Archive

Concrete Quality: How Bad Can It Get Before Structural Compromise?

Hello all,

Just a quick one to spark some debate and follows on from Ed’s the other day. I have been involved with the vertical elements of my project site which include columns and outrigger core walls. The pours have been going well but on opening the forms up today a number of elements have had issues. Multiplex have referred these issues to the consulting engineers and are waiting on their response for the required remedial action or acceptance as they see fit. Some of the elements where poured on different days using a mixture of kibbling and pumping. All are 80mpa which generally is being reached well before the 28 day mark with the columns feelably hot. The mix is designed to be self compacting with no requirement for vibration but the supplier has been having issues with producing consistently accurate mixes. These elements are on level 7 of 82.

Column 1 – Evidence of very small honeycombing and cold pour joints

I would suggest that no rectification is required for this column. Your thoughts?

Column 6 – Evidence of small honeycombing and cold pour joints

Again I would suggest that no rectification is required for this column. Your thoughts?

Column 7 – Evidence of cold pour joints and large scale honeycombing which is exposing reinforcement.

My feeling on this one is that rectification will be required. I think that as a minimum they will ask for the concrete to patched to cover over the steel work but that more extreme remediation could well be asked for.

Column 10 & Outrigger Core Wall 8 – Evidence of small honeycombing and cold pour joints isolated to a single batch of concrete. This was kibbled and you can clearly see the flow of concrete away from the column, which was the insertion point, into the rest of the wall.

As before I would suggest that no rectification is required for this column. Your thoughts?

Multiplex should be getting the consultants response shortly so I will update the post with this detail once received and you will be able to compare your thoughts to that of what actually happened.

National Trust vs Apple; Who will win?

This isn’t a technical blog, but a quick update to share experience of a heritage issue we are currently working through in my construction precinct. One of our three station entrances is to be constructed in an area known as Federation Square within the Melbourne Central Business District (images 1 & 2). Construction work was due to start on 2 September 2018, however, we have just been served with a 60day interim heritage protection notice for Federation Square. The protection notice is the result of an application by the National Trust to the Heritage Victoria Register, in response to the Victorian Government approving plans for the construction of the new flagship Apple store at Federation Square (image 3). The development of the Apple store requires the demolition and relocation of the Yarra Building which currently houses an indigenous people museum and arts centre (image 4). Federation Square was developed in 2002 as a central meeting place for Melburnians where the culture and heritage of the City could be displayed and public events could be held. The previous Melbourne City Square was sold for re-development. If Federation Square is granted heritage status then all current and future construction works, including our station entrance, will require to go through a lengthy permit process to ensure that the design can meet the criteria for constructing in a heritage area. The project is unsure which way the decision will go. There is currently no precedent for heritage status being awarded to such a young structure (16 years). However, the Victorian Heritage Act 2006, does not specifically define how old a place must be and the Heritage Victoria Register will consider any nomination put forward. The issuing of the interim protection notice has initiated talks with our Client (Rail Projects Victoria) to identify which clauses of the contract can be triggered now and what are the time and cost implications if the heritage status is granted. I will keep you updated with how this one turns out.

Image 1 – Aerial view of Federation Square. Proposed new station entrance bottom left and proposed Apple store center right.

Image 2 – Proposed new Metro Tunnel Entrance at Federation Square

Image 3 – Proposed new Apple store. View from Yarra River.

Image 4 – Current street view of Federation Square. Buildings on right of picture to be demolished for Apple store construction.

Point Cloud Survey

Just a quick one. I thought you might be interested in the point cloud surveys we have been undertaking. It has been a great resource but on this site has had significant security restrictions limiting its use to front of house areas where the public can see anyway and plant rooms to assist in services clashing avoidance. Enjoy!

Innovative Jump Form System for the Residential Tower

I have recently completed the area I was first working on and have now been assigned as the Site Engineer for vertical elements in the just started Residential Tower. From my first blog you would have seen Multiplex (MPX) fears over not winning this job and the congestion on site that would have caused. Well they needn’t have worried as they won the contract and have just started construction of the 80 story Residential Tower.

