Archive

Train Spotting

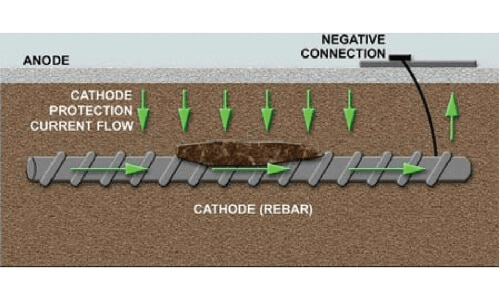

Now that I am officially into trains, or at least have been involved in metro, heavy rail and light rail projects, I wanted to write a quick blog about stray currents. Any current that leaks from the rails and conducts through any path, other than the dedicated return path, is known as stray traction current. As can be seen below stray current moves through the ground, ground water and potentially through surrounding structures.

Why this is important for civils, mech and elec? Corrosion. Whether you are designing and constructing the tunnels for the track to run through, station services and signalling, substations which power the rail and surrounding utilities protection against stray current will need to be factored into your design. Remember the school science experiment with a battery and beaker of electrolyte? Build a rail system and you have one big experiment, only now the corrosion will disintegrate your utilities pipe or the steel reinforcement in your concrete rather than the little piece of metal in the lab.

An electrolysis desktop study is used to identify the measures that should be taken to ensure stray traction current does not present a corrosion hazard to a proposed development. There are 4 key protection measures;

- The installation of heavy plastic membrane under (or behind) all reinforced concrete slabs, metallic platforms/gratings, piers/piles and metallic posts/bollards to electrically isolate from soil and the stray currents.

- Any steel reinforced piers/piles and metallic posts/bollards to be concrete grout encased.

- The use of plastic, rather than metallic, in-ground pipework where possible. In the event buried metallic pipework and/or cables are installed within the site, installation within sealed non-metallic conduit is recommended.

- The use of minimum 32MPa, high cover (min 50mm) concrete to limit moisture penetration to the embedded steel.

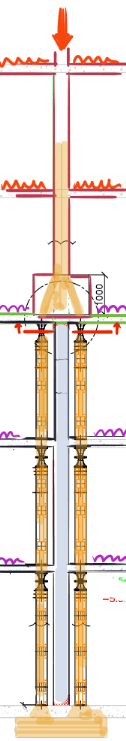

Infrastructure has a 100 year design life, beyond that of the measures listed above therefore cathodic protection is installed. Reinforcement bars are welded together to generate a loop through the structure. Generally two loops are created (redundancy) and tested for continuity prior to concrete being poured (site engineers ITP quality checks). An electrolysis point is installed at the surface of the concrete and a sacrificial anode can be attached.

Anyhow a little insight into stray currents and corrosion protection. I had never heard of this prior to arriving on site. Has anyone else had any experience?

Living a double life: Lessons from parallel careers in civil and military engineering

Upcoming ICE Webinar: Wed 19 May 2021 (1730-1900BST)

Link to book: Living a double life

If available please support a friend of mine, Captain James Glass, in his upcoming ICE Webinar where he will be discussing his experiences working as a Civil Engineer in the Oil & Gas industry and as a reserve in the Royal Engineers. Amongst other things, James was deployed on TRENTON 7 (South Sudan) as the Garrison Engineer and will be discussing the Bentiu quarry which he recommended the UN close due to significant risk to life. This segment of the webinar will include an overview of his quarry assessment and the remedial works completed to date.

ICE Event Summary:

Join ICE East Midlands Nottingham, Leicester, and Derby (NLD) Branch for a presentation from Captain James Glass of the Corps of Royal Engineers as he identifies from his own experience how the disciplines in civilian and military engineering differ in the 21st Century.

From a Civil Engineer in the Oil & Gas industry to an Army Reserve Officer within the 65 Works Group Royal Engineers, Captain James Glass has led engineering design and delivery teams on operations in Afghanistan, Iraq and South Sudan providing critical engineering support to Defence in the UK and overseas operations.

Captain Glass will draw on case studies from these projects, the challenges faced and the lessons that can be shared between engineering fields as he reflects on six years of his civilian and military engineering career and experience.

