Archive

Temporay Tunnel Ventilation Problem

As well as getting my head around the intense amounts of jargon I have been occupying myself with a problem facing the tunnel ventilation team.

Here is the BLUF: Each tunnel (East and Westbound) contains a couple of dirty diesel-powered locomotives and a workforce occupied with drilling holes in the wall. The upshot is that the air quality in the tunnels has the potential to become very poor as the M&E fit-out work progresses, and the permanent ventilation system is a year away from commissioning.

My placement company (ATCjv) are charged with the temporary ventilation to prevent this becoming a big problem. Unfortunately they are also preoccupied with the permanent M&E fit; as a result the temporary works are getting relatively little attention. The permanent ventilation fan system is eventually designed to provide 100m3/s into the tunnels at each station when running at steady state; in the case of a fire or terrorist gas attack it can blow or suck 600 m3/s at full whack. This is enough to create a 9.6 m/s (21 mph) draught down each of the two tunnels.

However, whilst each station is under construction the main ventilation fans are months away from being installed; the ATCjv ventilation team need to provide a flow from Bond Street station to give sufficient air quality for the workforce in the tunnels. The flow diagram of the temporary ventilation installation is shown in figure 1.

Figure 1. Bond Street section temporary ventilation flow diagram

The interim solution at Bond Street station until a large-scale temporary system is commissioned is to fit a 250 kW forced ventilation fan into a tunnel feeding the main running track, an image is shown in figure 2. The flow rate of ventilation air through this fan is measured using an anemometer held in the flow– not a particularly scientific or reliable method. Ideally the temporary solution will give a flow rate that is comparable to the finished station; the current measured flow velocity in the fan jet is around 24 m/s, giving a volumetric rate through the fan (velocity x area) of 8.64 m3/sec. This is way too low to meet the temporary requirement of 35 m3/sec. The solution is to rely on the noxious gas detection equipment with the workforce in the tunnels as a safety net and take the problem ‘on risk’ (i.e. no-one important has noticed yet).

Figure 2. The temporary ventilation fan in its feeder tunnel.

The final ventilation system will be commissioned with a much more rigorous ‘grid’ system of anemometers to measure the flow velocity throughout the tunnel cross-section (see figure 3 below) which will give a much more accurate flow value. However this hasn’t been applied to the temporary system – it is too expensive.

Figure 3. Approved tunnel ventilation measurement methodology. Survey points on tunnel cross-section show anemometer locations.

To keep myself useful I have tried to figure out a more accurate figure for the ventilation flow than given by the current improvised method. The ducted fan acts to fire a jet of high velocity air down the centre of the tunnel drawing further air with it from the surroundings (air entrainment). This has the effect of increasing the airflow down the passage. To add some detail I have tried to improve upon the simple flow model by considering an annular boundary layer around the ‘jet’ of high-speed air, as shown in a dodgy sketch below (figure 4).

Figure 4. Flow pattern from the ventilation fan, back of fag packet version.

V1 in the image above is the peak flow at 24 m/s, with the air velocity at the edge of the fan ‘jet’ being 8m/s. Using this new approximation a revised estimate of the actual flow taking into account entrained air through the 3-meter wide tunnel is 19.32 m3/s. Still off where it should be, but a little bit closer to the desired 35 m3/s. The construction manager posed with this solution was simultaneously pleased that it was larger than his number and completely unconcerned as to the reasoning behind it.

I hope at least Mark Hill was happy that I actually tried to apply some of the knowledge he threw at us in the second half of last year. Please consult Palmer TMR 1 for a more detailed description of where this figure comes from…. if you can stay awake.

CI’s thoughts on blogging…

I thought that a blog from the CI to offer some thoughts on attachments and blogging may help to ameliorate some of your concerns that I have been picking up during my discussions with you.

