Archive

Weeks 16-19 (16 July-19 August 2012). Juggling Nicely

16 July – 12 August 2012

Weeks 16 – 19

Juggling nicely

Wow there, things have been busy for Camp Warner in the North, so here’s a bit of a summary starting with the most exciting bit (that turned out not to be that exciting after all).

ETAP ALQ Survey

Well, after a bit of fighting and some determined conversations, I managed to get offshore, albeit without a chaperone. Luckily, the ability to walk around confidently ensured I could recce effectively, whilst the green hat policy (everyone wears a green hard hat for their first three months on any ‘new’ BP platform) meant that people were always happy to explain things. My method of interview meant that people were happy to chat away which was good because I needed to balance opinions. Even more than normally, people were keen to hear the Army perspective, and I think afterwards some of them viewed life on an ‘austere’ oil rig slightly differently. Facilities are really quite plush: shared-2 man rooms with Sky HD and all the sports channels (but not all the ‘other’ channels); free wi-fi in the quarters area; phones dotted around the place – press 9 for an outside line; cinema; TV rooms; quiet rooms; smoking rooms; gym; sauna; as much food as you can eat… The lads get good bonuses for working off-shore and huge ones if their flight home is delayed. As for wages, the HSE Advisor (HSEA – effectively 3ic of the platform) who I shared an office with is on a salary that equated to £120k a year. Not too bad when you consider the shift pattern of 2-weeks on, 3-weeks off.

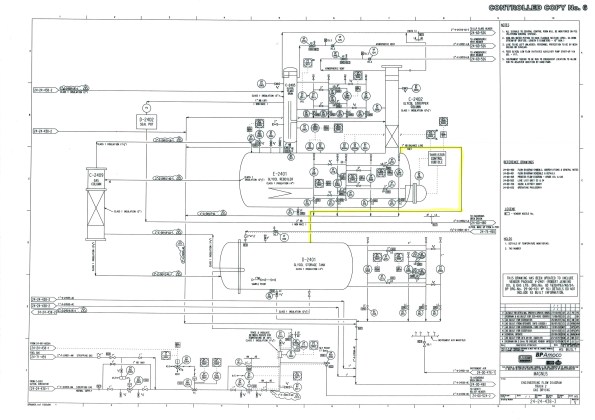

Anyway, as I was saying before digressing about my next career, the survey was incredibly useful and the following were appraised:

Location. From a previous study for the Search and Rescue Helicopter, the findings were verified and no major changes have been made since then to cause problems. Key factors will be the placing of a laydown area and bunded fuel storage above the accommodation – soundproofing must be considered as well as protective measures associated with the fuel. Site below in Fig 1.

Figure 1. Laydown area on ETAP QU Platform

Muster area/boot room. The muster area must have 0.35m2 for each person for mustering so will not be big enough if there are 30 more POB. As such, various options have been considered for enlarging this, such as breaking through into the Emergency Response Team (ERT) room (that will need to be relocated) or the dirty area smoking/non-smoking room. My plan would be to relocate the ERT – the dirty area rest rooms are the only respite for some workers (unless they de-gunge) during their shift; reducing them whilst increasing the amount of POB would not be sensible!

HVAC. Separate system required as the existing system will not cope with the increased demand without major internal changes

Electricity. Ample power available and distribution capability from existing switchgear

Potable water. Either capacity for this will need to be increased (difficult) or some desalination and purification required to slow down the rate of vessel supply. (For E&Ms, consumption is ~350l pppd)

Black water removal. Big problems with current drainage capacity so my advice is to run the removal on an entirely different system OR incorporate the refurbishment of the old system onto this project.

Lifeboat. One more required for the increase in numbers, suitable sites found – opne better than the other and should require little platform modification. It’s like it was meant to go there…

Camp Boss facilities. Ran by Aramark, messing and laundry facilities will cope with extra demand with 2-3 more staff. Rec rooms are sufficient although will be busier at peak times (X Factor/ Pop Idol/ major sporting events).

Other facilities. The old temporary living accommodation (TLA – the white boxes on the left in Fig 1) currently has some Cape and WG PSN guys using it as offices, but the TLA is in poor order (as befits a temporary structure living outside its expected life cycle) and consideration should be made for removing it. This would allow for more room for the ALQ but then what happens to the guys using it? My thoughts are: 1. do we care? 2. Do they have squatters’ rights, as that’s effectively what they are? 3. Do you want more office space building “whilst we’re here”. I can get these questions thought about in meetings mentioned below, but in line with good Front End Loading (FEL) we must consider this now rather than in a year’s time.