The Construction Playbook

Further to Jordan’s post. Another piece of signposting for essential industry reading. In December the UK Govt launched the Construction Playbook in order to help make sure Govt civil engineering projects, particularly infrastructure, are delivered in a more sustainable way and on time.

Government Guidance on sourcing and contracting public works projects and programmes.

Ten min intro video here: The Plan To Change Construction – YouTube

The United Nations Sustainable Development Goals – Essential for CPR

Yesterday I attended a briefing delivered by colleagues of mine at WHP who have very recently sat and passed their Chartered Professional Review (CPR) with the ICE. Lots of advice was given but I thought one piece that stood out as a quick win was with regards to attribute 7 (sustainable development). Several of my colleagues explained that they were asked about sustainable elements of their projects with direct reference to how they aligned with the 17 UN sustainable development goals.

I have included an infographic below which lists the goals and I’ve also attached the UN 2030 Agenda for Sustainable Development which adds a bit more meat to the list in the image. Richard has mentioned these to me a couple of times too so in preparation for the ICE CPR it’s probably worth learning them (if anyone can think of a 17 character CDRILS equivalent to remember them please let me know!).

The link to the UN 2030 Agenda for Sustainable Development report is below:

Bridge collapse New Delhi

Looks like a bridge collapsed in New Delhi over the weekend, no details on how or why it happened yet. I’m sure the details will be published in time but it is a reminder for those of us working in design offices that things like this happen. From the limited photos it isn’t clear if the failure was in the ground or with the temporary works.

Unforeseen consequences

This blog post summarises the unintended consequence of an energy optimisation measure and explains the chosen method to solve the issue.

Pool water recirculation pumps make up about 50% of the pools electrical energy demand, interrogating a pools recirculation rate can reveal unecessarily high turnover rates set during commissioning. Through the use of inverters (or the use of electronically commutated variable speed motors) it is possible reduce the frequency and speed of the pump allowing reductions in the power drawn thus enabling energy savings.

However, as was the case with the pool in question, a reduction in the recirculation rate affected the pool makeupwater control strategy i.e the pool water level dropped below its setpoint. Due to spatial restrictions this pools balancing tank is set lower than the height of the pool and a separate makeupwater tank could not be installed. Usually a makeupwater tank is separate to the balancing tank and is set at the level of the pool water. This balancing tank has been used for two purposes, the first to allow for ‘spill’ whereby swimmers enter the pool and increase the height of the swimming pool water and the second to allow for makeupwater injection.

The flow diagram below explains sequentially the consequences of reducing the pool recirculation rate to realise energy savings.

The chosen solution has been to seal the balancing tank and install an automatic air vent thus creating a closed loop system. There is an existing ‘siphon’ pipe (seen below) connected to the pool which shows the true level of the pool water, therefore a new float level switch is to be installed in this siphon pipe that will control the injection of makeupwater into the balancing tank via the solenoid valve based on the actual pool water level.

As far as allowing for ‘spill’ from swimmers goes (the function of the balancing tank), it was calculated that even if 12 120kg swimmers (Maximum pool occupancy is 4) entered the pool the water level would only raise by 14mm, this is well below the limits of both the siphon pipe and the pools perimeter construction.