My first top tip is to focus on the endstate – successful CPR. For those of you on Phase 2, you have over a year to complete all of your UK-SPEC competences (or attributes for you Cs as I have now been informed that development objectives are no longer in vogue…) Do not feel concerned that you might not be being exposed to huge technical detail during your site attachment. Be concerned if you are not being exposed to good commercial, financial and project management detail. The technical stuff will follow on Phase 3. If you are on Phase 3 and are experiencing a bit of ground rush, now is the time to really check your development action plan and ensure that in the last couple of months you close the gaps you have identified in your experience. I am sure that all of you are in a good place in this respect though; that is what AERs are for, to track progress and aid your planning of your attachment. Remember that this is an MSc and that you are all captains or majors working towards being chartered engineers – you own your journey.

My second tip is don’t just feel the need to write about your positive experiences. An important part of being an engineer is to be able to reflect and understand one’s limitations. Therefore, please do not hesitate in writing about your challenges, your incomprehensions and your failures. You will be a better engineer for it, as will your peers and as will we be as staff. Your blogs are some of the best CPD we have experienced.

Hence, the value of your attachments is in the journey taken to the endstate and what you extract from it. Some of the most valuable experience gained by students has been from small tasks, where a complete view of the totality of an issue can be seen. There is no need not to blog because what you have been doing is not as sexy or as complex or as large scale as the previous blog. The important element is what lesson or experience or development point can you extract from the experience? So blog away without inhibition (on professional engineering matters of course).

Most importantly: Enjoy the experience and size the opportunity!

SRL

Bruce C16 Caisson Swage Repair

If the title of this blog makes absolutely no sense to you then you’re at the same starting point that I was when this project was handed to me! This project is currently the top structural integrity concern in the BP North Sea portfolio but is actually relatively simple once you get your head around what’s involved. The project pretty much covers all the core competencies, focussing mainly on contractor management and project management, with a good dose of health and safety due to the nature of the offshore industry and some complex lifts which are required.

If the title of this blog makes absolutely no sense to you then you’re at the same starting point that I was when this project was handed to me! This project is currently the top structural integrity concern in the BP North Sea portfolio but is actually relatively simple once you get your head around what’s involved. The project pretty much covers all the core competencies, focussing mainly on contractor management and project management, with a good dose of health and safety due to the nature of the offshore industry and some complex lifts which are required.

Background

A caisson is effectively a big pipe which extends from the deck of an offshore platform down to below sea level. Its purpose is to minimise the effect of waves on seawater lift pumps (seawater being the obvious choice offshore for cooling, processing and fire fighting).

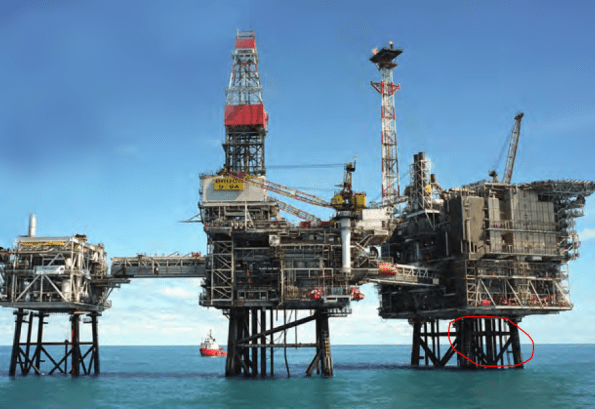

The BP Bruce asset, comprising of separate drilling (D) and process, utility, quarters (PUQ) platforms is located some 200 miles East of Aberdeen and was built in the early 1990s. The PUQ platform has a number of caissons which are shown in the images below and right (circled in the photo and labelled with hexagons on the drawing). The dashed lines in the drawing are the jacket (support legs and bracing) of the platform. The caissons are attached to the second horizontal brace down. Sea level is approximately at the midpoint of the top set of cross bracing.

