Archive

Week 2. 11th – 13th April 2012

Week 2: 11th – 13th April 2012

A short week with Bank Holiday Monday and Tuesday off (Liz’s birthday) to make up for Good Friday. The office is still very quiet but I have at least got a project firmly on my list, and that will start moving with time. Which leads me to some observations…

Pace of life here is slow. There is little sense of urgency anywhere, with most people thinning out around 4 pm – although admittedly they may get here before my usual 8am start. This may be a symptom of the Easter holidays (fair enough), or maybe just that contractors receive a daily rate and can get away with it…

Meetings tend to “go on”. I had 2 meetings on Thursday, both on Ish’s projects which will become mine as he is away for Phase 4 and departs after Phase 5. The first was a weekly update meeting on the Low Pressure Booster Compressor (LPBC) stack change around on Magnus. 13 people were around the table and the meeting lasted over an hour, most of which was a heads up on the tail-chasing that is project management – who’s done what, where sew-and-sew is with the other etc. OK, there were a few people ‘doubling up’ (myself included) but lots of the meeting was re-hashing old conversations and could have been done ‘in the margins’. – I’d better add that it wasn’t Ish that chaired the meeting, but one of the WGPSN Job Responsible Engineers (JREs) – effectively Ish’s oppo.

The second meeting was quite an impromptu chat with Tim Eley, the Business Developer for Linjebygg Offshore (LJB) who specialise in alternative crane solutions. He was bought in to offer a third solution to Ish’s big crane-change project on Magnus that has been put on hold, and may offer a better solution than the current plan which is to use a Heavy Lifting Vessel (HLV) (<$1m per day), and boy did he go on! He made some good suggestions and suggested a way forward, but then bored us by covering the same ground again and giving us more (irrelevant but impressive) examples of LBO’s previous jobs. If I was Ish I would have cut the meeting short after 30 mins rather than letting him go on for over an hour, but maybe I’m missing something…

Other things

Townhalls. I like these. These are BP’s open briefings, held at all levels, where teams are encouraged to get together for the lead and a guest presenter to bring people up to speed on what is going on. I attended my first of the fortnightly Engineering Services Townhalls on Thursday, presented by Tom Macartney (Team Leader) with a second speaker from another department. Although I didn’t stay for the whole meeting, it was good to get fed the information from the top, and he was open to comments from the floor (of which there were a few). The main part for me was the ‘blueprinting’, or standardisation of the different divisions (ours being the North Sea (NS)) so as to catch the ‘best practice’ – one of the buzzwords I liked as Ops Offr at Minley, sharing Best Practice with 1 RSME and Holdfast. For us, this means a few additions to the NS Engineering Services Team but there were no real surprises; probably because it was Tom that helper write the Global blueprint!

Jobs – my role. It is now confirmed that I will be the SPA for the bearing inspection platforms on Bruce, so next week I’ll be chatting to the Senior Structural Engineer, Colin Wilson, to discuss exactly what this might entail before having a free-for-all meeting with the main stakeholders and SMEs. Looking at the internal BP SOR, it was Colin who instigated the job so I’m sure he’ll have some suggestions!

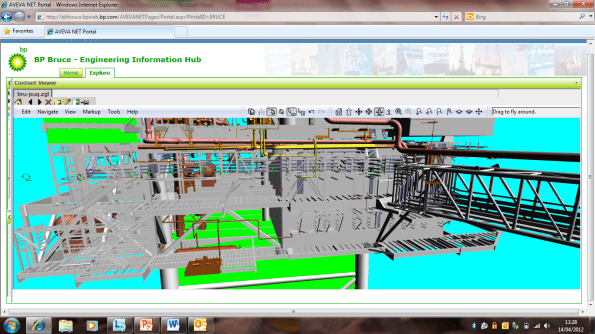

After a few hours of IT support, I finally got onto the computer modelling programme so can now see Bruce in 3D and yes, these rigs are complex beasties (Fig. 1)! It’s so easy to simplify something in your head, but as soon as you look at what exactly is going on, it gets a lot more interesting! I’m now really looking forward to meeting with Colin on Monday to discuss how to tackle this, and I’ll let you know how it goes. Clearly what I really need is a recce, so hopefully I’ll be getting onto site soon – but not until I’ve done a week’s worth of courses – with any luck these will be the week after next. Watch this space!