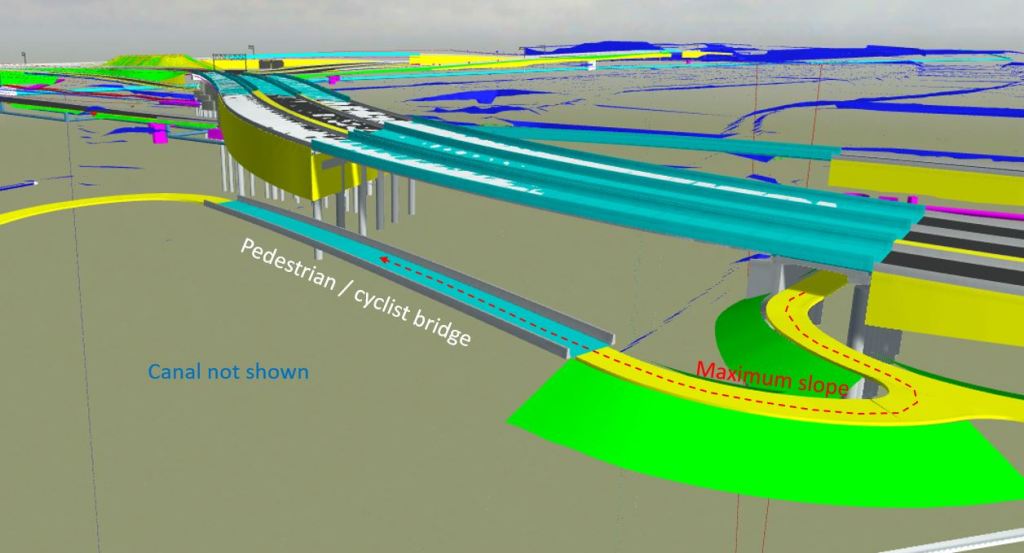

Ex BRIDGE reshow

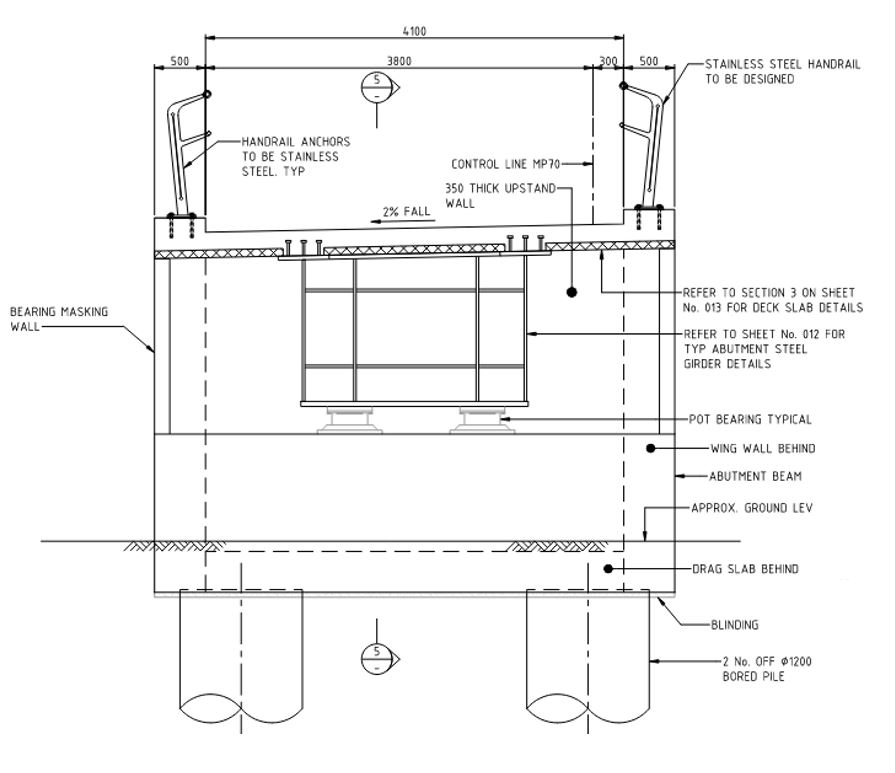

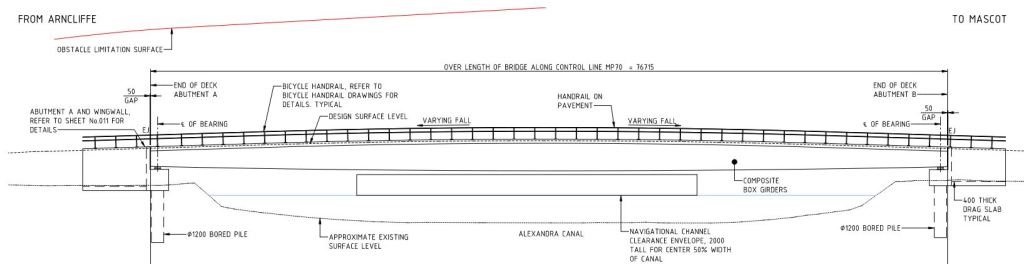

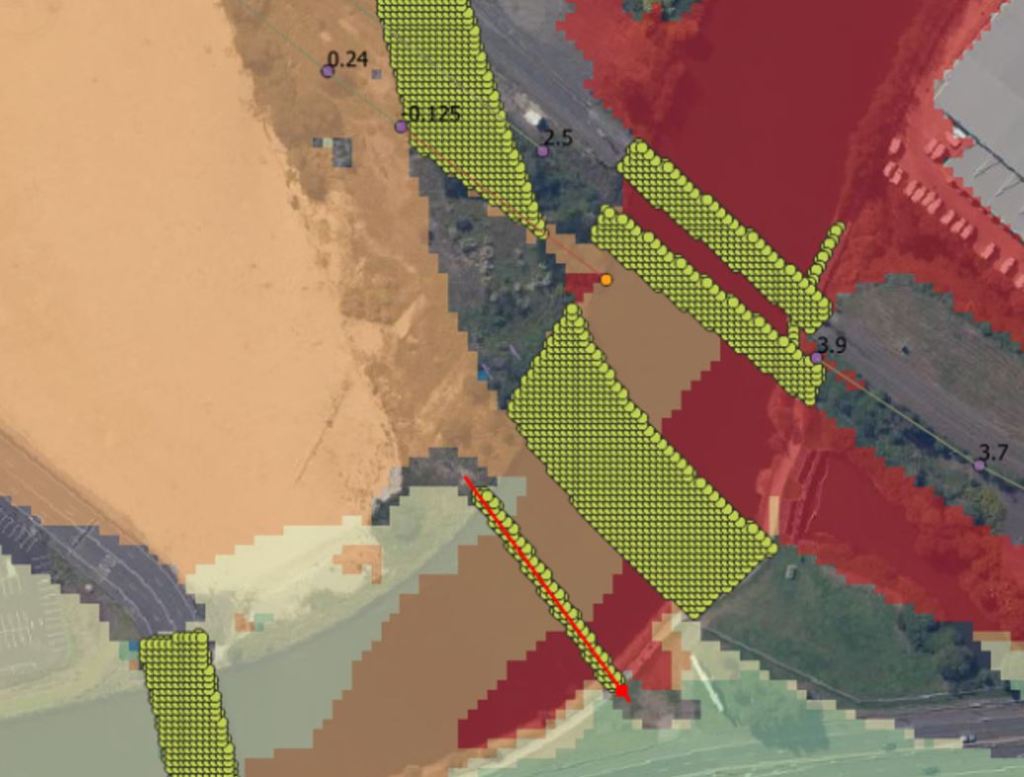

For my Phase 3 attachment I have moved to the Engineering Consultant BG&E and am working on a large road infrastructure project in Sydney. BG&E are designing the 13 bridges for the John Holland Seymour Whyte joint venture and I am leading on the pedestrian and cycle bridge over the canal to the north of the airport.

Spanning 75m it will be a steel concrete composite bridge with varying depth. The design interfaces with a few other design aspects and these have resulted in some very tight restrictions on the structure. Four key ones are:

Deck height

The deck is limited by the slope of the path from the underpass of the planned adjacent bridge to the centre of the bridge and the sight distance over the span. This slope is set to the maximum that is allowed by the disability act in Australia. This limits the max height at the centre of the span.

Bridge soffit

The underside of the bridge is limited by flood modelling. I assumed this would be set at 500 mm above the 1/100-year flood event as is stipulated in the contract. However, there is also a clause that the project cannot increase the predicted level of flooding at a substation 1.5km upstream during the Probable Maximum Flood (PMF).

The PMF is used to define the limit of flood prone land and has an annual exceedance probability of once in every 10,000 to 10,000,000 years. The issue is that the underside of one of the upstream bridges has already been set at the limit that causes an afflux at the substation, this means that the model is now very sensitive to reducing the height of my bridge.

The frustrating bit is that the substation will be flooded by 2 m during the PMF. The contract clause means this can’t increase to 2.01 m. I’m hoping sense prevails and this can be adjusted.

Alignment

This bridge was moved after tender submission and now the alignment is constrained by land ownership boundaries. When combined with the approach path radius it limits the angle at which the bridge crosses the canal. This pushes up the span to 75m.

Piers

Why no piers? This is because the canal is so heavily polluted form years of industrial use. Transport for New South Wales would rather pay for the bridges to span the canal, rather than deal with the risk of disturbing this pollution.

