Archive

First forays in America

Introduction

Howdy Y’all! Before coming out here Stu made me promise three things:

- Not to go native

- not to go ‘off grid’

- Not to get arrested/shot.

Because of that, I thought I’d at least try and stick to promise #2 by entering the blogosphere to provide an update on my attachment to date.

In all, getting Helen and I settled into the USA took the better part of an entire month. This was mostly spent running around trying to do things that we would otherwise take for granted in the UK but which are actually quite hard to do when you’re an alien in a foreign country. In America, you can’t do much without a social security number and a credit rating and this can complicate the already large task of setting up bank accounts, transferring a large amount of money from the UK, renting a house, buying a car, signing up for utilities and getting a phone. Most is solved by providing a very large security deposit for everything that you would normally pay by direct debit (which the US banking sector still don’t seem to have quite right…). To give a few examples, we had to pay the gas and electric supplier $300 dollars as security, COMCAST got a $150 advance for our internet, and AT&T wanted $1,000 as a security deposit for Helen and I to take out a phone contract – it was more than the cost of the handset and bundled tablet so we cancelled that transaction, opting for pay and go with a phone bought outright!). The arrivals process is also quite linear in so much as the outcome of one admin piece provides an additional proof of identity that gets you one rung higher on the ladder. Unfortunately, this means that any delays caused by an incorrectly filled out form, an absent member of staff, or freak weather event and you’re stuck treading water until you can complete that activity. Thankfully, most American institutions are surprisingly helpful and forward leaning. The process isn’t seamless (I’ve been to the Maryland Vehicle Authority twice and still haven’t finished the application for my driving license – a requirement for owning a car). Thankfully, the accent and a military ID gets you far; Helen was enrolled onto health care without a birth certificate despite it being an essential document… and I’ve only been able to get to work this last fortnight thanks to the MVA and car dealership allowing me to drive around with a set of trade plates.

…I am, however, less impressed by the embassy’s role in the arrival process who seem to hinder things more than they support…

But anyway; on to the engineering!!

The Project

Similar to earlier iterations, my attachment with the US Army Corps of Engineers (USACE) has placed me in the ‘East Campus’. This is located in Fort Meade, Maryland, which is just under an hour north of Washington, DC, and half an hour south of Helen and I’s new home in Baltimore. The East Campus “project” is actually a programme of smaller design and build projects, the focus of which currently sits with the Joint Operations Centre and its supporting infrastructure; the facility is essentially an attempt to create a “campus feel” and center of excellence attracting talent to an area that is already home to US Cyber Command, the NSA Headquarters, and a few other interesting organisations.

The main elements within the JOC project are:

- A 24/7 operation centre with “battle bridge” – Think of something akin to the Bourne series or even NASA mission control… but bigger.

- Collaboration areas / meeting rooms

- Office space

- Break rooms and canteen space

- E&M services and systems. This is going to become critical national infrastructure and pretty much everything has backups to the backup.

- IT and comms

- Security systems including everything needed to prevent surveillance such as EM and acoustic shielding (required for the structure to serve as a Sensitive Compartmented Information Facility – SCIF)

- Environmental and architectural features such as storm water management, replanted woodlands, and boulevards to create an “aesthetic open space” that earn the project LEED points (similar to BREEAM).

Where I fit in

Unfortunately, there’s not a lot I can write about yet… I have now been in the office for an entire fortnight but I’m still only part way through the bureaucracy of getting un-escorted access to the site and government IT systems. USACE is not the contractor for this project, but rather the client’s representative. As the interface between Henson Phelps (the principle contractor)and the government, USACE conduct quality assurance, investigate and respond to RFIs and administer contract changes on behalf of the clients (the ultimate owner of the site will be the NSA but different government departments are providing the funding for different elements of the project – current work is a mix of Air Force and Marine Corps).

There is also a project management element in terms of keeping an eye on the activity schedule and holding the contractor to account. By providing a pragmatic and technically-capable buffer between client and the principle contractor, I also believe USACE helps control the budget and schedule . In my two weeks here, I have already seen issues quickly resolved by USACE staff taking positions both in support of and against the principle contractor. This demonstrates a professional working relationship and makes sense. On issues where the contractor is more than likely ‘right’ or at least deserves the benefit of the doubt, USACE’s team can hasten a change in the contract and maintain momentum. At the same time, when there is doubt, the added rigor of the USACE team encourages the principle contractor to admit fault quickly and preventing unjustifiable increases to the client’s costs.