BP Bruce Asset (Seawater Lift Caissons Highlighted) & Jacket

Due to a combination of the age of the asset, climatic conditions and the corrosive nature of seawater, structural integrity is a constant challenge. The point where the caissons on Bruce are attached to the platform is the point of greatest stress and corrosion and caissons C12-C17 have suffered major cracking (example shown below in photo). Why this is such an issue is due to the ‘dropped object’ risk. If the caisson were to break at the crack then 30 m of 1 m diameter steel pipe would plummet towards the seabed. There is a risk if this happens of damaging nearby caissons (and therefore the ability to fight fires), the jacket (therefore putting platform integrity at risk) or equipment on the sea bed (therefore putting production and hydrocarbon containment at risk).

Bruce Caisson Crack

Options

In order to address this risk BP considered 2 options:

Option 1 – Replacement. This is something that Imran was working on several years ago and was cancelled due to cost. Replacement would involve procuring a new caisson and all the related deconstruction, transport and construction works. This represents a significant investment; whatever you think it will cost, add 3 zeros in cost and triple your time estimate for offshore! In the current economic climate costs are being minimised and so this option is unlikely to be funded. Equally the life of the new caisson would far exceed the expected life of the platform and greatly reduce any return on investment.

Swaging Tool and Liner

Option 2 – Swage Repair. This is the option chosen and the one which I will be responsible for executing offshore. First the caisson is internally cleaned using a tool which utilises a high pressure jet of water to remove marine growth and corrosion. An internal liner is then lowered down over the crack before the swaging tool is inserted (see image). The tool is pressurised to expand the liner beyond its elastic limit whilst remaining within the elastic limit of the caisson itself. The liner is thus held permanently in place and seals exactly to the shape of the caisson. The process is illustrated in this handy video.

The Project

The main contractor for the project will be BP’s engineering partner, Wood Group PSN (WG PSN). Two specialist sub-contractors (known as ‘vendors’ due to BP’s global nature) will be involved. Sparrows are an offshore lifting contractor and will be responsible for the lift plans, rigging and executing the lifts (example shown in image below). Oil States, an offshore engineering specialist, own and operate the swaging tool and have fabricated the liner. I recently attended the 6 week constructability review where, as the client, I approved WG PSN actions thus far and the offshore execution schedule. Additionally I have carried out the project risk assessment in line with BP’s risk matrix and HSE guidance. This led me to identify the risks associated with the lifting and I have raised these with Sparrows. As this is the third project in a series of 4, the remainder of the risk assessment related to on-going risks and those identified previously.

Example of Complex Lift Procedure

The C14 caisson on Bruce underwent a similar repair in September 2015 and the procurement for the project included that which was required for C16 and C15 (I will likely take on C15 as a project once the C16 repair is complete). The liner and additional fabrications required are currently in storage and I am assured they will be inspected and re-certified prior to project mobilisation. Mike has blogged previously about some of the issues with materials going missing offshore so this is an area of concern for me. Other than a substandard bill of materials I was handed in the 6 week review I have had no issues so far.

Other concerns relate to the site itself. The laydown area outside the pump room where the swage repair will take place is fairly tight for space (see image below). I am competing for time in the asset schedule with another project which also requires the use of this laydown area. This, combined with the fact that the crane needed to lift my containers onto the laydown area is out of action until 4th July is already causing project delay to creep in. I will shortly be having a meeting with the other project team and the asset engineering team to de-conflict the projects and discuss the crane issue. The meeting may also see the scope of my project expand to include the C15 repair immediately after C16.

Bruce Laydown Area

Finally there is one fairly show stopping problem with this project in that the very expensive, vendor owned swaging tool might just get stuck in the pipe! Luckily Oil States have a procedure for this and the tool has a number of shear pins which can be broken by using an over pull tension in the lifting cable. Unfortunately the overhead gantry crane in the pump room is not rated for this. Fortunately a ‘strong back’ frame was fabricated for the C14 repair, which combined with some big jacks can be used to produce the required tension. Unfortunately the deck plates on the floor of the pump room aren’t robust enough to support the strong back frame. Fortunately some large steel plates were fabricated for the C14 repair which can be placed on the deck to spread the load. Suddenly it can be seen where the extra cost and time comes in for offshore projects!