Impact

Because of all these factors the bridge has ended up with a span to depth ratio of 26 and about 130 tonnes of steel which has to be in one lift. My main concern is bridge dynamics as pedestrians are far more sensitive to bridge movements. Guess there could be a blog post in it…

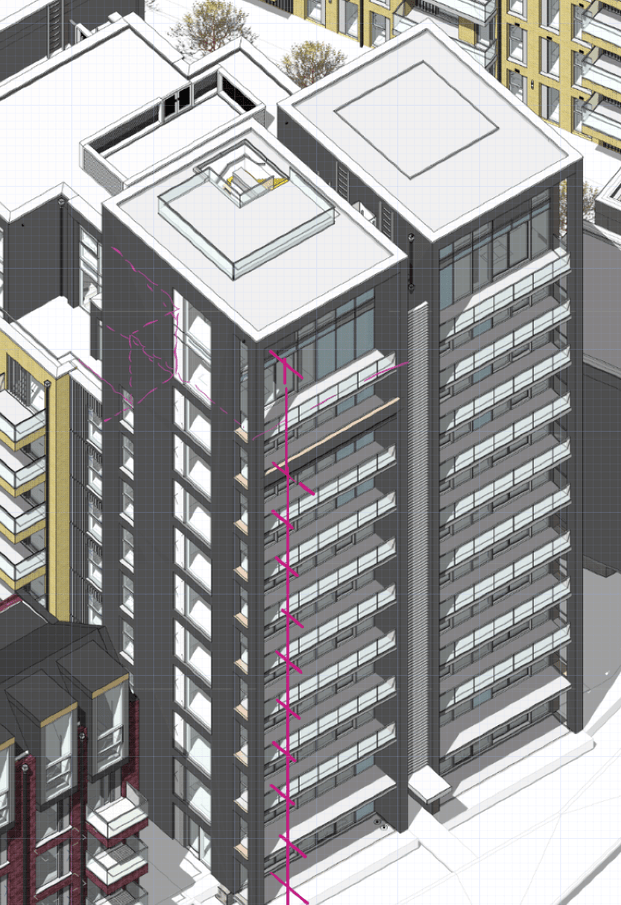

Assessing Plant Loading on Concrete Slabs

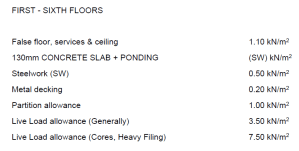

For the last couple of weeks I’ve been working for a Client (Keltbray) who was awarded the work to re-purpose a 7-storey office building at St. Pauls, London. As part of the structure re-purpose, Keltbray are required to conduct a full soft-strip and a partial demolition of certain structural slabs, beams and walls.

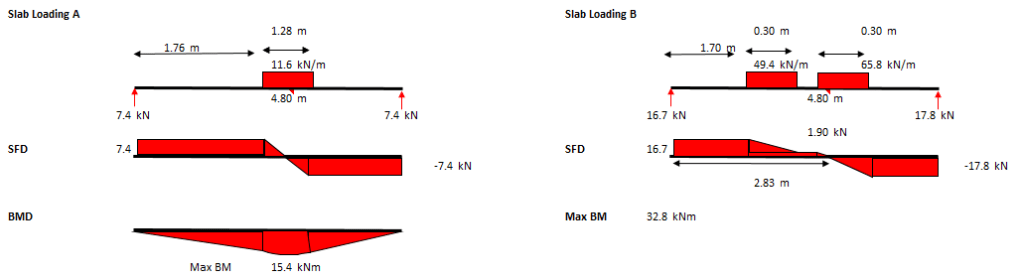

One of the design briefs issued to me was to confirm that the structural slabs on each floor had the capacity to support various plant including a Bobcat T450 compact track loader (see below). The T450 has an operating weight of 2,961kg, a track length of 1.28m and a track width of 0.3m.

In this post i’m going to summarise some of the quirks associated with plant loading and their load cases, and summarise some of the different methods I used to assess an in-situ slab.