Are people in the UK or AUS seeing similar relationships, maybe with independent auditors?

My tasks thus far:

- Support to the QA team. After shadowing team members on site visits and observing their interaction with the contractors. I’ve now supervised a handful of relatively small concrete pours and a close-in inspection (prior to an internal wall having the plasterboard fitted, there is a detailed inspection of all the features inside to ensure it’s according to the specification – due to the nature of the site, this is taken very seriously). There’s an interesting dynamic that sees construction supervisors from the NSA providing a QC/QA function over sub-contractors, the principle contractor, AND USACE. It’s been interesting watching the resulting discussion when the NSA reps make demands that both the contractor and USACE disagree with… potentially a topic for a future blog post.

- Oversight of the construction of 18 small concrete footings for columns that will support cables connecting two generator farms. This is a simple job complicated by one of those farms being active and inside a separate and very restricted area of this already secure site. The task is made even more difficult thanks to the following:

– critical underground services (gas, electric and diesel) very close to the surface.

– a large open excavation adjacent to the only route in.

– the need for continued work in the generator yard (including testing and commissioning!)The contractor is avoiding the problem so USACE plan on presenting them a construction method to force them into action.

- Oversight of the construction of large numbers of bio-swales (flood attenuation and contamination control features) across the site.

- Investigation of cracked flanges in a series of “vaults”, underground chambers for electrical/mechanical works. There are a number of theories as to what might be happening ranging from subsidence of the pipes connecting them all, buoyancy of the vaults themselves, or simply damage caused by trafficking of overweight vehicles.

Hopefully, I’ll have enough for a decent blog post on the above over the next couple of weeks. I may also post some more detail on the arrivals process and the issues Helen and I have faced. The US attachment has a tradition of updating and passing down an admin instruction to those preparing to come out, however, a quick summary might be useful to those at the start of phase one or in case anybody else is assigned here in the future.

In other news.

As I can’t really upload photos from the site, I thought I’d post a picture of the new car (or at least a picture from google of the same model and colour):

If you drive really carefully and turn the A/C off she almost manages 24mpg; compared to the 50mpg in the old estate, it pretty much counteracts any savings I make from fuel being half the price! Now I just need to go out into the wilderness and justify the fact I own an SUV.

You also can’t take personal vehicles onto site so I’m also now driving these bad boys around (standby for the emergency CASEVAC to the UK once I get un-escorted access and decide to test out the off-road capabilities!):

100 Years Since the Start of WWI….

Something non-engineering for a change. Yesterday I attended an event in Baltimore to commemorate the centenary of US entry into WWI. I was half expecting something stereotypically American about WWI beginning in 1917, and how the US effectively won the war by bailing out Britain and France who hadn’t been able to finish it off for themselves! I was pleasantly surprised to find the version of events portrayed (generally) accurate, and there was even a high-ranking speaker from the French Embassy in Washington striking notes of liberté, égalité and fraternité. The only awkward moment came when the colours were marched in and I had no idea what etiquette dictated I should do! In the event I saluted when they were marched in, but not during the national anthem (which caught me by surprise when it was struck up), but then saluted again during the bugler! I think I got away with it! I was also only asked once by a very elderly veteran if I’d come dressed as a WWI solider! The eagle-eyed amongst you will notice that I’m wearing leathers, hat (and medal, yes it’s TOSCA but it still counts!) indoors. Just to confirm; in true American tradition this was an outdoor event held indoors, complete with complimentary burgers and hotdogs! I did however remove my gloves!

Maj Harrington, Lt Col Morgan (Deputy Comd) and myself at the WWI commemoration

Attending this event reminded me of the other military events I’ve been fortunate enough to be part of during my time here. This includes a battlefield study and trip to Westpoint, a leadership staff-ride at Gettysburg, and a trip to attend a USACE conference in Alabama of all places (where I stayed on a university campus with no bar!). The US exchange first and foremost offers engineering experience (obviously). However, there’s another side to it which shouldn’t be underrated. I’ve found it absolutely fascinating to be part of USACE, to operate with them, and to see how they go about their business. From a military organisational point of view things are certainly different over here, and a year ago when I arrived I found it almost impossible to compare USACE with the Royal Engineers; they’re simply poles apart in terms of structure, capability and function. There are of course some things they do badly. For example (in my opinion) separation of combat and trade engineer skills, which reduces flexibility and increases reliance on non-organic support and sub-contracted work. There are however a number of lessons we might consider paying attention to, for example they are very good at fully integrating their reserves and have an extensive reach-back capability. Overall from a developmental point of view I’ve found the social and cultural emersion to be just as interesting and useful as my day to day work.

