Archive

Damage to buried pipelines

Whilst enjoying a Friday morning lull in tempo, I thought I’d produce a quick post updating everyone on a small portion of my work on the Joint Operations Centre (JOC) Project; a part of the wider East Campus program.

Work thus far has been varied with business as usual mostly focused on construction contract administration, quality control management, and project engineering. Additionally, the project’s lead engineer often gives me additional tasks which can almost be viewed as projects. The latter mostly concern issues on site that need a combination of both project management and technical understanding to resolve. As an example, one of the first tasks given to me concerned cracked valves in one of the underground pipe networks, which will be the topic of this blog post:

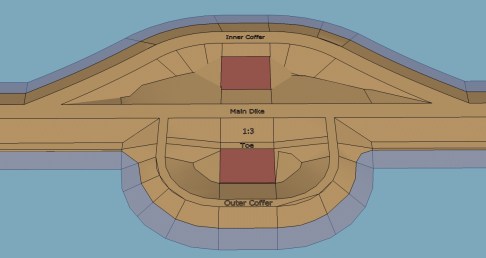

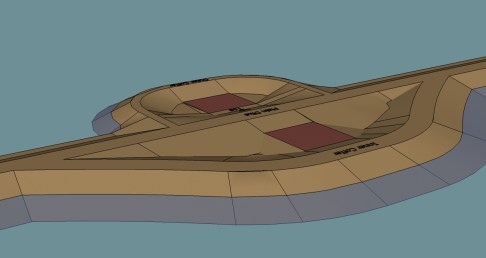

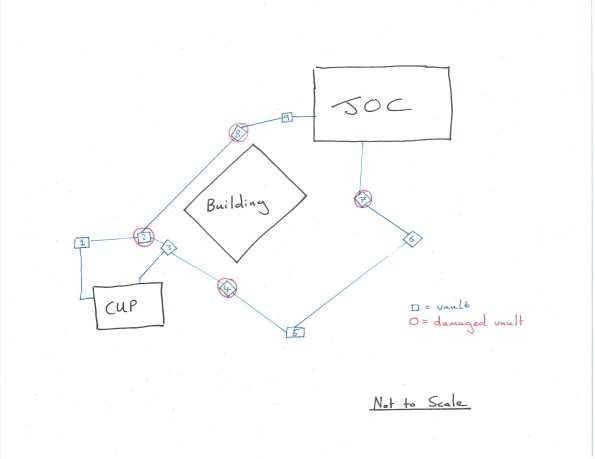

The majority of the JOC’s cooling is performed by chilling water in a separate building, the central utility plant (CUP). Chilled water is pumped from this plant to the JOC, where it is warmed at heat exchangers before returning to the CUP to repeat the cycle. The path between CUP and JOC is interspersed with mechanical vaults that allow maintenance and access to a number of valves on the underground pipe network (See hand sketch below – the blue line indicates the pipeline and includes both supply and return pipes; note the redundancy with two paths). Unfortunately, a number of valves within these vaults became damaged with large cracks appearing in the fittings. Testing of the valves confirmed the damage was to be caused by flaws in the design or fabrication of the valves. I was tasked with leading the root cause analysis and resolution of the issue.

Surveys of the damage suggested the cause lay in excessive settlement of the pipes between several mechanical vaults. By modelling the pipes as strip foundations, I was able to use Burland and Burbidge’s method to produce a ‘fag-packet’ calculation of expected settlement that corroborated this hypothesis (survey data indicated actual settlement almost 3x greater than predicted).

I was then responsible for co-ordinating numerous meetings between contractor, client, the designer of record and ourselves (USACE are the client’s representative) in order to agree a path forward. As you can imagine, nobody admitted fault and neither was anybody prepared to spend money to prove where fault actually lay. Stuck in a catch-22 situation, I was able to persuade the general contractor, Hensel Phelps (HP) into hiring a geotechnical engineer to investigate the issue. I was also able to secure financial authorization to get the designer (AECOM) to evaluate the results of my own investigations and provide recommendations. This was to also include copies of the designer’s original work, confirming the expected settlement of the pipe under assumed loading. This report, after a number of returns due to missing information, finally arrived yesterday. AECOM’s design used the modified Iowa formula – a well-recognized method of calculating displacement in laterally loaded “flexible” pipes (I must admit, one of the surprising revelations during my analysis was the fact such large steel pipes are considered flexible). The difference between using my Burland and Burbidge method and the modified Iowa formula was my results suggesting 50% more settlement (3/8 inch compared to ¼ inch). However, this may have also been caused by AECOM’s grillage analysis and subsequent live loading on the pipe being slightly less than my own.

On site, HP, has already completed replacement of damaged pipe sections. They have also performed additional remedial work within the vaults by unbolting undamaged connections, allowing free ends to deflect and reconnecting with specially fabricated ‘offsets’. On the basis that the soil is coarse grained (so long term settlement is less of a concern) and the stresses from settlement have been released through the disconnection program, it is “hoped” that the issue has therefore been resolved.

Presently, the plan is to attach strain gages to the newly connected sections and monitor for future settlement; my work to confirm what happens (and who pays) if the strain goes beyond the agreed threshold continues. The contractor is only liable for damages and the costs of repair and replacement for a year after final acceptance – after which, the costs sits with the government who would then need to prove fault and take legal action to cover damages from either the contractor or designer.