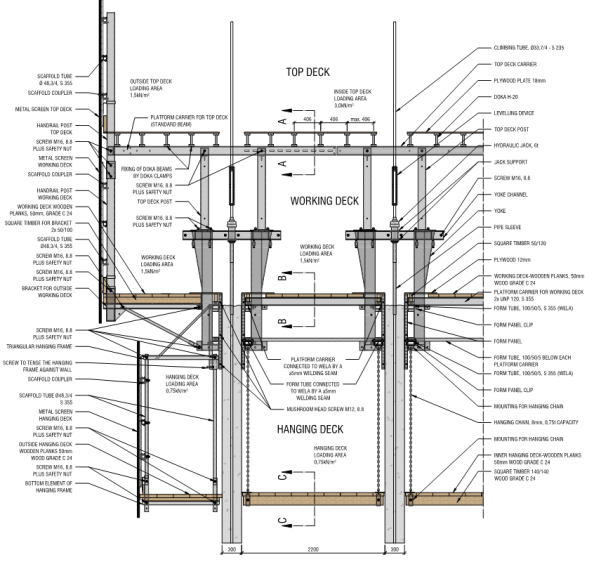

The system of jump form that has been selected is causing some excitement in the office, so I thought it was worth sharing with you here. It is apparently so innovative that most in the office have never even heard of it let alone seen it. Before we look at the new system it is worth just understanding how a traditional jump form works.

Traditional Jump Form Tower Construction

Traditional jump form systems form the core only, several levels higher that the decks. The video below shows the normal sequence for a core only jump form.

The foot print of the jump is normally only a fraction of the buildings and space is very tight at the top. Below is done pictures of the traditional jump system being used for the commercial tower on my site.

The decks are then constructed using either structural form work (i.e. bondeck which provides form work initially and then becomes part of a composite slab once the concrete has cured) or traditionally using removable form work that is supported by a lattice of props and beams. Critically this leaves the columns to be poured separately once the deck is in place. Again this is normally done using a traditional form which must be set up individually for each column adding days of delay. To get around this on the commercial tower on my site are using hollow steel sections as form work then pouring concrete into them to create a composite section. Below is some more pictures of the commercial tower this time of the the decks being constructed.

Oliver Moore (OM) Jump Form Tower Construction

This new OM jump form is radically different in that it covers the whole footprint of the building and allows the construction of all vertical elements simultaneously and at the same level i.e. the core, columns and shear walls all done at the same time and same level. When fully constructed the system also contains all structural and external façade works minimising the risk to workers and the general public. This is achieved by having a set of screens directly attached to the top of the jump which hang down 5 levels to enclose the horizontal structural works (in this case PT slabs).

From the bottom of the first screens a monorail system is connected which allows a winch system to manoeuvre around the whole of the building for façade install. This eliminates the risky use of mini crawler cranes that have to dangle massive glass panels over the buildings edge to get them installed. These works are similarly enclosed by a second screen system cantilevered from the first hanging down 2 levels. The connection to the primary jump system means both screens and monorail will move as the system does. When this happens an externally complete building will emerge from out of the bottom of the jump.

Multiplex have set an ambitious completion program that has been written into the contract. Once fully launched the jump has been set a 5 day cycle which means all steel work will have to be completed in 8 hours and post tensioning work completed in 4. I have yet to dig in to the program so don’t ask too many questions on this just yet.

The new jump system is also getting an extensive vertical transport system to support the cycle time. The movement of men and materials will be supported through a number of systems, three high-speed site hoists will be installed along with two tower cranes and an integral cantilevered jump lift. A single car site hoist will move through penetrations left open in the podium slabs before climbing the exterior while a double car site lift on the other side of the building will climb up the exterior of the tower from ground level. These hoists will be extended in line with the jumps to ensure quick access is always maintained to the top of the jump form. There is also a cantilevered integral materials lift that is connected to the jump system moving as it does, the lift will be used for the movement of materials up to 5 levels down from the top deck. This is needed as normally the cranes would land materials directly on the decks but with the jump system covering the decks materials must be landed on the decks and subsequently transported down.

This is all shown diagrammatically in the images below however I suspect they won’t come up large enough to see the detail, so please click here to access the source documents.

Hopefully that has been interesting and provided a snap shot of what I am up to. Please feel free to fire any questions you have at me and I’ll do my best to answer them. The jump isn’t on site yet so I’ll probably follow this post up in a few months once it’s running to give you some real pictures and let you know how it works in reality.