Next steps. I’m meeting up with my Runcorn based design team on Tuesday to get them to move forward with the appraise study of different options, and following this I will get the key stakeholders (Area Engineering Support Team Leader (AESTL), Offshore Installation Manager (OIM), Business Manager, JRE and HSEA) together to Set Business Priorities – i.e. fully understand the Project Objectives that they see as most relevant; and hopefully gain some consensus on them! We will then get the Appraise study complete and get the same stakeholders together for a Peer Assist; their buy in is important as it is their platform we are making the modifications to. Getting the FEL right will save lots of pain later. I can then produce the DSP and move forward to Select.

Timelines. To be discussed on Tuesday, but I’m hoping to complete Appraise by the end of September and Select by the end of the year. This will allow me time to finish Define by the end of June so on-shore Execute can happen July 13 – April 14, and offshore Execute May – June 14. Easy – and it will play perfectly into whoever’s here next (if anyone).

In other jobs

Also this month I’ve:

- Covered the installation of Ish’s exhaust stack change out; it’s currently 11 days ahead of schedule.

- Got frustrated with the lack of work done on the Magnus TAR mods (Glycol balance line and conde pumps). These jobs have been bounced between Runcorn and Hull and are back to Runcorn again but with a mostly new team. My main aim this Tuesday is to bang heads together by charming them into working better as a team – or maybe just working full stop. The piping engineers are going out to survey next weekend so I need to renew the leadership piece and ensure they’re motivated and aware of what is required. I fear a lot may have been lost in the movement of the jobs their end.

- Investigated failings related to the Andrew Meter Prover project and found out a lot about FEL, Value Improving Practices (VIPs) and equally importantly, methods of ensuring that only the correct projects are selected to be developed within a portfolio.

- Investigated the bunkering of fuel oil and potable water from a supply vessel, through a flotel, and onto Magnus. Currently, I’m sorting out a trip to Gdansk to survey the Safe Caledonia flotel (454 bed floting caravan. This thing is bigger than Magnus, which is the biggest single permanent structure in the North Sea) before it departs for Andrew in November, so a bit of a deadline since any mods are likely to require long lead items.

Figure 2. Safe Caledonia Flotel

- Worked on the W160 gas-lift tie in; this will be kicked off in September, straight into Define.

- Taken on 5 more jobs on Magnus. These are all at different stages and are being handed to me by one of the lads on the graduate scheme. They are:

- Cold Relief Boot upgrade

- Compressor vent mods to improve the shaft sealing systems on the export and flash gas compressors.

- Decommissioning of redundant Flash Gas, Export Gas and Chill Gas Trains 1 & 2

- Train 1 Export Gas & Flash Gas Compressor Lube Oil & Seal Oil Modifications

- Train 2 Export Gas & Flash Gas Compressor Lube Oil & Seal Oil Modifications

- I am out surveying my original TAR jobs on Magnus in October, so shall ensure I can have a good survey of the new ones whilst out there.

In other news:

- Finished 28th in the epic (4700 ft ascent over 14 miles) Dufftown Highland Games hill race – was fine going up the hills but got smashed on the descents – my new training regime incorporates “negative hill sprints”.

- Went to Kari Sims’ wedding to Andy McGee down the way in Inverary. An excellent Scottish wedding: highland dancing, a great selection of single malts and midges.

- Heading to the Deep South this weekend to see the Olympic mountainbiking in Essex

- And last but by no means least; we’re off on Honeymoon at the end of next week. 10 nights of adventure in Borneo followed by 4 nights of that relaxation stuff on Pangkor Laut. Back in time to see Nick Beighton in the Paralympics.

Weeks 14-15 (2nd to 15th July 2012)

Weeks 14 and 15. Shovel it my way please

The last fortnight has seen a good amount of progression on my existing jobs, a bunch more arrive on my desk, and a visit from the CI and SI.

