Archive

Steady away..

EDC SOLARWALL

As everyone is on time codes around here, they get protective over them and I had to kick the authorising office to release funding for our ConRep here on site to book his time to. I get a distinct feeling that if this had not happened then we would find ourselves locking horns further down the line trying to justify the hours. Thankfully HRH The Queen has not asked for a time code and my time remains free of charge to USACE unless I can come up with a cunning plan to make some money out here…..

During the weekly meeting I enquired about the findings of the investigation of the existing wall construction and the contractor made an almighty slip up in blabbing about extra costs and the conversation quickly turned into a regain when they realised the Client was listening in. The phrase – “please stop talking you’re scaring scaring the government” really made my day. The contractor was invited to consolidate his (collective) thoughts on how best to approach us with cost variations instead of just banding ideas around in an open forum. Have heard nothing back as yet, but having reviewed the documentation it looks like the cost will be materials based. This highlights the beauty of the ‘option’ system of bidding within a government environment. It allows a bid price to be put in with several options, meaning that whatever level is actually approved can be spent and in instances such as this, the options can be tweaked to make sure you still get the best value for money without the whole project falling through.

I have also been coordinating potentially useful information for the contractor to use when compiling his method statements (de-conflicting site specifics and coordinating with facility managers and trying to pre-empt what they will need.) This is in the hope that subsequent submittals will be approved without the need for further comment and keep the timeline on track.

Reviewed design submittals – approved with comments back to contractor.

ECIP Project – Bldg 732 / 760

Attended kick off meeting for the installation of Solarwall on 2 other buildings on the depot. These are in concept phase and Rob Duke is involved from the E&M side of life.

School Visits

Have volunteered to take part in the outreach programme to go and promote science and engineering in the local schools. My first assignment is a careers day at a Baltimore Middle School – 12 – 14 yr olds, due to take place on 1 June. Further events will be planned provided I don’t get arrested at the first event.

Ashley Reservist Centre

Undertook further investigation and data collection for use in TMR1. Suicide level increasing.

And in other news….

This feature is temporarily cancelled due to lack of interest….

McFry – Out.

Week 6 7th 1 11th May 2012

Week 6. 7th – 11th May 2012

Bank Holiday weekend – well, I took the Monday morning off (recovery from a 125 mile bike ride in the snow, and a 20 mile run up some mountains), so that was nice!

But what else, I hear you say? Well, the week was very much focussed around my Runcorn study into Distributed Engineering which has changed with time as my research developed. What began with an investigation into methods of Cost Reporting and Cost Estimates – these being the much heralded excuse for delays from PSN’s Runcorn Design House, my recommendations came back saying that:

- Communications between Project Managers is excellent

- Current Cost Reporting methods are suitable; delays are inevitable and this can be relieved by a few more Cost Engineers in Runcorn

But more surprisingly (and damningly),

- The leadership from the PSN Aberdeen Delivery Manager and his Delivery Focal Points is weak

- The Delivery Manager in Runcorn needs to play his part as a leader better, and get himself a Project Services team ASAP

- If they don’t start working on morale, and make the (Runcorn) team feel like part of the Focus Project, they’re going to lose them, fast!

We sometimes forget how good people management is in the Army (compared with PSN, anyway!)

Some context… BP contract most of their design work to Wood Group PSN (abbreviated to PSN), who work alongside us (BP’s Projects and Mods Team) in Aberdeen as part of the Focus Project (fully integrated etc etc). Because there is such a huge demand for work, they have a ‘third floor’ of the building situated in Runcorn, Cheshire, which currently employ 72 staff (compared to ~130 in Aberdeen). A bunch of us from BP and PSN visited for a conference on Tuesday and frankly I was shocked. The BP staff all got there on the red-eye flight, met the PSN guys in their office and put faces to the voices we’d been dealing with on the phone; really good stuff and great for cementing relationships that you can’t do by email. The PSN guys rocked up late for the meeting, and didn’t even meet the main part of the team in their office, just the key management in the conference room. And then were all out of there the next day at lunch, cutting a meeting short to do so! We (BP) were there til mid-Wednesday afternoon and so could chat through all the bits and pieces; or use the wireless to crack on with routine work otherwise. With this being the first conference of its type in Runcorn (the office was established in June 2011), most of the PSN (ABZ) contingent had never been there and seen the offices.