The whole experience has taught me a lot about the contractual relationships within both construction and also large government projects. It’s also developed my management skills in terms of co-ordinating multi-disciplinary and stakeholder meetings (in this instance mostly mechanical engineers are involved as it concerns their feature of work, but I’m also getting a lot of exposure to electrical and commissioning engineers in another of my roles).

Finally, I’ve noticed that I’m far more understanding of the general contractor’s stance during periods of conflict compared to USACE management, who are often very untrusting; I put this down to my relative independence compared to the rest of the team here but I suppose it could also be a result of something personal, cultural, or my military background. Has anybody else observed something similar or different on their projects?

Finally, a teaser for anybody on phase 1 currently considering the USA as your attachment location. the rendering below shows the initial architectural concept for the East Campus program (It’s one of the few images of work that are releasable – The JOC and its large rounded roof is on the far left of the picture). There will be work here for at least another decade with multiple opportunities to cover several projects simultaneously, all at different stages of construction. If you’re interested and would like to know more (both civil and E&M), just get in touch!

Life as a mechy

With less than a fortnight before I relocate 40 miles up the road to Kinloss I thought I’d give a quick update on my life as a mechy.

Flowserve. I had a look at what I was achieving here and quickly came to the conclusion that the limited gain I got from it was not commensurate with the travelling and general faff that came with it and as such have pretty much removed myself from the project. My lasting legacy? Communication has improved between Flowserve and Woodgroup and I produced a small piece of paperwork (TMR length) on sticking points from a Flowserve perspective that was greatfully received from the BP management. It was essentially a constructive critique of Phil the package engineer – who sits opposite me within WGPSN and is technically very competent but personally a bit of a knob and as such can be a real hindrance to the project. His abrasiveness and unwillingness to communicate has greatly stalled things but understandably he is not without blame. Anyway, with over £500k of project variations and the expected completion date now 6 months to the right I’m not unhappy to be letting that one go.

Sparging. My sparging pipe (OK, Swift’s sparging pipe really) is looking pretty good. We had the design review last week and I’m currently doing check calcs in Finglow to ensure the vessel into which it is being installed is suitable. It blatantly is, but it’s good for me to be doing the calcs. I did my own designs for connection methods and ran them up on Autocad too (I figured I needed to become proficient in it sooner or later) so that was good.

Pressure Vessel Calcs. I’ll be spending tomorrow and maybe Thursday reviewing some pressure vessel calcs against ASME VIII. These are for the Lube Oil Skid on the PWRI Pump – a beast I can’t escape!

SPA work. With the TAR due to start in a month I’m still chasing round BP engineers to get projects signed off. This is a common occurrence with all SPAs as the BP management realise that yes, they too need to take some accountability for the modifications. All going well though.

Touching children’s minds. Imran and I have been down the local school teaching kids how to build cars from shoe boxes and dowel. We’ve done two sessions now and go back next week (they’re decorating them this week) to see how they fair going in a straight line down a ramp. This is part of the primary engineer programme, stimulating interest in Britain’s future engineers.

Next Week. As well as an obligatory leaving drinks/dinner in town and the car race at Kingswells Primary School I’ll be mostly handing over my Mechy and SPA work and reminding myself what I’ve done since last April so I can impress the IMechE panel on 1st August!

And away from work.

- Been swimming with dolphins in the North Sea – the water’s actually quite nice once you get used to it but the dolphins had disappeared by the time I got far enough out.

- The move to a quarter in Kinloss “seems” to be sorted and we’ll be moving in in a fortnight’s time. Housewarming on 13th July if anyone fancies it?

- I officially smashed the Edinburgh marathon with a time of 2:56:54, raising £550 for Combat Stress – that’s over £3,000 for the charity in the last year!

- And Imran’s found himself a new line of work… having been asked to see Pete (Head of Projects and Mods) yesterday he thought there may be some high-level project work for BP on the horizon. Turns out that Pete was after someone to dress up in “Army rig” and do a little display on Beaver Camp this coming weekend! Get in!!!

Where does the time go? 21st May

Well then, sat in the KLM lounge at Schipol, supping on Bombay Sapphires, I thought that now was a perfect time to update you on my goings on. Generally I’m in a bit of a three-way: on Tuesdays I’m in Etten-Leur, progressing the 3rd PWRI pump, while the rest of the week is roughly an 80/20 split between WGPSN’s mechanical team and BP’s Projects and Mods team. Life is good and busy as ever, and since I’ve been talking specifics recently I’ve added a few figures to this month’s blog!

- Flowserve. As BP/WGPSN’s technical expeditor I’m the interface that has been credited with getting the £3.5m 3rd PWRI Pump project up and running again. Most of this is done by ensuring that conversations are “more friendly” and that all parties are aware of the others’ issues. I am projecting my personality to get the best out of all involved and as such the project is progressing much better. This gives me a great insight into relationships and all that management stuff, but also the intricacies of a project and the little things that make a big difference and delay projects. This includes:

- Documents not being signed off in a timely manner – when I started the project there were 44 outstanding documents for review (by WGPSN); today there are only 6.

- People (BP management) getting angry as they’re not in the loop on what’s going on.

- The WGPSN package engineer and Flowserve project manager having a pissing contest and looking for faults rather than workable solutions.

