Archive

WSP and Dan – 2 weeks in

So it’s almost the end of my second week, and I’m thoroughly enjoying my new existence as a consultant. Having thought I knew a thing or two, towards the end of my contractor attachment, I’ve landed firmly back on the learning curve. Here is a little bit about my first two projects.

Lot 460 – Mechanical, hydraulic and fire design

My first job was to do the mechanical (HVAC), hydraulic and fire designs for a block of 40 flats. IN the end I have handed the mechanical design off to another engineer because the other two have turned out to be much trickier than they first appeared.

There was little water under the bridge here as this is a project that had received some preliminary work in the past before being mothballed when the developer ran out of money. Now he is back in the cash and so the project is back on. Unfortunately the engineers working on the design before me no longer work here at WSP. The upshot is that I’ve had to do a bit of back and forth with the client and some digging in the archives to find out what has gone before and to avoid repeating completed work.

The developer has been very keen on reducing the noise inside the flats as much as possible, and so hired an acoustic consultant to do a report. Some of the measures he suggests would indeed reduce the noise but would result in an extremely expensive building. The developer, as you’d expect, wants all of the benefits of the acoustic report but none of the costs.

One example of conflict of objectives between the acoustic and hydraulic performance has been in the design of the bathroom drainage. The acoustic engineer wanted separate branch drains from each fixture to a soil stack located in an acoustically treated plumbing duct. His idea is that by eliminating all changes of direction in branch drains, which sit in the ceiling void of the level below, no annoying swoosh sounds will be transmitted to the bathroom below when the sink of shower is used. I wanted to collect the fixture arms (not the toilet obviously) at a common trap to the floor waste and empty through a common branch drain to a stack in a normal plumbing duct. My idea being that this would ensure the floor waste remains charged and so make sure no drain orders escape into the bathroom. This is the standard drainage strategy in WA and can achieve relatively quiet performance when the pipes are lagged, though there can be problems with quality control and maintenance of lagging. By having only one 2 connections to the stack, my proposal also reduced the required size of the ceiling void. In the end I was able to placate the acoustic engineer by specifying all drain pipes be formed of Gerberit PP-SK (http://www.geberit.com.au/web/appl/au/wcmsau.nsf/pages/prod-drai-ppsk-1), a pipe with acoustic attenuation properties better than or equal to plain PVC. In my experience on site, the marginally higher cost of PP-SK over PVC is offset by the ease of installation, offered by its push-fit assembly, reducing labour costs. It also offers better quality control over lagged pipe – often a job given to the apprentice. As a result, the acoustic engineer, the architect, and I, are going to visit another job where a plumbing sub-contractor I have used before is installing PP-SK. Hopefully they go for it.

The fixture arms collect at a common trap to the floor waste to keep it charged. Fewer branch drains means a smaller ceiling void. Skew P trap pans allow the nastiest noise to be kept in the room of origin. Partial shot of the BIM built in REVIT.

Another interesting aspect of this job has been the design of the stormwater drainage system. The local authority mandates that storm water is disposed of within the confines of the site, so I have designed a series of soak-wells to sit under a car park on the ground level of the building. It has also been instructive to work with the structural engineer in specifying so pipework to be cast into the structure of the building without compromising the structural design.

Design of the fire hydrant system has been a little tricky. I picked up a design done by another engineer for the hydrants that had previously been sent to the architect. Unfortunately the other engineer had misread the Australian Standard and so had under specified the system. The developer, understandably with a prime focus on profitability, wasn’t too happy when I explained the system was going to be about 30% more expensive than originally planned. I’ve booked some time with a fire engineer next week so may be able to come up with some other scheme to reduce the costs, but I’m not hopeful.

The Red Barn – Rural waste water treatment

I am designing a waste water treatment scheme for a client in a remote area, where it is not possible to discharge into a public sewer, and where there is no watercourse nearby. I had been looking at a number of options, the most promising of which was to use a primary stage septic tank followed by a secondary stage reed bed then discharge, following a pass through a UV sterilizer (unnecessary but required in WA for reclaimed water), to a pumped irrigation system serving an adjacent vineyard. Unfortunately WA does not approve of reed beds. I spoke to the Chief Environmental Engineer at the Department of Health who told me, and I’m not kidding, ‘we don’t like new things here.’ In the end I’ve gone for a septic tank followed by a set of leach drains. I’ve positioned them uphill of the vineyard so that the water may leach in a useful direction.