Finally, one last photo from the Baltimore District military ball! If there’s one thing we’re undeniably better at it’s uniforms!

Military personnel at the Baltimore District Ball

Contamination Crisis – UNSW

G’day gents (had to do it). Australia has experienced a record breaking 23 days of continuous rain, so I have managed to maintain my pasty complexion. Quick orientation – My site is at the University of New South Wales where there are effectively three separate projects. The main event is the Science and Engineering Building (SEB). The substructure consists of a contiguous pile wall (CFA piling), followed by a bottom-up concrete sub/superstructure. The Roundhouse is a refurbishment (including significant structural steel strengthening) of the University’s precious student union. It’s the oldest building on campus and there is a big push to complete before Christmas for obvious reasons. The Hilmer building is a M&E services fit out project.

Contract arrangements.

Shock – none of the projects has a formal contract. A letter of intent was issued only last week to continue with works on the Roundhouse and the SEB contract is still being negotiated (current works including piling mattress form part of the early works letter of intent). Multiplex are pushing for a Design and Construct (D&B) contract, but the client wants more influence via a managing contractor contract. In addition, the SEB still doesn’t have Development Approval (DA) from the council and the delivery of the piling rig has been pushed to the right by another 2 weeks as a result.

Contamination Issues.

The Geotechnical Engineer found no evidence of ground contamination during his GI. However, whilst the SEB site was being excavated to formation level in preparation for construction of a piling mattress, bonded asbestos was identified on site (believed to be old formwork panels from previous construction that were dumped in an excavation!).

There were 2 potential remedies. First was to employ a hygienist to sift through all excavated material and inspect each load as it left site. Or alternatively just remove the first 1.5m from across the entire site and classify the whole lot as General Solid Waste Asbestos (GSWA). Surprisingly, this was only $2/tonne more than normal GSW and therefore a mere $26,000 of additional cost. The total effort was 13, 000 tonnes of waste material that required approximately 600 “truck and dogs” (Aussie slang for a truck with a large 12 tonne skip on the back). I was involved in producing high risk workshops and removal control plans for the site. Clearance certificates were issued for the site and piling mattress construction has begun.

On the roundhouse, the existing steel structure was covered in lead paint (for fire proofing I assume). This was obviously identified and considered in the programme, but the length of such a process was hugely underestimated. The programme is now 4 weeks behind and only 30-40% of the paint has been removed. The first option considered was to sand blast it off. However, this idea did not survive very long due to the clean-up effort required and the difficulty of containing air particles. The second option proved mildly successful and involved soaking the lead with a gel before blasting off the lead with dry ice pellets in a spray gun. See dry ice pellets and gun operator below.

However, although successful, it is a painfully slow process, even after reinforcements arrived with additional guns. Yesterday the subcontractor switched to a soaked paper peel that is applied overnight before being peeled off with ease, bringing the lead with it, the next morning (very effective). Unfortunately, whilst everyone was high-fiving each other, some of the solution dropped onto the leg of one of the workers and it burnt straight through his PPE! All work has been stopped until a new Safe Work Method Statement (SWMS) is produced by the subcontractor and reviewed by MPX. That is tomorrow’s problem…….

How your Great Grandad built a Chimney.

Figure 1: The original construction of Battersea Power Station’s chimneys.

English Heritage had many stipulations before planning permission was granted for the redevelopment of Battersea Power Station, a key one of which was the restoration of the iconic chimneys. These had to be built using the same methods as they were in the 1930s, which has led to some interesting issues during construction.

Jump forming over slip forming.

The original proposal was to slip form the main shaft of the chimney using a smooth form, and then go back and attach the ribs, which are mostly cosmetic and contain no reinforcement, afterwards as well as marking on the day joints (Figure 2.) However, the use of jump forming was enforced as this was used during the original build. This is where the formwork is lifted 1.22m (4 feet as per original design) every other day, building the chimney in a series of rings. This results in the horizontal rings, or day joints, as a by-product. The ribs are cast at the same time during jump forming. Having not been involved in slip forming I do not know if these ribs could be included in a slip form, could someone enlighten me? To ensure that there is an interlock between the pours, the top of the pour is sprayed down at the end of the day to remove the grout and expose the aggregate, allowing the next pour to bind to the previous one.

