Archive

Would Photovoltaics Cut the Mustard

The sustainability goal for the project I’m currently working on is a 554,000 kgCO2 (554 carbon tonne) emission reduction per annum, and it is to be achieved by project completion. Due to two late design ommissions of wireless thermostatic radiator valves and large scale photovoltaic arrays it is projected that this carbon target won’t be realised. To offset these ommissions it is suggested that a heat pump be utilised to provide low grade heat to a suitable application: which the design consultant has identified as the on-site swimming pool hot water demand via two existing plate heat exchangers. To amplify the carbon savings of the heat pump it has been suggested that photovoltaics can be used to provide the electrical demand of the heat pump, there are no explicit calculations to support this assertion.

Design consultant calculations:

Between 38 – 58 kW water heating demand based on modelling software.

That is all the design information that the consultant presents, below are some of the questions that I’ve worked my way through to arrive at an overall conclusion.

Small Selection of Heat Pump Specific Questions:

Can the consultant software be relied upon?

Can I validate their hot water demand calculation with an energy balance equation?

What local viable heat sources are there?

What are the seasonal temperature profiles for each source?

What are the theoretical seasonal co-efficient of performance (SCOP) associated with each heat source?

Why use SCOP? Does the heating demand of the pool vary with the season?

What is the real SCOP likely to be based on empirical evidence?

Is the hot water demand of the pool constant? 24/7? all year round?

How do I obtain an electrical energy load profile for the heat pump?

Won’t the electrical demand of the heat pump vary with source temperature profile?

What should I consider to determine worst case operating conditions (Highest electrical demand for the heat pump) i.e highest flow temperature required, coldest heat source temperature, lowest plate heat exchanger efficiency…?

Small Selection of Photovoltaic Specific Questions

What determines the viability of a photovoltaic solution: cost, land required, installation practicalities, servicing requirement?

Is battery storage necessary and if so how will it be designed to modulate the electrical supply and demand between the PV array and heat pump?

How can I best estimate the annual PV energy yield of different sized systems?

How can I validate the PV energy yield software/calculations?

Can I utilise a two-axis tracking system? Would the extra cost be offset by the increased annual energy production?

In a nutshell: Due to space environmental set point temperatures, the swimming pool hot water demand can be approximated as constant all year round with the energy balance equation resulting in a loss of 31.2 kW (Mostly through evaporation and mains temperature renovated feed water). The best heat source is the lake due to the highest SCOP, the COP for the lake can drop as low as 2.6 in winter conditions with a corresponding heat pump electrical requirement of 12 kW. Based on the SCOP (for the highest flow temperature of 65°C, SCOP = 3) the annual electrical energy demand is ≈ 96,000 kWh, with an average electrical requirement of 10.4kW. For a monocrystalline flat panel PV array in London, with a 180° azimuth, 33° tilt to the horizontal, module efficiency of 19% and no shading losses an area of ≈ 500m2 is required to provide the average annual electricity requirements of 96,000 kWh. That area requirement exceeds the space offered by the swimming pool roof, and adding into contention the significant shading losses (Due to nearby buildings) and sub-optimal orientation angles from the slope of the roof, it would be necessary to either increase the size of the system or relocate it (introducing the potential for significant voltage drops and increased cable size and cost)

The added complexity of utilising battery storage to modulate and supply the varying electrical input from the PV array to the heat pump would be the next steps to assessing the viability of the coupled system.

In short, the consultants assertion is likely to be impractical.

West Gate Tunnel Project Contract Dispute Continues…

This week there was some interesting developments in the ongoing dispute between the WGTP Client and Contractor. As a reminder, Transurban is acting as the Client and funding ~£2.8Bn with the State Government funding ~£0.82Bn.

Australian Financial Review Article

In summary, Transurban is seeking an injunction at the Supreme Court to prevent ‘premature’ arbitration by the Contractors over the disposal of contaminated soil. In Supreme Court documents, the contractors have stated Transurban has engaged in “misleading or deceptive conduct…in relation to the extent of PFAS affected spoil likely to be encountered at the site.”

This case highlights the importance of ‘back-to-back’ contracts as Transurban have repeatedly approached the State Government requesting to terminate the Project Agreement if the Contractor’s claims of a force majeure event are successful. The Victorian Government’s response so far is “that no force majeure event has occurred”. I think the merry-go-round will continue to spin for a long time yet.