Figure 1. Screenshot of image of one the bridge linkages on Bruce. From what I hear, the hydrocarbon pipes going 1/3 up the height of the bridge are around the same height of a person.

Figure 1. Screenshot of image of one the bridge linkages on Bruce. From what I hear, the hydrocarbon pipes going 1/3 up the height of the bridge are around the same height of a person.

Week 5 – 11-13 Apr 12

Another short week following the Easter R&R period has been jam-packed with activity as the package leader is heading home to Ireland on Saturday for a 2 week break which means we’ve been thrashing ourselves to tie up all the loose ends. Having just been in the handover meeting I’ve ended up with a fair amount of responsibility in his absence, particularly chairing the weekly meetings and liaison with the design team. This should not be an overly onerous task and the extra responsibility will be good for raising my profile a bit with the key players.

My main effort has been finalising a contract for the pile cut off platforms which is going to end up in the region of $110,000 and the enabling works for the project site which is about $250,000 all up. I’ve also been investing time in the junior engineers, sweeping up their basic skills such as the production of meeting minutes through to formatting documents and improving the general professionalism of our products.

A new task this week has been investigating, researching and selecting the method for abrasive blasting over the water as well as the painting of the welded areas of the Jetty structural. This will probably be the subject area for my first TMR and will therefore leave the meat of the detail for that. What I will say though is that convincing people that the ecological/environmental benefits outweigh the financial is a very difficult task to which there is significant friction!

The plan for next week sees our team halved for the first part whilst the PL is on leave and our graduate engineer on a JH trg package for 3 days (opportunity to have some beers on the company is the basic aim) so I’ll be fairly busy. When this is combined to the fact that Lisa is going to be pushing towards 39 weeks pregnant it will be a tough balancing act. We’re all set though with friends appointed to take the kids during the birth and an escape plan hatched to get me off the island when the time comes!

The latest news I have had for a start date is that we won’t commence until 25 June 12. Whether this includes the enabling works is uncertain but I will keep PEW updated and the review of DOs due on 21 May should give a decent perspective of where I’m at. Not an issue yet at least.

So overall, things are ticking along. The long days are taking their toll but it makes the day off on the weekend very much appreciated and the management here are allowing me the time to undertake my coursework as and when required which means that the time off is largely dedicated to the family.

Until next week, Au Revoir!

Week 4: Edges and Arguements

Period Covered 10 – 12 April 12

Summary: Edges and Arguments

At last I have been on site for a continuous period of time and as a result feel like I am now bedding in and understanding the daily rhythm on site and getting to grips with the detail. Though my role has not altered, my responsibilities have grown – as a result of knowing a little bit more but mainly covering people who are away on Easter Leave.

During this period I have completed the following:

- Supervision of GMF ground work contractors – bulk & detailed excavation and pile cropping

- Application of SQE RM Course – Completed Task Risk Assessments for elevated work

- Review of drawings – answering Sub Contractor queries

- Concrete Pour Quantities and ordering deliveries for site

- Safety Supervision

- Programme co-ordination meetings

Work on site. Work is frantic at the moment with a big push to complete the service tunnel which as I mentioned before is the first milestone for the project and will be how the State judges John Holland. The good news is that there seems to be a real sense from the sub contractors that they will do what it takes to get it done for the handover (first section of tunnel to be handed on 28 Apr) however I have a feeling real life (Murphy’s Law) and a fundamental procurement problem with the waterproofing solution (more to follow) will mean we may miss the deadline.