Summary

So yes, that’s it, after months of the PET course and highly technical study, I have been placed in charge of a project to put a pipe inside another pipe! There is a lot of de-confliction which needs to happen to get the project mobilised but I have taken over at a time where the onshore execute phase is all but complete. Next month I should be offshore during the swaging process and will report back on the offshore execution.

Podcasts

Following on from the recent CPD theme another avenue for easily accessible CPD is podcasts. I have started to become a bit of a podcast enthusiast since starting phase 2. Mainly to fill my 2 hour commute after repeats of the Taylor Swift album became a bit too much. Clearly there is a wealth of podcasts out there and I have to confess that I have only recently realised it is a good way to get some CPD in. There aren’t a huge number of engineering ones that I have found so far but in the interests of kicking off a list that others could add to here are a few:

NFPA: This is from the National Fire Protection Association. The organization is based in the USA, where they are neurotic about fire, and provides updates on their codes and digs into other topics. I wager that the US are a way ahead of us in considering fire protection so it is worthy of a listen.

HVAC 360: You guessed it, it’s about HVAC. Presented by a commissioning agent he explores issues and technologies. I have listened to a couple and both were interesting.

Another potential is ‘The Civil Engineering Podcast’ though I haven’t listened to it.

One to avoid is ‘Engineers and Coffee’ as it appears to be about computer programming. I listened to about 10 minutes of one episode before I fully confirmed I had no idea what they were talking about. If you speak binary or java script then you might be able to keep up…

For a slightly wider audience ‘Freakonomics’ is an interesting podcast. It explores a wide range of interesting topics with a critical eye. If others have relevant ideas, add them to the comments.

Up the creek, without a paddle

So, whoever said demolition would be easy, obviously has not visited this site. The newest problem that we have faced involves a nearby hotel (a key stakeholder in the development), a blocked foul drainage pipe and an excavation full of yesterdays dinner!

Last week there was a distinct smell of faeces in a nearby pedestrian street. The PM mentioned this to the Construction Manager and asked him to investigate. The next day, said CM was moved to a new job (polite way of sacking someone in the civilian industry). Therefore the investigation never happened.

Yesterday morning the hotel manager contacted us through the liaison manager for the project to inform us of a drain that was backing up just outside of the hotels loading bay. The hotel is located uphill from the demolition site and the previously mentioned pedestrian street (a pedestrian street that was created as a temporary diversion at the start of this demolition).

The hotel loading bay – In the background the drainage SC

Carillion, being the forward leaning, considerate constructors that they are, offered to investigate. This consisted of a drainage sub-contractor opening a drain cover on the pedestrian street and saying “Oh yeah, that’s full of Sh*t”. They had already identified the bottom of the private drainage run, that was clear, so the problem lay somewhere in between the two. They are coming back this morning to try to jet the blockage and get the flow moving.

Three tanker loads have been removed from the drain to buy some time.

First tanker from Burntwood SC

The cause of the blockage is yet to be established, although we think it was probably the SC who installed the pedestrian street and potentially damaged some of the pipes or left debris inside. However, previous drainage reports from prior to the street being installed, all mention debris in the system.

Votes on causes please:

- Debris from street construction.

- The hotel has eventually blocked it with their own fat/waste from kitchens and toilet paper from rooms.

- The flow has reduced to a level below that required to keep the drains clear. The hotel is the top of the run and it’s occupancy has dropped since demolition started, the office block that also connects to the drain is now unoccupied.

- Other.

In other news:

Laura is pregnant again – due mid November.

I have built a huge deck in my Garden – due May bank holiday!

Don’t mention Heathrow!

Ever wondered where your bags go after you drop them off at flight check in? Probably not, however below the glamour of the airport departure lounges, there exist dungeons otherwise known as ‘baggage halls’ where kilometres of conveyors and machines screen and sort your bags to their appropriate flights.

