Archive

A night in the life on a rail project: how much time do you have to work on the night shift and how many people does it take to do anything? Spoiler: not a great deal and flipping loads.

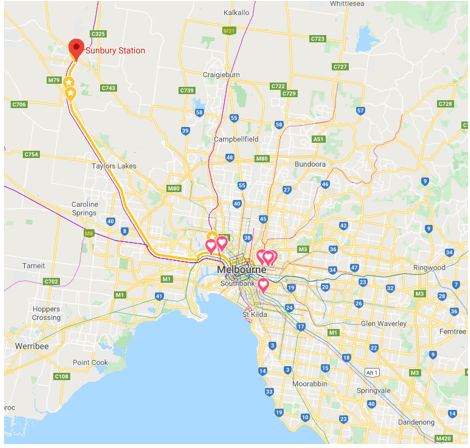

As part of one of my ongoing jobs, I have been asked to facilitate and manage the surveying and site investigation of Sunbury station and surrounding areas for a future upgrade and track widening.

As part of this project, there was a requirement to capture the last 10km of track from Sunbury towards Melbourne digitally. This involved mounting a machine onto a ‘hirail’ modified ute and driving up the track. The data capture is akin to google street maps but captures enough data to create a 3D model of the surrounding area and skinned with high quality photography. Accurate to about 5mm. I can write another little blog on this kit if people want to get their geek fix. Photo below shows the data capture machine mounted to the rear of the ute.

The hirail modification can be seen in the photo above too. The ute operates like normal, but once over the rails the steel wheels that are raised in the photo at the rear of the vehicle then lower and engage with the track. The ute’s normal wheels drive the vehicle forward, the rail wheel keep it on track.

Working on the track is called an occupation (occo for short; Aussies abbreviate everything). This type of occo that occurs over night is called an ALBF (After Last train at night Before First train in the morning).

Originally, I had thought I would need a lot less manpower and have a lot more time than I actually did for this simple job. I’ll run through what we actually needed.

The Plan

Manpower and Resources

- HiRail Ute

- TVO (Driver)

- Data collection wizard (Veris)

- HiRail Unimog

- TVO

- Signals Engineer

- Traffic Management

- 2x vehicle with 4 crew (Holden Road Xing)

- 2x vehicle with 4 crew (Gap Road Xing)

- Free running Vehicles (each in their own Ute)

- Project Manager (me)

- Track Force Protection Coordinator (TFPC)

