Archive

APMP in practice…

Guys,

One of the introductory packages I was given was all about project management within USACE and it reeked of the APMP BoK stuff we did just before we were set free and released into the wild. I have spoken with the guys that run the systems here and they have agreed to release it from the secure part of the USACE intranet, the idea being that it might be useful to see the subject matter in a military construction management setting.

There is a ‘tool kit’ in hard copy that I will arrange to be sent to PEW via the SI to see if it is suitable for wider consumption – most of the language is the same as with APMP. I have also been invited to see their software tools at District office that they use for running these sorts of things which I should be able to scope out either on phase 2 or phase 3, whichever is most appropriate.

I have my first mini-project for the retro-fit of $3,500,000 worth of solar walls to one of the storage facilities here at DDDS. It seems to be another one of those projects where no one is sure who’s doing what. Another birds nest to unravel but it’s early days and shouldn’t be an issue. First meeting is tomorrow.

Essayons!

McFry

Week 3 – 26-30 March 2012

Week 3 as a JHG employee has seen the Jetty project team grow from 3 to 4 engineers, of which worryingly (for the package leader) I am the second most experienced in the construction industry. What does this mean? Well I’m being leant on to look at some of the more tricky elements of our preparations and providing that mentoring/guidance role to the 2 junior guys. All good really and nice to have that little bit of responsibility.

The week started with a 2 day design review, where the Brisbane based design manager, his procurement lead and 3 senior engineers from ARUP visited the Curtis Island site. The whole design was scrutinised and at times it was painful but in the end I came away from the review with a better understanding of some of the detailed/technical elements of the design. It was more of a listening/ non-speaking part for me but interesting to see the PM at work and gauge how his mind works. The project is certainly global as at one point we had a telephone conference with Bechtel in Houston, the design review team (for Bechtel) in Malaysia and us. Interesting to be a part of it and start to understand some of the politics involved.

The remainder of the week has been focussed on the preparation of a Marine Execution Plan, which is basically re-writing a previous plan from the MOF/Fisherman’s landing task originally prepared by a Mr R Marsh. The document was not adhering to JSP 101 but my revision does now! I’ve also been focussing my efforts onto some commercial aspects including obtaining quotes for the fabrication of pile cut off platforms and setting up contracts for the installation of a RC abutment / temporary footings for the canti-traveller.

I was also invited to attend some fatigue management training laid on by JHG. All of the site personnel attended in small groups over the course of 2 days and it was okay. I was expecting it to be disappointing but actually it was well presented and most took on the points. It will be followed up in a couple of weeks time with a practical workshop so I’ll see how that goes.

I’ve been in contact with the ICE Queensland branch and disappointingly they do not hold any events outside of Brisbane. This means that it will be unlikely for me to attend anything for my CPD until I move there in December due to the time needed and expense involved (JHG do not pay for this). I will do my best though.

On a personal front we have had some issues back in the UK with our dogs. My father has kindly stepped in and now has them. This has caused some angst but should now be sorted. Not much you can do from the other side of the world and I think we’ve now used up this years worth of favours! We’ve also attended the hospital for Lisa’s first ante-natal appointments and all is well. She is now 36 weeks and ready to pop.

Next week is a short week, finishing on Wednesday with a R&R period from Thursday through until the following Tuesday. Leave pass has been submitted on JPA for the Bank Holidays over Easter. The other days are project Rostered Days Off (RDOs). Annex B of my AER 1 will show this clearly. The AER will be submitted (assuming the moodle works okay from my JHG laptop) on Monday in line with the submission timetable.

NFTR at this stage.

Madness…

28 March 2012

The Mechanicsburg project which is about to run out of cash due to unforeseen ground conditions opened my eyes again today. I asked whether or not it might be possible to get the contractor to agree to allow the Corps of Engineers to resolve the issue. The logic being – there is no budget here to allow contractor to to remove the rock, therefore project will come to a halt and become a big white elephant and contractor will not get the work / money he wanted. I suggested trying to get a ‘training exercise’ for the green skins to do it from one of their training budgets and get their kit dirty for a change, thus allowing the existing money to complete the job and thus the contractor gets a bigger lump of cash and we don’t end up with a big white elephant……..you’d think I just crapped in their swimming pool by the response I got. Enough said. It’s just as barking mad as it is in the UK.