Having spent the past two weeks immersed in the baggage halls of Gatwick Airport, I can say with some confidence that I must be the RSME’s new expert on airport hold baggage systems (unless Jim can still remember from his time here?). This blog very briefly introduces the Programme and my role.

The Programme

Every bag that is loaded into an aeroplane’s hold must be scanned for suspicious substances prior to loading. To meet the latest EU regulations, Gatwick must (barring any Brexit effects) upgrade all 30 of their screening machines prior to 2018 at about £1m a piece. Unfortunately it is not a simple case of swapping the newer ones in for the older ones. Due to increased power and cooling demands, as well as severely restricted access to the machines, a programme of enabling and upgrade works to all the current baggage handling systems is required. The budget of the Programme is £139m and it is split into 9 different projects, all to be delivered with no interruption to daily baggage operations.

Pilot project – 6 tonne Explosive Detection System being lifted into position for trialing.

My role:

As the Mechanical, Electrical and Plumbing Building Services ‘specialist’ within the Programme team, I will support all of the nine Projects by managing a) the MEP designers during design stages and b) managing the MEP sub-contractors during construction stages. Work on the first of the nine projects is due to start in July so I’ll be concentrating on design reviews and contractual work up to then.

![]()

Typical baggage hall conveyor – these bags are in ‘quarantine’ – they have gone through the explosives scanner but await decision if they are safe or not.

Typical sorter – once scanned, bags are individually loaded onto trays that then flip your bag into the bin designated for your flight. All governed by barcode readers and PLCs.

In terms of experience so far, I found that the principle designer has fudged their concept lux lighting level calc’s worse than a Phase 1 PET student, and that Heathrow is referred to only as ‘the other place’.

A genuine offer; if anyone is flying from Gatwick over the next year, please do give me a shout and I can go into more detail over a departure lounge coffee!

CPT GREAT BRITAIN (or so my email address says)

Right, my first foray into the ‘blogosphere’! I understand I’ve been a little ‘under the radar’ so far, but fear not! It isn’t that I haven’t been reporting on all the exciting Engineering that I’ve been doing, more that to date there hasn’t been much exciting Engineering to be reporting on! However, last week I was finally granted access to site, and later this week the final part of the enormous and unwieldy security clearance ‘jig-saw puzzle’ which began in November last year should finally fall into place! It makes me feel slightly better when I hear that senior level civilian and military personnel from my office have been waiting for over a year for this honour, still with no end in sight! So in some sense (particularly with regards to any US Federal organization [sic]) I’m actually still well ahead of the game! So where will I be working, and what have I been doing so far:

East Campus

The overall program on which I’ll be working is called ‘East Campus’ and it’s essentially the re-development of the Ft Meade golf course into a super-duper all-singing all-dancing state of the art complex for a ‘high security’ client. Currently the level of ‘agreed’ government investment stands at something near $1.4bn! This is clearly a lot of money even for the US, and especially a Democratic government (we’re standing by for the blank cheque in November if Mr Trump continues to do well), so it hasn’t all been coughed up at once. Congress finds it much easier to write these cheques if they’re asked for in smaller bite-sized chunks over a period of many years. The afore mentioned $1.4bn is only what has so far been approved, and should take the programme out in construction terms to round about 2021. However there are four more phases yet to be put before Congress that would take the build out towards the end of the 2020’s and cost who knows what. As it was put to me, “It just depends on the demand and political circumstance”. The obvious down side to this ‘bit-part’ approach is that each ‘bit’ of secured funding equates to a completely separate project which is being constructed on a shared site. There are currently four projects being constructed simultaneously on the one site. All have different contracts, designers, contractors, funding arrangements and timelines, and as if that weren’t mad enough, some of the projects even tie-in structurally to each other! It should be quite chaotic, particularly as all parties share the same site access; however someone had a cunning plan which involves not enforcing any sort of traffic management plan and only vaguely checking who moves to and from site, which has alleviated some of the congestion. More on this in following weeks I’m sure.