Seismic Assessment of a Structure – Fundamentals (Direct Displacement Based Design)

Introduction:

- I’m trying to get my head around some seismic design for the building I’m working on. I’ve done a bit of reading – here is a quick description of my understanding so far, anybody else done any seismic and can collaborate? Any thoughts or corrections?

Assumption:

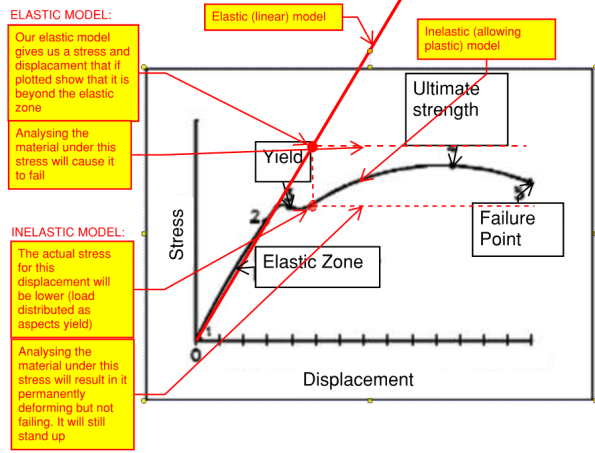

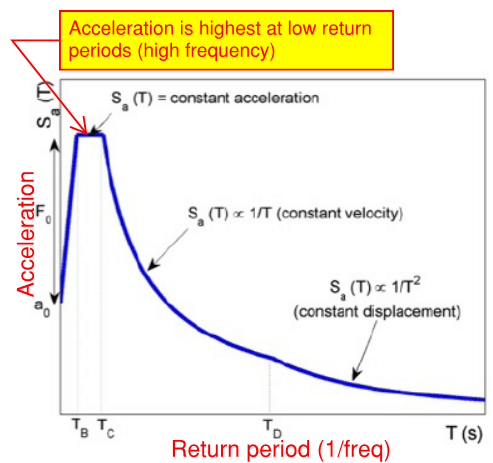

- EQUAL DISPLACEMENT RULE. (total displacement of an element is roughly the same whether you treat it as fully elastic or non-linear) – proven empirically but the theory is that energy is dissipated when a material yields and therefore the demand on the element is reduced.

Graph:

Process:

Process:

Elastic Model (or elastic calcs) – FORCE BASED DESIGN (what we are used to):

- Input: Apply seismic loading

- Output: Displacements and stresses

- Compare displacements to SLS criteria (eg inter storey drift max = 0.015 x storey height)

- Check materials can withstand the stresses (in the example in the graph, it will fail)

- However the results may not be truthful to how the material/structure will actually behave – you may be in the plastic zone and as a result, overestimating the stress in the material. There are factors you can apply to bring the stress down but a more accurate approach is to use DIRECT DISPLACEMENT BASED DESIGN

Inelastic model (or non-linear calc iterations) – DISPLACEMENT BASED DESIGN:

- Input: Displacement – input the displacement our elastic model gave us (equal displacement rule). (if you are designing a new build then set your target displacement and start here). The target displacement is then sub divided to create start and end points for each stage of analysis.

- Iterations must be conducted in order to find the critical mode of deformation.

- Output: Stresses

- Check materials can withstand the stresses (in the example above, it will now pass (permanent damage but no collapse))

Other:

- When setting up the model, applying high levels of fixity at connections is conservative (the opposite to what I think is intuitive) because:

Summary:

- Force based design does not allow an accurate estimation of stresses within a structure for material that is beyond yield. Direct displacement based design allows for a more accurate estimate because displacements are more proportional to non-linear behaviour/energy dissipation?

Lighting System Replacement

I am managing a project to replace the lighting system in a British Airways Container Handling Store at Heathrow Airport. The store is a 75m x 50m portal frame warehouse, fitted with 20 lanes of industrial conveyor belts. The facility is used to temporarily store aluminium air-freight containers between connecting flights. As you might imagine, it is a hive of activity with a continuous flow of electric tugs towing long trains of baggage trailers.