Carson Roberts – Horizontal drilling promotional material

Not the video I wanted to show you – but shows the same company on another project doing the same thing but bigger.

Boring……

27 March 2012

Intro

Another day another site. Today it was a 3 hour…yes…3 hour drive one way to see a drilling site in Towanda, PA. In order to help their town prosper and grow / expand on the North bank of the Susquehanna river the town folk have dug into their pockets and joined forces with the federal government (part of Obama’s stimulus package) to install a water main under the river. This will connect fresh and foul water supply to the far side so they do not have to rely upon storm drains and septic tanks. Department of agriculture has stakes in this small $1M project. Project is currently 1 month behind schedule and this is the contractor’s first project with USACE. Total length of bore is 1600ft (480m)

Conditions

Loose silt by river sides – line of pipeline runs under 1 x railway and a road. Extensive ground investigation material available from PENNDOT (Pennsylvania Department of Transport) when the nearby road bridge was constructed.

Method

Large diameter steel sheaths hammered into the silty layers to prevent ‘frac out’ of the drilling fluids (bentonite) when drilling starts. Will try and attach a video of how it”s done. Once the sheath is in place a drill will be steered along the required path using electromagnetic positioning (all except in the middle of the river where they will be going ‘blind’.) The drill is extended out using flexible shafts.

Once the drill emerges at the far side of the river, an auger will be dragged back through the bore hole to widen it. The process will be repeated until it is the required diameter. At this point the plastic piping will be dragged through the hole to form the completed pipe line.

On site

Very few personnel required. Picked them up for not providing cover from view between the public and the welding operation. PE concurred and added to daily report accordingly. Witnessed a full rotation of positioning of steel sections, welding and driving before the 3 hour drive home……The process is likely to be repeated until the full depth is achieved at which point drilling will commence. I don’t think there will be much to see until the drill emerges at the far end and some more exciting engineering can begin.

Asside

The CEO of the company did not appreciate the fact that I found his video most entertaining. The fact that the word ‘boring’ appears repeatedly to a really intense soundtrack seemed incongruous to me.

It’s all about personalities….

21-23 Mar 12

Having had a chance to see the Ashley reservist centre site again there is some noticeable difference in the pace of work and there are actually more people on site, but still not what you would expect of a contractor who is working to try and recover delayed schedule. A few more things have become clear also – the main thing being that the contractor representative (CONREP) is adversarial with the contractor and this possibly also explains why there are communication breakdowns. We sat in a progress meeting where the CONREP hit them with deficiencies they had never been made aware of previously. Blind siding the contractor in a progress meeting with deficiencies does not promote good will or mutual understanding. The CONREP has told me now in private that he would like to shut down the contractor for failure to meet the quality control criteria and some health and safety issues. He takes photographs and sends them direct to head office to get their opinion (The equivalent of going 4 up to us!). The contractor was certainly using the right language that would engender at least the impression of mutual cooperation, but this was met with a stony silence from the CONREP. (I will stop talking about this individual now incase this ever gets leaked and I get sued!….but you can imagine I have clear opinions of whether this individual should have been retired a long time ago.)

Now pan out and scroll across to another reservist centre in Mechanicsburg. It is the same type of building and is also awarded on a design – bid – build contract. There is a similarly slow pace, not because of constantly changing staff but because of unforeseen ground conditions that have led to USACE having to go back to congress for additional funds. There is perhaps a month or so of funding left before the contractors will have to be told to down tools until additional cash is sourced. There is a team at work trying to figure out if the requirement can be adjusted to accommodate at least some finished structures that will add value to the existing facilities. The CONREP on this job greets the contractors with a huge slab of elk meat that has been shot by a co-worker and an impromptu afternoon bbq is arranged. All the workers take 20 minutes off to come eat burned meat and talk about women, beer and cars. Progress is discussed and the contractor confirms that the last punch list (snagging list) items have been addressed and offers the papers to prove it. Afterwards a brief walk around identifies more items for the punch list and the principal contractor immediately tackles the sub contractors involved. One of them is on a second warning for not having a non-return valve on an acetylene torch and is warned that a further infringement will result in him being removed from site, but nobody falls out because of the manner in which he is told…..clear…direct…factually…not personal. I found a strip of spent percussion caps from a nail gun and pointed it out to the CONREP (trying to be helpful). The strip is tossed to the ‘superintendent’ (the site manager) with a playful quip that it’s a $1000 fine for every cap (spent or not) according to the contract, meaning the guy is now holding a $10,000 fine in his hands. The superintendent disappears to find the offending subbie and the CONREP is happy that it won’t happen again.