My assessment is that Transurban’s attempts to delay arbitration proceedings is to buy time to gain a better understanding of their predicament. More time gives the lawyers more opportunity to find wiggle room in the Project Agreement. Knowing where they stand with the Project Agreement provides increased certainty on where final arbitration costs or penalties could end up (quite literally passing the buck…). If Transurban enter arbitration proceedings knowing the Project Agreement is/isn’t going to be terminated, they will have a stronger negotiating position and will know how much they will need to ‘invest’ in the process and their lawyers’ fees.

Work on the project sites continues however job losses are now at 450 (~11% of the workforce) due to the impasse. Although initially targeting site operatives this month the engineering and management teams have been hit with further cuts at engineering level expected. On the day John Holland posted a ~£33M annual loss, its ironic that the only winners in all of this will probably be the lawyers…

Defence Lecture – Sustainable Engineering: Carbon Neutral by 2050

The ICE members will have recieved the June newsletter yesterday with an invite to online lecture on 22 June. For the E&Ms the good news is the lecture is sponsored by the InstRE so I’m hopeful you can also attend for free. As an added sweetener, Maj Gary Jackson (E&M) is one of the 4 speakers.

Registration is via the ICE website (link below) or the InstRE website (details to follow).

https://ice.org.uk/events/defence-lecture-carbon-neutral-by-2050-london

I thought this is an excellent CPD opportunity for us all as military engineers and is likely to be a dominant theme for the rest of our careers so is probably not one to miss! The only down-side is it starts at 0330 (3 June) for the Australian students but a more reasonable 1830 for those in the UK.

As military engineers are we asking questions like Why are existing MOD buildings not covered in solar panels? Why there aren’t more wind turbines in training areas/camps? and Can we make more use of rainwater harvesting across the defence estate?

Why do I think sustainability will be a dominant theme for us in future? Below are some references for your consideration.

ICE sustainability Route Map and links to UN Sustainability Development Goals: https://www.ice.org.uk/knowledge-and-resources/sustainability-route-map

How is DIO promoting sustainability? https://www.ukconstructionmedia.co.uk/features/dio-promoting-sustainability/

Sustainable MOD Strategy (2015-2025) https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/498482/Sustainable_MOD_Strategy_2015-2025.pdf

Sustainable MOD Annual Report 2017-2018 https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/754154/SustainableMOD2018.pdf

DE&S Sustainable Procurement https://www.asems.mod.uk/sites/default/files/documents/EMP/Sustainable%20Procurement%20V2%20Intro%20Guide.pdf

When British isn’t Best….

I would just like to signpost you to a great article by Rob Ridley on defence connect comparing of British and other national approaches to infra. Some very valuable observations are made, and no doubt all of you are vectors to influence future change beyond PEW.

CI.

Polystyrene Formwork

Some pent up blogs to follow now that I have permission from the project office to blog. * DISCLAIMER. The contents of this blog have been made available to the author for academic purpose and are not to be disclosed other than for academic use.