- Technical Authorities (TAs) getting “overly” involved (maybe – see below).

It’s also been good to see the parts coming in from the supplier and getting fabricated – although I’m sure I could tick this box by visiting a fabrication shop (as indeed I have done!)

- WGPSN Mechanical Team. Based in the same office as BP (part of the Focus contract), I’m now working as a [mechanical] discipline engineer alongside two CEngs and a lad on a graduate scheme. My work is primarily based on the 3rd PWRI pump and has included/ includes the following:

- Checking valve spec for the lube oil skid for the 3rd PWRI Pump. This was good as it allowed me to get stuck into BP’s Engineering Technical Practices (ETPs) and other documents – mostly ASME and API, that are the industry standard.

- Writing the specification for pickling and passivation processes that must be followed after a test fit between the super duplex shaft and a carbon steel replica of the housing (for the PWRI pump). This was good as I had to research exotic steels, the natural passivation of stainless materials, the pickling process that allows the surface microstructure to be “cleansed” and then methods for testing the purity afterwards. I then submitted this to WGPSN’s Quality Assurance (QA) for approval and it will be used in the future.

- Looking at the NDE for the super duplex components. This is interesting but I’m still trying to find the line between getting overly and unnecessarily involved because the TA is mad-keen on it (everyone needs a hobby and his is metal) and ensuring the right QA is met and the super duplex components are the right spec.

- Working on the most-hated project (by both me and the new SPA) that I was SPA for, the “compressor mods” project (currently valued at £2.3m). I’m now responsible for the mechanical work on the degassers – vessels that “bubble” nitrogen through a sparge pipe to remove hydrocarbon gasses from the seal oil that is recycled through the system (Figures 1&2). This is good as includes me researching sealing methods, cutting, confined spaces, and working with the supplier, Swift. It is also good to be a small part of a project that I was running a few months ago, as I can now see the frustrations the mechy had!

I’ve also got some good CPD done: a trip to Exona materials lab to see their testing methods (very similar to what I saw at uni a decade ago) and a Factory Acceptance Test (FAT) of a pig launcher that’s being installed at the end of the Magnus TAR. There’s an IMechE lecture in town tomorrow night about the Pelamis Wave Generator – I can’t wait!!!

- BP Projects and Mods. Here I’m carrying on with the two remaining projects that I have sole responsibility for: the insertion of a glycol balance line (£67k) and the replacement of single isolation valves with a double block and bleed system (£250k). This has included some risk management meetings relating to the management of change – essentially making sure that there’s full agreement (from the Asset) on all the changes that I’m making to the plant so that if it goes tits up in the future then my decisions have some higher-level sign off. No problems so far, I’m pleased to say.

I’ve also been I’m also been advising on some of the projects that I’ve handed over, including the decommissioning of various gas trains (£550k) and the automated relief of the cold boot (£670k) that are being executed this summer, and the exchange of the B Crane (c£8m) and the installation of additional living quarters on ETAP (c£10-15m) that are still in development.

- Other news (the interesting bit):

- As I’m getting thinner (now at 68kg in prep for the Edinburgh marathon this Sunday) Dougal is getting bigger and now weighs over half what I do. To Liz’s delight he is also learning how to leopard crawl through the dirtiest of ditches (Figure 3) and frequently finds tadpole-filled ponds to swim in. He’s amazing.

- Liz and I both raced around Balmoral in various trail races a few weeks back – Liz finished in the top half of the 10k race and I was 12th (from 297) in the 15 mile race.

- I did some climbing instructing in Wales this weekend on the REMEC meet, really good to be out and about with sappers again and surprisingly good weather.

- We ticked off another idyllic island a few weeks back: Lewis and Harris, with some beautiful white sand/ blue sea beaches (and drizzle). Off to Orkney for a long weekend at the end of the month too – see if I can get Liz up the Old Man of Hoy?

- Looking further forwards, we’ll be moving to a quarter in Kinloss in July. After Phase 4 I’ll be based around Aldershot whilst I do my PDT/MST and then deploying on HERRICK 19 as SO2 Infra from November (subject to the SO2 board – otherwise I’m jobless!)

- And finally – I got a business card from someone last week and it listed MInstRE with his post-nominals. Turned out he’s in The TAs and was a thoroughly nice chap. However, I was a little bit sick in my mouth when later on I saw the reverse of the card: a ¾ profile mug shot of the said engineer! Have any readers of this blog had similar suprises with business cards?

“Living in America” (cue James Brown…)

Finally after 5 and a half weeks we are nearly settled in the US and actually have working internet!! From turning up at Dulles Airport (of Die Hard 2 fame) on a sunny Friday afternoon in mid March with only a couple of suitcases and 2 hyperactive children, we now have a fancy town house (terraced house in English) with a SUV and convertible parked outside (to blend in), we own smartphones and a smart widescreen LED TV, broadband internet at 20Mbps and today our stuff arrives from the UK. I will not go into the heartache and pain (not to mention the $23,000 we have spent) to get here (most of it actually reimbursable) but needless to say it all takes quite a bit of time. Yes the Colvins have finally joined the 21st Century! We have received a tremendous amount of help from Matt, Ulli and Ben who having been through this already and helped make the process as painless as possible. Barbecue at ours, once I have bought one!