The existing system consists of 192 x Thorn Titus 3x 49W T5 fluorescent lights (incl. 54x self-contained emergency variants) and 13 x 400W external halogen floodlights, which are all connected to a central Digital Addressable Lighting Interface (DALI) control system. The installation has now reached the end of its life. Several luminaires have failed in addition to three of the six DALI gateways which means the lighting in certain sections of the building cannot be controlled. A recent test of the emergency lights also revealed that the batteries were only lasting for 25 minutes – well below the required 3-hours.

Another driver for this project is energy efficiency. Since most of the lights are used on a 24hr basis, there are savings to be made by replacing the fluorescent and halogen lights with LED equivalents. Photos of the existing installation are shown below.

Luminaire Selection

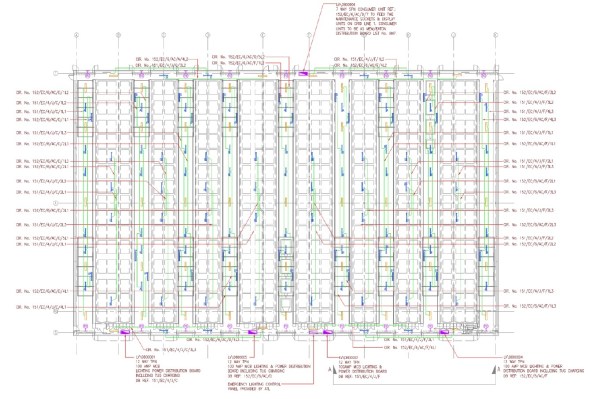

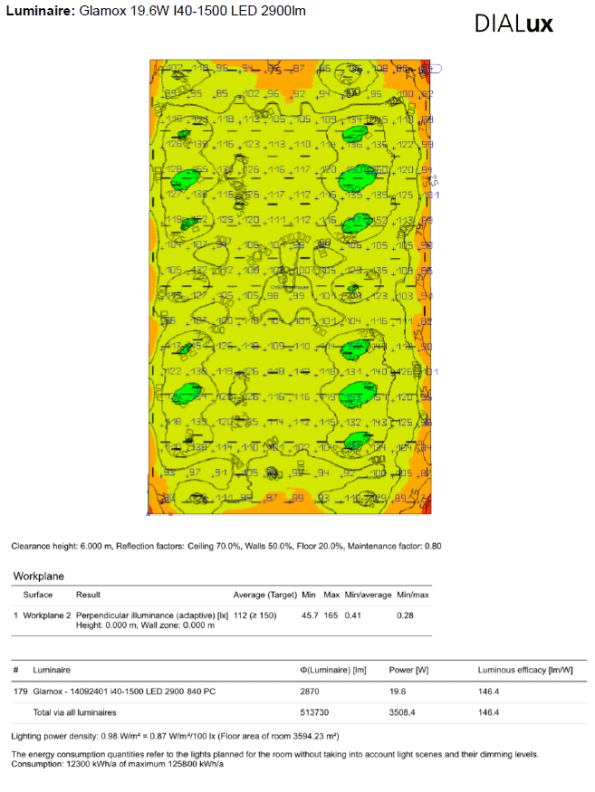

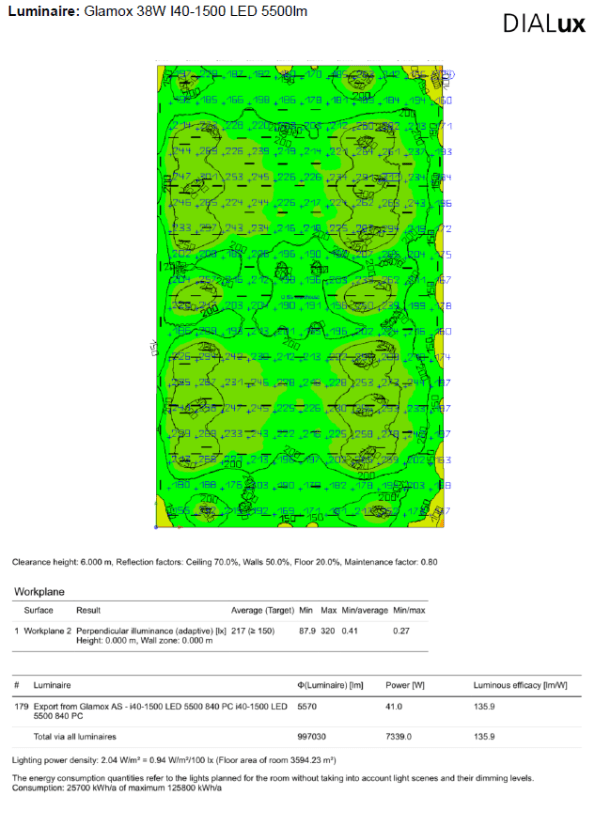

I was initially advised to install Glamox 19.6W I40-1500 LED 2900lm luminaries in the warehouse, as there was surplus residual stock of these units. However, I was concerned that these luminaires would not provide sufficient output so I obtained the necessary Eulum data files from the manufacturer and undertook a more thorough analysis using DIALux.