- Survey Manager

- Track Certifier and Supervisor

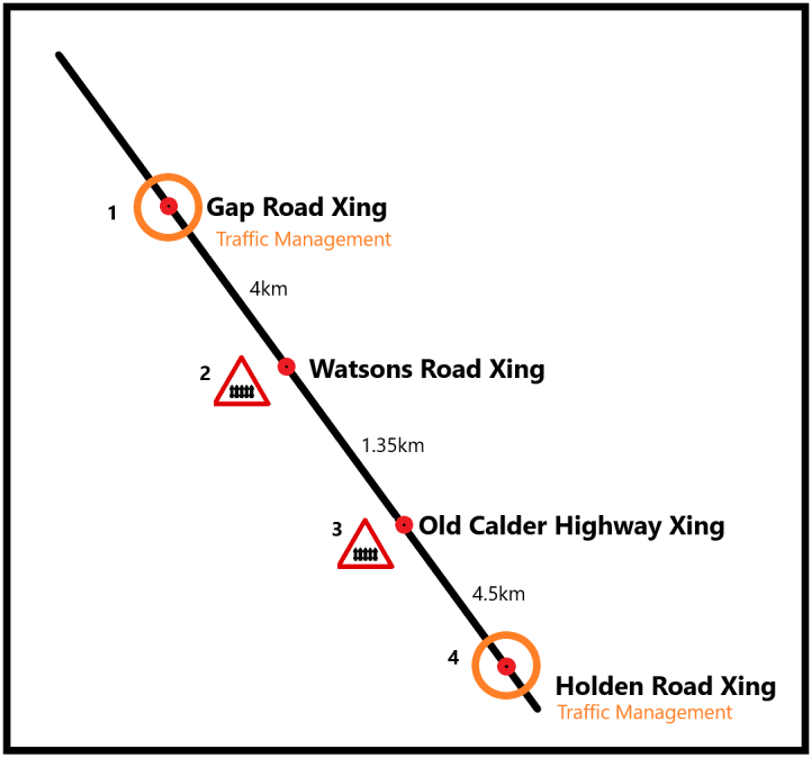

- Level Crossing Controllers

- 1x TFPC at Old Calder highway

- 1 x TFPC at Watsons Road

Permits and Certifications

- Permit to Work

- 2 x HiRail Vehicles must be track certified, John Holland inducted, isolation checked and PlantGuard checked. (All different online systems, need VRN of vehicle)

- Each member must ‘sign on and have their ‘Rail Industry Worker’ Card checked for currency.

- 35 page Works Group document.

(Lets skip to…) What happened

At midnight I briefed the workforce of the plan, H&S and all that good stuff. Then they had a bit of time to get into position. When planning these things, you don’t actually know exactly when the last train will pass AND the safety team have put out their signage. The last train, I learnt, was 0130hrs, the works group plan told me that we must be off the track no later than 0400hrs. This gave me 2.5 hours to play with.

At the given time, the two HiRail vehicles would get onto the track at Holden Road under traffic management. They would start to move up the track, optimum speed would be at least 20kph, but for the first run on a new track the signal engineer had to check the signals were ‘ok’ (more info if anyone would like me to explain) before moving on. The two crossings would have the booms manually operated to allow the two vehicles to pass without slowing down. At the Gap Road crossing, under traffic management the two vehicles will turn around and return.

One loop (there and back) would be ok, but every other extra loop would increase the quality of the data capture and reduce the chance of repeating this work. A workforce that knew this and knowing their part and everyone else’s parts would give us the best chance at getting this evening to go smoothly.

We waited for the call that the rail line was clear to drive on. 0140hrs, 0155hrs, the time went on. At 0205hrs we got the call. Oh, and just before the formal briefing to the workforce I also learnt that we would have to be off the track at 0330hrs. My 2.5 hour window was reduced to 1.5 hours. Within this time, we just got in 1.5 loops which was acceptable. No one was hurt and we didn’t prang a vehicle, so I consider this a success.

Summary

For 1.5 hours worth of work and a simple plan, it took 12 vehicles and 14 people to enact. I spent 1.5 days in preparation as well as plenty of random actions to tidy up loose ends. I was massively surprised that this seemingly simple job took so long in planning and sucked in so many resources. Bed for 0430hrs, back in fornt of my computer by 1100hrs. zzz, apologies for any typos caused by sleepiness at the keyboard.

Benny Hill Show in the North Sea

Thought I’d share with you all my slightly chaotic first experience of being responsible for a contractor deploying off-shore!

Background

The Glen Lyon Floating Production Storage and Offload (FPSO) vessel (pictured) requires an upgrade to their existing Helideck Management System (HMS) to bring it into line with upcoming legistlation changes from the Civil Aviation Authority (CAA), no later than 31 Mar 21.

I am the project engineer responsible for delivering the upgrade.

Fugro Engineering (HMS vendor) had taken part in trials with the CAA earlier this year and as such, their HMS was the first to be certified as compliant with the new legislation. It was decided that although they will not be the chosen vendor for the installation, we should employ Fugro to conduct a survey of the existing HMS and ask them to come back to us with a detailed gap analysis and proposed modifications. This gap analysis would then form the basis of the client SoR that I am writing later this year.

I liaised with Fugro and arranged that 1 x service engineer would deploy off-shore for a period of 7 days to conduct the survey. They requested that I provide them with an array of documentation (block diagrams, commissioning reports, general arrangement drawings) prior to deployment. After checking that releasing documentation to Fugro was ethically sound from a commercial perspective (they are a competitor to our existing HMS vendor), I obliged. I would later come to regret not asking them whether that was all they required.