So what is the main difference between the two projects that really ought to be the same? It’s the working relationship and how the rules of the contract are enforced. You can smash the contractor until he is in a position where he is underfunded, on the back foot, off guard and becomes more and more open to further criticism until the project grinds to a halt. Alternatively you can work together, cut him some slack when it’s appropriate and keep them all on side in a spirit of mutual cooperation. Both projects are failing for very different reasons, but the difference is that for one them it is not necessary!

Wanted to take some lovely pictures for you guys to see – but I fear I might just get arrested. No photos allowed on a military base I’m afraid. I need to get a media pass and show all pics to the guard staff on departure….but what they don’t know can’t harm me. Will endeavour to indulge in subterfuge for the cause.

26 Mar 12

Contractor on the Mechanicsburg site has been ‘blessing’ the concrete pour as high winds were making a lean mix difficult to finish. CONREP has informed them that if this develops tension cracks they will tear out and replace at their own expense, but again, no love lost. I am fascinated by the fact that the client’s representative on site is expected to be an engineer and a clerk of works at the same time. He carries a specification with him for the job and is expected to do all the tasks that would be expected of the clerk of works. (I for one would not have spotted the missing non-return valve on the acetylene tank). I think it works though because the contractor is responsible for the Quality Control issues with the CONREP and PE focusing on Quality Assurance so the checks should be for back up anyway.

Have completed the first of my compulsory training……drug abuse and suicide. I thought I’d be free of MATTS for at least a short while!! Apparently if you suspect someone may be having dark thoughts you have to just come right out and ask them. I have been asking the office repeatedly if they are thinking of killing or harming themselves as a precautionary measure.

Vehicle registration fail….doh. But on the plus side, child number one has been safely deposited state-side…..doh.

Supervision, a spoon drain and SCAB!!

Period Covered 20 -23 Mar 12

Summary: Supervision, a spoon drain and SCAB!!

Work as a supervisor has begun in earnest with safety (monitoring on site, paperwork audits etc) and sub contractor co-ordination my top priority. I am understanding how the site operates, meeting the sub contractor supervisors and building a working relationship with them

During this period I have completed the following:

- Supervision of GMF ground work contractors – bulk excavation and pile cropping

- Risk Assessment and Hazard Inspection Audit

- Co-ordination/supervision of Union Rep

- Service tunnel spoon drain – liaison with design team and contractor (contract dispute)

- Reports and returns – Site Diary etc

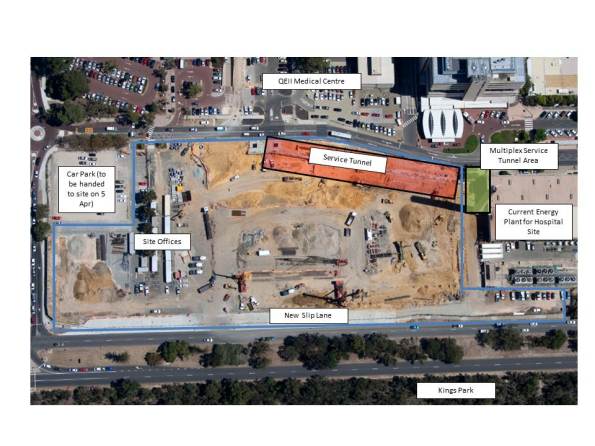

Aerial Photo

Work on site. No Change – less GMF (cropping pile team) and Crown (concrete capping beam team) contractors have been stood down until Wednesday as a result of safety concerns in order to allow adequate working space between piling and other contractors.

Issues. Considering the site has been going for only 10 weeks there seems to be a growing number of problems. The highlights are:

1. Congestion of Site/Possession of Northern Boundary by Multiplex. The first milestone on the project is to handover a new service tunnel to link the services to a new constructed energy building. This is driving the programme and the focus is to deliver the first stage of the tunnel to the client on 2nd May and the whole thing on 29th May.