So one of my Programme Managers asked me my opinion, and I told it was all pretty piss-poor and bad mannered really; we’re all supposed to be the Focus Team, but PSN (ABZ) clearly didn’t give a flying fook about their staff in the South, who it transpired were kept massively in the dark on the big picture and thought it was all doom and gloom on the forecast (it’s not, its booming and they’ll be expanding!). And clearly, that’s no way to run a team. I continued to say that unless they bucked their ideas up they’d be haemorrhaging staff when better options come along (which is likely as there’s a big engineering boom around there). Oh, and also that the presentations were pretty lame, there was no clear aims of agenda, the IT broke down (at one point their Plans man was talking with an A3 graph held up in front of his face) and they should be embarrassed. So guess who gets to lead the next one! Me and my big mouth…

The weekend – TMR writing and a bit of open water swimming at Loch Morlich – bloody freezing, but good training for the CELTMAN!!!! See www.justgiving.com/chriswarner for more information 🙂

Week 9 – Paternity Leave and a bit of temporary works design review

So this week I have mostly been on paternity leave. This has simply added a new string to my “work avoidance” bow with an upcoming TMR deadline. That said, I have managed to do the little and often approach, although not as often as I would have liked! Harrison is now 15 days old, doing well (as is Lisa) and Team Serevena is semi ready for my return to work.

I did spend a day in the office this week and after the many back pats and congratulatory pleasantries (I really didn’t do a great deal) spent Thursday undertaking a design review of the Jetty temporary works. I needed to be in as one of the discussion points was the pile testing, the part of the scope that I am solely responsible for (and this ties in neatly with my thesis proposal – I love it when a plan comes together!). As well as the pile testing, we also looked at the traveller in detail, including the construction sequence, operation and reconfiguration for phase 2 of the Jetty trestle installation. Several areas of concern worked through but no pressing challenges relating to the traveller for me to raise in this forum.

The only potential challenge that I’m open to suggestions for is how to splice piles and their reo cages when working over the water. Concept is to drive a 30-32m section which is as long as we can drive with the likely barge/crane configuration and then have to undertake a vertical splice of the last 10-14m pile section. Typically this would be done in a nice jig but it’s not that easy on this occasion. Thoughts welcome from one and all.

That’s about it really this week. I return to work on Tuesday, CIs visit at the start of the following week and then pedal to the metal with pile testing for me! (Although we still don’t have any idea of a start date – we’ll be poised like coiled springs)

Good News Everybody!

Exciting news, I moved into a new flat last night. Within 2 minutes, I was greeted by one of the neighbours. I was initially a bit wary of the 6’4, 120kg maori approaching me in the dark corridor but was soon put at my ease. He and his wife even helped me unload the car – unlike the neighbours at the old place they actually put the stuff in my house.

Quick SolarWall Update

Hobbit 108 asked for some adfditional info on this stuff. I have been given a link to a web site that follows live data from a building that has this installed. It may offer a semi hardon to those inclined that way, but not for me. Rob Duke may be doing a TMR on something like this as he’s getting involved in some actual design (design being…step 1 – fit solar wall – step 2 – enjoy.) I also have some other docs for you to have a look at but haven’t yet figured out how to put pdf’s on here.

https://www.hobolink.com/p/19ce52151e42cc6c8fa66fdca93b35db

Laters.

Weeks 7 & 8 – Work drying up, Anzac Day & a new addition to Team Serevena

So I haven’t blogged for a couple of weeks, although I have maintained a heckling watch on posts, due to Lisa giving birth and our lives being a bit crazy with the change that baby Harrison has brought with him. Time is tight, so I will be brief, but also there is very little to report in terms of “work”.

Week 7 was the 2nd week without Barry the Package Leader and our work had slowly dried up. We got to a stage where we (me and the 2 junior engineers) had done as much as we could without input from the PL and the PM didn’t really want to know. The resultant was that we trudged through as much as we could in terms of work and had started to try to re-work some of our previous efforts. Luckily though an opportunity arose for the end of the week to complete a lift planning package that would mean we could plan and execute the lifting of the piles on the Jetty project. As a bonus it also meant that we got a late start as the course was on the mainland and a free lunch on the company!

Before the course though was Anzac Day, 25th April. After trying to get some sort of response from BDLS as to what was expected of us, attendance requirements, protocol (of course I received nothing as usual) I decided to attend the dawn service to pay my respects to our allied troops. My neighbour (works for JHG on the MOF and is a veteran) took me down and I was glad that I experienced part of the Australian culture with him, although I respectfully declined the opportunity to drink many a rum toddy and indulge in the games of 2up afterwards for fear of the pain that Lisa (39 wks, 4 days pregnant) would have unleashed on me. Well worth attending – just wish that BDLS would send some advice out on significant events in the calendar such as this).