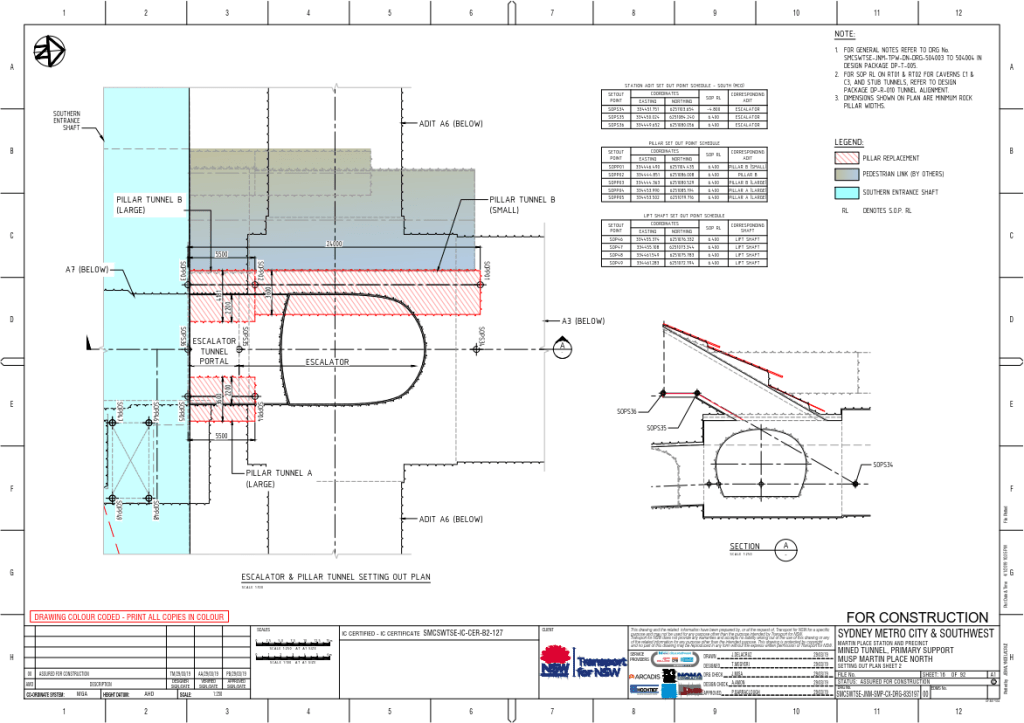

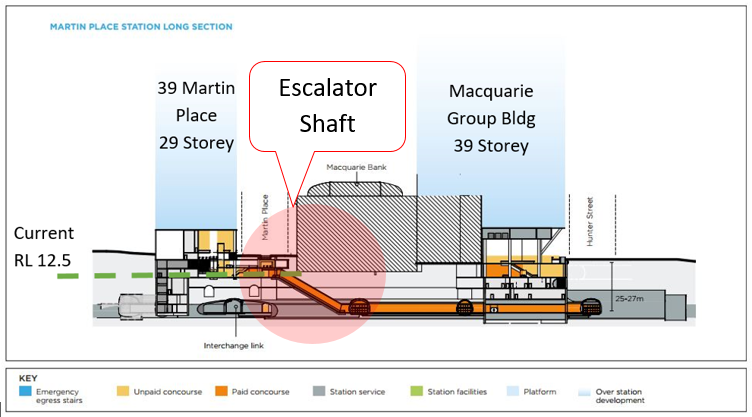

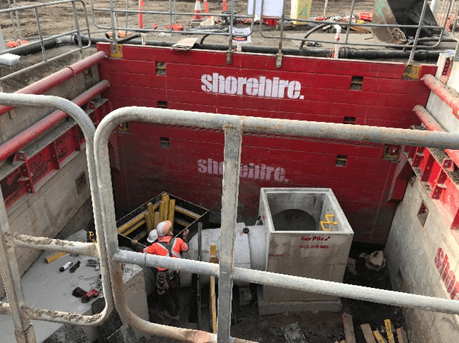

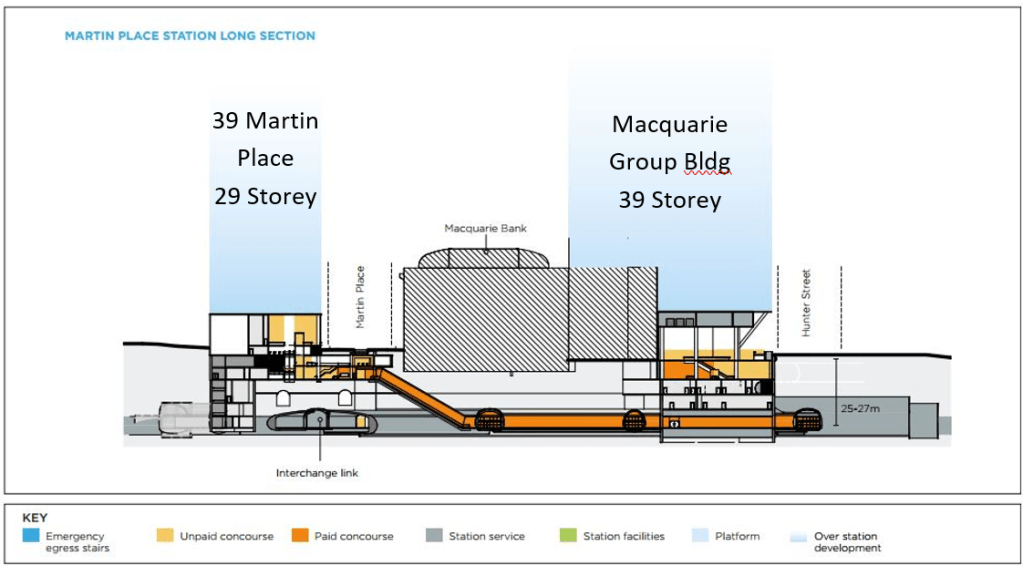

The Martin Place Metro Station site has two deep excavations either side of Macquarie Bank, a heritage building (Australia’s equivalent of the Bank of England and looks a bit like Gringots!). As per my last blog, the North Site has since been purchased by the bank, as has the over station development rights for the South Site. Long and short of it we have tunnelled beneath an important historic landmark and now need to excavate a diagonal escalator shaft from -10m below the front door, back underneath the bank and into the station cavern below. Best not to crack any of the marble…