New jobs

Mungo W160 Wellhead

This fortnight I’ve been getting to grips with the principals of getting oil out of the ground through a tube in a series of casings, sometimes within a caisson, and as with everything, everyone (Mon the project engineer, Abbas the petroleum engineer, and Gavin the drilling engineer) has a different idea of what we need to do. But I’ve got it sorted. The problem is that there’s a leak in the 10¾” casings around 2km below the sea bed, so a 75/8” casing is going inside the 10¾” casing and a new tube (4½” rather than 5½”) going inside that. This requires a new spool (designed by Cameron) which means pipework modifications to the gas inlet (we pump gas back in between the casing and the tube to lift the oil out).

So, after getting my head round the technical version of the above, I’m going to go out to Mungo (a Normally Unmanned Installation, or NUI) that ties back into ETAP, to do a cloud scan (think Batman’s phone) of the wellheads area so see exactly where everything is. I’m then going to get the drawings of the new spool (pipe) that goes onto the wellhead and work out how the new gas lift supply lifts, how the control mechanisms change, how this affects the stresses on the wellhead and how we go about the execution of the project.

And when I say “I” and “we”, I mean that I’ll lead a team from WG PSN to do all this.

Magnus Bunkering Lines

So, after next year’s TAR and my previously mentioned Magnus tasks, a flotel will pull up alongside with 100+ beds for drilling season. However, the place the flotel parks itself is slap-bang where the fuel oil and water resupply vessel would normally dock to. So, I need to ensure that there is a system in place to allow the resupply vessel to dock to the flotel, the fuel oil and water to transit through, and then onto Magnus.

Problems here will include the sizes of the attachments, lengths of hoses, quick-release mechanisms, flow rates, a variation in flotel docking and stability mechanisms and the fact that should we need to modify the flotels or hoses, we need to get hold of them! Drillfest starts in Sept 13. The flotel for the first 6-months will be Prosafe’s Safe Caledonie (Currently in Gdansk, and then onto the Andrew platform), after which we have COSL’s Rival, which is with Conoco Philips, undergoing marine assurance right now.

I’ve met with a Dutch engineer who’s on BP’s Renewals team (he’s new to the offshore industry) and a Northerner from England who’s BP’s flotel expert. I’m going to get some initial funding to have a kickoff meeting with WG PSN who will do the define and execute the modifications under my watchful hand.

What the hell happened with Andrew’s oil metering prover???

(Note, Andrew is a platform, not a person). For this project (yet to start) I’ll be working out why a £750k project of installing a metering prover ended up costing £3.3m, and looking like a dog’s dinner. Perfect for critical analysis, I think, and maybe even a good TMR…

In other news

Liz and I met a whole new part of society we never knew existed at T in the Park last weekend

Liz has completely taken over as Adjt 39 so we’ll be seeing even less of each other during the week

The period of blazing sunshine I reported about in April – that was the summer

Roadworks really are sh*t when you’re commuting by car – currently adding a third hour of driving to my day

And London to Brighton is my next challenge – no, not the cycle ride or the mini rally…

Weeks 12 and 13 (18-29 June 2012)

Weeks 12 and 13.

So what have I been up to? Nothing particularly new really.

Magnus jobs

I’ve dug further into these so I can become a ninja on all related questions, and this has been informative, digging through P&IDs to find the most up-to-date version, and chasing CTRs so I can get a purchase order for the work. This was not easy as the Runcorn-based JRE was off-shore for a few days, but I caught him when he got back as he dropped into the office. “Oh no, that’s being moved to the Hull office” were his comments on the subject. Cue some mild annoyance, a few conversations and me finding out that Runcorn had tried to pull that stunt, but it was later brought back to Runcorn. This week will I see if that message has been passed on…

All in all though, the work’s going well and I should get out to survey early August.

ETAP ALQ

I’ve tied in with the Renewals team to hear what their plans are, and they’re more than happy for us to progress through Appraise, so it can be compared to equivalent costs of “walk-to-work” (a boat dropping folk off in the morning and picking them up at night) or a flotel (floating hotel that is anchored in and fully hooked-up to one side of the platform for a period of months). The CTR is in for me to sign off and I’ve picked up a handful of points for clarification. The crux of me writing the Appraise and producing a Decision Support Package (DSP) lies on a survey, which is proving next-to-impossible with their TAR starting in August. Presently I’m pencilled in for late July, but not getting my hopes up.