Finally I warned off the off-shore team that there would be a contractor deploying to conduct a survey of the HMS.

What Happened

On the first morning of the survey, after conducting a visual inspection of the system and looking through physical documentation, the Fugro engineer then inserted his own USB hard drive (big no no!) into the BP system to, in his own words, “download recent service visit data for data integrity verification”.

This hard drive then “accidentally” fell off the desk and swung into an open cabinet beneath and hit what I can only imagine was a big red button. This consequently managed to shut down the Integrated Marine Monitoring System (IMMS) and the Differential, Absolute and Relative Positioning Sensor (DARPS). In short, this meant that the whole HMS was effectively shut down, meaning that no helicopters could take off or land. The engineer was unsurprisingly stood down, pending a review of the incident.

Key Mistakes

Thankfully there were no serious consequences arising from the incident and the HMS was back up and running in short order and the engineer erased all of the data extracted from the system onto his hard drive. There were a few key mistakes leading up to the incident which could have easily been avoided:

1: Failure to confirm data requirements. As mentioned above, I had naively assumed that the documentation I had sent over prior to the survey was sufficient for their needs. I should have confirmed this and asked whether there were additional data requirements from the live system. This would have then enabled me to warn off the off-shore team, who could have ensured that the engineer was adequately supervised.

2: Inadequate Survey Scope of Work. The “normal” procedure for off-shore surveys is the production of an “survey scope of work”, which is typically produced by the off-shore sponsor. This job fell between the cracks because the survey was co-ordinated between the Aviation Technical Advisor and my department, both of whom are on-shore. The consequence of this was that when the engineer arrived, the off-shore team were not entirely sure what the purpose, scope and limits of his visit were, which ultimately resulted in the incident occurring. It was an assumption (that word again) of mine that the off-shore team were fully aware of the survey and would be on hand to ensure that it went smoothly.

3: Inadequate off-shore induction. The particulars of BP’s policy on IT security were not included within the induction briefing given to the engineer, specifically the use of unauthorised USB devices.

Key Takeaway

*Stakeholder Engagement is vital!* “Stakeholder engagement” is a phrase that I have glibly written numerous times of the course of phase 1 exams and projects. This experience has certainly brought to the fore that the lack of it can has calamitous consequences. As a project engineer and single point of accountability in BP, there is a lot of work that goes on around me and it is ultimately up to me to ensure that everybody is suitably informed, briefed and fully understands what is happening, when and by whom. This is doubly important in the oil and gas industry; I’m in the awkward position of being ultimately responsible for contractors off-shore, without the luxury of being physically present to ensure that it runs smoothly!

Making assumptions is a dangerous game and a mistake I will certainly not make again. To finish with the universally applicable advice of my first Troop Sgt – “Sir, it’s good to trust, but it’s much better to check”.

Pile Cropping

Debond, Debond, Debond!

An interesting loop hole/oversight, that we have come across on site. The main bars for the pile cage are de-bonded using foam down to cut off level.

The designer will never approve foam all the way down to cut off level in case of any drop in the reinforcing cages. (They allow 50-100mm). The piling subcontractor have a tolerance of cage level of -50mm and +150mm in accordance with the ICE Specification for Piling (SPERW). In this case, we have both extremes of +100mm and +150mm, which has resulted in 250mm of bonded concrete.

Normally, this would be easy using a pile cropper or diamond drilling company but not when it is bonded. Back to pneumatic picks by hand.

The drawings and tolerances were all checked by the piling subcontractor, principal contractor, designer and client’s representative. All failed to spot the issue, myself included. I would expect the piling subcontractor to be fully aware of the issue but again nothing was mentioned.

Contractually, nothing that we can do. The pilers are within these individual tolerances. Unfortunately, it falls on the next subcontractor to work through the issue. This means a lot of time and especially Hand Arm Vibration (HAV) as they work around the main bars.

The lesson here is even though the tolerances may appear acceptable in isolation. The sum of these tolerances have resulted in extra time, cost, and H&S risk.