Using a septic tank and leach drains – surprisingly reed beds are not allowed in WA. My sketch for initial planning authority submission on top of architect’s outline sketch – the notes about Hardenbergii and Brachychiton are the Gardener’s.

Anyway, that’s it for now. I’m going to ask for a mechanical project next as I think I’m being used for all of the hydraulic jobs no-one else wants, but, as the wise man said, ‘society needs good plumbers as well as philosophers, otherwise neither the pipes nor the ides hold water.’ Boom Boom!

In other news, the weather has finally cooled down to something liveable for the last few days; over Christmas we had day after day of filthily hot weather. Tasha has got a new job at the Children’s Hospital (the one that the one Steve was building will replace – does that make sense?) near our house, and I’ve joined the office 5 a side team – we’re 4th in the league. I’ve also been roped into an inter consultancy triathlon. It’s pretty tame compared to the ones Chris does though: just 250,10,5.

Gas regulator indoors?

Hey everyone. Has anyone ever come across a gas regulator indoors?

This one will soon have an AHU just below it that supplies air to an industrial kitchen. Is it even legitimate to have the regulator in an enclosed space? They work by venting gas to atmosphere – which in a plant room seems like a bad idea. The reason I’m worrying about it is that the Consultant, no stranger to a Spanish practice, says not to worry about it. Are the quantities of gas these things put out so small that it isn’t a problem?

I’ll dig out the Australian Standard, but if anyone has seen this before I’d be grateful for a heads up.

Mineral Insulated Metal Clad Cable Blow Out – Calling All Cars

Last night (5pm) we had an electrical fault, which knocked out all mechanical services to just under half of the hospital. I’ve just ( 2pm) got the power back on, and am going for a beer with the boys (this is Australia after all), and then home. The work required a bit of on the hoof engineering but went well, but the cause of the fault, and so who pays, is contested. So I thought I’d ask you lot what you think; here goes.

At about 5pm, I was doing end of day checks after we’d been doing some work on the mechanical chilled water system. When I went into the plant room above the older section of the Hospital, I discovered that power had been lost and the air handling units were off. It turned out that the HVAC system to two blocks of the hospital was inoperable. I sent electricians to the Mechanical Services Switch Board in the Plant room, and to the Main Switch Board, from which it’s supplied to see if a breaker (fuse – these are old and crappy boards) had gone. A fuse on one phase of the sub main from the Main Switch Board to the Mechanical Services Switch Board had blown. As nothing appeared to have operated in the mechanical board, I sent a team to trace the sub-main between the boards to find the fault. It was pretty quickly obvious that one phase of the sub-main, an old (~35years) Pyro (Mineral Insulated Metal Clad – MICC) Cable had blown – picture below.

MIMS cables are formed of one or more copper cores, surrounded by mineral powder (often aluminium oxide) encased in a copper sheath and possibly a PVC outer cover.

The pyros had been fixed to a cable tray using steel bands –apparently this is how it used to be done in Australia – instead of the copper straps recommended by the manufacturer of the cable. This is a picture of the type of gear they used.

On the tray, some demolished cables, had clearly once been fixed with the approved bands.

On inspection it seems that many of the steel bands had broken, and that the copper cable underneath was scored.

To me this suggests that over tightening of the straps has occurred, and, because the steel is harder than the copper cladding of the cable, the cables have been damaged. I suspect that a small penetration of the cladding may have occurred on installation, or as a result of vibration worsening damage caused by an over tightened steel band. Over time, moisture may have infiltrated the mineral insulation, breaking it down, until the a short occurred between the conductor and the sheath. My point is that this, in my opinion, constitutes a latent defect that would have eventually led to a fault, and that the client should seriously consider replacing the others cables that are in a similar condition.

The client’s representative, normally a mild managed man who just wants to be left alone, see things differently, however. He contends that either, the cable has been hit, or that excessive vibration has caused the cable, which he insists was not damaged during the original installation, to be cut by the steel strap. In either even, he insists, the fault, and so the cost, lies with us, the builder, and so he does not want to pay us for the repair work (~Aus$15,000).