Ish’s LPBC exhaust stacks

Ish’s beloved exhaust stack segments were at ASCO’s holding yard in Peterhead today, so we went to have a look at the assembly rehearsals before they’re taken out for the forthcoming TAR. This reminded me of a “Weeks 1-5” platoon harbour area rehearsal, as the staff p*ssed about in super-slow time working out what went where. The lifting bridles weren’t numbered which led to some confusion and only two members of staff were allowed to operate the spanners. (21mm hand spanners; they didn’t have air/electric ‘drivers). Oh, and not all the holes on the flanges lined up with the bridle holes either. Oops. The smoking policy for the site was “it’s OK if you’re not inside a building”, and so fags were hanging out of their mouths most of the time, and I had to ask one of the (many) supervisors why the guys in the cherrypicker were wearing harnesses and landyards if they weren’t clipping them in before anything was done about it. Fortunately, things got done in the end and, importantly, the parts are now ready to go.

I’ll be covering this for Ish while he’s back for Phase 4, so will get a full handover this coming week.

Bunkering lines for the Magnus flotel

I asked for more work, and just before Hugh (programme manager) left for his holidays, an SOR appeared in my inbox for me to investigate, review and re-issue. On inspection, this is a survey and modification of the bunkering lines for potable water and fuel oil that are required when a flotel docks with a platform. More in due course, avid readers!

And in far more interesting other news…

Celtman 2012

I raised over £2,000 (inclusive of gift aid) for Combat Stress last weekend by completing the inaugural Celtman event on the West coast of Scotland. This consisted of a 2 mile jellyfish-riddled swim (reduced from 2.4 as the water was just 11 degrees), 125 mile cycle (that was an utter ballbag; most unpleasant as I’ve not been able to fit in many long rides) and a mountain marathon (that was pretty easy in comparison). Everyone at work was incredibly supportive and it turned out to be a very easy way to get known around the place! More information on that at www.justgiving.com/chriswarner

Weeks 9 – 11. 28th May – 16th June 2012

Weeks 9 and 11.

It’s all “normal jogging” at the moment here in the Dyce office, with the following keeping me ticking over:

[Magnus] Glycol pressure relief system. Hugh (Programme Manager) and I worked through the Appraise and Select gates for this, and I’ve now kicked off the Define phase of the project with the WG PSN design house in Runcorn. Their piping, process and structural engineers will all work on the specified design piping design, whilst further contracting out the installation of Passive Fire Protection (PFP) to the glycol reboiler and heat exchangers. This new design must be executed during next year’s turnaround (TAR) window that starts 1 June 2013. During the TAR the whole platform is closed down, costing £m per day in lost revenue.

The pressure relief system is fairly simple in itself; a change from a 1” pipe to a 2” pipe. From the P&IDs (Piping and Instrument Diagrams) there is even a spare 2” nozzle to tap into, but looking at a photo (below) it’s not immediately clear where this is, and we may have to tap into the bridle instead. If I ever get offshore I may be able to have a look…

As the SPA for this, I ensure that WG PSN aren’t wasting time (£) producing nugatory work throughout the phase, and also grip them when things slow down. I report to Hugh and liaise with the TAR team – and do my bit to stop them from putting their noses in too much!

[Magnus] Installation of DBBs on the Condensate Pumps.

Just as the glycol pressure relief is required because it is currently ‘unsafe’ (if there was a fire, it’s calculated that the pressure increase in the boilers would be well above the design pressure and lead to catastrophic failure), the conde pumps are not SIRPS (Safe Isolation and Reinstatement of Plant) compliant, meaning that the pumps (the two conde pumps operate in parallel) cannot be taken off line without a complete train outage. So… some new valves need adding – simples! And it does seem pretty simple really! Because the installation will be conducted during the TAR, the trains will be fully bled and the new valves installed in place of the old ones. The new double block and bleed valves will allow for work to be done on the plant whilst the other part of the system remains leve

Is it really that easy? Of course not. The P&IDs show that the pipework is made of Incoloy 825, and so any new valves must be of the same material. Are these available off the shelf? Almost undoubtedly not, and so are a long lead item. One of my main deliverables at the kickoff meeting was to find the lead time for these – it might be that they are sourced and the pipework designed around them if the lead time is that long!

ETAP ALQ.