My Responsibilities

So what am I going to be doing? My role and site experience will be quite different to that of everyone else. Instead of working for a contractor during this phase I’m going to be working for USACE (United States Army Corps of Engineers), which aside from wearing green kit all day means that as a team we are responsible for overseeing the contractor and acting as the client’s representative on site. It is worth pointing out at this stage that USACE is completely different to the Royal Engineers. Whilst there is an ‘Engineer Regiment’ as we might recognise one (mobility, counter-mobility, survivability etc etc), USACE takes a far more active role in civilian projects than the RE and have some quite staggering capabilities. For example USACE provide and manage something like 25% of the American hydro-electric capability (nationwide)! In my office of perhaps 50 personnel there are maybe four military personnel, the rest are Engineers or other specialists all working for USACE.

I’ve not been in the office long enough to really nail down exactly what my responsibilities will be. There is certainly a huge amount going on here and the potential is huge. However after reading a number of the other blogs I’m a little concerned about how much ‘crunchy’ engineering there is to do here. The project I’ve been put on is something like 65% complete already, and much of the remaining work for us appears to be in checking and verifying what is already being built and making sure that the contractor doesn’t take too many liberties! I’ve also been given a few rather menial paper-pushing tasks. However, I’m still battling to understand exactly how everything around here works and fits together, so my plan is to work hard, try and create a name for myself (in a good way) which means I’ll be able to grab the opportunities when they do arrive. Two of the other projects on site are just coming out of the ground and I know there is scope to move around if I need to gain experience in a particular area so I may well get to do some mud-licking yet (John the soil here is most definitely ‘yellow sand’, or maybe ‘well-graded yellow sand’). The real positive is that everyone seems really friendly, approachable and genuinely very happy to have an exchange Officer with them. Everyone in the hierarchy here has expressed the importance of me achieving my objectives, so they understand my situation and it’s up to me to make it all happen.

Other News

I have an American driving licence, or more accurately a Maryland driving licence (it’s done on a State by State basis). To achieve this I had to do a three hour drink and drug awareness course (so I now know where to find drink and drugs in Baltimore), then drive round in a circle for 15 minutes making sure I went through all the appropriate red lights. I’m the proud owner of a Golf GTI (sorry McClure, but the GTI is the smallest car you can legally buy in the USA, fact). It recently passed its bi-yearly emissions test, presumably because it has emissions, and also because it’s a VW. Apparently there’s a certain amount of pollution a vehicle has to produce which is written into the Constitution.

I’ve been asked if I’m Australian a worrying number of times, but after that the accent seems to do wonders. I’m constantly thanked for my service, but then neglect to tell people my only ‘tour’ was in flip-flops and polo shirt in Cyprus!

When dealing with Federal or State agencies, if the computer says no, the computer really says no and nothing will change it. I was recently asked for my UK address. Unfortunately England wasn’t available on the computer, no Great Britain or United Kingdom either, we looked for GB and UK just to check, but neither or these worked so in the end I had to settle for Watford, Germany. But the computer was happy so all was good.

More technical blogs will follow (I promise)……

Talking out of my ASS

So I saw Chris Holtham’s awesome post and decided I should probably put pen to paper (in a digital sense) and bring you up to date with what is happening in the ASS heap that is Hope Street. For those that are seeing my entry for the first time ASS stands for Acid Sulphate Soil or Sulfate as they spell it locally – apologies for the odd bit of colonial lingo slipping in Neil.

The meeting to end all meetings.

We were 25 days behind schedule thanks to the worlds biggest props on site and the decision to weld rather than bolt them together. The safety manager had been fired and the contracts manager had quit from stress. The Project Engineer was no longer speaking to the subbie PM and I was placed in charge of the excavation and ground anchors.

I held a trades risk workshop for the ground anchors and rather than focussing on the risk, my Project Engineer and Site Manager ended up having a spectacular fight with the subbies over the lack of a plan. To sum it up never in the history of construction has the ‘C bomb’ been dropped so much, by so few.

Never forget it is always about people and relationships.