The Art of Blogging / a belated mid-year resolution.

Since leaving Phase One I have submitted 1x very short blog post. This is significantly less than the recommended minimum of one/month.

Meanwhile the client’s representative on my project has no issue filling my inbox with updates from site, which, to be clear, is currently a hardstanding awaiting the delivery of some site offices.

How can they produce so much content from so little?

The updates are short and sweet but make a point. A geo-tagged photo with the comment: “Hoarding sign has come away. Stronger cable ties required.”

Clearly, a balance needs to be struck between aimless waffle and a blog to assist in the Professional Development of the collective but my question to the floor is have we gone too far the other way?

Do we all just view the blog as a chore at the end of a long day / yet another thing you need to research and produce? Would a quick update about something you thought was interesting, sent direct from your mobile, increase the frequency of Blog posts and allow us to know more about each other’s experience?

I don’t know the answer but will try and blog a bit more in the 2nd half of the year… So long as TMR 2, Thesis Form B, TMR 3, AER 3 and Thesis Form C don’t get in the way. 😉

On the bus, off the bus, repeat.

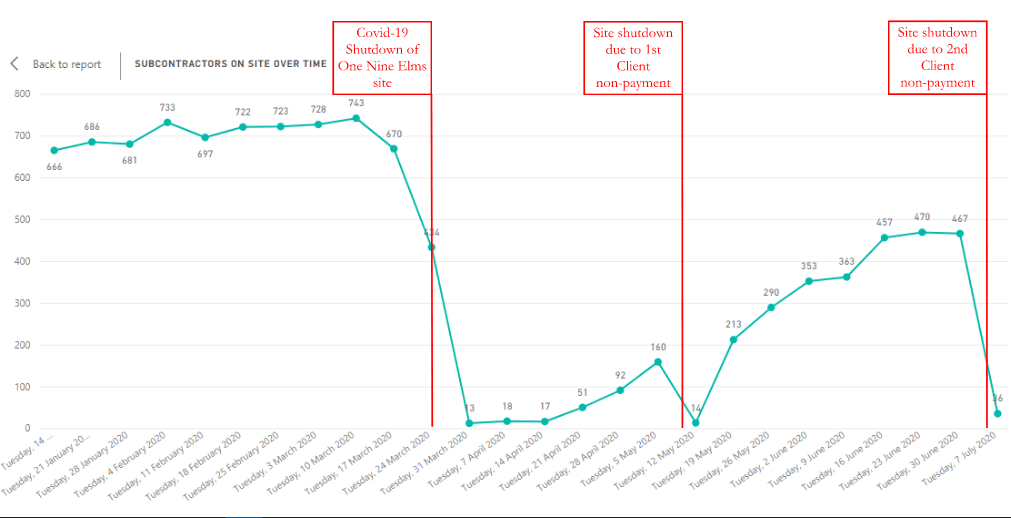

Prior to Covid-19 hitting the UK, the One Nine Elms (ONE) site in London was operating at 600-650 operatives each day. Running two jump forms, pre-stressed slabs, facade installation, large raft slab pours, demolition, blockwork the site was in full swing.

When Boris announced that we all must stay at home, Multiplex (Principal Contractor) assessed the situation and took the decision to shut the site until such time as mitigation measures had been put in place to make the site as safe as possible. Significant time was spent re-configuring the canteen and welfare areas to allow social distancing rules to be adhered to. When site opened back up on 20 April, it was running at 50-70 operatives for the first week with phased increases in subcontractor numbers on site to safely manage the new measures.

A mere three weeks after returning to site, Multiplex took the decision to cease works, this time due to non-payment by the client – the monthly valuation was priced at just shy of £13m. Thankfully this closure was short lived as the client paid up after only 2 working days lost on site.

Fast forward to now. Last Monday 29 June, notice was issued to all subcontractors and consultants of our intention to suspend works due to non-payment of the client, come Sunday night no payment had been made, resulting in a cessation of works on site at COP Monday 6 July.