I’m going to prepare a technical report form my PM about what the possible causes of the failure are, and what was most likely, and what the risk is of this happening to one of the others.

So there it is. What do you guys think? In particular, I’d be interested to hear if John has seen this before.

Dirty Tricks and Business Trips

Because one of the projects we have going on is the building of a new kitchen inside the old hospital, I’ve been looking at refrigeration a lot recently. Whilst we have a consultant for almost everything, commercial refrigeration seems to be viewed as something of a black art in these parts. With a mechanical consultant unwilling to commit to a design, and a fit-out consultant who would only provide a performance specification (‘How do I build it then?’ was my question), I was asked to do some work with a number of WA refrigeration contractors to come up with a suitable design. Immediately, I found that the gene pool was shallow, and, like the shallow reefs off this lovely coast, dominated by a rouge predator (did you know Perth is now the great white shark attack capital of the world?). It was fairly obvious that one of the contractors had managed to cut himself a deal with some of the major WA suppliers and was muscling out the others (some even told me they had been warned off); unfortunately, WA is not unfamiliar with price collaboration and corruption.

So I got the only contractor (he of the shadows) who would even talk about tendering in so we could discuss the design. I had billed it as a bit of a workshop where we could turn the performance spec into an outline design. Two things were obvious within a few minutes: firstly, the refrigeration exercises we did at Chatham were very useful, and have made us easily as competent in refrigeration design as the jokers we have to work with (thank you Mark and Jim); and secondly, that this guy didn’t know his psychrometric chart from a hole in the ground. Eventually, I was told that the price was the price ($1.3M by the way), the design was the design (done by someone else with his margin, rather than the performance spec, in mind evidently) and that I could take it or leave it, ‘but if ya leave it mate, there’s no one in the State that’ll touch ya.’ It was a little like something from Goodfellas. Anyway, it turns out he was right; no one else would talk to us and he wouldn’t budge. He was mightily displeased with me into the bargain, since it turns out he has been bamboozling us, and our client, for some time.

Having discussed this all with my PM, I was tasked with finding an alternative, which I have been doing over the last few weeks. The guys I’ve recommended we sign up (I find out for definite tomorrow, but it’s really a no brainer) are based in Melbourne, will have all of the cold room components and the chiller units assembled in Melbourne, will fly a team of technicians here to do the build, and are still significantly cheaper than the, frankly, criminals we’ve been happy to work with in the past. The result is that we save in the region of $300K and get a system that is much better suited to the client’s requirements than to the contractors profit margin, as was the case before. A bonus for me was that I had to report on the Melbourne contractor’s previous projects, the standards at his factory and of his suppliers, and the technical competency of his team to produce a suitable design. We did a test design exercise together based on the scout hut problem.

Social

Apart from the trip to Melbourne (I took Tasha along too), we’ve managed to fit in some excellent Aussie fun recently. My office took Tasha and I to watch an AFL (aussie rules) match the other day, which was excellent, and we’ve made friends with a player for Port Melbourne in the VFL (Aussie Rules but limited to Victoria, cheaper, and with more fighting) who’s invited us to the grand final in a few weeks’ time. Tasha is studying hard and has her entrance exam in Melbourne on the day before

2 Months In

Hi everyone. This is a shamelessly AER focused post so please feel free to lambast me for my dryness. Lambast me baby! More interesting (picture based) posts to follow shortly…

Here are just a few of my general experiences and observations from the first 2 months on site. I’ll do more on the technical nitty-gritty of the tasks over the next few weeks.

Experience: Updated Roles and Responsibilities

So, I’ve picked up a few extra responsibilities over the last few weeks; I’m now Services coordinator for all Public and Public/Private Shared facilities, Site Supervisor for two discrete projects, and the Services Defects Manager for all areas of the Programme already completed but still within their defects liability period. Sir John is certainly getting his dollars’ worth out of DDK.

On the public/shared side of the site, that means I’m overseeing the coordination of services in a surgical day procedures unit, a theatre recovery ward, a catheter laboratory (more on which later), a new kitchen, a medical records and training facility, a supplementary services (chapel, AV etc.) unit, a central energy building, and a heat distribution plant room. All of these involve refurbishment or expansion, and so working around other live services and, mostly, in areas where patients are still being treated.