Figure 2: Original chimney, showing taper, day joints and ribs.

The taper.

As can be seen in Figure 2, the chimneys taper as they rise. This is achieved by using removable plywood panels within the outside formwork (Figure 3), which have a slight taper and are trimmed by 1.5mm per side per jump. They are sized to fit between each of the ribs. To make this small cut easier, there are 3 sets of panels, so after each form is used it is trimmed by 4.5mm on each side and introduced back into the cycle. The ribs themselves are a constant size throughout. As there are no ribs on the inside, the formwork is simpler and consists of metal sheets which can slide over each other to reduce in size.

Figure 3: Formwork.

Concreting.

Due to the low quantities of concrete required per jump, a concrete pump was not suitable as more concrete would be required in the hose to achieve the height required than is actually needed in the formwork. Instead, there is a 600L hopper on mini train track installed within the hoist (Figure 4), which is filled from the onsite batching plant (which is purely for the chimneys and can only produce 300L per batch) via another hopper on a set of forks. The hopper is then pushed back into the hoist and ascends. At the top this hopper is used to fill 4 wheelbarrows, which are moved in a one way loop around the top of the chimney, pouring into the formwork via a wooden slide, before continuing around to be filled again. There are two wooden slides (Figure 5) which leap frog each other around the chimney, and despite the system being so low tech, it is remarkably efficient. The workforce of 7 (4 on wheelbarrows, 1 on the hopper / hoist, 1 with a vibrating poker and 1 supervisor / slide mover) quickly pour the 600L into place. Using this system they are now able to achieve 1 jump every 2 days.

Figure 4: Hopper on tracks.

Figure 5: Wooden Slide.

Reinforcement.

This is shown in Figure 3 and Figure 5, and it consists of an inner and outer mesh which is constructed from straight bars every other day, in between pours.

Future use.

There are Halfen channels cast into the inside of the chimneys, as there are various fixtures being installed later on. All will have internal ladders for maintenance, one will have 5 flues for the various plant rooms across the development (so that the chimney will “smoke” once again) and 1 will contain a glass viewing platform in a lift which Willy Wonka himself would be proud of, as shown in Figure 6.

Figure 6. Glass Elevator in the North West Chimney

Summary.

I think that this construction method proves two main theories; keep things simple where possible, and that repetition will improve speed. Firstly, I think that there will always be a place for the simple, low tech solution in construction. Although simpler methods may not be as quick as more modern techniques, the potentially low set up cost and running costs, coupled with the speed at which they can commence, could often offer a more affordable solution. Clearly this may not be the case if the task is on the critical path where time is likely to be the main driver. Secondly, where things can be designed to be repetitive, they should be. There are a total of 4 chimneys to be restored, each requiring over 40 jumps. The overall process is becoming slicker each jump, and although the crew quickly reached the maximum allowed rate of 1 jump every 2 days, the total working hours to achieve this has reduced.

Figure 7: The view from the top (looking at the NLE.)

The chimneys are now finished, and a construction enquirer article has been written.

http://www.constructionenquirer.com/2017/06/05/two-year-rebuild-complete-of-battersea-chimneys/

Acoustic barrier

I’ve been working on a project designing a variation of a demountable acoustic barrier for use between the entrance to TFL tube stations and busy roads. It uses a new noise attenuation cassette produced by Echobarrier and potentially geopolymer or wood concrete base units and a titanium dioxide additive to the surface to reduce NOX levels.

The basis of our appointment is initially to act as structural engineers on the design and installation of a prototype. The total budget for design and construction is 300k. The real money will be made through IP rights and by successfully developing the prototype into a system that can be deployed more widely. For this reason the project is relatively confidential so please don’t discuss outside the course (not that anyone is interested anyway).

Due to the low budget, initially, we need to stay close to existing systems to assist with the client risk appetite, ease of installation etc. But we also need to demonstrate options for increasing beauty, function, speed of deployment, improvement to pedestrian safety, longevity, flexibility etc. and to that end i’ve had initial discussions with the architects and a small pre cast company specialising in low cost prototypes, and BRETT Group for delivery of a scaleable solution.

So far i’ve looked at design actions and produced the structural basis of design. All relatively simple stuff. Future work will look at the options for the concrete bases, and detailing for the connections between the posts and base (likely to include a cost comparison of bespoke cast in channels, and off the shelf resin anchor systems.