However as a result of the client handing the most northerly section of the tunnel to another contractor work in this area by JHG sub contractors has been severely restricted. In an attempt to catch up time the piling, pile cropping and capping beam contractor were all compressed in the same area. This led to lots of co-ordination/in fighting with the sub contractors (good work for an army officer acting as a supervisor). This went on for 2 days until a call was made that it would be safer and more efficient to pull everyone less the pilers away from that area.

2. Spoon Drain. The service tunnel has a spoon drain at the bottom of it to collect and drain water running along the inside of the retaining piles. This was a detail which though pretty simple I spent a lot of my time this week dealing with. Until I got involved there were no dimensions or levels for this, and it took a lot of going between the Architect and the Structural engineer to determine who was responsible for this detail and to get the required dimensions.

Along with this the earthworks contractor initially refused to do the detailed excavation required for this work and it took the involvement of the Works Package Manager, the contracts administrator and myself to get to the bottom of it. It transpired that detailed excavation was not included in the Lump Sum part of the contract but was included 5 sections later under a schedule of rates section….problem solved after a bit of tension.

3. Trade union relations. Australia has a very different set up with powerful trade unions which are normally part of/affiliated with construction companies. John Holland has a different view and believes it can have a better relationship with its workers directly. This seems to work fine, less the relationship with John Holland and the Union Reps. Recently on site the Reps are coming on site to cause trouble and on one occasion the police have been called. As a supervisor I was responsible for babysitting the Rep during his last visit to site and ensuring he followed the rules. Interesting but a little weird!!

4. Oh Shit we hit something. Initially on site there were many services crisscrossing site and these have mostly been removed with a plan to remove the final few in the next 10 days. On Friday however whilst excavating the service tunnel a 150mm water pipe was struck and water released onto site. Emergency plumbing works will finish the diversion of this sewer over the weekend and the site was lucky as the water was “clean” (cooling tower condensation water) and will easily disperse in the Sand. Of more of a concern is that there is a High Pressure Gas main in the north of the site which we are still waiting permission from state to relocate….lets hope we don’t hit this!!

My Experience. I’ve been amazed at the speed of progress on site. The excavation progresses at 100 trucks a day as well as 10 CFA piles per day. My role has developed with me deputising as site manager on my third day, as the real site manager was on a training course and I have worked more with the engineers, trying to sort out the spoon drain detail – this has also given me some commercial experience and my initial naive thoughts of working as a team have been banished as commercial arguments have occurred this week.

I have observed the difficult role a managing contractor has. There is a balance bewtween a working relationship with the subcontractors and acting in clients and John Holland’s interests. This becomes evident with Safety v productivity issues. My view is that John Holland as an excellent paperwork system which should ensure safety on site and this understood by the Engineers and the Management but there is still a core of Supervisors who see safety as getting in the way – this will mean a constant battle to keep on top of this.

Finally, I have realised the importance of sketching. This is how I have been communicating with all of the subcontractors this week. Whether it be simple site plans or more complicated design detail being able to sketch quickly and clearly is obviously an art which I need more practice at!!

Week 2 – 19-24 March 12

This week I have mostly been finding my feet (try and say it like the fast show character). With the arrival of a mobile phone, a temporary laptop and having acquired a desk by buttering up the PMs PA, I have commenced working. At the start of the week it was a bit slow as we moved into our house and I had to deal with the removals arriving, but from Wednesday on it was all work, work, work. Well at least until 11am when the heavens opened and we had 120mm of rain in 2 hours. Oh how I love my scooter in the rain, particularly when water creeps into the engine and it keeps stalling!

Rain does not however stop the office which continues to be a hive of activity until about 2pm on a friday when people start to sly away for flights home if they’ve got Saturday off. This week I am not so lucky and am on the saturday shift but at least it’s an early finish with an 8 hour instead of 10 hour shift. It’s also giving me the opportunity to write this!

My roles and responsibilities are slowly taking shape and I’m running with the enabling works for the traveller to construct the jetty. We had our first meeting with a contractor this week and I will take the tender forward for revision of the scope of works before advising my package leader as to when to award the contract. This is only a measly $250,000 but it is something none the less and I am happy for it. I shall be looking to squeeze the contractors price in order to maximise profitability balanced against the fact that we still don’t know when the start date will be. We are waiting on Bechtel to issue permits for construction and from that point it will take about 8 weeks until the first boots on the ground.