Issues/observations. I have picked out three things that have interested me in the last couple of days:

a. When is a fall from height a fall from height. The rules at working at height have recently change in WA and from an arbitrary 2m, the rule now states that it is when the risk is felt to be too great. I have been giving this some thought and it is a very subjective view on what constitutes working at height and more pertinent to the groundworks when is an edge an edge and require a barricade: And then when a barricade is required is it a soft barricade (bunting/Mesh) or a hard barricade (Water barrier, Earth Bund). The photos below hopefully illustrate this a bit better…but all of this means on site plenty of discussion from subcontracors before they do what we tell them.

b. Safety v Relations with Subcontractors. Having just come out of a safety meeting which had specifically directed that steel fixers walking on 1.2m high reinforcement cages was not to be tolerated, I felt on pretty safe ground when on my safety walk around I saw two fixers doing exactly this. What I was not prepared for when I told the supervisor this was not to happen was a heat exchange about what did I Fxxxking know and to shut the f**k up. Moral courage tested but not broken I stood my ground and expected him to see the error of his ways, what really happened was that he collected his team and tools and walked off site!!! This left me thinking momentarily if I really had done the right thing.

Thankfully a radio call to the site manager headed them off and after another heated debate a safe solution was found – so though the end result ended in the work being done safely. I have reflected that I still need to work on how I talk to Sub Contractors.

As an after thought a lesson for when I design – it was obvious whoever had designed these capping beams had not considered a safe method of work for the steel fixers to construct the reinforcement cage.

c Programme Changes. A weekly team and subcontractor programme meeting occurs, however the programme changes on an hourly basis. This is being mainly driven by the site manager who is keen to capitalise on any opportunity to “speed” up the programme. In some cases the benefits are massive but I am concerned that by constant, spur of the moment programmes changes this unsettles the sub contractors and at worse is not communicated to all on site, leading to an eventual delay!

My Experience. It is been a busy few days since Easter but it’s been great to get some consecutive days on site. Responsibilities and experience are growing steadily but I still have loads to learn to ensure this progress.

The site has recently been delivered site radios so I having been teaching everyone voice procedure… we’re not quite up to SOC 4, obstacle crossing yet but we’ll get there….so now even my armoured engineering experience has been useful!!

Further Work

- BIM Meeting tomorrow with AEC systems as part of TMR research

- Thesis Topic – I am starting to research into a pile thesis, I have discovered that the service tunnel and the hospital have been designed as separate structures and have different load profiles, as they will be connected I have been informed that the piles have been designed separately to ensure settlement occurs equally and differential settlement is avoided. The settlements will be monitored so this can be compared to the design values (A phone call to JM to follow very soon)

- Consolidate work on site

Week 4 – 2-7 Apr 12

This week was a short one with the project (all GLNG works on Curtis Island) being stood down for 6 days after cease works on Wednesday. In typical army fashion, this meant that everyone started to close down from about mid day on Tuesday and thus next to nothing seemed to be achieved. That said, work carried on for the Jetty team with the production of more reams of paperwork, safety plans and activity method statements! I also continued to plough on with my contractor negotiations for some enabling works which are almost sorted now…they just need to sharpen their pencils a touch more and we’ll then sign a contract for $225k.

Most importantly however was 1430hrs on Wednesday when we were stood down for R&R. For team Serevena this meant jumping in the car early doors of Thursday morning for a drive to the Sunshine Coast for a bit of sun, sea, sand and SCUBA DIVING!!!!! So we were away for all of Easter at Noosa, which was very nice, and had some quality family time prior to the arrival of youngling number 3 in the next 2-3 weeks (touch wood). So to compensate for the fact that there are no site pictures as yet (mainly due to the fact that we still haven’t got access to the site!) I have added some gratuitous underwater shots of me below on the wreck of the HMAS Brisbane from Good Friday. Enjoy!

Last couple of Admin Weeks and First Day at work

The First Blog

Having now completed my first day in work it seems appropriate to add a blog update for the past couple of weeks of Admin fun.