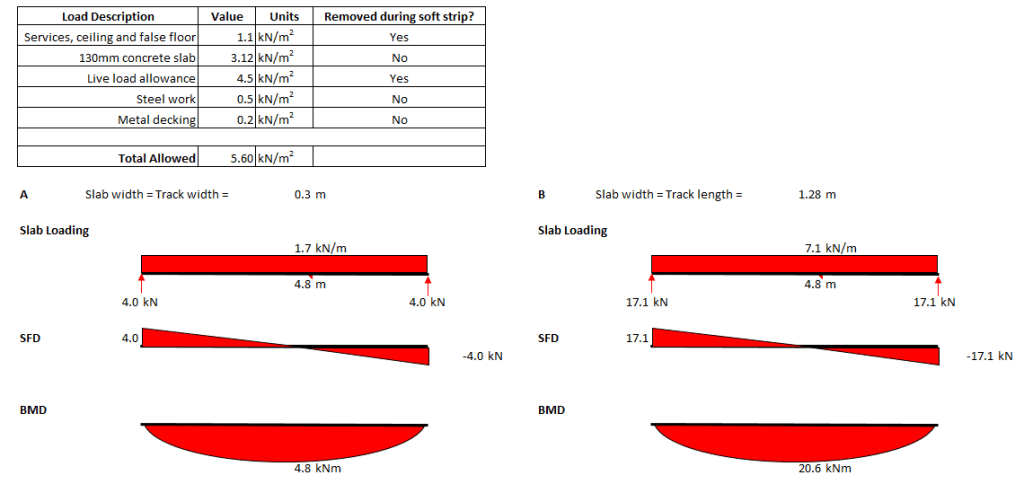

Check 1 – Structure Design Loads

Fortunately the Client was able to provide me with a demolition specification document which defined the working loads for which the structure was designed originally. If these are available, of course the simplest check to do is to see if the pressure exerted by the plant is less than the allowable loads as specified in the design load. In this instance I knew that after the soft-strip all false floors, services, ceilings, partitions and any other variable and quasi-permanent loads would have been removed. This consequently left me with 5.6kN/m2 slab capacity, unfortunately a very crude calculation showed that the load exerted by the plant would result in a pressure of nearly 40kN/m2.

Note – When using this method there is no requirement to factor the plant loads.

Check 2 – Check Max Bending and Shear

If check 1 fails, as it did for me, the next consideration should be that whilst the plant exerts a much greater pressure than the design loads, it is only exerted over a small area, compared to the design loading which could be exerted over the whole slab span. To do this I needed to consider the various loading combinations of the plant.