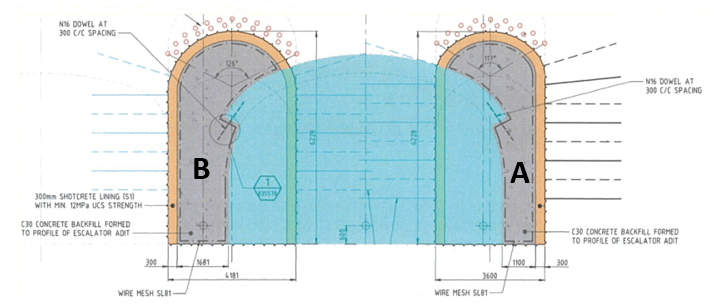

To sure up the Hawkesbury Sandstone rock beneath the bank and prevent settlement the designer has proposed three large reinforced concrete pillars be installed beneath the bank. Pillars A and B have been installed since I have been on site. The requirement for Pillar C is yet to be determined based on monitoring the bank buildings response. Pillar C could be constructed in the future by the follow on contractor, Lendlease when they start the tunnel and station fit out contract early 2021.

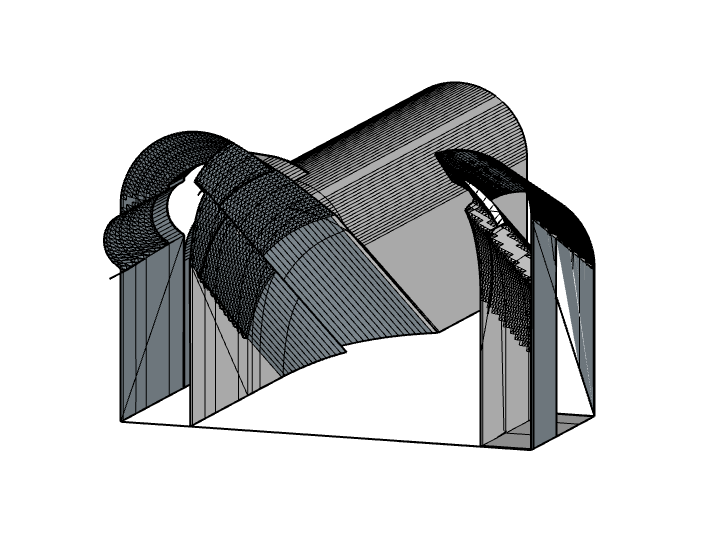

The profile of the escalator tunnel is constant as the portal descends. At the tunnel opening and throughout the descent there is a portion to be excavated which overlaps with the pillar tunnels leading to a challenging shape. Approximately half of each pillar tunnel will overlap the escalator tunnel portal. The notches at either side are critical for the installation of lattice girders, providing temporary support as fresh rock is cut, prior to temporary support (lattice and shotcrete) and the final reinforced concrete lining. A derivative of the New Austrian Tunneling Method. The challenge was how to create such a complex shape.

1. Change the design;

- Alter the profile of the escalator tunnel crown so that it is consistent for the whole profile

- Change the profile of the lattice girder support of the escalator tunnel crown and where they sit on the side walls.

These ideas were briefly explored by the senior site engineer however the time it would have taken to push through the RFI process and redesign would have caused delays. We have had to accept the challenging shape and come up with a temporary works design solution for the formwork.

2. Change the method;

- Pour half of the pillar with the notch space created by formwork

- Pour half of the pillar and fill in the notch or block it out

- Pour the whole tunnel with reinforcement through half and create a block out notch within the pour

The Formwork, Reo, Pour (FRP) Senior Engineer and Shaft Senior Engineers did a quick appraisal and cost for each scheme. We have a very experienced concrete subcontractor on site (Kenny’s) and they also could not find a cost effective formwork. In the end we opted for the whole pillar pour with a block out.

3. Selection of materials for a block out;

- High Density Cardboard had been used as a block out elsewhere on site earlier in the project – needless to say it didn’t work as cardboard is porous it turned to mush and did not prevent the ingress of cement and leave the desired shape.

- Wood creates a splinter hazard when hammered out and could have caused shrink/swell issues with moisture. It was also relatively heavy to manoeuvre into position within the tight reinforcement cage. The weight of wood also made it difficult to create an internal supporting structure within the form. It was have been hard to form a seal between sections of wood too.