Work started well meeting up with Matt and Ben as well as all the other Army Officers in the district for the OPD week as Matt has described. The Dinner Night should get particular mention (great effort from Matt and Ben) because it is the first one I have had in a floating restaurant on a reservoir at sunset and also it was our introduction to the USACE Dinner Night traditions, in particular the brewing of the of grog. In a nutshell, the junior officer makes a dirty punch for everyone to share but with some poetic significance attached to each of the ingredients to produce a potent but enjoyable brew that is then used to liven up the festivities. A USACE dinner night should be tried at least once in a life time.

Initially I spent 2 weeks in the USACE Baltimore District Office. This was to get my USACE email access applied for (still not got it after 3 weeks!) as well as meeting the various departments who I will be responsible to or might need to contact when out in the field, from the design teams and contract managers to the environmental and legal teams. I was able to go on a field recon of a potential project (a boiler house refit in a barracks block) before going to my field office in Harrisburg, Pennsylvania. The project I will be working on as the only resident E&M engineer is a $53 million roof replacement of a main distribution depot on site. This place is enormous, with a site footprint of 43 acres (1.9 million square feet) which uses an internal Scalextric track of trolleys to move orders around the site. It runs 24 hours a day and cannot be interrupted in its operations during the refit because it supplies operations overseas (photos to follow once I get clearance…). The roof has been redesigned and all mechanical and electrical services are being upgraded to improve efficiency. Currently Matt’s Solar Wall is not linked in with any other environmental condition monitors and each work station (an open area every 2om in every direction) on the shop floor has its own heating/cooling controls for that area making for a very inefficient heating and cooling system. The new system upgrades all heating and cooling machinery and attempts to centrally control the environmental conditions. At present the work has not started as there are RFIs and pre construction issues being ironed out. This a Design Bid Build Contract where an Architectural Engineering company has produced the design for USACE (who only design 15% of their projects) and a contractor has been selected for the construction. Thus there are complications arising from drawing interpretations at all levels!

And in Other News

Aside from terrorist bombings, fertilizer factory explosions, shootings, gun control debate (why should people need checking before buying a gun and ammunition at a gun convention?), live terrorist hunting and a hurricane warning, it has been relatively quiet. However a leading Yoga clothing outfitters company has suffered huge losses on the stock market after it was ‘revealed’ that its leading style of yoga trousers had a faulty batch where the material was see through once worn. Apparently during the “salute to the sun” warm up exercise people at the back of the classes were being treated to a view of the moon and more – (underwear ruins the line………). Customers are being offered a full refund.

Roadkill Count (back by popular demand)

6x Racoons

3x Deer

2x squirrels

8x anonymous piles of dried out fur

1x Owl

1x St Bernard

Country Song Titles

“Come and take a ride on my big green tractor (if you scream we can go faster)”

“I wish I had been a cowboy”

“God is great, beer is good, people are crazy”

“I am old school (and won’t cheat on my wife)”

See y’all!

Its been a while, but things are ticking along fine in the design office

Hmmmmm, been a while since I’ve written one of these, anyone would think that a thesis, several reports, a day job and moose-dodging in the Alaskan wilderness might use up one’s blog-writing time…..!

For the serious stuff (if like me you read the funny stuff first, scroll down to the bottom):

I’ve now been working the Mechanical section of the USACE design office for a couple of months, and am enjoying the work greatly, the 3 hours each day wasted in the Baltimore commute not so much, thankfully though no car accidents yet.

The largest single piece of work I’ve been working on has been progressing the design of a renovation of some military accommodation in Boston. As handed to me, this was at a very early stage of development and so I have been able to take responsibility for the advancement of the mechanical design. This has been considerably slower than I would have liked due to the necessity of learning several of USACE’s software programs that I am unfamiliar with (I long for HEVAComp!) It does seem that every individual step requires a new piece of software, so whilst I am broadening my horizons dramatically, I am getting a little frustrated with it all.

I am currently evaluating which technology to employ for the updated HVAC system, thus exploring many HVAC options, ruling out the truly ludicrous, and conducting an annual energy analysis of the most likely. The most feasible few, I have explored in more detail; 2-Pipe, 4-Pipe and Water Source Heat Pump in order to cost the initial retro-fit installation. I produced a whole-of-life costing for each option and this is leading me towards the WSHP. The next stage of this will be a more detailed design of the WSHP, although this depends on future funding approval (see below – sequestration). One other frustration is that I have had to work entirely from poor quality pdf As-Builts, given that the opportunity for a recce (jolly) to Boston is not on the cards. It certainly hammers home the importance of good quality As-Builts.

Other responsibilities within the section include inspection of completed drawings for adherence to fire regulations, which gets considerably easier once you understand the basics of US regulations and can anticipate common problems. It was slightly embarrassing to have to point out an error made by one of my mentoring co-workers in a drawing already released to the contractors, which seems to have now highlighted a serious and complex problem that I am now required to help him fix (whoop!). The problem was that he had implemented a system that would easily end up using the main through corridor as a duct, never a good idea! Clearly this is difficult to solve, but much better to have caught it early.

Problems at the SSP continue to roll on.

I am still maintaining a link with the construction work happening at the SSP and USAMRIID. The USAMRIID is moving into the fully fledged commissioning of all the diverse systems, and also getting closer to the point where the contractor ceases to be able to argue that his schedule is true to life. The communication within the SSP project appears good on the surface yet very little work is actually happening and almost inevitably it will move to litigation in due course. I am hoping to be able to observe this.