Heathrow Airport Limited (HAL) Lighting Standards stipulate a the lighting requirement in all areas of the airport. Cargo handling facilities must be lit to 150 lux at floor level with a limiting glare index of 25 and max power density of 2 W/m2/100 lux. I imported the AutoCad schematic (shown below) of the facility into the DIALux and used this as a template to position the luminaires.

Container Handling Store AutoCad Schematic

I simulated the luminance produced by the 2900lm units based on a maintenance factor of 0.8. The results of this analysis confirmed that these luminaires were not suitable. I experimented with various different options which enabled me to confirm that the Glamox 38W I40-1500 LED 5500lm would provide sufficient lighting. The results of this analysis are shown below.

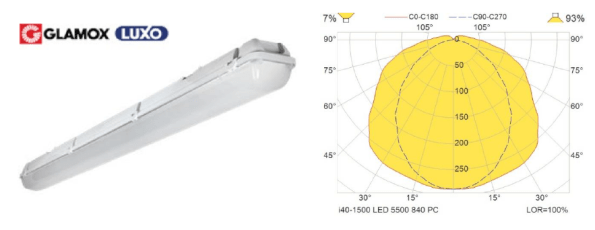

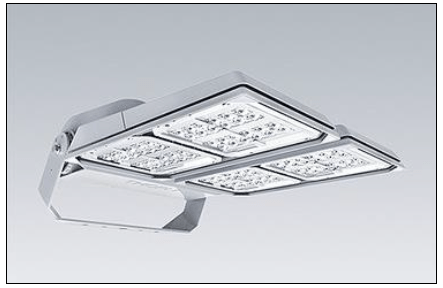

I decided to use Glamox 38W I40-1500 LED 5500lm luminaires, which are slightly brighter than required. However, the power output can be reduced to the required level using the DALI controls., which will also reduce the energy consumption. The power output may need to be increased in the future to compensate for performance degradation. I also selected Thorn 205W 96L70-740 LED 24394lm floodlights for the external areas of the warehouse. Images of these luminaires are included below.

Glamox I40-1500 38W 5500lm LED DALI PC

Thorn 205W AFP 96L70-740 W LED Floodlight

Lighting Controls

Having not had any experience with DALI lighting controls I undertook further research and consulted with engineers from Schneider Electric to gain a better understanding of how these systems work. This research enable me to produce a detailed scope of works and proposed installation methodology to maximise efficiency and minimise the impact on operations. A picture of the DALI gateway is included below.

DALI / KNX Gateway N141/02

Each gateway can interface with up to 64 luminaries, providing control and fault diagnostic capability. They also provide an interface with the KNX system, which is standardised OSI-based communications protocol, which allows the lights to be monitored by the Building Management System (BMS). I have advised the principal contractor (Dyer & Butler) to employ Schneider Electric as a subcontractor to commission the new DALI system due to their specialist expertise in this area.

Constraints

Operations. The CHSS facility is operational during working hours, therefore all works must be undertaken at night between 1130-0430 hrs. This leaves a very short window of opportunity after allowing for set-up and clear-up time. I am therefore working closely with the contractor to maximise efficiency by planning how the work will be sequenced and the methods that will be used.

Access. I have confirmed that a scissor lift can be used to access the lights above the walkways. However, some lights are fitted above the automatic, multi-directional conveyor. This system will need to be isolated to ensure that it will not operate while the work is being done. I considered the possibility of laying plywood panels over the conveyors to provide a stable surface for a scaffold access platform. However, this would necessitate the removal of the guardrails which would have been time consuming and further reduce the working window. After considering the size of the manoeuvring space available and the height of the guard around the conveyor, I identified a suitable MEWP for this application. A video of the Nifty Heightrider 12 is included below together with its capabilities. I advised the contractor to hire this equipment to test its suitability during the pre-works survey.