I have also been tied up in classic Sqn 2IC business, proof-reading the work of junior personnel. The project plans (there are numerous including, traffic, safety, environment, etc) all need to be submitted for signature by the PM before being approved by Bechtel. I’ve been going through each of these in turn and conducting the proof reading, re-formatting, etc but it does give me a strong understanding of the project. I have also been amending accordingly, adding what engineer value I can where appropriate. Disappointingly they do not conform to JSP 101 but they will by the end of April when I’ve finished with these docs! The package leader is semi-impressed with my OCD and attention to detail but would probably prefer me to be a bit quicker.

In terms of engineering, I’ve not seen much as yet as the Jetty project will not be starting until May. However, the commercial side is ramping up and I’m going to be getting ticks in those boxes at least. I am going to be responsible for the test piles and their testing and to save money I am currently trying to use existing pile cut-offs that would otherwise be sent for scrap. The concept is to weld sections together in the hope of saving on the outlay for a 40m length of 1200mm diameter, 25mm pile. This might work but I need to do a bit of work on the strengths of welds, etc to ensure that they don’t fail in the testing. Watch this space.

I’m also designing (well on a fag packet as John would say) a concept pile cut off platform by bastardising (technical term on site here) a 3 pile group platform that was fabricated and not used on the MOF project. This is a work in progress and once I’ve done some calcs and with a bit of builders eye, I’ll hopefully be able to send my design off to the fabricators for said bastardisation!

Moving to off-site matters, I have spoken with John Reddie this week who was keen to learn from our transition from the UK to Gladstone. We certainly had a better one than the Marsh family but I suspect it was more to do with personality on my side and subtle/gentle persuasion as appropriate. That said, the PM won’t let me have international dialling on my phone! I’ve also been in contact with a communications executive (media man) from JHG who met me on a site visit. He’s going to run an internal JHG piece on me (us – I let him know of Steve, Ros and Dan’s existence) so there may be more to follow on that.

Family is all well. Lisa is now 35 weeks pregnant so the final push is getting ever closer. She is more relaxed now with us being in the house which is allowing me to focus on work. It’s long hours so we don’t see each other much in the week but any more and I might spoil things! Lisa has successfully filled the house with tat and I’m amazed at how much she sent without me knowing, particularly cushions, throws and bunting! Most importantly though is the fact that the kids mountains of toys are here, my dive kit (not that there’s any dive clubs in Gladstone as it’s only in the barrier reef national park) and of course, Austyn’s birthday presents!

All-in-all, life is good. More of the same is to follow and I’m still enjoying it (apart from the 4am wake up call). No photo’s as yet as I’m awaiting permission from Bechtel but this should be through soon. Otherwise I will set up a covert OP and they’ll never even know….

TTFN,

Roy

Progress…..

12 hours later – success – Common Access Card in hand and hopefully the paperwork is queued up for Ben Hancock now as well.

Vehicle fixed without requirement for payment or for state police to get involved.

Next up – compulsory computer training with USACE, medical registration for family, driving tests to be booked and then any other hoops they want me to jump through….come on USA – what other admin you got!?!?

Initial Start on Site

Period Covered 16 -20 Mar 12

Summary: Initial Start on Site

I have now started on site and my initial impression is that it is a great time to start. There are currently only 12 JHG personnel on site (Engineers, site manager, supervisor, H&S, Labourers) and approx. 60 sub contracting personnel. By October there will be 1000 people on site!

During this period I have completed the following:

- Meeting with Site Engineer and Manager

- On Site Induction (4hrs)

- Initial situational awareness, familiarity with site and subcontractors

- Right Of Entry/Union Training

- Meeting with QA

- Handover of duties as supervisor

Orientation to Site: (Server error on site, site plan and aerial photo to follow)

200m x 100m

Photos

1. Showing the congestion on site and the importance of co-oridnation and safety of subcontractors on site

2. Showing the start of the basement construction

3. Showing the problem of not using a debonding agent when breaking out the blinding layer

Work on site. The focus on site currently is five things:

- CFA piling to retain basement perimeter for basement excavation

- Excavation of basement level to RL 4.5

- Construction of New Service tunnel (150m) to link old services to new Energy Building)

- Final construction of Slip Lane (loading and offloading)

- Diversion of existing services

Issues. Considering the site has been going for only 10 weeks there seems to be a growing number of problems. The highlights are:

- High Pressure Gas Main under slip lane. The building of the slip lane next to Winthrope Ave (East) is key to the logistic plan and successful construction of the project. The slip lane provides the only onsite loading and unloading point once the basement has been excavated. A Just in Time logistics plan is being developed and tower cranes (5 eventually) will be used to unload the material. However the slip lane has not been finished as a High Pressure Gas Pipe runs across the proposed slip lane access. The State were approached 3 months ago to redirect this service but nothing has happened yet. If a solution is not created soon then this will delay the project.