One of the problems that may critically affect the entire future use of the SSP is the poor concrete quality in the basement, which leaks ground water, not ideal for a bio-containment facility….. If this cannot be solved it may force extensive rework.

New projects on the burner.

I have a couple of new projects on the go, both of which are basically writing specification documents. One is for the plumbing of the renovation of a military building, and yep, you guessed it, it requires me to learn yet another piece of software (and liaise with the IT department for installation, which in itself is a mighty challenge!). The other is editing an Request For Proposal (RFP) for the fire suppression systems of some US Airforce installations in Abu Dabai. This is an interesting insight into the requirements of the fire suppression system and the USACE standardisation (or lack of) of specification documents.

Sequestration concerns.

I’m sure the media has adequately relayed that the US Government’s inner workings are about as cooperative as a box of coathangers, so they have rolled from one near financial miss to another, and the current solution appears to be implementing a four day week for Government workers. This is yet to be finalised within USACE as many people are employed as part of the project funding and thus making the situation more complicated. The lack of clarity is generating lots of rumour control, with people trying to work out what they will do with an extra day off a week (and 20% pay cut). This may affect project budgets but no one is sure yet.

In other news.

Close but no venison steaks for the Hancock family after a hunting season where something called a thesis was getting in the way of a good hunt! I’ve heard that there is to be a deer cull in the UK, hopefully I can help!!

We had a brilliant delayed honeymoon to Alaska, where oddly enough it was quite cold! We stayed in a wilderness hut at -30C on Valentines Day – I really know how to treat a wife on a special occasion….. We did see the Northern Lights, learnt how to husky sled and snow shoed up a mountain until we almost caused an avalanche (we snow shoed down pretty quick!)

I also managed to convince a co-worker to go on sabbatical last month – which management was pleased about, not because she was bad at her job but rather that she had been planning to quit outright, this way they get to hang on to her for a while.

Sarah is looking forward to quitting her job – having recently had to fire a temp for sleeping on the job, mainly bad because he was the site nailgun operator and was standing up with his finger on the trigger.

I hope that everyone is getting on well with their theseseses, it seems very close to hand in date and to us all getting back to the UK. Aaaaaaaah, proper Cadbury’s………

Phase Three coming right up…

Phase Three coming right up?

After months of wrangling about me getting some real technical experience (A and B competencies – aka design office experience) to complement the wealth of project management, team leading and communication skills (C, D and E competencies) I’ve amassed over the last 11 months, I’ve finally got somewhere – but a little further afield than working upstairs for WG PSN who are our main contractor for our technical engineering…

The reason? Well, it seems that although WG PSN’s mechanical engineers are incredibly busy, they don’t really have the work here [in Aberdeen] that their Engineering Manager, Ian Maycock (FIMechE) thinks is suitable for me to develop the competencies that I require to be able to sit and pass chartered review six months from now. And my management (the Team Lead, Peter Neilson and our Engineering Guru, Martin Fragell, also a FIMechE) agree.

But what they (BP and WG PSN) do require, is someone to go and work alongside one of our suppliers, Flowserve, who are currently falling behind on a rather large and quite expensive, produced water re-injection (PWRI) pump. It’s not completely clear what my ROE are just yet, but it seems like I am to go and work with them at the factory/design office in Breda for a few days a week, analyse the problems, and then come back to communicate these problems with the BP management and WG PSN engineering team in Aberdeen, with a view to being able to resolve the problems quickly and effectively back in Holland the week after. I’m told that it is excellent engineering, very mechanical and really technically detailed and complicated, so it does tick the A and B boxes – mostly because I will have to get well and truly immersed in it to understand, and develop, the damn thing! From what I understand, this is one of ETAP’s big process concerns right now (and notably, will be one of the biggest pumps in the North Sea upon completion), and there is plenty of engineering to see me through til Phase Four.

Good thing or bad thing?

Well, if I’m honest, Liz and I do quite enjoy living together, so starting the weekly commute in March rather than August is going to be a bit of a blow, but the hard facts are that working on my jobs hasn’t (in my eyes) given me enough technical clout to sit chartered review right now, nor by July. Could I have done things differently? Well, I’ve worked well (by all accounts) on the jobs I’ve been given, it’s just that BP don’t do the detailed engineering themselves, we just assimilate the information from our teams.

The technical piece is something I’ve been pushing since November, and pushing strongly since January, but with changes of management it has fallen by the wayside and I’ve let it go on, so maybe it’s just me to blame (sob, sob). The weekly commute will be a pain in the arse, as will living out of a hotel week-on-week, but hey I’m not here for an easy ride, I’m here to become a chartered engineer! Hua!

Anyway… other jobs as follows:

ETAP ALQ: Getting handed over to Cat B projects this month, or possibly next, on completion of a structural engineering review by AIG

Bunkering Lines, Cold Boot and Post-TAR decommissioning: Getting handed over this week

Decommissioning, DBBs/SIRPS compliancy and Glycol Balance Line – I’m keeping these as I just can’t let go! This way, I will see them from Appraise through to Offshore Execute. (Well, not decom as I inherited that, but it’s been my most hassle-free project, so I’ll keep the coals burning til offshore execute and “tick off” three TAR jobs).