Since then I have fought hard to form a working relationship with the subbies. I have had actively manage the senior management within BM, who take micro-management to Lego Movie proportions (if you have kids or nephews you will understand). The passage of information around the project is appalling and as a consequence I have instigated a regular daily conference with subbies and then briefed the senior management because they can’t be in the same room together.

As the project has gradually come back on track, relations have gradually thawed. I spent today detailing a kind of visual programme/ cartoon method statement for how the job will get down to the foundation level. If all goes well I will have made back the 25 days and will be back on programme. I will handover to the other site engineer, who is not an engineer, but is in charge of the structural part of the construction while I apparently need to do the services – he is the same genius who worked on the struts and walers. How’s that for outside the box thinking?

So What?

Here is the rub. While the last 6 months in Chatham, have given me the confidence and skills to call people out on talking engineering rubbish (and I have). The majority of what I have done in the last two months could be done by any army officer. The ability to talk to people like a normal human being, to state your case in a logical yet firm manner are key transferable skills that the civilian world needs. The civilian world has the perception that soldiers act in a way reminiscent of full metal jacket. I think they could learn a lot from us. Communication is key to any undertaking, taking a robust position does not necessarily mean having a blazing row. Firm, respectful and logical beats idiotic rants any day (although this article may seem like one).

Other stuff that has happened. That I will write about soon.

- The braces of the loading platform buckled (my structural site ‘engineer’ colleagues responsibility) – TMR gold apparently.

- How to build foundations straight onto rock.

Crossrail Tunnel Ventilation Team

My feet are now well beneath the desk and am getting stuck in with my attachment within the Alstom, TSO and Costain joint venture (ATCjv) working on the Crossrail tunnel M&E fit-out contract (contract number 610, shortened to C610). The aim of this blog is to briefly outline the role of my team and my tasks over the Phase 2 placement.

Figure 1. Another day in the office, looking East from Canary Wharf – the only station remotely on schedule. Note the absence of any building services!

C610 Team

The team consists of around 80 engineers, supply chain personnel and construction managers. The C610 contract and associated track power contracts total a third of the entire Crossrail budget (in the region of £350M over six years). In contrast to the other discrete station sites the C610 contract deals with the entire tunnel system (all 22 km) and needs to interface and deconflict with 14 separate stations and ventilation shafts; each with their own principle contractor. Standby for future blogs and TMRs regarding PC interface issues….

The C610 elements include:

– Tunnel ventilation.

– Tunnel drainage.

– Tunnel overhead lines.

– Tunnel fire and LV power installations.

– Temporary works during construction (e.g. temporary tunnel ventilation, construction power)

Paddington Station

I am part of the permanent tunnel ventilation team and have been designated the lead engineer responsible for the construction planning and installation of the equipment for Paddington station. I feel well prepared for this task as I once managed the build of a toilet block in Kenya. All tunnel ventilation systems are embedded within the station designs; requiring the M&E works to take place within another Prime Contractor’s’ jurisdiction.

The Paddington installation includes:

– 6 x 250 kW axial forced ventilation fans (each fan weighing 8.8 tonnes).

– Associated power-operated dampers, attenuators, transitions and ductwork.

– Variable speed drives, control system and SCADA interface.

– 11kV power supply.

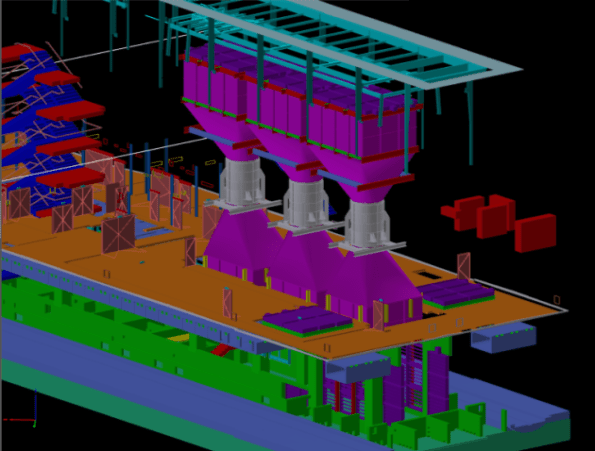

Figure 2. CAD Image of Paddington station with station box cut away. The fans are shown as silver cylinders with ducting transitions and dampers shown in purple; the blue stairwell at the left of the image gives a sense of scale.