Observation: The moto in all of this is very much hospital first and, as the hospital seems to have a pretty much zero tolerance approach to any disruption what so ever, this means anything that affects a hospital service or operation, generally occurs at midnight or on a Sunday, or (and this is my favourite) both.

Analysis: It might seem that the programme planners were rather short sited in developing this strategy; the CI remarked that it would probably have been a lot cheaper to simply build a new hospital next door and then knock down the old one. It is certainly true that the cost of the constant frustration of progress, because of the need to work out of hours, is significant; the hourly labour rates, probably the most expensive element of any work packet I’ve been involved in so far, doubles as soon as 4pm passes.

The reason is threefold:

1. There is no space. The city of Joondalup, and the suburbs around it, are expanding so fast (in no small part driven by the influx of Irish, Spanish, Italian, and British workers fleeing the hopeless prospects in Euroupe, lending Joondalup its nickname of ‘Pom City’) that there is simply no space to build a new hospital other than inside the old one.

2. Australia does not have publicly funded hospitals in the same way the UK does. Many facilities in the existing hospital are privately owned and funded. No one would pay to replace or relocate them, when they are perfectly profitable where they are.

3. Each ward or facility is in fact a business in its own right. When the refurbishment of one affects the operation of another, there may be significant compensation claims. As such the hospital’s operator, Ramsey Health Care, is particularly unwilling to sanction any interference with business as usual, unless it absolutely can’t be avoided. With each patient paying, on average, $1000 a day, not to mention the everyday exigencies of any hospital, the choice between closing beds and making builders work overnight is a simple one.

The bottom line is that it’s too difficult, and too expensive (to individual business units) to do anything other than refurbish and expand the hospital from the inside out.

Experience: I’m also the site supervisor, normally a role given to a bricks and sticks man, for the Central Energy Building and the Heating Plant Room. This means that in addition to coordinating the services, I’m also supervising and coordinating all of the civil (not that much) and general building works.

Whilst the civil and building things I’m involved in aren’t particularly technical – we have consultants for that – they come in tremendous volume, and I’m having to learn about slab, column & beam construction, sub base properties, and general building techniques and practice. The civil training we E&Ms get at the RSME is very useful here, but more knowledge of the difference between an PFC and a Z Purlin, for example, would be useful to us.

Analysis: Perhaps the steepest part of my learning curve has been to do with simply understanding what it is that the consultants and contractors are talking about. Whether talking about an purlin, a reveal, or a bulkhead, there is a good deal of terminology, that any engineer, regardless of discipline, needs to be conversant with.

Recommendation: I have found that 2 books have been invaluable as desk guides. First is the Building Services Pocket Book, published by Newnes. This is a very good practical guide to services in any building; focusing on mechanical services – which I now know dictate the design of all high level services layouts – it offers invaluable notes and is simple to understand in a hurry. The second is the Architect’s Handbook, published by the Architectural Press, which is an excellent general guide to building. I’ve also see the Building Construction Hand Book, published by Butterworth-Heinemann, but this is a little basic compared to the other two. I would recommend that all students on PET be issued with the first two books, or something similar. Alternative suggestions anyone?

Experience: Finally, as the Services Defects Manager, I’m responsible for receiving, understanding, and assigning the Client’s defects notifications, as well as identifying many of them myself. I rather walked into this job, as I found so many defect as I walked around the place, that it became easier to deal with them myself than to staff them to someone else.

Analysis: Essential to doing this properly is the ability to compare what is in from of you with the drawings. I have found that it has taken me a few months to understand, quickly, the myriad of technical drawings that are encountered on a construction site. Because the difference between a quick and amicable solution and a protracted and increasingly entrenched e-mail rally often lies in understanding the drawings and specification the fastest, the ability to rapidly interpret technical drawings would enhance the preparedness of PET students for Phase 2 work.

Recommendation: More technical drawing comprehension should be incorporated into phase 1; everything from the EWIS to the structural steel. I have plenty of PDF example drawing that could be used to set such exercises and can send them if required.