The snag is that funding has been put on hold currently, but we should get news later this week from the Client on when it might be re-initiated.

Pipes and shit

Whilst I’m pleased to see the Phase 2s on here so the Phase 3s can now wind down the blog contributions, I think RF is under the impression I may be hiding under a rock again, so below is a brief summary of some of the work i’ve done recently using a calculator and felt tip pens. They’re all work in progress so feel free to comment with any suggestions, advice or queries.

Selfridges Drainage Management Plan

Below is the latest of 4 technical notes i’ve produced as part of the Selfridges Drainage Management Plan. They’ve let their drainage get in a bit of a mess and there are literally places where shit has hit various fans (or more importantly some expensive handbags). Expedition were initially engaged to summarise the issues. They reviewed the drainage systems and produced 20 recommendations thinking that Selfridges would say thanks but no thanks. Un/Fortunately depending on your perspective they turned around and tasked Expedition to enact every one of them. There started 2 years of work for the civils team charged out at 15k per month. What a terrible example of poor asset maintenance I hear you cry! But is it really? £15k is probably two of their mid range handbags….retail space is worth a hell of a lot more to them when it’s operating than when a contractor has some hoarding up so they can do maintenance. In retail, as in construction, decisions are made on a commercial basis, and sometimes this trumps engineering factors. If you can’t understand a seemingly ludicrous engineering decision, make sure you’re considering all the wider factors.

That said their latest idea to put a new toilet block on a part of the system that’s potentially already overworked (the exact drainage routes still aren’t known) seems truly crazy, and the work below (still in progress) is me trying to work out exactly how crazy it might be, and how to politely tell them.

EXP 326-4 Outfall 2 Assessment[2015]

Taipei Airport Drainage

Expedition are completing the concept design for the drainage masterplan for a new terminal at Taipei airport. The detailed design is being done by Arup.

I was looking at the structural support for the downpipes. There were a number of constraints. The design requires twin stainless steel downpipes (circa 500mm diameter) to be supported from the roof truss and at berm level, but unsupported between so they resemble steel columns. Large thrust forces will be developed at the pipe bends, high wind loads are expected, differential movement is expected between the roof and the ground (+/-45mm horiz. and 15mm vert.), seismic effects must be considered.

I initially looked at cantilevering the pipe 8m from the ground to alleviate the differential movement issue, which required me to assess the dynamic response of the pipe to the expected wind load, and the thrust of the water hitting the top of the hopper. However the lead engineer wasn’t entirely uncomfortable with this, with too many variables for us to mitigate the risk without unwarranted analysis at concept level, so I then had to look at options for supporting at truss and berm level.

The latest (although potentially not final concept) using WGS 77 Victaulic couplings as a “flexible” (the meaning of the word here is relative as their flexibility is limited 9mm per m length) is shown below. Although we calculated the forces and specified the couplings we omitted this from the concept document. We’re not paid to develop detail so why take on the liability. I also got slapped on the wrist for writing “WGS77 or similar”. Despite seeing this approach numerous times on site it’s avoided in the design office as it opens up all kinds of legal issues if a “similar” product fails.

Formation level at Hinkley Point C

I’m currently not allowed to upload photos onto this site – I’m trying to sort out permission from site. So I will keep it brief until I can provide a decent intro to site with some phots. I just wanted to show the formation level on the site where I will be managing the install of the main site office (OIC portacabins). There is a 48hr exposure rule due to oxidisation of the ‘blue lias’ rock which can become weathered very quickly, so I’m lead to believe. So the inspection and blinding is fairly slick to minimise further excavation to fresh rock. Is this level of cleaning excessive in your experience? Or good practice? (Conscious that this is a picture – but it’s just stones) Dan Porteous.

Angel Gardens Teaser – Darwin Award nomination

Stadium Australia

Built for the Sydney Olympics, Stadium Australia originally looked like this…

After the Olympics, the stadium was expected to attract smaller crowds and so the terraces behind both goals were reduced. This modification has resulted in the present day configuration, see below.

The owners now want to make two further modifications. Now that the running track is redundant, the first alteration will see the seating brought much closer to the pitch, adding to the capacity and atmosphere. The second alteration will see the addition of a roof, see below.

Whilst both endeavors are intrusive, the alteration of the seating arrangement is the greater challenge. This is because the trusses which span over the length of the stadium were designed with a roof in mind – bonus.