Having arrived in Washington, we set things in motion to avoid the bear traps that Matt was carefully marking for us, and so rapidly set up a Bank account and mobile phones (my phone number is +1 202 415 0907).

We received the embassy brief on Monday the 26th March, which for the most part was swept up and beneficial. Matt had prearranged for the majority of the Common Access Card admin to be ready for us so this made life easy, and we managed to have these ID’s issued to us very quickly (in comparison to what might have been, so thank you Matt.)

Once we arrived in Frederick things became a little more fun, trying to get a suitable house was interesting due to the bidding system here, that means that several people effectively give closed bids on a property, and are then informed several days later whether they have been successful, this coupled with a sporadic rental market meant that with two rejections we were running very short of time. We did however manage to get a fine property and moved in over the weekend just past (Easter Weekend).

The Americans also seem to love bureaucracy, those people who work in the Social Security and Vehicle Licensing Office more than most. So a few days have been spent in their various offices, waiting in lines, with only a butchers slip booking. It really vexes me why they can’t manage something a little more advanced…

I now have:

A vehicle – Jeep Grand Cherokee which manages 20MPG, making it cost the same per mile out here as my little 50MPG back in the UK, and it handles very similarly too!

A Social Security Number, which now allows Utilities and Broadband to be connected to my house.

A house – walking distance from the Camp – this really confuses the Americans – “walking”

Insurance

I still need:

Maryland state driver’s license

Internet connection

A lawn mower

A hunting bow

________________________________________________________________________________

Some Brief Background

The USAMRID project is classified as a Partnering project

It is currently about 50% of the way through, with 60% of pay given to the contractors

First Day at Work

Having tried to get an IT account for a couple of hours this morning I was then due in the Monday morning staff meeting, discussing the key issues of the week and progress expected.

Most of the discussion today hinged around the program of works. Part of the problem appears to be the management of snagging lists (“deficiencies”) The contractor is pushing (successfully) for the line items on the program to be declared complete when they are only at 95% or so. They have the work that actually needs to be done added to the deficiencies list. This maintains cash flow for them, and means that they don’t actually need to complete the task before they get the payment – very convenient!

However the deficiencies list has now gotten too large to be able to track effectively, and so contractors appear to be able to get away from actually finishing the work…

How to get the project back on track is a political issue as the project has been reported more complete than it truly is, and the money has already been spent. It is also a very large organisation that has significant momentum.

This is only my first day’s impression, so I am sure that there will be much more depth to the situation than this…

We had a meeting with a contractor in the afternoon. This showed a more healthy side of the “partnering spirit” as cost effective solutions to problems were discussed, and the contractor was flagging up problems he had foreseen, and suggesting possible solutions.

Tomorrow I will be observing part of the testing and commissioning of the steam sterilisation plant, which has been caught by several problems over the past few weeks, but when you see the complexity of the plant it is hardly surprising.

Valuable lesson learned over the weekend…

Week One 2-6 April 2012 – take two

Not sure what happened to the first version so here is take 2…

Week One: 2nd – 6th April 2012

Well, it’s good to see that BP operates in a similar way to the Army, by which I mean the following:

- It takes a while to get your IT sorted

- Everyone goes on leave at the same time leaving a few people covering all the desks

- Bank holidays are as sacrosanct as Wednesday sports afternoons

and all is going well. Having popped into the office last week to meet the Projects and Modifications Team Leader, Paul Mullan, it was good to arrive fresh faced on Monday morning to see that people did know I was arriving, even if there was no computer terminal. And the printers were down. But before long, the necessary inductions were done and I had a few documents to peruse through, an SON to have a look at (an access platform for the bridge bearings on Bruce) and I knew where the coffee machine was. And that was Monday really!