And Finally: In an effort to prevent this from being the driest post since, well ever, here are some pictures of the weather in Perth over the last few days – get it? ‘Dry’? Yack yack!

And worse is forcast for tomorrow – last week it was 30 and sunny?!?

Good News Everybody!

Exciting news, I moved into a new flat last night. Within 2 minutes, I was greeted by one of the neighbours. I was initially a bit wary of the 6’4, 120kg maori approaching me in the dark corridor but was soon put at my ease. He and his wife even helped me unload the car – unlike the neighbours at the old place they actually put the stuff in my house.

Barrington Digital Library

Hey everyone.

Has anyone been able to access the BDL from overseas? So far I’ve not been able to get through using either of the URLs they gave us or by linking from the VLE- http://diglib.shrivenham.cranfield.ac.uk/ and http://barrington.cranfield.ac.uk/. Can you get at it from the UK; maybe it’s broken?

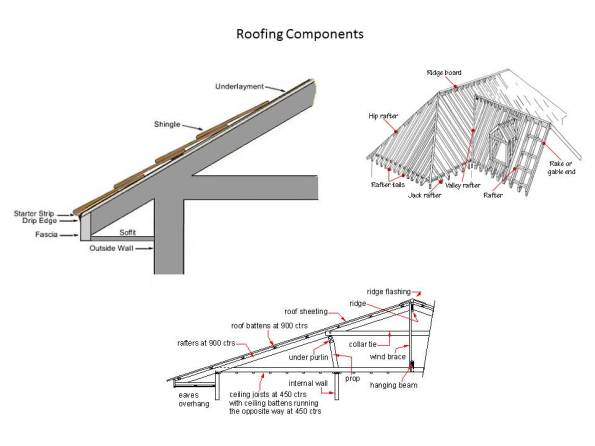

Roofing Components – Learning To Speak Builder

Have spent much of the day trying to understand what the hell my mech sub-contractor is on about. He has been telling me where he’s going to put his screws (not as funny as it sounds), but it seems all builders speak Klingon. I didn’t know half of these words so have made myself a translation slide – though you guys might find it useful if you ever need to sort a purlin from a rafter, or if, like me, you don’t believe that underlayment is really a word.

Arial Drainage – Anyone?

Has anyone ever come across ariel drainage? I haven’t been able to find anything on it from my own cursory research. I’d like to know a little about it because the hydraulic consultant on my site is telling me that it is because he has employed an ariel drainage strategy that the soil stacks and vents don’t line up. This is a man who I’ve caught out telling me porkies a few times already so I’d like to know my onions before I challenge him about it. I had understood that it was standard practice to have a soil stack that rose from the sewer in the ground slab through all floors to the roof where it vents, and that the drains at each floor run into it. I know that sometimes the stack has to make a slight detour, because drainage falls below mechanical services and structural elements in the priority of change, but thought that any deviations would be minimal and with a big radius. The deviations I’m talking about use 90deg bends and are across many meters on a single floor.

The job I am working on is a little unusual, in that there is no services riser. The section of the hospital that we are currently re-fitting was originally built as a single story, and then converted to a double, then a triple storey affair. Things seem almost to have been piled up on top of each other as the various re-fits and expansions have taken place over the years – even the structural columns have moved around (Mark, this probably answers your earlier question about the location of the med gas isolation valves – As is happening with this referb, they seem to be thrown in wherever they are needed to allow the next extension to be built). Here is a drawing of the new drainage system in my referb area, with my annotations of where the soil stacks are located on the floor below. The stacks and vents are linked by a vent header system in the ceiling above the floor shown.

Do you think that the use of air admittance valves on top of the stacks might be a more economical arrangement than using the vent headers?

Project Great – Scuba Awesome – House a Bit Tasty

Well hello everybody – I’ve finally found some internet! Hope you are all having a good time. Well done us all on APMP – I wonder how that bloke did – you know the one. Also, we all got 61% for our final design exercise.