And in other news:

Liz and I went out with REMEC last week to their Winter Meet based near Fort William. As well as outstanding conditions, it was also good to meet up with Lachlan Robertson and Paul Golding, who are both due to assume STRE command this summer. With the meet being an informal part of the Himalayan expedition selection (Sept – Oct 13) it was good to chat to them about my odds of being able to get away from work to be a part of the expedition; clearly, a lot depends on being in the ‘right’ STRE – and not theirs, as they want to be going away too! Fingers crossed…

Oh, and Dougal the “wonder pup” has passed 30kgs. He’s going to be a machine…

Offshore on the Magnus platform

Offshore!!!

After three cancelled trips I finally got onto the Magnus platform to have a look at the jobs I’ve been working on for the last ten months – and now I’m stuck here!!! Having been delayed on Shetland on Saturday night we got in on Sunday morning and I was supposed to head back around noon today but alas, the fog stepped in once again and here I am, sat in a cabin at the top of Magnus (itself sat in 190m of water, 160 km NE of the Shetland Isles). Not a bad place, but having had family (younger siblings and spouses) up with Liz in Huntly since Saturday evening I’m feeling a little sorry for her!

So what’s it like? Well, in many ways it’s a 30 year-old rust-bucket! It’s quite strange wandering round actually, as all the photos I’ve looked at and plans I’ve studied are now there in front of me and some things seem very small and others a lot bigger. Inside the quarters there are nine floors up to the helideck and a broken lift, and “outside” in the process (working) areas there are 3-4 floors and an open piping deck, with an ALQ perched in the middle as well as the prominent cranes, drilling derrick and flare stack. It’s certainly impressive, and although its only 56 x 62m width-wise, getting anywhere takes a fair while due to the labyrinth of walkways and closed off areas, interspersed with stairwells and heavy, sealed doors. Geeks (you know who you are) – you will like this New Scientist article (from before Ben’s time!) that shows the scale of it: http://tinyurl.com/ayvb98l

Anyway, it’s been brilliant here, on a kind of treasure hunt looking at where the Piping and Instrument Diagrams (P&IDs) tie into the real thing. As most of my jobs are in the execute stage it has been a bit of a sightseeing tour since most of the engineering is done, other than looking at the Bunkering Lines job which is just going into Define…

Bunkering Lines

If I was to listen to our contractor, WG PSN, this job is bigger than Ben Hur. But going out to look at it, we are removing the existing fuel and water hoses (they’re replaced every 2-years anyway) and adding a semi-permanent fitting so they can be extended onto the flotel’s gantry when it pulls alongside in 12 months’ time. Which is all of 15 foot away. Difficult as it is to actually get a survey booked and done, the adage holds true: time on recce is seldom wasted!

Cold Boot

Two blogs ago I explained that the Cold Boot project had been delayed – but didn’t quite realise the implications of leaving it as it is. And this site is secure, right?

So… currently (and this has been the case for 4 years now), the boot drains “fluid” (mostly water and a few hydrocarbons) into the open drains. In doing this, the nearby gas monitor is switched off, but not the others (as this is judged to be too many). So, last week they drained it and the gas monitor picked up some hydrocarbon and caused a “yellow shutdown” which caused a partial but not complete shutdown. Without going into too much detail as this is now subject to a lot of investigations, this led to a build-up in pressure further down the system and kaboom! A 22” water pipe, specced at around 60 bar was subject to approximately 140 before it exploded and split wide open. Fortunately there was no one present as they would have been royally f*cked. Anyway, there’s lots of folk looking into it – predominantly because the pressure should not have built up like that and also because the platform’s been shut down since. So that’s nine days now that Magnus has not been pumping something like £1.5m worth of oil and gas. A day. Ouch.

Understandably, I’ve got a meeting lined up for when I’m back in to let people know how the project is progressing so it won’t happen again; they’ll love it when I tell them we’re looking at 1Q 2014 at the earliest!

Other jobs:

Bravo Crane has now finally been handed over, the last piece of which was a few days at Kenz in Zaandam, near Amsterdam last week. Finally, I thought, four of us going out for Amsterdam, what could possibly go wrong? Well ladies and gentlemen readers; never overestimate the power of civvies. After a good steak dinner, we retired to the hotel. I could not believe it, sat on my bed at 2130 hrs because the others were all tired/under the weather. Maybe I should have dragged them on my run (minus something in shorts and t-shirt in central Amsterdam, aah yeah) a few hours earlier to get some life into them. It just felt wrong (and I did check that they weren’t just going out without me…). I did consider having a night as the lone ranger but clearly hanging around civvies has made me weak too!

ETAP ALQ is nearly ready for handing over to the Renewals Team/ Cat B projects, as being £10-20m it’s outside of the “remit” for projects and mods. Shame really as it was interesting.

And design work (me doing some technical design) is due to start in March – better find that calculator of mine!

And in other news:

I’m doing a presentation to BP’s graduates (there could literally be a hundred but I’m expecting a few less) on leadership on Thursday as part of their “lunch and learn” series where they have a non-O&G developmental presentation. I think I’ve got a copy of MATT 6 somewhere…

Running on the Shetland Islands is windy and rainy; running on a running machine is just plain dull, but I’ve got to fight the pounds somehow!

Spare time offshore would be ideal for getting work done if the internet wasn’t as slow as it is (hence no sexy oil platform shot today folks). In all, this makes the “free time” all the more frustrating!