With the Appraise resting on a survey (recce), one may be mistaken that this would be a priority and a 6-week waiver given for my visit. But alas, the Offshore Installation Manager (OIM) hasn’t granted this. Cue a few terse e-mails from John (Programme Manager), and now we are just waiting for them to assess their priorities. Still, no rest for Warner – I’m digging further into the proposal and meeting the Renewals team leader tomorrow to see what “their plan” is. It may be that they’re either tackling it from another aspect (floatel) and we can tie in together for the business case. From a Plans point of view, all they really want from me is the broad brush of how much it will cost to install and operate. Wait out…

Magnus boom rests.

This is one of Ish’s I’ll be running with whilst he’s on Phase Four, and as far as I can see, currently consists of looking at big bits of steel meccanno which are being fabricated at a nearby workshop. Once complete they will be stuck on to some raised bolts on the platform’s floor and allow the cranes’ booms to rest upon them. Difficulties will involve ensuring they are manufactured to a tolerance of 5mm, and then lifting these 30-40m hunks of steel into place and bolting/welding them together. At some point in the next month I expect to have a formal handover of this project.

More work please

I’ve asked for more and will hopefully be getting some pipelines to work on. These are very good from an engineering side of things, and also (so John tells me) need to get done soon, which means I may get to see some of my work through to completion! We are looking at installation of these in November, so will be a fast turnaround.

Week 10 – Island Hopping (Scottish style)

Whist the South was suffering rain over the Jubilee Week, Liz and I took to the Inner Hebrides and had a week of uninterrupted sunshine! Did some good scrambling and walking, the occasional sea swim (not long til the big race) and then finished the holidays with the Lowe Alpine Mountain Marathon. I got back to work bronzed and rejuvenated (Liz got back to work shattered…)

Exploiting civvies…

If there’s one thing civvies do that the military don’t, its sponsor you! Maybe it’s because we’re all earning less money than they are, or maybe also because we find others’ challenges less impressive as we are all legends anyway, I don’t know, but the support I’ve had for my latest challenge (2.4 mile swim in a sea loch followed by a 125 mile cycle and culminating in a mountain marathon) is huge – complete strangers donating £50 and sending me e-mails of support! Check out the donations here: www.justgiving.com/chriswarner

Week 8, Ubique. 21st – 25th May 2012

All over the place this week as the title suggests.

Lifting Appreciation Training. This course was an introduction to moving things offshore, and included LOLER standards, lift planning, rigging, and practical exercises; it’s easy to forget that in the offshore environment you can’t just drive forks everywhere and so rigging is used far more than I had imagined. Indeed, for BP, a person is not allowed to lift anything above 20kg and so other means are standard practice. The practical exercises included establishing rigging systems for moving things (in this case a dummy motor) through an area with beams and pipes in the way; and also playing with a 40 tonne pillar crane.

Maximo Work Management One Day Essentials. This was an essential course teaching me how to raise work orders and requisitions. What I found interesting were the teaching methods; lots of magnetic labels to position in a team, and also good use of IT so we could all work on the software on a simulated database. If only JPA was taught so well… Oh, and the handouts were issued on a memory stick at the end of the course. I love civvies!

Runcorn kick off meeting. And the ETAP project is under Appraisal! Finally held teh meeting so that the study can now get under way to estimate the costs of ALQ on ETAP. What they can’t do, however, is work out the operating costs, so there’s still a lot of work for me to do on that. Still fighting through the red tape to get my flight booked offshore, but that will happen with time.

Design Work. Had a good chat to some of our (WG PSN) engineers to see if I can get involved with some in-depth technical design, so I can be 100% sure to tick off competencies A and B. The two lads there (the team should be six!) are both chartered through IMechE so know the score and it will be good to work with them. Interestingly, Ish’s engineer for the LPBC exhausts has just been moved by WG PSN, so I might be filling in that role!

In other news. Damaged my calf in a race, so resting that at the moment before the two marathonesque races that face me over the next month. Open water swimming is still proving to be awesome although the most recent places were quite tame, taking the form of sheltered lochs; cycling is giving me some sharp tan lines, even this far North. Liz is now fully trained as Adjt and looking forward to lead elements of 39 moving up in June. The Waterbeach summer ball was good fun but not the epic that it was a few years back, where I first met Steve and Faye…

Week 7, Steady. 14th – 18th May 2012

Really quite steady this last week. I’ve finished the SORs and got requests for Requests for Initial Funding (RIFs) for three projects signed off, so finally kicking those off on Wednesday/ Thursday in Runcorn. They are:

ETAP – ALQ as discussed in previous blogs – an awesome project I’m quite excited about

Magnus – Conde Pump upgrade. Install some new spools with double block and bleed valves; and add an integral bleed port; on to both trains on the condensate pump.