- Polystyrene. Create a custom shape blockout to fill the entire void within the form. Light weight, easy to work with, can be purchased to exact size and dimensions.

The polystyrene block out worked really well however the choice to pour the entire cross section of the pillar caused a one week delay to the programme during excavation as the 50MPa concrete was difficult to break out. Two unforeseen secondary effects also occurred. Excavation in sandstone generates a lot of silica dust and water suppression is vital. Pumps operate daily to remove the slurry and water from the blinding slab. Broken segments of polystyrene and the tiny balls within it subsequently blocked and damaged two pumps and polystyrene still litters the site nearly two months since it was dug out. Secondly, the spoil disposal subcontractor picked up on the polystyrene content of waste leaving site. Virgin excavated natural material (just the rock) costs $29/tonne. General Solid Waste Recyclable costs $115/tonne. For the rest of the 320m3 (7680 tonne) of excavation the spoil was often reclassified as GSWR. Not all loads were deemed GSWR but those that were costed the site an additional $15,000. Perhaps the complex formwork would have been cheaper after all.

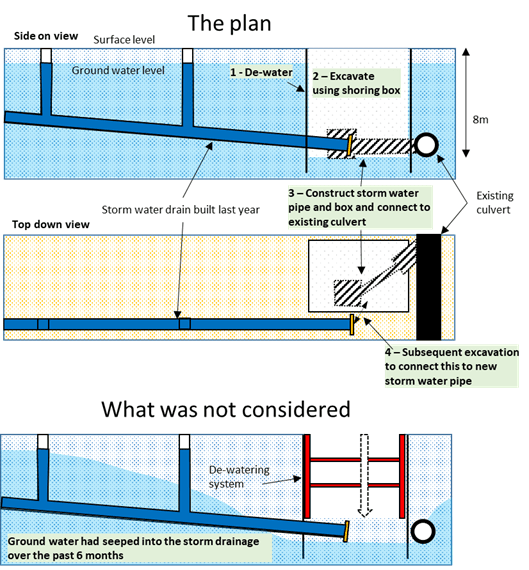

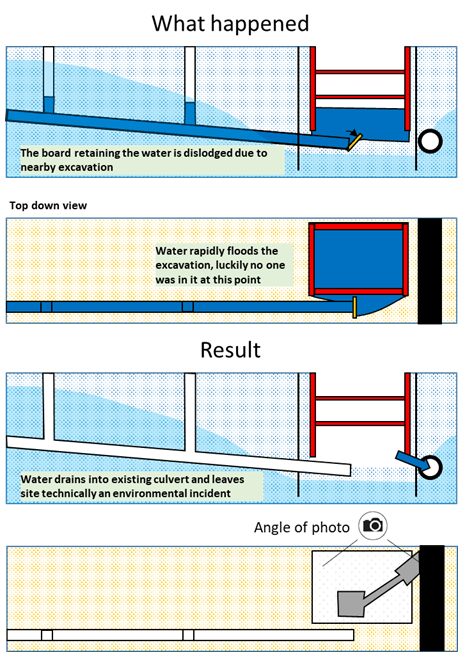

Don’t forget the drain

An excavation on my site unexpectedly flooded the other week. It was to connect into an existing storm water culvert at about 8m below surface level, thankfully no-one was in it at the time.

This could have easily been prevented by pumping out the water in the storm water line. It was simply an oversight by the engineers planning it.

As the ground water is contaminated (heavy metals among other things) and this water counts as waste water from a construction site this is also a reportable environmental incident.

Guess the lesson here is not to forget about what you have put in the ground… and maybe check your drains.

An NHS View On ‘Military Planning’

I stumbled across an interesting perspective on ‘military planning’ in the British Medical Journal here: https://www.bmj.com/content/369/bmj.m2055. It offers a valuable external perspective on how we work, plan and operate which should serve as a useful reminder for those who are growing comfortable in their civilian attire. Have a read, and for those in Ph3 moving to Ph4 it will serve as a timely reminder and look forward to….