Stakeholder Engagement

There are various stakeholders involved in this project as show below:

- Contractors. I have established a good relationship with the contractors (Dyer & Butler Electrical and Schneider Electric) to refine the methodology and confirm the alterations that will be required to the wiring system.

- Suppliers. The lighting suppliers have assisted with the process of selecting the appropriate luminaires to ensure compatibility and provided the data to enable me to undertake a lux assessment.

- Assurance. Prior to commencing works, I must gain approval from the Chief Electrical Engineer who provides technical assurance of new installations / modifications to the electrical systems.

- Safety. All works at Heathrow require a necessary work permits and authorisation to proceed, which can involve a protracted process – but this is essential to de-conflict works with other projects. In addition, this work will require electrical switchboards to be isolated which must be performed by a nominated Authorised Persons via the Airport Operations Centre in accordance with the HAL Electrical Safety Rules.

- Customer. It will also be essential to maintain a continuous dialogue with BA to ensure this work does not affect operations. I will also need to coordinate with them to ensure the baggage lanes are clear each evening, to facilitate access to the lights and avoid the potential for delays and compensation events.

Financial Appraisal

Based on my analysis of the power and operating times of the existing lights, the current system consumes a total of 212,000 kWh per year. Heathrow Airport currently pays a special rate of 9.47 pence per kWh. Therefore, the existing system costs just over £20k per year to run.

By replacing the existing lights with LED equivalents and optimising the control system with PIR sensors and upgraded DALI gateways, the power consumption of the new system is expected to be reduced to 60,000 kWh. The cost to light the facility will therefore reduce to £5.7k per year, which will deliver annual savings of £14.3k.

Taking account of the costs for new luminaires, DALI gateways and installation fees, the final budget for this project has been estimated at just under £50k. Therefore, based on energy savings alone this project is expected to deliver a payback period of 3.5 years.

How to Splice up your life?

Just a quick post to see if anyone has a solution to the following issue which has arisen on my site, thought not in my immediate team.

BLUF: As I briefly mentioned in a previous post in order to avoid excessive wear on the TBM cutting head the designers have specified Glass Fibre Reinforced Plastic (GRP) reinforcement bars in the piles making up the head wall, through which the Tunnel Boring Machine (TBM) will eventually punch a hole. These have finally arrived following a series of delays but now there is some uncertainty on how the bars will be spliced together, as the team want to avoid the use of steel couplers.

Below is a picture of the GRP bar and the initially proposed method of using steel couplers;

My initial thoughts are that while I understand the use of GRP bars to avoid cutting through masses of steel I am surprised that relatively small gauge steel couplers will have much effect on the cutting head of a behemoth 15m dia TBM? Surely a monster of this size will just tear through the GRP bar and spit the couplers out whole at the other end?

If the couplers are likely to have a detrimental impact on the cutting teeth, then what might be a viable solution to forming a credible bond between sections of cage?

I welcome people thoughts and solutions.

UPDATE – 16/07/18

I don’t think my original description of the issue was very clear and what looks like a threaded end on the GRP bar in fig 2 might have been misleading. The bars were always going to be lapped (fig 1), but with U-bolts as seen below holding them together (I incorrectly called them couplers in the original post).

fig. 3 – U-bolt

Although these appear quite insignificant, the TBM guys have said they don’t want any steel, including these, in the piles when they cut through the head wall.

A number of possible solutions were investigated including cable ties as was suggested by Jim in the comments. However, these were deemed insufficient as the lapped connections will need to support the weight of a lower cage during installation.

Each cage is made up of two cages of around 15m in length. in the worst case loading the weight of the lower cage, 1200Kg is supported over 4 spliced connections as shown in the fig 4 below;

fig 4 – cage cross section

The solution that was put forward and adopted was to drill and fix 7 GRP pins through both GRP bars at each of the splice locations as outlined in fig 5.

fig 5 – proposed solution

In order to adopt this as a solution, the connection had to put forward for testing to check that the strength of the connection was sufficient. The test load was based on the following;

- 1200Kg/4 splices -> 300kg per splice -> design load = 3000N

- Load test to 3000N and hold for 5 min

- Load test to 7500N (2.5 x design load) and hold for 5 min

- load test splice to failure (hopefully achieving 5 x design load, 15000N)

the image below shows the testing rig that was adopted by the lab;

The test was repeated three time on the test pieces and yielded positive results with each test reaching 1500Kg with no defects, defections or cracking observed. This has now been adopted as the preferred solution.