Liz and I haven’t entered any gnarly races this year (boo!!!!!), just the toughmudder, Edinburgh marathon and Balmoral trail race. Am considering running the Spey Way (60 something miles) at the end of June – can’t wait til the thesis is smashed and I can have my life back again!

And once again, Dougal is still getting bigger…

Verifying references (thesis)

Guys – don’t do this as it causes pain!

Joking aside, I just thought I’d confirm a study from Deloitt (Wauld, C, on fuel usage (it’s steadily increasing to 22 gallons/soldier/day on average) with some figures from their Government Accountability Office and Congressional Research Service (should be pretty solid). But oh no, whilst 68 million gallons of fuel, on average, were supplied by DOD each month to support U.S. military forces in Iraq and Afghanistan (Solis, 2009) there were 188,000 “boots on the ground” (Belasco, 2009). Which means a paltry 12 gallons/soldier/day.

My only thought is that Solis’ figures somehow don’t include airpower. In which case they are hugely misleading as the figure should be much more (124 million gallons a month). All the more confusing is that I imagined that there might be more fuel requried (because of air/avn) rather than less.

Any thoughts?

References:

Belasco, A. 2009. Troop Levels in the Afghan and Iraq Wars, FY2001-FY2012: Cost and Other Potential Issues. http://www.fas.org/sgp/crs/natsec/R40682.pdf accessed 9 Feb 2013

Solis, W. M, 2009. DEFENSE MANAGEMENT. Increased Attention on Fuel Demand Management at DOD’s Forward-Deployed Locations Could Reduce Operational Risks and Costs http://www.gao.gov/assets/130/121644.pdf accessed 9 Feb 2013

Wauld, C, 2009. Energy Security, America’s Best Defence. http://www.deloitte.com/assets/Dcom-UnitedStates/Local%20Assets/Documents/AD/us_ad_EnergySecurity052010.pdf Accessed 30 Jan 2013

All Change in the Aberdeen Office

All Change in the Aberdeen Office

Well, a month back and there’s a good amount of stuff going down in the Dyce office.

Staff changes

Promotions all round in my department which his good, as my Programme Lead (1-up), Eugene is keen to iron out those things that frustrated him when he was an SPA. (He’s replaced Hugh, who was a little bit “wet” at times). Similarly, Pete Neilson has taken over as Team Leader (2-up) and he’s pulling no punches in holding WG PSN to account. A few of their management have been “moved on” since his promotion and he’s bought in new staff to oversee their methods of working. Pete is taking a much keener look at the individual projects and our management and initiation of them. His predecessor, Paul Mullan, was good but never seemed to be around, basing himself in the main BP office rather than our separate office. This may have been good for him personally, but I think the leadership of the team suffered for it.

At my level, we have a new SPA who I am handing over the B Crane changeout to. While this is a shame as it was a good job to be running with, it will eventually give me time to get stuck into some discipline engineering. This is something that has been amiss on my placement but I’ve just came away from a chat with WG PSN’s engineering manager (a Fellow of the IMechE who sits on the interview panel) who is reading through my Personal Competence Statements in order to find the best projects to get me through Review.

It may transpire that I actually hand over all my jobs, which would be a big shame as they’re not due for offshore execution til July and I’d like to get them there! Still, no time for sentiments when I’ve got a thesis to write and A and B competencies to develop.

Contractor Changes

Such is the nature of this kind of work there’s been a good few chaps from the office move on over recent weeks. As well as being paid anywhere from £60-100+ an hour, contractors are on 1-weeks’ notice (either way). This means that if a new job comes along they are more than happy to move on within that length of time; regardless of a successor being lined up or not. With some drama, our lead process engineer was told to clear his desk then and there, whilst one of the construction planners sat next to me managed his full 5-days before moving on to better and brighter things. With one of the SPAs off at the end of March and the BP planner away at the end of February, there are more and more empty desks by the minute. This is causing some problems already; our cost estimator left in November and still hasn’t been replaced. The comment of there being far more jobs than “qualified” people in Aberdeen has never been truer.

My jobs

These are all progressing well with one notable omission, that of the Cold Boot upgrade…

This has massively stalled due to two main factors: the postponement of the Controls Improvement Project (CIP) and the realisation that there is no suitable pump to empty the boot (a vital part of the project). Being located at the bottom of the platform, already having a low NPSH, potentially having muds within the “fluid” and being at low temperature (JT effect kicking in there too) there really is nothing on the market that can cope. Separately, the postponement of the CIP means that any tie ins to the ESDVs will have to be through old-school “manual” logic gates cards – literally hardwired AND/OR gates that slot in to the old control panels (Ben would love it). So, while I can still get most of the TAR work completed, I am redefining the complete scope to use a N2 blow-down system instead; something that is so very different it will need a new HAZOP and LOPA to be done to ensure it is safe. Furthermore, when we re-connect the ESDVs we may need a gas outage to allow for them to be programmed; this is where it will get painful…

While this is a motherfudger of a change, I am thankfully not entirely responsible having inherited it midway through Define (plus, the CIP project only got postponed in December). Still, it is a bit of a nightmare and something I want to get back on the straight and narrow before handing it on. To be fair, having HAZOP’d the old (pump) system we are in a far better place for getting this N2 system right after a good Define.