Thursday 26th was day 1 of the lift planning course. It was split into 2 parts; Part 2 – Lift planning overview and part 3 – lift planning tool. For those clever enough to have noticed that there is no part 1, this is covered in the JHG induction and thus I’d already passed. Part 2 was covered in the morning and was just a safety induction in greater detail. It was interesting and gave more meat on the bones as well as a greater overall awareness. Part 3 however involved the use of a scientific calculator, determining load paths and other exciting structures mathematics so the brain got going. The afternoon was when the learning started but the real meat was to be on the Friday.

Friday 27th did not run according to my diary and at about 0130 Lisa woke me to tell me that her contractions had started. Immediate concern was that I was going to have a steak for lunch (JHG were paying) to make up for the healthy salad option I had embarrassingly chosen on the Thursday and that I would miss out. Apart from this, I called the hospital whilst Lisa completed her nesting, booked us in for the morning and went back to bed (on Lisa’s instruction) as I needed my rest.

Shortly after 0600 I got up, sorted out the 2 boys, deposited them with a friend for the day and then took Lisa to the hospital at 0800. No detail necessary for the next few hours but at 1153 Harrison was born! Weighed in at 8lbs 8oz. After the post birth admin was completed I left Lisa and Harrison to get some rest and went for a celebratory Hungry Jacks (Burger King) which didn’t make up for the missed steak opportunity, picked up the boys and then went home before returning to the hospital at 1800 to pick up Lisa. We were home by 1930 just in time to watch the Broncos on Friday night football! So a busy day all in all.

3 brothers – Future England three-quarter combo?

3 brothers – Future England three-quarter combo?

Week 8 – Paternity Leave – little sleep, madness, need I say more….same again for week 9 no doubt!

Barrington Digital Library

Hey everyone.

Has anyone been able to access the BDL from overseas? So far I’ve not been able to get through using either of the URLs they gave us or by linking from the VLE- http://diglib.shrivenham.cranfield.ac.uk/ and http://barrington.cranfield.ac.uk/. Can you get at it from the UK; maybe it’s broken?

Big touble in little….town in the middle of nowhere.

Covers Period 30 April – May 4:

The best week so far at work! Plenty of variety and a chance to get the boots dirty, thus avoiding paper cuts in the office.

EDC SloarWall

At the end of the previous week the contractor had sent me a Risk Assessment (Called an Accident Hazard Analysis AHA over here). Essentially this was pipss poor and far too generic. I bounced it back to them with comments along the lines of ‘take this seriously or I’ll cancel your investigation’. This resulted in them sending ther H&S guy to supervise the task and conduct the relevant briefs and incorporating the issues that I had raised. Even so – our COn-Rep picked their guys up for lack of high-vis clothing, baseball caps under helmets, impropper ise of helmets, not using fall arestors when on the platform. Each of these issues were addressed on site before work continued but it was a constant bug-bear. The contractor has left with a much clearer perspective on the standards that the Corps requires. I have followed this up by sending the chapter and verse out to all parties who are expected to produce the AHA’s. In this respect we demand 100% commitment and complience – or they get 0% work completed at their expense…….I look forward to the inevitable repeat prescription on this.

Have been able to get the tech guys to be less vague about how they intend to deal with the roof ducting – as this overlaps two projects and had not been clearly defined as to where the responsibility on this project ended and the next one began. I was uncomfortable with the initial response as although everyone was happy to carry on working, it left contractual vagueries – and we all love those.

Ashley Reservist Centre.

Issues over defects on a loading ramp have come to a head and I have been giver catre-blanche to go and sort it out. This is going to be the basis for TMR 1 for me as there are opporetunities for technical analysis and research as well as contractual issues to solve. I booked the hotel etc and set off to spend 24 hoursd on site to investigate the defects, interview the contractors and gather evidence.

Breaking down the issues this is a historical birds nest of problems which will take a while to consider and provide appropriate solutions, but the best thing I was able to do was to apply the ‘big levers’ principle as preeched by the Moran and the Farmer. Cutting away all the chaff allows me to find the lever that allows the issue to be resolved and for work to continue. Bottom line solution is that the contractor will undertake spectrographic testing of the placed concrete to prove ifit was up to specification. This then triggers a decision point. If the concrete is up to standard, they recommend and submit remedial actions for us to authorise (at their cost). If it is sub-standard I will work with them to prove the extent of the sub-optimal concrete and the questionable areas will be removed and replaced (at their cost). Simples – but there are a plethora of other issues that also need to be resolved, some of them diplomatically, some of them bluntly. Other issues that need to be resolved are:

– Contractor’s Quality Control procedure has been historically lacking and is still not up to speed.