The role will include managing suppliers, the site owners/prime contractors and installation sub-contractors as well as planning the logistics of the task in a congested London site. As construction actually starts at Paddington in Nov this year I will also be on-site working as part of a team of three engineers managing the installation of the identical ventilation equipment at Tottenham Court Road and Bond Street stations. Surprisingly I am the oldest member of the team at the tender age of 30! This work started last week, and will allow me to ‘tick-off’ a few more of the CEng competencies in the near future, as well as identifying all of the problems for ‘my’ station late in the year.

Figure 3. Fan halls waiting to be filled with shiny new M&E equipment; photo taken at ground level -3 floors. Not the tidiest site I have ever seen.

Otherwise, the attachment has started with a swift pace and no shortage of work to get my teeth into. Also, one of my team happens to be an Aussie – I welcome any cultural advice from my colleagues in the Southern hemisphere.

Regards,

Mark

Modules Anyone?

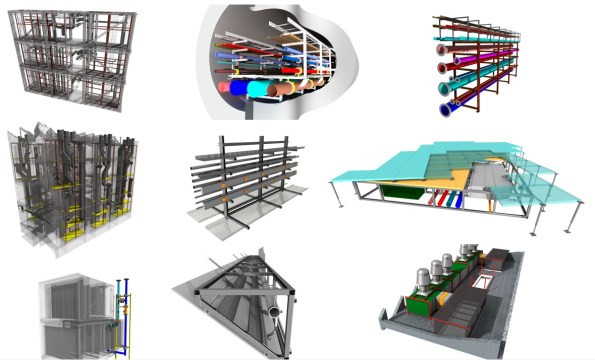

The project I am working on is making extensive use of pre-fabricated modules and so I thought it might be of interest to the other E&Ms. Here is a diagram showing the major module units that have been designed for the two buildings and tunnel being constructed as part of the project.

Figure 1 – BIM Model of 9 of the module units

Description

Top Left – Energy Centre Rises that connect to the tunnel modules

Top Centre – Tunnel Modules (3.5m Wide, 6m long and coupled together with a centre walkway)

Top Right – R&D Building Services Ring

Middle Left – R&D Risers (3 risers in total)

Middle Centre – Lab spine (medical gases, domestic services and 3 phase-busbars that can be tapped off anywhere in the labs)

Middle Right – Underfloor modules

Bottom Left – Cooling/heating Coils.

Bottom Centre – Sprinkler modules (600 of them concealed in the saw-tooth roof of the R&D centre)

Bottom Right – AHUs

Lab Spines

Of these modules, I think the lab spine modules may be of particular interest to the military engineer as recent operations have proven the necessity of rapidly deployable and easy to construct medical services. These modules would support this requirement very well and could provide a variety of services from medical gases and domestic services to power and data distribution.

Figure 2 – Showing the variety of medical services included

In order to install this spine system, each module is elevated and suspended from the ceiling and then the modules are braised together which also means that the level of craftsmanship required for installation is very low.

Figure 3 – The Lab Spine layout showing the tap-offs and outlets

This system is incredibly versatile and acts as a universal busbar where a tap-off can be placed anyway along the spine and the user can draw off 3-phase power, hot water, cold water, medical gases and compressed air.

Figure 4 – View of the medical gas outlets

In addition to providing services, the spine also acts as an open air cable tray, providing a tidy solution for internal wiring and data cabling.

Figure 5 – Electrical services are located at the rear with a busbar at the bottom and cable trays above

These modules are not due to be installed until April next year and so sadly I will not be involved in their installation and commissioning but I hope to be involved in the tendering and final specification as part of my phase two attachment.