variant can be deployed by 2 people without any training in under an hour and is ready to use in only 24 hours. Essentially, CCS are inflatable concrete buildings.” (http://concretecanvas.com/).

I think they also featured on Dragons Den but didn’t get funding. I think it’s a great product. The shelters could perhaps be beneficial in longer term displaced persons camps owing to the fire resistance, although the market has been a lot less interested in these potentially (I assume) down to the increased cost, logistics and complexity compared to canvas/plastic alternatives.

On the other hand, the canvas rolls have sold very well worldwide, as it is a much cheaper alternative to reinforced concrete for non-structural applications, and is cost effective even when the cost of shipping to Australia is included (although this reduces the environmental credentials). Costain have used a lot of this stuff for lining ditches, stormwater channels and ponds, and bunds. The EA have used it for flood defences, and they also report the military have used it in Afghanistan (I think for improving Hesco and ditches).

The company has secured compliance certificates for fire resistance, age testing, abrasion resistance, chemical resistance, and impact resistance (for pipeline coatings). The use of the product in non-structural applications supports product development by allowing them to secure the accreditation above, provides funding and increases market awareness. But their ultimate aim is to push the product as a structural application. Due to the increased risk this poses, there are many more barriers, and more checks and balances required. It’s easy to get something into the non-structural market, essentially just prove that it won’t kill fish and newts. Proving that something won’t fail and kill lots of people is much harder. The future is also uncertain for manufacturers – will Brexit change the nature of BS EN accreditation, raising the bar or making investment in securing accreditation now irrelevant in the future? The Institutions say not – but who knows for sure?

Blog 3 – the third and potentially final blog in the Tony Strachan innovation series will look at the Stavros Niarchos Foundation Cultural Centre and how innovation was achieved by Expedition (and others). This featured in the January 17 issue of The Structural Engineer in case anyone wants a spoiler of the article I will be shamelessly presenting.

Update: I checked the info that concrete canvas sent through ref the previous military uses for their product. The case studies are linked at the top (as it’s the only place wordpress will let me put it) for info – but don’t let them stifle your creativity! I’m not aware if they’re working on military projects currently.

Technological innovation in construction

I’ve been involved on the periphery of a few discussions with innovation in construction recently so I thought i’d type out my musings in case I want to use it in the future. Plus i’ve just ordered on Deliveroo so i’ve got some spare time tonight. Unlike the beautiful “E&M cut and pastes” from a TMR it’s not neatly formatted, more like the words have just fallen out of my head (akin to JMs feedback).

Firstly I attended a talk at the ICE on technology as a management tool, delivered by Highways England (should be available as a recorded lecture soon at http://www.ice.org.uk/recordedlectures , along with other videos for filling a boring winter commute). They’ve seen tangible improvements in management or delivery from technology in the following areas:

- Remotely Operated Temporary Traffic Management System (ROTTMS)

- Stationary vehicle detection software to prevent, detect and monitor incidents.

- Integration of design, operational, construction and environmental risks onto BIM 3D modelling.

- BIM 3D and “4D (cab view)” safety briefing and supply chain planning.

- Real-time view of national traffic conditions via the National Traffic Info System (NTIS).

- A digital component library – “design once, use repeatedly” (although you need to be careful that the use of standardised designs doesn’t stifle innovation).

- Drone surveys – reduction in risk to manpower on highways

- Data acquisition and analytics during construction to develop a “Haynes manual for construction”.

- Live task monitoring and reporting of progress, resource levels, reserves etc.

However, despite the successes above they admitted that introducing innovative technology is not straightforward. I’ve read that BIM will mean we don’t need to rely on physical surveys anymore. Great news, but as they said in the presentation, surely we shouldn’t have had to do that since CAD was first used if it was properly employed. Therein lies the problem, before introducing a new technology you first need to make sure the people and processes are ready for it. Definitely a lesson in there for the military (MAKEFAST?, MOSS?, JPA?, ORIENT?)

Look at the people (why are they not already doing it and are they ready for it?) look at the business model and processes (what is the need and what are the limitations?)

Barriers to adoption of technology can include confusion (certainly in my case), training burden, hardware and software costs, data storage costs, security of data, reliance on specialist personnel for operational continuity and what if it all goes wrong?

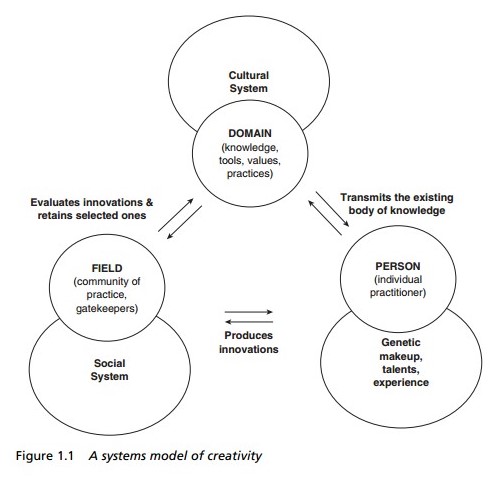

I attended a workshop on innovation as a test for some training the Think Up are delivering (https://thinkup.org/) and this presented a similar idea to that which I think was first coined in a systems perspective of creativity by some author with a crazy name full of consonants (http://www.sagepub.com/sites/default/files/upm-binaries/11443_01_Henry_Ch01.pdf).

He presents it diagrammatically as:

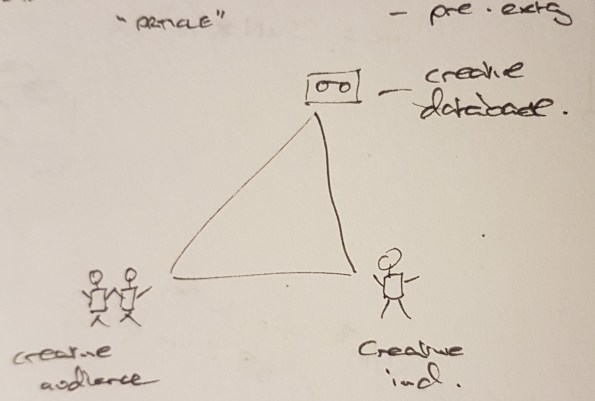

I prefer my own notes from the workshop:

The workshop concluded with a discussion on how Expedition can encourage innovation internally. There were many suggestions including having a “dunce in residence” to ask seemingly stupid questions that then spark innovation (a role I am happy to fulfill), more talks from suppliers, innovation reviews at key design stages. They were enthralled by my suggestion of “tea & toast” as a useful discussion forum when I said the military do it. They thought it showed the military as a creative and forward leaning organisation allowing daily sessions for open discussion of ideas without an agenda. I did point out that it was just an opportunity to eat toast and occasionally drink port but I think it may make an appearance in the office soon.

As a look forward – the next installment will feature how we can use innovative materials. There may or may not be a quiz afterwards with Champagne (Asti) up for grabs.