Speculation within the project team has been made as to the cause of the non-payments. Some think that this is part of a strategy by the Chinese client (R&F Properties), I think this unlikely as these stoppages are likely to cause delays to the programme and, in the form of loss and expense claims from subcontractors, significant excess costs. The delays to the programme are only exacerbated by subcontractors being unable to mobilise operatives quickly following the recommencement of works. Numerous subcontractors have already warned of delays of up to six weeks before they would be able to achieve full strength on site.

My estimation is that, more worryingly, R&F are facing significant cash flow issues. R&F owns four development schemes in London valued at £4.5bn, of which One Nine Elms is likely to top out at £1bn. With these significant costs and with delayed payments becoming a worrying trend, it will be “interesting” to see how this situation plays out. With the number of projects in the UK and Australia backed by Chinese investors I’m curious if anyone else has faced any issues recently, or if I’m just the lucky one?

Long term lessons learnt?

Yesterday during the Comdt’s backbriefs the issue of lessons identified/learned was raised. This prompted me to finally write the blog post I planned to write a while ago and never got round to completing but with different conclusions.

The apartment I’ve been renting in Melbourne has 14 storeys above ground and a 2-storey basement. As far as I can establish, the building was around in 1996 so is at least 24 years old but could be older (internet research is currently drawing a blank).

Why is this important? Yesterday we discussed whether we are failing to truly identify and learn our successes or failures immediately after an event. Generally, the consensus was that we are bad at ‘learning lessons’. If we fail to do this in the short term, I suggest we are even worse at identifying our successes or failures further down the line… say 24 years later.

Our car parking spaces are on basement level 2 so approximately 6-8m below ground level. Following rainy weather, there is always water on the floor of the basement (Melbourne’s climate is similar to the UK so there’s a fair bit of rain). The water appears to enter the basement around the service penetrations (ventilation ducts) and through construction joints in the diaphragm walls and at the wall-column interface. I’ve taken a few pictures to show what I mean.

(Note the water penetration is from the vent ducting at the top of the picture and not the pipe.)

Why is this an issue? Well for me and the other residents our stuff gets wet. This is annoying but can be worked around. The bigger issue is structural durability because the ingress of water can increase the reinforcement corrosion rate and could lead to early failure of the wall. At the service penetrations and column-wall interface, there is likely to be sufficient cover to protect the reinforcement however at the mid-height wall construction joints there won’t be. I’ll hedge my bets that the contractor didn’t apply an additional protective coating to the rebar at this location meaning the reinforcement will corrode quicker.

So here are my thoughts on reviewing the construction/design issue 24 years later:

- Why were construction joints used at mid-height?

- Could the pour height have been increased so the basement walls were poured in one go? If not (due to concrete drop height or safety issues) could additional reinforcement be provided at the construction joint or a protective system employed to mitigate against corrosion?

- Was the ventilation service penetration part of the original design or was it added at a later stage?

- Was the sealant around the ventilation penetration fit for purpose and was it installed correctly?

- Has the sealant’s design life been exceeded and not replaced? Is poor building maintenance an issue here?

- Have any of these issues been highlighted to the Designer/Contractor to influence their future decisions/works? I suspect not.

My consultant does a lot of inspection of old bridges for asset owners which allows them to identify issues with historical designs that can be adapted or mitigated in their current designs, hopefully avoiding similar issues in the future. I’m not sure if the same exists in the vertical construction space but a feedback loop from building condition surveys to designers would be one way to improve future designs. I admit I don’t have the answers but hopefully, this post will spark some further discussion.

FPE Basics

I stumbled across this at work today. It’s an article published in The Singapore Engineer in April 2018 and is written by engineers who work in one of SMEC’s sister companies.

The article covers Singaporean legislation requiring buildings to be protected to prevent terrorist attacks. From what I remember of the FPE Level 1 training on RETCC and subsequent insights at 170 Engr Gp it also covers the basic FPE assessment process and principles.