On the plus side, it also looks like a much better solution that might be fully ETP compliant and so a permanent modification, rather than the pump system which was only a temporary solution until 2016.

Extracurricular Activities

How are you all getting on with CPD? The IMechE meetings here are at the opposite end of town, so I’ve only gone to one so far (it took 90 mins to get through the traffic and then it was really boring anyway). Still, BP are hosting one later this month so that will just be a trip to the other office. As for now, I’m just about to head into town so I can get stuck into some fun with the Young Members’ Panel; what better way to spend a Tuesday night?

Purple Monday

Poplar Island: Last time I blogged I had a conundrum on suitable temporary coffer dam configurations for the installation of the proposed dual purpose inlet / spillway structure. The proposed solution seems to make better use of equipment and resources and avoids re-mobilization of manpower and equipment. There are other potential benefits in so far as one of the temporary structures may be able to provide another dual purpose by acting as a ‘check dam’ for later stages of the project but I need to research this a little more first.

I have begun the stakeholder engagement to see if the proposed structure could have any wider benefits to the other users (such as the Ports Authority, University of Maryland or the Environmental Protection Agency) as I have seen testing stations precariously jerry-rigged to similar structures around the island. I basically want to see if we can incorporate something into the design that will make life easier for others. The initial response has been one of outright flabbergast. Apparently people don’t normally think outside of their bubble and the invitation to have input has so far been well received…..though I may live to regret it and start sticking to my own bubble as a result!

My current puzzle is to figure a way to make stop-log structures stop leaking without introducing bulk heads or spending any money…..this will be a fun one. [Richard – I’m sure you’ve puzzled over this in a previous life, perhaps during a long pause in a bell-ringing session – any thoughts or guidance will be gratefully received (bell ringing or otherwise)].

Building 45 Seismic analysis: Having been totally flummoxed by random circular references in the codes I have finally made some headway. The problem is that it’s not just the building codes that count, it is also subject to additional requirements because it is a federal building….which also references more design guides but in a way that only serves to complicate the issue. I have since discovered that because of this they have had to produce a ‘codemaster’ booklet just to help us poor mortals actually put pen to paper instead spending a lifetime reading in circles. I have undertaken a pretty extensive desk study and created the framework for the report to hang off of as well as generating a field check list for the survey itself to make sure we don’t miss anything. Thankfully the seismic analysis is based more on empirical data and observations of particular building types and their observed responses to seismic activity from previous events as opposed to having to come up with a super cone-head analysis and FEM….phew. Unfortunately the owners appear to want the moon on a stick included within their scope of works and now the whole renovation is in jeopardy unless they can trim it down somewhat.

Levee Screenings:…are long and tedious. Thankfully they spread the love on these so I won’t be stuck in damnation for too long. They are actually a really good way of learning from the experts, some of the knowledge they’ve spent a lifetime building up so I won’t complain.

Occupational Health and Safety Audit: Me and my big mouth. Having done my last TMR on H&S and asking lots of H&S questions of everyone, when the shit sandwich of dealing with the baseline info for the ARMY wide review came in – guess where it fell. I did a bit of questioning with the poor soul at the next level up who was eating an even bigger sandwich, it turned out the deadlines for this were tighter than PET student with a 75% thesis submission due. Ultimately I devised a questionnaire, gathered a sample set of folks, got the data and turned it around in quick time with a whole bunch of wider recommendations to push up the chain. It’s all gone quiet again for now but the next phase will be to revise the office H&S procedures, update the risk assessments and make sure everyone is processed….perhaps I will fake a heart attack that day.

Officer Professional Development: The most recent OPD was a trip to Washington DC with the other ‘green skins’ to have a look at the Federal Emergency Management Agency (FEMA) and the USACE HQ to see how they deal with emergencies, coordination of resources and command and control. Having comfortably making it through security to the briefing room FEMA decided that they still haven’t forgiven the Brits for that little misunderstanding in 1812 and ejected Ben and myself. Not to worry – we caught up with everyone for the USACE HQ brief where we got all the info anyway (go figure). Unfortunately I made a comparison of us being the foreign soldiers creating admin issues to the floppies at Sandhurst. I think Ben is now paranoid that the USACE lot think we’re the floppies….sorry Ben.

The OPD concluded with ‘Chem-Ops’ – the codename that was applied for us going to one of the officer’s houses and learning how to brew beer….all educational. Ben and I added to the educational theme by delivering a presentation on the history of the Corps, key achievements, current day and future……while they drank beer. I found that this makes an audience much more forgiving and would like to propose that this is how we should undertake the senior officer de-briefs in phase 4.

Other News:

I’m quietly confident that my long term light-rail stalker has moved to Canada – I feel safer already, but I appear to have picked up a stalker from the IT department now and am convinced he’s even more dangerous. I’m considering tracking down George in Canada to tell him all is forgiven….or better still – hook him up with IT stalker.

Ulli has progressed well with her horse riding and took part in her first fox hunt recently…..I didn’t ask what was for dinner that night.

…And the Baltimore Ravens have taken the Superbowl. What a game! They were…….running…..and hitting each other……and sometimes kicking the thing. I really have no idea what was going on, but if they had lost I am led to believe that Baltimore would be in flames about now. The parade is this Wednesday – so I will acquire a giant purple foam hand and show my support….and hope that nobody asks me anything about the game.