The week progressed well though, with my time spent on further inductions; off-shore medicals; sitting in on some of Ish’s meetings; a Projects and Mods Team meeting; and delving into the world of BP’s North Sea Intranet to find out their methods of working. I also had a good chat with the Engineering Services Manager, Tom Macartney in a chance-meeting. A quiet start, but the work will arrive after the Easter break I am certain!

Phase 2/3 role

Throughout this placement I will be based in the Focus Office where Projects and Mods, its contracted engineers and its main contractor of Wood Group PSN (WG PSN) all work. I’m still not 100% sure of the relationship between BP and WG PSN so shall explain it better at some point in the future.

Once I’ve ticked off the various sea-survival courses I’ll be able to get onto the platforms, although this will be a rarity due to their limit of personnel on board (PoB).

I am working as a Project Engineer in the Projects and Mods Branch of Engineering Services. Engineering Services is part of the Operations sector within the North Sea area. At this stage I will naïvely say that this covers topside (above-sea) alterations to existing platforms up to a value of $15m (BP net value). I might be getting involved with the following:

- Bruce P60 Bridge Access Platform. This is to engineer, procure and install access platforms to provide access and maintenance of the support bearings for the Bruce P60 bridge (Fig. 1).

- ETAP Accommodation Fit. I’ve not seen an SON yet but this might be the physical accommodation “bolted” onto the side of an existing platform with its building services and everything else that goes with it. I am already aware, however, that during the Appraise part of the Common Value Process (CVP), it may transpire that a better option is the use of a floating hotel, or “floatel” as they are commonly known. For the sake of adding some more pictures, ETAP itself can be seen at Figure 2.

- All of Ish’s stuff, more of which in a later blog I’m sure, but essentially replacing an existing turbine chimney. I will be covering Ish while he is on Phase 4, and taking over what projects are outstanding when he finishes Phase 5.

Site Description

Throughout this placement I will be based in the Focus offices where BP, its contracted engineers and its ‘main contractor’ of Wood Group PSN (WG PSN) work. Physically, this is a two-story building just over the road from the (much larger and more impressive) BP North Sea HQ (NSHQ).

Getting Chartered

I had initial reservations about the amount of in-depth technical work and site experience I might gain from this attachment, but this has been somewhat alleviated having spoken to our Project Services Lead, Martin Fragell. Martin (covering for Paul this week) is very much involved with getting two of their “Challengers” (graduate training scheme) through a programme that will eventually see them chartered, and we’ve already had a chat about ensuring I can do the right amount of A and B to qualify myself.

To follow

With Paul and more of his Programme Leads back in next week, I’m hoping they’ll decide which job to give me and let me roll with it!

A Good Friday to Blog…

3-6 Apr 12

So – we don’t appear to recognise religious holidays over here, but never mind, we’ll make up for it.

Progress has now been made with log on details for the CAC and I now have access to an official e-mail address and some of the compulsory training.

Further progress has been made on the driver’s licence front. My wife, as she is German, has no need to take her test due to a reciprocal agreement between states…..and even though I did my test in Germany – muggins here has retake it anyway. I attended a compulsory 3 HOUR class on drug and alcohol awareness and let’s just say it was a good job I’d already had the suicide prevention training at work! The test is booked for 18 April in Annapolis (about an hour and a half drive away.)

I bumped into some of the sub-contractors for the Solar-wall project during lunch break and after the initial ‘oh crap – it’s the Client!’ sort of introductions they finally opened up a little to just chat about projects and work for the Government. I discovered that having just got my head around the whole ‘let’s spend $3.5M in the name of science to see if this stuff works.’ it now turns out there is another existing building with this system already installed. Upon asking why we aren’t just measuring energy usage from this building compared to an equivalent sized building on the base, nobody could say….and I’m now asking again why we’re spending so much money making sure the national debt is kept up to world expectations. I’m probably going to get punched soon for pointing this stuff out all the time.