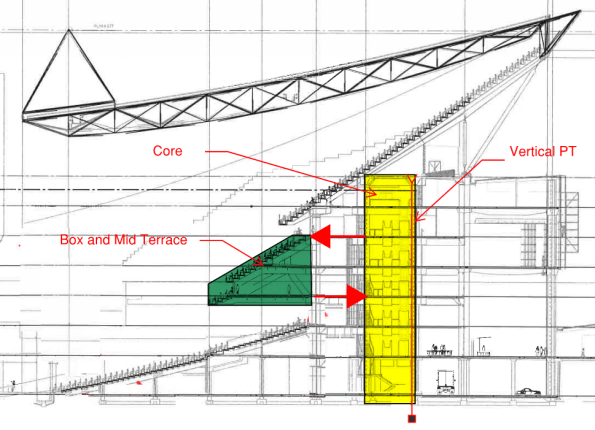

The box and mid terrace which run the length of the pitch are cantilevered from the main structure. The lateral push / pull loads are transferred to the core via the floor plates. Without a balancing load, this would cause the core to deflect towards the pitch. To counter this, vertical post tensioning runs the full height of the core, on the wall furthest from the pitch, see below.

Key: green = terrace, yellow = core, bold red arrows = forces in floor plate, red line at back of core = PT.

To reconfigure the seating, the box and mid terrace will need to be demolished. The requirement therefore is to identify a methodology which allows the removal of the terrace without causing an unacceptable imbalance with the post tensioning.

My first intention is to track down the original construction methodology. Has anyone else been exposed to the modification of PT structures during their Phase 3? Suggestions on a post card please…

Piling case pulling out reinforcement – Request for advice.

I am working on Phase 2 of the Battersea Power Station redevelopment, inside the power station itself. Within this I am managing the piling package inside the Boiler House, which in way of orientation is the main, central building of the power station, with the towers and chimney in the corners.

I have recently encountered my first issue, and although we have found a solution to allow construction to continue, we have not found the cause. I was wondering if anyone has any previous experience of this and knows the cause, so that hopefully I can prevent it happening again.

The design for this pile had the toe depth located in London clay, and as such the casing was used to seal into the clay, but no further, with the undrained strength of the clay allowing the rest of the bore to be drilled without the need for bentonite support. However, after over drilling beyond the London clay layer and into the aquifer below, and with the bentonite plant not yet operational, further casings had to be used to prevent the Thanet sands from collapsing into the bore. With this new depth a pile redesign was required, resulting in little more than a longer length of reinforcement cage needed, which was spliced on, and the concrete pour went without incident.

A total of 30m of casing was installed on this pile, far more than had been designed for, and it is when the casing extraction began that the issue arose. As the second section (3m) was extracted, the reinforcement cage rose with the casing. The cage had somehow become stuck in the casing and was being pulled out with the casings. Bauer (the piling contractor) were unable to push the casing back down, and after numerous attempts to rectify the situation, Bauer made the decision to remove the entire cage for the pile, and core through the existing pile to form the new one.

Unfortunately the first (top) splice joint in the reinforcement cage failed (it was not designed for tension with a load a wet concrete on it) during the casing extraction, and only the top cage (approximately 12m long) could be removed. After several hours of failing to dig out the cage (I believe the concrete was still too wet) it was left as is. Currently the dip to concrete is 7.3m from ground level and there is 8m of casing on, but lifted above the concrete.

It has been decided to backfill the void and to place a new pile either side, with a capping beam on top, rather than try to rectify this pile. Space allows for this and schedule is the driving factor, with this being put forward as the quickest solution.

Where I am after advice is what caused this to happen. Currently there are 2 possible options being discussed, but I am having difficulty accepting how either of them could have caused the issue. I have outlined the options and my thoughts on each below:

- The cage was simply caught on the teeth of the casing. The spacers should have kept the cage away from the teeth, and if this was the cause then I can struggle to see why only the top cage was caught. It would make more sense to me that the entire cage would be pulled up if it was caught on the teeth. Or am I missing something?

- Grout loss during the pour. If there was a large amount of grout loss then could the denser concrete and increased aggregate have simply jammed the cage into the casing? If this grout loss was towards the top then I can see how that could explain why it was only the top section which was jammed, but I fail to see how there could be grout loss inside a casing?

If anyone has any further information on either of these options, or has other theories to throw into the mix, then please get in touch. I have about 200 piles to go and would like it if the rest went more smoothly!