- Historic Services/Asbestos Pipes. Even though a site survey was completed and each subcontractor scan the site before commencing any digging to get a permit to dig old services and pipes are still being found on site. This has included asbestos pipes. As a result a specialist contractor has been required to clear these when they are found.

- Rainwater “Urban” Drainage. At the northern end of the site is the old energy building, which will eventually be knocked down. At the moment however it’s rainwater drainage flows directly into the site. As a result 6 x soakwells have had to been installed which collect the rainwater and disperse it away from site into the sand.

- Removal of Excavated Sand. The ground work subcontractor GMF are falling behind schedule with the removal of excavated material from site. Due to the limitations of site space if they can not get the material away excavation work ceases. GMF do not have their own drivers and rely on a fleet of private drivers. JHG are being told that there is a lack of drivers in the city as they have all gone North to the mining site.

- Use of debonding agent. To assist in the construction of the capping beam above the CFA piles a blinding layer has been added to enable the works. This is then broken off as the excavation is dug. There have been issues with the capping beam being damaged when this has been done, so a debonding agent is now being used to minimise this damage.

- Shotcrete metal content and Z bars. The CFA piles are covered in Shotcrete. This has a metal content and has been designed to waterproof the piles and ensure water runs down them and into drains and the bottom. There have been issues with the metal/concrete mix and initial high ratio metal content mixes were unworkable, as a result a lower metal content and 2 meshes are being used instead. Though the engineer on site believes this is not structural, the design has required Z bars to be used to go around corners and pile caps. These are additional to the original design and not on site.

- Noise and Dust Control. The site’s proximity to the hospital site and residential areas means work can only commence from 7am to 7pm Sat – Fri. Along with this there are environmental controls and monitoring in place for noise and dust. Dust is being controlled by water spraying and the road is swept when required. As the work falls behind schedule then I believe an application to work Sundays will be submitted.

My Experience. Currently I have been given this week to get myself bedded into the site and work with the Engineer in charge of the excavation so my responsibilities are growing. I am expecting to move into supervising role later this week and then move onto more of an Engineer role once I have bedded in.

My Observations.

- Safety. I have a sense of disappointment that the safety message is not matching reality on site. Though paperwork is thorough and briefing continue there are many safety errors and the subcontractors seem to have a very relaxed attitude to safety. As I am likely to be in charge of the West of the site I will be considering some safety incentives and improvement schemes to implement. (And ask Rachel for UK Best practice and incentive schemes!)

- Co-ordination between Architect, Design, Construction. The detailed design really is only being signed of days if not hours before construction starts on site. This has already caused an issue with the Z bar/Shotcrete issue on site. With the Z bar on site and no on site “fixes” allowed by the designers the Z bar had to be ordered by the subcontractor = extra expense on site. Today I was told an extra 2000m of piling had been added to the plan once the piling had started as the design changed!

- Management Contracting in action/Partnering. I am finding this very odd. It will take me a while to find the balance between commercial and partnering relationships. In the short term there is limited commercial awareness on site and the refreshing overriding attitude is that whatever needs to be done to keep the project on track is to be done. (There is an unconfirmed value of liquidated damages of $140,000 per day the project is late)

- Co-ordination. There is a new team working on site from John Holland and the command structure is developing rather than being regimented. This ends up with information being lost and sub constractors beign told different things and confusion. Myself and the site manager are sorting this out, and as I move into the supervising role this will become clearer.

- Water Level – engineering rigour. More details to follow – but my initial reaction is there is a lack of engineering thought on site. For example no one is able to tell me the GWL on site and no seems to no where the bore hole logs are from the SI!!

Further Work

- Take on supervisor role, deputising for the site manager – co-ordination of sub contractors and monitoring logistics and health and safety on site.

- Continue to understand the site and the sub contractors.