We had our first RFI’s in on the solar-wall project relating to the construction of the internal racking system which actually forms the structural support for the roof itself. The structural engineer needs to prove that the existing walls and structure can hold the proposed solar-wall and needs certain ‘as built’ info. I have done some digging around and it turns out that the whole roof is to be completely replaced in the near future….so now I’m concerned as to whether or not the structural engineer needs to be worrying about this at all and if it would be better to get the structural engineer from the solar-wall project and the structural engineer from the roof project to liaise directly to save on potential cross-purposes and wasted effort. The issue arises because for maintenance contracts, the Defence Logistics Agency runs and manages it’s own projects, no matter how expensive, but for new works projects of over $750K they have to use USACE for the contract administration and quality assurance and quality control and hence the oversights. Hence we have two projects on the same building that involve different organisations. I have since booked in a meeting with the engineers at DLA to further orientate myself with the local procedures and will also go and see the overall project manager from the DLA for the solar-wall project to iron out these RFI’s in a sensible manner. I am sure that all of this has been considered and thought through and it’s now just a case of making sure communication channels are established.

Have booked in to go on an Officer Training Day with the Corps next month looking at how they clear and maintain the bays as well as some media training.

Child number 2 has arrived safely. Now trying to find non-expensive ways of entertaining the damn thing. (We love him really).

Enjoy the Easter break guys and gals!

McFry

Week 3 & 4: Training

Period Covered 23 Mar – 4 Apr 12

Summary: Training

A brilliantly frustrating 2 weeks which has been characterised by a whole host of training courses. On one hand this has been great as the courses have been really useful and have possibly inspired my second TMR topic but at the same time frustrating as they have come at a time when I was just establishing myself on site and I have just sat in a classroom for 9 Months (fear not PEW lecturers I did not give the Aus lecturers an easy time either).

During this period I have completed the following:

- Supervision of GMF ground work contractors – bulk and detailed excavation, pile cropping

- Set out and supervision of service pits in service tunnel

- Qaulity Assurance pentrometer testing

- Risk Assessment and Hazard Inspection Audit

- Programme co-ordination meetings

- Operational Safety Quality and Environmental Risk Management Course

- Louts Notes and Project Pack IT Training

- Working Safely at Heights course

- Reports and returns – Site Diary etc

As a result of all my training courses I do not have much to write about this week. As a result please see a shamelessly large number of photos.

Work on site. I have been impressed at the pace of work on site. The amount that has been achieved has been incredible. 120 x 20T trucks a day of spoil has been removed on site and the ground excavation is really progressing. This is beginning to open up the site and for a short time will alleviate the space shortage. The service tunnel to the West of the site is still the priority as this is the ONLY milestone in the programme less practical completion!!

Issues. A couple of issues to think about:

- How are tenders one? I have not yet had experience of the complete tendering process but I am beginning to understand how business is done; though a lot has been made about employing quality rather than the lowest bid, this has not been borne out by the earth works contractor, who I know was the cheapest tender by a considerable margin and in my opinion have bid to low for the job and are currently under a lot of pressure to minimise overheads. This creates a lot of day to day friction and from a managing contractor view means we can not capitalise on opportunities as GMF to do not have the resources to be flexible. On the other hand the concrete contractor, Crown, are falling over themselves to be proactive and helpful (and in my eyes professional) as they want to win the contract for the superstructure construction and as a result are desperate to impress. The earthworks contractor has no such incentive.

- Stopping in the Rain? Unbelievably we have had a few showers in Perth over the last week. I have been bemused by the immediate reaction to stop work as soon as it rain. It is a shame this safety culture does not extend to every practice on site!

My Experience. I am still having a really positive time on site but I have been frustrated by the number of times I have to tell someone to do something. This apparently is a normal frustration for attached officers according to my Works Package Manager who has worked with a few sappers before….why can’t civies do what they are told!!

Finally I undermined all my good first impressions by getting my UTE bogged down in a particularly soft patch of sand on site….