The work bit first…

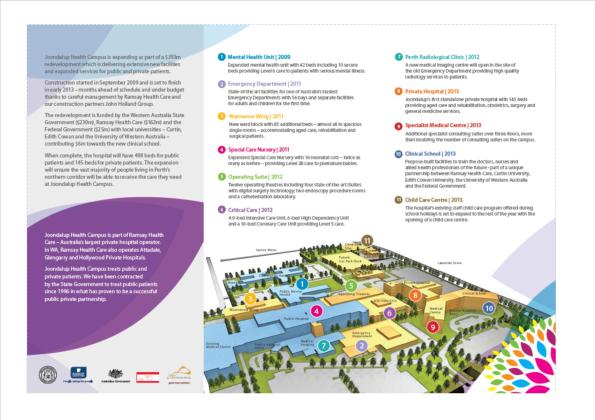

My phase 2 attachment is at the redevelopment of the Joondalup Medical Campus, which comprises the refurbishment and extension of an existing hospital and the construction of a second, private, hospital and teaching facility, including the modernisation of all services. On site interdependent projects have been let to and formed by John Holland Group, into a programme of projects – The APM would be proud. The procurement strategy selected by the client, Ramsey Health Care, is a combination of a management contract and construction management (some sub-contracts are directly let by the client), with the addition of a target price agreement. The details of the head contract are a little opaque; the Programme Manager is keen on keeping the financial stuff to himself. In any event the project is, at least overall, ahead of schedule and showing a healthy gain share for all concerned.

My role, initially, is to be the Services Coordinator for the project that will deliver the refurbishment of the existing hospital.

The nomenclature used by the Organisation differs from the standard APM model, in that the post that the APM would call the Programme Manager is referred to as Project Manager, whilst the posts that the APM would label the Project Managers are known as the Site Managers.

Attached is a briefing slide giving an overview of the programme; my project/role is concerned with elements 4, 5, 6, and 7. Because these elements are to be delivered during the period of my attachment, I will have exposure to procurement, demolition, installation and commissioning of a wide range of services.

Specifically, I’ve been given responsibility for a smaller project within element 5 – the refurbishment of a day procedures surgical unit, to be delivered by the end of August – all very exciting but I’m having to learn pretty rapido. Mostly, I’m reviewing tender submissions in the office, whilst acting as a middle man between the clients design consultants (from whom I have to get permission for almost every change), the clinicians (who want it finished yesterday but won’t let me turn the water off for half an hour) and the sub-contractors (Who ‘just wan’a smash it in mate; what’s the blady howld ap?’) on site. The work is being let piecemeal so there is much frustration, for the sub-contractors as well as for us, in getting the approvals required to put hammer to wall.

The hospital is still running as we build, and taking over the new facilities as they are completed. This poses some unusual challenges – I had to scrub in the other day so I could poke about in a live theatre looking for an elusive set of medical gas isolation valves. The mantra is very much hospital first, building site second. My little project is linked by a door (now chained shut) to a post op recovery suite. One of the others is in the space between the theatres and the recovery suite – the bricks and sticks men are being very good at not swearing to loudly.

The hospital is still running as we build, and taking over the new facilities as they are completed. This poses some unusual challenges – I had to scrub in the other day so I could poke about in a live theatre looking for an elusive set of medical gas isolation valves. The mantra is very much hospital first, building site second. My little project is linked by a door (now chained shut) to a post op recovery suite. One of the others is in the space between the theatres and the recovery suite – the bricks and sticks men are being very good at not swearing to loudly.

Mark was right to tell us that we would have a technical edge on most of the others on site – much use of Darcy’s equation to explain why ‘that duct isn’t going to be big enough’. I’ve not had to invoke rule number 1 yet, but rule number 2 is becoming my go to option, since one of the things I have to do is review the detailed technical designs produced by the sub-contractors, and then persuade the client’s consultants to give us authority to proceed. In some ways there is tremendous freedom to make engineering decisions but on the other hand much is tediously bureaucratic.

Away from work, there is much wailing and gnashing of teeth with finding somewhere to live. The place they have put me in is frankly…, well it’s not nice. Burnt out cars, no hot water, red back spiders, and a curiously persistent shopping trolley in the last few days alone. I will be moving soon!

Mine are a little bigger than this one :-).

On the other hand, I managed to do some awesome scuba over the Easter WE; I came face to face (well almost… ok, it was about 20m away) with a juvenile (2m) Tiger Shark. Was very cool in any event.

That’s all for now folks. See you here again soon.