I thought I’d share for two reasons:

1. As basic revision prior to the Phase 4 FPE Level 2 training.

2. So we can compare UK military practice to the civilian consultant approach. At this stage, I suspect they are very similar.

Protecting Infrastructure Against Terrorist Attacks – Surbana J (sorry for the poor quality of the images but a pdf print copy was the best I could manage).

Phase 2 attachments – Client or contractor side? Which offers more value?

Greetings everybody from North East Scotland!

The relative utility of taking on a client-side role during phase 2 was a subject that I broached in my most recent AER. Following on from this, I’m keen to stimulate a discussion amongst my wider peer group, past and present, as well as academic and military staff, as to the merits (or otherwise) of taking on such a role when compared to the more “traditional” phase 2 experience of working for a principal contractor.

As a basis for discussion, I’ve included below what I believe to be some key pros and cons of working in such a role, based partly on my experiences to date at BP. My intention here is not to launch a scathing indictment of client-side roles, more to enable a forum for people to share their lived experiences.

Pros

Risk Management Exposure – As the client’s representative, it is highly likely that risk management and mitigation will feature very highly on your list of priorities, due to the accountability that you have to the end user. In BP speak, you are the ambassador for ensuring that the business priorities (read design philosophy) are adhered to and are empowered to hold the contractor accountable. This in turn gives you more license to “steer the ship” in the name of ensuring that business priorities are met and ultimately that the benefits are realised by the end user.

Refinement of Engineering Vision – On the client side, the production of a fit-for-purpose Statement of Requirement (SoR) is arguably the most critical responsibility. Even the slightest ambiguity over the course of a complex project could lead to significant divergence from the initial vision. Being on the client side offers the opportunity to practice the art form of being specific but not prescriptive in your needs. This in turn forces you to practice using engineering judgment to get to the core of the problem and articulate this in a simple, easy to understand way.

Comparatively Slower Day to Day – As the principal contractor is likely to be shouldering the majority of the day to day management of a project, this could enable the opportunity for a PET student to diversify his/her range of responsibilities, with a view to ticking off some of the more niche areas of the UK SPEC/ICE competency requirements. This could, for example, take the form of leading a design review (if, like me, your phase 2 and 3 is combined), taking on a sustainability initiative and chairing a business ethics working group.

Cons

Costing/Scheduling – In many cases, the exposure on the client side to costing and scheduling for one particular project is confined to setting the initial goal posts, followed by scrutinising and responding to any requests for change. This then limits a students learning potential by not having the opportunity to experience the complexities of day-to-day project management, the pressure of operating under financial headroom and the engineering challenge of using the resources and subcontractors at your disposal to complete a project before a deadline.

Construction Practicalities – Whilst refraining from using any ivory tower analogies, the argument that not having day to day site management experience is a disadvantage is a valid one. A client-side attachment limits exposure to the complexities of getting a project off the ground in the real world. This is particularly relevant when considering our future roles within 170 Gp; not having a depth off on-site experience could lead to the setting of unrealistic targets (scheduling, buildability) for MCFs or other contractors.

Implementation of Relevant Legislation – A client side attachment limits a student’s experience of actually implementing pertinent legislation – HSWA, CDM Regulations, IET Wiring Regulation etc, alongside secondary or locally produced standards (JSPs, BP ETPs etc). This blind spot in competence could limit a student’s pragmatism in the future, for example insisting on implementation of British Standards in construction activities on operations, despite the practical constraints of doing so or the irrevelance or certain guidelines to the situation at hand.

If you’ve made it this far, well done and thank you! I’m very interested to hear what other people’s experiences have been, on both sides of the fence. Feel free to let me know if you think I’m way off the mark!

Writing an Effective Scope of Services – NEC3 Professional Services Contract

I’m currently in the process of preparing an Invitation to Tender for six sustainability consultants. My first task is to create a suitable scope of services within the framework of the NEC 3 PSC, which I’ve completed in draft form, I’m waiting out for feedback from the procurement and contracts manager. In the meantime I was wondering if anyone had any advice or experience they could share regarding writing an effective scope of services?