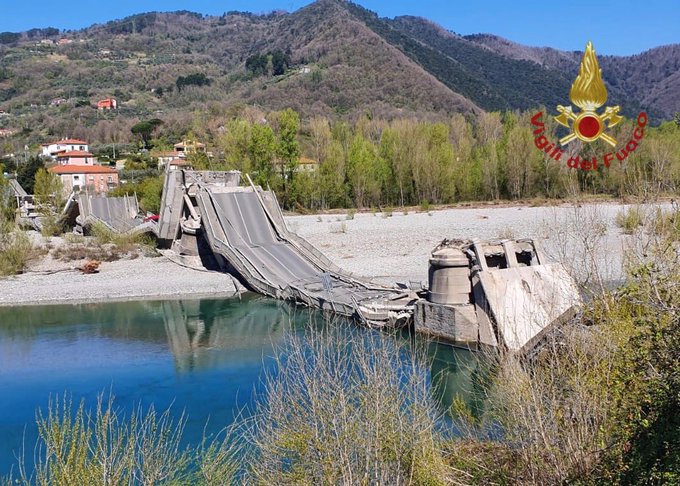

Italian Bridge Collapse / Textbook Demolition Job

Thanks to lockdown in Italy only 2 people were injured when this 240m bridge collapsed at the beginning of April and, perhaps as a consequence, it has seen less media coverage than the Genoa motorway bridge collapse in 2018.

The bridge had six 40m RC arch spans between stone piers. All spans collapsed completely and at least two of the five piers were toppled in the process leading to a pretty thorough demolition job.

The state of repair of the Italian road network is clearly under considerable scrutiny and it seems likely that this bridge collapse is, at least in part, due to poor inspection and maintenance. Cracks appearing in the deck can be seen on street view and have been growing since 2011. These cracks were inspected in 2019 but no action was taken. Read more…

Air do we go from here?

In the coming weeks it looks like we will begin the return to normality and to start occupying the spaces that have been the reserved for the essential workforce. As the built environment begins to take higher occupancy levels there is a need to deal with the risk of a person-to-person transmission of Coronavirus.

It is generally accepted that when a person coughs/sneezes/talks the Coronavirus pathogen is spread in one of two ways. The expelled droplets either behave ballistically and land on another person/surrounding surface or the droplets are aerosolised and are subject to air-buoyancy effects. The later of these mechanisms is where HVAC systems play a key role in controlling infection.

Given the novelty of the Coronavirus there still exists considerable conversation over how best to manage the ventilation systems of occupied spaces in order to reduce this risk. I have collated below the information from key groups (CIBSE, PHE, REHVA and ASHRAE). As you can see there exists conflict around topics such as RH and ventilation rates. I would be interested to know if there are any other individuals who are dealing with the same risk and having to implement a new or revised HVAC/building utilities strategy.

| CIBSE: CoVID-19 Ventilation Guidance (Summary) v1 9 May 20 Well ventilated rooms dilute pathogens and poorly ventilated areas carry a higher risk of airborne transmission Fine aerosols (from coughing and sneezing) remain airborne for several hours Duct cleaning has little or no effect on the prevention of spread of pathogens Specific guidance: Open doors and windows as much as possible to increase natural ventilation. Keep WC windows open as much as possible Maintenance staff to wear adequate protection when changing filters on A/C units Avoid recirculation where practicable Heat recovery devices in AHUs to be turned off |

| Public Health England: Infection prevention and control guidance – 27 Apr 20 “In light of limited data for SARS-CoV-2, evidence was assessed from studies conducted with previous human coronaviruses including MERS-CoV and SARS-CoV. Human coronaviruses can survive for up to 5 days at temperatures of 22 to 25°C and RH of 40 to 50%. The rate of clearance of aerosols in an enclosed space is dependent on the extent of any mechanical or natural ventilation – the greater the number of air changes per hour (ventilation rate), the sooner any aerosol will be cleared. The time required for clearance of aerosols, and thus the time after which the room can be entered without a filtering face piece (class 3) (FFP3) respirator, can be determined by the number of air changes per hour (ACH) as outlined in WHO guidance.” Specific guidance: “…A single air change is estimated to remove 63% of airborne contaminants, after 5 air changes less than 1% of airborne contamination is thought to remain. A minimum of 20 minutes (recommend 2 air changes) in hospital settings where the majority of these procedures occur is considered pragmatic” |

| REHVA: CoVID-19 Guidance document (Summary) – 3 Apr 20 Large and small particles (aerosols) are ejected from an infectious person. It’s the latter which are of concern for HVAC systems. Well ventilated rooms dilute pathogens. Poorly ventilated areas carry a higher risk of airborne transmission Heat recovery devices in AHUs usually work poorly and leak. Areas which have comfort cooling or heating need intervention. RH has little or no effect virus susceptibility. Specific guidance: At nights and weekends, do not switch ventilation off, but keep systems running at lower speed Ensure regular airing with windows (even in mechanically ventilated buildings) Avoid open windows in toilets to ensure the right direction of ventilation. Mechanical ventilation to run 24/7. Instruct building occupants to flush toilets with closed lid Switch air handling units with recirculation to 100% outdoor air or 400 ppm max of CO2 Do not plan duct cleaning for this period Regular filter replacement and maintenance works must be performed with PPE including respiratory protection Maintain social distancing measures to guard against person-to-person transmission |