They keep slipping up

A really juicy one here on concrete for the E&M’ers to get their teeth stuck into.

Here is something to watch out for if anyone is involved in slipforming.

-

- The four shear cores in my area at Battersea are being built using slipforms. The main benefit of this method is that it can be constructed very quickly (if carried out by a competent contractor with adequate round-the-clock quality assurance).

- Quick recap on Slipform: Shuttering (the formwork) is attached to yolks, which are held up by climbing tube. The slipform rig is held up entirely by the climbing tubes which run to the base of the slipformed wall, and the jacks are almost continuously lifting the slipform rig. The concrete that is exposed below the shuttering only needs to support it’s own weight, which is continuously checked as the slipform is lifted.

- The axial force produced by the jacks must overcome the friction between the shuttering and the concrete to allow the shuttering to move up. However, if the shear force due to friction between concrete and the shuttering overcomes the shear strength of concrete then the concrete can fail at the surface, resulting in poor finish. If the concrete has cured and the shear force overcomes the tensile capacity of the concrete then whole sections of wall can be dragged upwards. This happened on one of the cores in Battersea, resulting in large tear-outs and long delays.

- Sub-contractor’s reasons: The high strength C75/85 concrete that was used in this particular section of wall was going off too quickly, resulting in it adhering to the shuttering. A possible but flaky argument trying to transfer the blame to the concrete mixers.

- Weapon fires, weapon fires, weapon stops… The concrete was repaired using traditional formwork on the hanging deck, and after 8 days of repairs slipforming continued as normal… for a few days until the same thing happened again in an area where the normal C50/60 concrete was being used.

- What was the reason for failure? Slipforming is supposed to be a continuous process, so that the concrete is given time to harden in order to support it’s own weight, but not given too much time because it can adhere to the shuttering. Also, this means that there will not be weak ‘construction’ joints with the concrete below which will give the concrete poor tensile strength.

- First incident (photos below): There had been a long pause in order to fix some large steel embedment plates before the concrete was poured. The concrete was poured on the night shift, where as it later emerged, the subcontractor had no QA managers working and an inexperienced concrete foreman/supervisor. It is possible that the high strength concrete was going off quicker, but this should have been anticipated and either arranged to be poured quicker or designed with admixtures to slow the curing process. An operative on site also let slip that the concrete looked as if it had gone off when it was poured.

- Second incident: (photo below) After the first incident, the exposed shuttering was cleaned, however the shuttering overlaps the concrete at the bottom by about 0.4 m to allow a good seal when pouring concrete. It is likely that in this area there is a film of concrete that has stuck to the shuttering, which makes it much easier for fresh concrete to bind to the shuttering. The failure occurred after a very hot day, which is likely to have compounded the problem due to increased speed of curing.

- After some investigation it seems as if the most likely problem is that the sub-contractor has not been managing their logistics well, allowing concrete to stand on site, or having large quantities turn up at once causing queuing. It seems as if there were two failings here; in logistics managemnt and in Quality Assurance. A real Sliphopopotamus.

Construction micro-organisms: Anthrax from contaminated land and buildings

I have just had to do this weeks “Safety Moment” presentation for my Programme Office. For this I decided to do an unusual risk but one that is present on my site and could be present when we as the Army operate overseas.

BLUF: A very small likelihood but given a lot of attention due to the possible consequences.

- What is Anthrax. Anthrax is primarily a disease of herbivores (plant eating animals). Humans contract it as a result of contact with infected animals or animal products. In humans, the disease takes one of three forms, depending on the route of infection. Cutaneous anthrax, which accounts for more than 95% of cases world-wide, results from infection through breaks in the skin; intestinal anthrax results from ingestion of spores, usually in infected meat; and pulmonary anthrax results from inhalation of spores.

- Anthrax in the UK. The UK has an exceptionally low rate of anthrax, and nearly all cases since 1981 have been associated with imported material. Of the 19 cases reported, in England & Wales between 1981 and 2009, all but one were cutaneous.