– USACE Quality assurance procedures are not being followed and need resolution.

– Materials testing documentation is not clear enough to give contractor the level of assurance he needs.

– USACE ConRep is not working cooperatively with the contractor…and vice-versa.

– Deficiency reporting procedure is not working or being applied appropriately.

– Communication on site is inadequate and will continue to cause further delays and disputes.

– Areas of the specification do not comply with the working drawings. Essentially we have 2 song sheets and each party is using whichever suits them best.

From here a quick and dirty report will be produced to get the ball rolling on the resolution. I will then drill into the detail and generate two versions of the findings. One for consumption within USACE and one for the contractor to see. Wrap all of this together and hopefully a TMR will fall out of the other end.

DDSP ECIP Buildings 732 / 760

Used our ninja APMP qualification and skills to review and comment on the proposed PMP for the energy efficiency projects for which I will be Project Engineer.

And in Other News

Enjoyed a site visit to the Mechanicsburg Reservist Centre project which appears to be running on fumes as far as funding goes……they said no blasting as well and look where that got them.

This week’s road kill includes deer, blackbird, hedgehog and possum…although the possum may have been pretending.

We enjoyed our first ever Cinco de Mayo celebrations / Kentucky Derby day. We attended a party where I now see that the theme was meant to be Kentucky Derby (i.e. posh hats and day at the races atire)……I went with the Mexican theme instead. And when we were in the fancy dress shop I saw the coolest Iron-man mask and simply had to have it. So to keep in the theme (or what I thought was the theme) I went as Iron-Man dressed as a mexican (with grigo moustache attached to the mask). In the group photos from the party there is one character that looks decidedly out of place.

Commercials on TV continue to horify me. Apparently your kids can get premature wrinkles. So if you really care about your kid’s future, you owe it to them to treat them with child friendly botox.

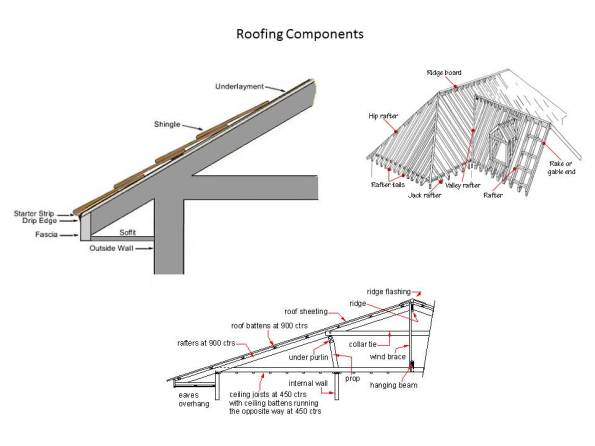

Roofing Components – Learning To Speak Builder

Have spent much of the day trying to understand what the hell my mech sub-contractor is on about. He has been telling me where he’s going to put his screws (not as funny as it sounds), but it seems all builders speak Klingon. I didn’t know half of these words so have made myself a translation slide – though you guys might find it useful if you ever need to sort a purlin from a rafter, or if, like me, you don’t believe that underlayment is really a word.

Arial Drainage – Anyone?

Has anyone ever come across ariel drainage? I haven’t been able to find anything on it from my own cursory research. I’d like to know a little about it because the hydraulic consultant on my site is telling me that it is because he has employed an ariel drainage strategy that the soil stacks and vents don’t line up. This is a man who I’ve caught out telling me porkies a few times already so I’d like to know my onions before I challenge him about it. I had understood that it was standard practice to have a soil stack that rose from the sewer in the ground slab through all floors to the roof where it vents, and that the drains at each floor run into it. I know that sometimes the stack has to make a slight detour, because drainage falls below mechanical services and structural elements in the priority of change, but thought that any deviations would be minimal and with a big radius. The deviations I’m talking about use 90deg bends and are across many meters on a single floor.

The job I am working on is a little unusual, in that there is no services riser. The section of the hospital that we are currently re-fitting was originally built as a single story, and then converted to a double, then a triple storey affair. Things seem almost to have been piled up on top of each other as the various re-fits and expansions have taken place over the years – even the structural columns have moved around (Mark, this probably answers your earlier question about the location of the med gas isolation valves – As is happening with this referb, they seem to be thrown in wherever they are needed to allow the next extension to be built). Here is a drawing of the new drainage system in my referb area, with my annotations of where the soil stacks are located on the floor below. The stacks and vents are linked by a vent header system in the ceiling above the floor shown.

Do you think that the use of air admittance valves on top of the stacks might be a more economical arrangement than using the vent headers?