| ASHRAE: Position document on infectious aerosols (Summary) – 14 Apr 20 “…Even the most robust HVAC system cannot control all airflows and completely prevent dissemination of an infectious aerosol or disease transmission by droplets or aerosols. Ventilation with effective airflow patterns is a primary infectious disease control strategy through dilution of room air around a source and removal of infectious agents. However, it remains unclear by how much infectious particle loads must be reduced to achieve a measurable reduction in disease transmissions.” Specific guidance: Air distribution patterns have an effect on distribution of aerosols Differential room pressurization can influence air flows Higher efficiency filtration (MERV-13) reduces concentrations of aerosols Increase outdoor ventilation as close to 100% as possible, 24/7 UV light with 265nm wavelength provides a good germicidal effect RH of between 40 and 60 RH is optimal for reducing microorganism survival Bypass energy recovery systems |

| World Health Organisation – Getting your workplace ready for CoVID-19 (Summary) – 3 Mar 20 No specific guidance on HVAC systems or strategies is provided in relation to COVID-19. |

Monopoly Rule No. 8 – Once you own all the properties of the same colour you may develop them…

Board game rules apply in Sydney CBD – a benefit to the community chest?

My first few blogs should be approved by the end of the week but in the meantime, this is public knowledge and interesting.

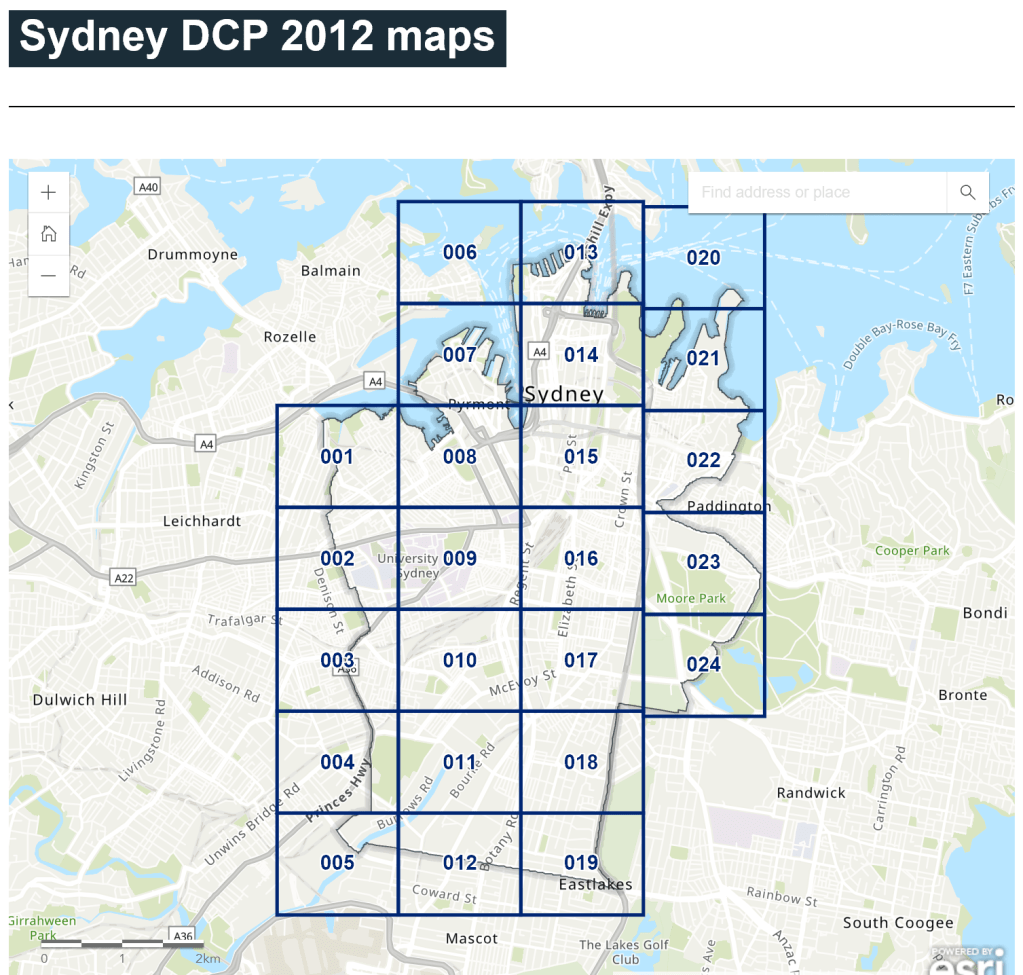

The City of Sydney or the Central Sydney Planning Committee is the consent authority for development other than major projects; there are currently 16 major projects (Figure 1), plus an additional 19 development control plans, dictated by area (Figure 2).