Magnus – Fire relief on Glycol boiler. Investigate the best method of pressure relief on the Glycol boiler; currently the 1” pipes are undersized, so we need to look at some alternative options. Mark, see Figure 1.

As for Bruce access platforms – Hugh’s got no money available at the moment so they’re on hold til the books can be rebalanced.

Right, last proof read of the TMR and then to bed. Exciting day tomorrow as I get to play with some big cranes! Doing a 1-day acquaint course which should be fun. On Tuesday I’m doing Purchase Order training that will be a lot less fun.

Week 6 7th 1 11th May 2012

Week 6. 7th – 11th May 2012

Bank Holiday weekend – well, I took the Monday morning off (recovery from a 125 mile bike ride in the snow, and a 20 mile run up some mountains), so that was nice!

But what else, I hear you say? Well, the week was very much focussed around my Runcorn study into Distributed Engineering which has changed with time as my research developed. What began with an investigation into methods of Cost Reporting and Cost Estimates – these being the much heralded excuse for delays from PSN’s Runcorn Design House, my recommendations came back saying that:

- Communications between Project Managers is excellent

- Current Cost Reporting methods are suitable; delays are inevitable and this can be relieved by a few more Cost Engineers in Runcorn

But more surprisingly (and damningly),

- The leadership from the PSN Aberdeen Delivery Manager and his Delivery Focal Points is weak

- The Delivery Manager in Runcorn needs to play his part as a leader better, and get himself a Project Services team ASAP

- If they don’t start working on morale, and make the (Runcorn) team feel like part of the Focus Project, they’re going to lose them, fast!

We sometimes forget how good people management is in the Army (compared with PSN, anyway!)

Some context… BP contract most of their design work to Wood Group PSN (abbreviated to PSN), who work alongside us (BP’s Projects and Mods Team) in Aberdeen as part of the Focus Project (fully integrated etc etc). Because there is such a huge demand for work, they have a ‘third floor’ of the building situated in Runcorn, Cheshire, which currently employ 72 staff (compared to ~130 in Aberdeen). A bunch of us from BP and PSN visited for a conference on Tuesday and frankly I was shocked. The BP staff all got there on the red-eye flight, met the PSN guys in their office and put faces to the voices we’d been dealing with on the phone; really good stuff and great for cementing relationships that you can’t do by email. The PSN guys rocked up late for the meeting, and didn’t even meet the main part of the team in their office, just the key management in the conference room. And then were all out of there the next day at lunch, cutting a meeting short to do so! We (BP) were there til mid-Wednesday afternoon and so could chat through all the bits and pieces; or use the wireless to crack on with routine work otherwise. With this being the first conference of its type in Runcorn (the office was established in June 2011), most of the PSN (ABZ) contingent had never been there and seen the offices.

So one of my Programme Managers asked me my opinion, and I told it was all pretty piss-poor and bad mannered really; we’re all supposed to be the Focus Team, but PSN (ABZ) clearly didn’t give a flying fook about their staff in the South, who it transpired were kept massively in the dark on the big picture and thought it was all doom and gloom on the forecast (it’s not, its booming and they’ll be expanding!). And clearly, that’s no way to run a team. I continued to say that unless they bucked their ideas up they’d be haemorrhaging staff when better options come along (which is likely as there’s a big engineering boom around there). Oh, and also that the presentations were pretty lame, there was no clear aims of agenda, the IT broke down (at one point their Plans man was talking with an A3 graph held up in front of his face) and they should be embarrassed. So guess who gets to lead the next one! Me and my big mouth…

The weekend – TMR writing and a bit of open water swimming at Loch Morlich – bloody freezing, but good training for the CELTMAN!!!! See www.justgiving.com/chriswarner for more information 🙂

Week 3. 16th – 20th April 2012

Ask and you shall be given

Just as it seemed there would be little work to do, I am now working for 3 different programme managers on three completely unrelated tasks – in fact I’m wondering if one of them has any relevance for me at all… In addition to the Bruce P60 Bridge Bearing Access Platforms (I’ve written the SOR which is now being reviewed by the Programme Manager) I am working on the following:

Study into the Eastern Trough Area Project (ETAP) platform POB (Persons on Board). Prior to putting more accommodation modules (or similar) on the ETAP platform I have been tasked with working out what the addition of manpower would mean – more lifeboats (certainly); more kitchen space (probably); increased electrical demand, HVAC, water and everything else (you betcha), another helipad (maybe not). Presently ETAP can hold 113 POB, so 30 more is a fair increase. I also need to delve around and see if the figure of 30 is an ‘all-in’ figure inclusive of logistics (cooking, cleaning etc) or if that is for drilling alone, and so more support staff would be needed. And work out who said 30 in the first instance anyway!!! Having not been onto ETAP or any other platform yet I’m still not completely au fait with the goings on off-shore, so a recce is definitely required!

Depending on the results of this self-defined study, I might find myself designing new accommodation to go on the platform or doing a cost-analysis of different options – accommodation barges for peak periods, daily commutes or use of floatels. Although this analysis is not engineering per se, this task (which could end up pretty huge – we’re talking about spending many £ms here) will require me to get involved with many different departments in the SPU (Strategic Performance Unit – I am in the North Sea SPU) and test my critical analysis. It will almost certainly get me off-shore too which will be good.

ETAP Platform at night

Runcorn – is it working? Nine months ago our main design-house contractor, PSN, were asked by BP to expand their engineering capacity. They did this by forming an office in Runcorn, Cheshire, who now deal with some of our design tasks and other engineering. But – as I found out first-hand at our team meeting a fortnight ago, the BP staff are rather dubious about its effectiveness. Here, the PSN guys here can easily be called in for meetings, or chatted to informally, but there is a thought that Runcorn is taking a bit longer, and so steps in Captain Warner to investigate. This is clearly not engineering, but very much focussed on management of contracts and HR. Will it be useful for me? I think it will give me a better idea of how things work/ don’t work and certainly it will build my business acumen as I delve into hours worked and Cost Value Reporting (CVR) by different offices. Some indications actually suggest that the engineering done there is better than here and that the only problem lies in the cost reporting: maybe all that is required is a restructure and better use of conference calls or Skype – most of us have webcams on our work laptops, after all!

Other bits – work

Courses completed this week include on-line and face-to-face Management of Change training, something that BP are very big on, having put a failure of Change Management down as a key factor in both the Flixborough and Grangemouth disasters. I can now start the procedure of affecting any process, plant or people changes on the system.

This week I also got to wear my PPE, as I watched a rehearsal for a crane lift of a piece of duct. Yes, really. This is one of Ish’s jobs that will get handed my way: taking off the old Low Pressure Booster Comressor (LPBC) stack off Magnus and replacing it with a new one. Every lift of anything <25kg is a big deal offshore, and as I understand it must be done using a crane or similar. People get very worried that if anything falls off the platform it may come to rest abruptly on some pipeline a hundred metres below, and we don’t want that!

Next week I am away on course all week, completing the 2-day Minimum Industry Safety Training (MIST) and 3-day Basic Offshore Safety Induction and Emergency Training (BOSIET) courses, which will finally allow me to go off-shore.

Other bits – not work

The cycle to work (70-mile round trip) is not pleasant with a headwind in the rain.

Running in the Cairngorms is awesome, no matter what the weather (last weekend). Scrambling in the Cairngorms is still ‘winter conditions’ as today proved, and outstanding.

And I’m getting to meet some of the local community: in my role of the incoming Adjutant, Capt Warner’s husband, I went for (Queen’s birthday) drinks yesterday at the Lord Lieutenant of Moray’s house and tipped my hat to the local MP, a retired General and various local dignitaries.

APMP…

Kenny found my results in the Mess pigeion hole, seems I got a high of 100% for question nine, low of 48% for question four and an average of 63%. Seems that leaving the KGV at midnight (following Geek Club) paid off. How did everyone else do?