Further Work

- Continue on site as supervisor, deputise for site manager in his absence

- Hold Safety workshop with Safety Advisor to encourage UK best practice and culture (try to attend Strategic Safety Course which is focussed at culture change – possible TMR 2 Topic)

- Begin research on BIM for TMR 1

- I am currently all out of Thesis topics. I have been canvassing on site but the general impression is that building a concrete box on sand is not really that cutting edge, so I would be grateful for any help from anyone in the UK to focus my thesis thoughts!!

- Conitnue to train for Corporate 14km race in May…Charity appeal to follow

Transpired Solar Walls

Transpired Solar Wall – what’s that?

It’s a heat absorbing panel placed on the south facing elevations of buildings which creates a warm air pocket.

Great….so what?

The warm air is then ventilated around the building to reduce heating costs. It can be bypassed all together if required during warmer months.

Cool…who’s idea was that?

Obama’s – he freed up a whole bunch of cash to make the world a more energy efficient place and win the hearts of the people.

Nice – but it sounds expensive.

Yes it is…..$3.5M expensive for a trial run at the largest warehouse on the Defence Distribution Centre here in Harrisburg. Initially there were going to be 6 walls covered, which has now dropped to a couple of walls plus a number of ‘options’ if sufficient cash becomes available.

But it will save a whole bunch of cash in the long run right?

Well…..I’m not sure. My first set of questions included:

- What’s the current cost of heating that place?

- What’s the life expectancy of the building itself?

- How long do these panels last and how easy/expensive are they to maintain?

- Do the number of effective years available from the system multiplied by the annual energy savings add up to more than the cost of installation?

And you know what?

What?

Nobody could tell me.

So DO the savings outweigh the expenditure?

That’s what we’re trying to establish. Part of this project is to analyse the energy usage of the building as it is now and compare it to the usage post installation. I suppose if it’s a raving success we’ll be throwing this stuff up everywhere we can…..provided the funding is there ofcourse.

Hmmm – this sounds very Electrical and Mechanic-y.

You’re right – it is, but there’s some structural stuff in there, like making sure the walls are capable of holding the panels and the additional furniture, such as lights and CCTV etc. A large section of the structural integrity of the building itself is provided by the storage racking itself. There is a need to retro-analyse the racking to ensure that additional roof loads do not exceed design limits….but mainly it’s very E&M flavoured.

So what’s McFry doing on it?

Well so far I’m using this as an opportunity to get my head around the project management systems and the ways in which business sis conducted. As the project Engineer I will be doing a lot of contract administration and answering submittals. Those that are out of my area of knowledge I will allocate to someone who can deal with tn and I will ensure all info is turned around in good time. I act as the Clients’ engineer and make sure the contractors are hitting the correct quality standards etc. I will have a CONREP (contractor representative) who has lots of experience from the construction side of life to keep an eye on things too. I will need to get my head into the RMS software package for contract administration and will also have to use DR Checks which are for ensuring that professional types have approved documents where necessary (i.e. that design calcs are checked by an approved individual).

So what’s next?

After a ‘kick off’ meeting today I need the contractor to review his schedule so I can work out any critical time line issues and see how they may affect the contract. It’s complicated by the fact that the ‘body of excellence’ within USACE is in Alabama…….so they have the real technical know-how but we’re the local eyes and ears, so the submittal review process was described in a very vague way. I have been clear that I need to know delineations of responsibility – otherwise things will go Pete Tong. (After a brief discussion about Pete Tong it was agreed that the responsibility will lie here with the local office and that technical advice is called upon as needed.) Either way – before I get my soul dirtied by contract administration, I still need access to computer systems and complete the induction packages……yes the system is still not as it should be! In the meantime – it’s ‘broadening and deepening’ of my knowledge on how things work around here.

Any other news?

I have found that teenagers that normally sit in front of a screen all day and do very little will do exactly the same thing when transported across the sea to America. Also – my colleagues have been getting brave and have tried to emulate the British accent…..now they sound Australian.