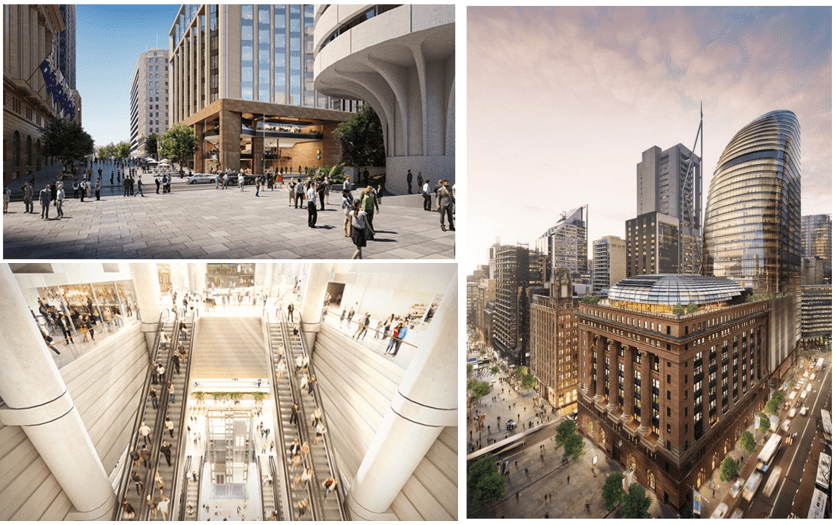

Now that you can picture the board. In square 014 is my current project, Sydney Metro Martin Place Station. Martin Place is a pedestrian mall in the middle of the CBD and has been described as the “civic heart” of the city as it is home to the Sydney General Post Office, the Seven Television Network News Centre, Cenotaph and the State Savings Bank building. As an iconic, cultural and historic area of the city planning permission is limited to 20 storeys. That is, unless, you own all the properties on the block. In which case the permitted number of storeys (and thus sqm of new office space) can be spread amongst the properties on the block.

Fig 3. Satellite image of Martin Place and the heritage bank.

Macquarie Group is a financial services provider who own the heritage listed State Savings Bank building at the Centre of Martin Place. The new metro station tunnels beneath the bank and the station entrances are currently being excavated to the North and South (Figure 3). Work on site began in January 2018. By March that year Macquarie Group submitted an unsolicited proposal to the Government of New South Wales for two Over Station Developments (OSD). The towers would be predominately commercial, with Macquarie Group occupying both. The concept for the north tower was more than 40-storeys with a podium to be integrated with the existing 50 Martin Place (bank), while the south tower was to be more than 28 storeys.

In May 2018, a site-specific amendment was made to the Sydney Local Environment Plan. The new planning provisions for the Martin Place Metro Precinct permitted a larger building envelope for the South site. The State Savings Building is only 10 storeys high yet by planning controls it could be 20. Thus, by owning all the properties on the block Macquarie Group were able to exploit a loophole and by September an agreement had been made for Macquarie to deliver the new station and two new towers by 2024, along with construction partner Lendlease. The North tower will be 39 storeys and the South will stand at 29 storeys. Transferring their available storeys (houses or hotels!) to a neighbouring property (Figure 4).

Community Chest gained $355 million as the Government sold the air rights above the new metro station. Macquarie will spend a further $637 million on the construction and delivery of the new underground Martin Place station integrated with a retail and recreational precinct, two new office towers and the existing Martin Place railway station.

Cost of the new station $378.6 million

Fee paid by Macquarie $355 million

Cost to the Taxpayer $23 million

Once the new buildings are complete in 2024, Macquarie is also likely to make another payment to the government to reflect the increased value of the land; as the world’s largest infrastructure asset manager, they should know. Macquarie now own the rights to one of the most coveted corporate addresses in Sydney. New metro trains are due to deliver thousands of customers from the suburbs straight to their new towers every four minutes. By 2056, New South Wales will have more than 12 million residents and Sydney is predicted to become a global city, similar in size to London or New York. Time will tell whether Macquarie’s investment will pay dividends, but I have a feeling owning the site of Sydney’s largest public transport hub will mean that the bank inevitably wins.