Week 2. 11th – 13th April 2012

Week 2: 11th – 13th April 2012

A short week with Bank Holiday Monday and Tuesday off (Liz’s birthday) to make up for Good Friday. The office is still very quiet but I have at least got a project firmly on my list, and that will start moving with time. Which leads me to some observations…

Pace of life here is slow. There is little sense of urgency anywhere, with most people thinning out around 4 pm – although admittedly they may get here before my usual 8am start. This may be a symptom of the Easter holidays (fair enough), or maybe just that contractors receive a daily rate and can get away with it…

Meetings tend to “go on”. I had 2 meetings on Thursday, both on Ish’s projects which will become mine as he is away for Phase 4 and departs after Phase 5. The first was a weekly update meeting on the Low Pressure Booster Compressor (LPBC) stack change around on Magnus. 13 people were around the table and the meeting lasted over an hour, most of which was a heads up on the tail-chasing that is project management – who’s done what, where sew-and-sew is with the other etc. OK, there were a few people ‘doubling up’ (myself included) but lots of the meeting was re-hashing old conversations and could have been done ‘in the margins’. – I’d better add that it wasn’t Ish that chaired the meeting, but one of the WGPSN Job Responsible Engineers (JREs) – effectively Ish’s oppo.

The second meeting was quite an impromptu chat with Tim Eley, the Business Developer for Linjebygg Offshore (LJB) who specialise in alternative crane solutions. He was bought in to offer a third solution to Ish’s big crane-change project on Magnus that has been put on hold, and may offer a better solution than the current plan which is to use a Heavy Lifting Vessel (HLV) (<$1m per day), and boy did he go on! He made some good suggestions and suggested a way forward, but then bored us by covering the same ground again and giving us more (irrelevant but impressive) examples of LBO’s previous jobs. If I was Ish I would have cut the meeting short after 30 mins rather than letting him go on for over an hour, but maybe I’m missing something…

Other things

Townhalls. I like these. These are BP’s open briefings, held at all levels, where teams are encouraged to get together for the lead and a guest presenter to bring people up to speed on what is going on. I attended my first of the fortnightly Engineering Services Townhalls on Thursday, presented by Tom Macartney (Team Leader) with a second speaker from another department. Although I didn’t stay for the whole meeting, it was good to get fed the information from the top, and he was open to comments from the floor (of which there were a few). The main part for me was the ‘blueprinting’, or standardisation of the different divisions (ours being the North Sea (NS)) so as to catch the ‘best practice’ – one of the buzzwords I liked as Ops Offr at Minley, sharing Best Practice with 1 RSME and Holdfast. For us, this means a few additions to the NS Engineering Services Team but there were no real surprises; probably because it was Tom that helper write the Global blueprint!

Jobs – my role. It is now confirmed that I will be the SPA for the bearing inspection platforms on Bruce, so next week I’ll be chatting to the Senior Structural Engineer, Colin Wilson, to discuss exactly what this might entail before having a free-for-all meeting with the main stakeholders and SMEs. Looking at the internal BP SOR, it was Colin who instigated the job so I’m sure he’ll have some suggestions!

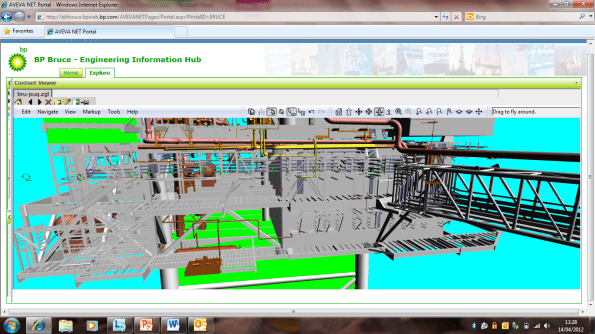

After a few hours of IT support, I finally got onto the computer modelling programme so can now see Bruce in 3D and yes, these rigs are complex beasties (Fig. 1)! It’s so easy to simplify something in your head, but as soon as you look at what exactly is going on, it gets a lot more interesting! I’m now really looking forward to meeting with Colin on Monday to discuss how to tackle this, and I’ll let you know how it goes. Clearly what I really need is a recce, so hopefully I’ll be getting onto site soon – but not until I’ve done a week’s worth of courses – with any luck these will be the week after next. Watch this space!

Figure 1. Screenshot of image of one the bridge linkages on Bruce. From what I hear, the hydrocarbon pipes going 1/3 up the height of the bridge are around the same height of a person.

Figure 1. Screenshot of image of one the bridge linkages on Bruce. From what I hear, the hydrocarbon pipes going 1/3 up the height of the bridge are around the same height of a person.