- Cutaneous Anthrax Explained. Cutaneous anthrax usually occurs through contamination of a cut or abrasion, although in some countries biting flies may also transmit the disease. The first sign of an anthrax infection is a small painless inflamed swelling like a pimple or boil.

- Pulmonary Anthrax Explained. In pulmonary anthrax, inhaled spores multiply to cause disease that affects the entire body instead of a specific organ. This is an occupational disease encountered in industries in which the workers are exposed to high levels of spores in dust. Pulmonary anthrax, although exceedingly rare, are both more dangerous than the cutaneous form because they are usually identified too late for treatment to be effective.

- Anthrax in construction and demolition. Animal hair has been used as an ingredient in internal plasters for centuries. The best hair was obtained fresh from the tanners yard. Controls for the prevention of anthrax have existed since 1919; however, there is no guarantee that hair in plaster used before 1900 was not contaminated in the construction industry. In addition controls were not greatly enforced until after WWII.

- Risk. In reality, the risk of developing an anthrax relating infection is low so long as suitable and sufficient risk assessments and management plans are adhered to.

- Mitigation Methods.

- Basic.

- Cover cuts and abrasions

- Keep hands clean

- Wear suitable PPE (e.g. disposable gloves, overalls)

- Prohibit smoking and consumption of food and drink

- Ensure plaster is handled and disposed of in accordance with local and statutory controls and dust generation is minimised.

- Personnel informed of the risk and the risk management system.

- Respiratory Protective Equipment (RPE) – wear RPE if removing old plaster containing animal hair. Choose RPE with an assigned protection factor of 20 (eg FFP3 disposable mask or half mask with P3 filter). For longer duration work consider powered RPE with the same protection (eg TH2 powered hood / helmet).

- Basic.

- Military Construction. The Royal Engineers need to recognise that in the future operating environment a large amount of construction will be refurbishment of existing buildings on brownfield sites. Contamination of these sites is to be expected and the only tools in the military’s arsenal to deal with this is CBRN equipment and TTPs. The Royal Engineers should consider gaining the skills necessary to deal with its own contaminated sites overseas whether it be Anthrax, Industrial Chemicals or Asbestos.

Future Phase 3 (Civil) placement in London

Hi everyone, not a technical blog, just passing on contact details of my Phase 3 in case anybody wants to go there next year.

I have been working for Wentworth House Partnership (WHP), who are part of the Keltbray Group. Keltbray are a specialist contractor, traditionally in demolition, but have expanded into piling, asbestos removal and rail amongst other things. They have recently set up a structures business (concrete framing) in its own right, and have just won the contract to build Battersea Phase 3A.

WHP are the design consultancy for Keltbray, but do about 25% of their work for external companies. Most of the work is for temporary works, which means fast paced designs and a very varied experience. I cannot say if this is better or worse than a permanent works design office as I’ve not worked in one, but it has suited me. More hand calcs, less importance put on things being used to 100% of their capacity, as long as it works and is 80%+ efficient it is usually good enough.

I have designed in steel, timber, concrete and lots of design work using scaffolding and other off-the-shelf solutions. Some geo too; there is a geo ‘department’ (4 guys) but I have only really dipped my toes into the water there and done the simple analysis. All in there about 45 engineers and technicians in the office.

The three directors are all Fellows of the ICE and IStructE, and two are active ICE reviewers. They know what you need to pass CPR, and are a really good source of advice. They arrange weekly CPD in house over a free lunch and at any one time probably have about 5 or 6 of their own staff going through the Chartership process.

Stuart Marchand (the managing director of WHP) was a founding member of the temporary works forum and a previous chairman. Tim Lohmann (another director at WHP) is the current chairman, and the final director (Stuart Vaughan) probably will be chairman in the future. My point is that WHP is a very good place to learn about temporary works, which I think share many characteristics to a lot of military engineering solutions.

The office is in Esher, so really handy if you live in The Keep. If not it is a 24 minute train ride from Vauxhall. The full address is: Wentworth House Partnership St Andrew’s House Portsmouth Road Esher KT10 9TA.

If you’re interested, email the directors and mention the PET Course, they have hosted myself and Fred Kiddie before me so they know what the course is about.

director@wentworth-house.co.uk