Step 1 – Establish loading configurations of plant

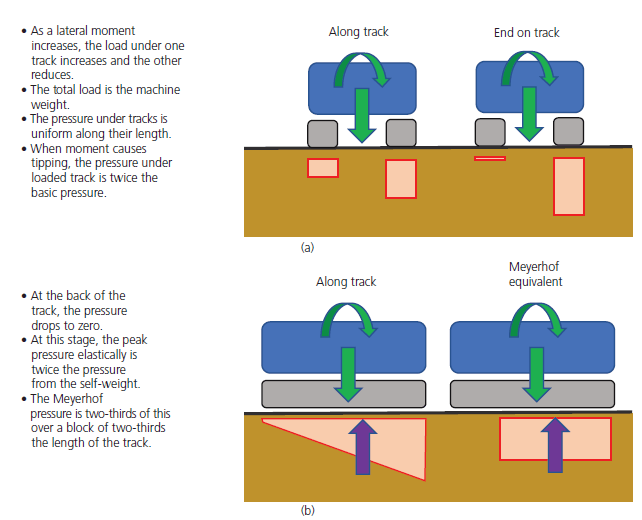

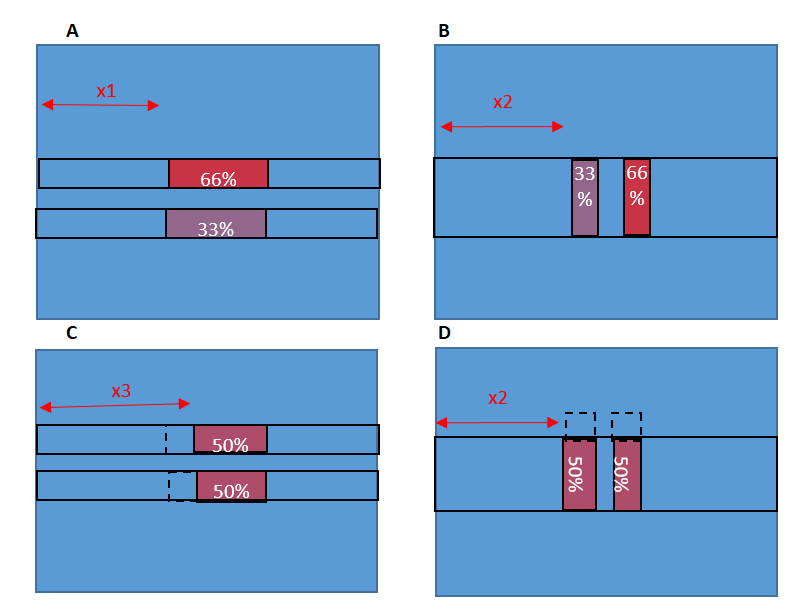

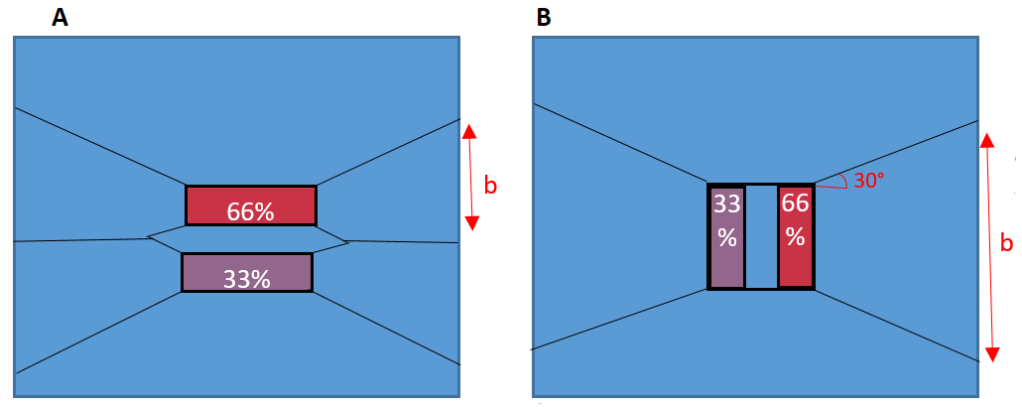

Tim Lohmann, Director at WHP, wrote an article in the ICE Forensic Engineering Journal explaining that the moments experienced by plant (through their typical construction activity) can cause an imbalance of loading. When these moments are perpendicular to the direction of the tracks, it can lead to up to 66% of the load being transferred through a single track. When the moments are in the same axis as the track direction, they can lead to a 33% reduction of effective track bearing area to due to the Meyerhof principles.

These principles are demonstrated in the figure below, for more information the article can be read by clicking ‘download’ below.

Because the slab I was assessing was one-way spanning, I had to consider both cases (a) and (b) above for the plant sat parallel and perpendicular to the slab direction. The four cases considered are in the diagram below. To find the max bending moment, the plant has been modelled at the mid span of the slab.

Step 2 – Calculate max SF and BM due to plant loading

The maximum bending moment and shear should then be calculated for each of the 4 combinations shown above. The SFD and BMD for cases (A) and (B) above are below.

Note – Ensure that the span you select is the maximum slab span anywhere on the floor you are assessing, as this is where the maximum BM will develop.

Note – The loading due to the plant should still not be factored.

Step 3 – Calculate Max SF and BM due to slab design loading

Using the design loads for the slab (5.6kN/m2 as determined from demo spec), the maximum SF and BM that the slab has been designed to withstand can be calculated. Below are the max SF and BM for cases (A) and (B) above. The 5.6kN/m2 pressure has been multiplied by the width of the one-way spanning slab being assessed which is a track width for case (A) and a track length for case (B).

When compared to the max BM due to the plant in step 2, you can see that the SF or BM due to the design loads is significantly less than the SF and BM developed by the plant loading. If, when checked, it is found that these BM and SF are greater than those developed due to the plant, the assessor could safely say that the slab does have capacity for the plant.

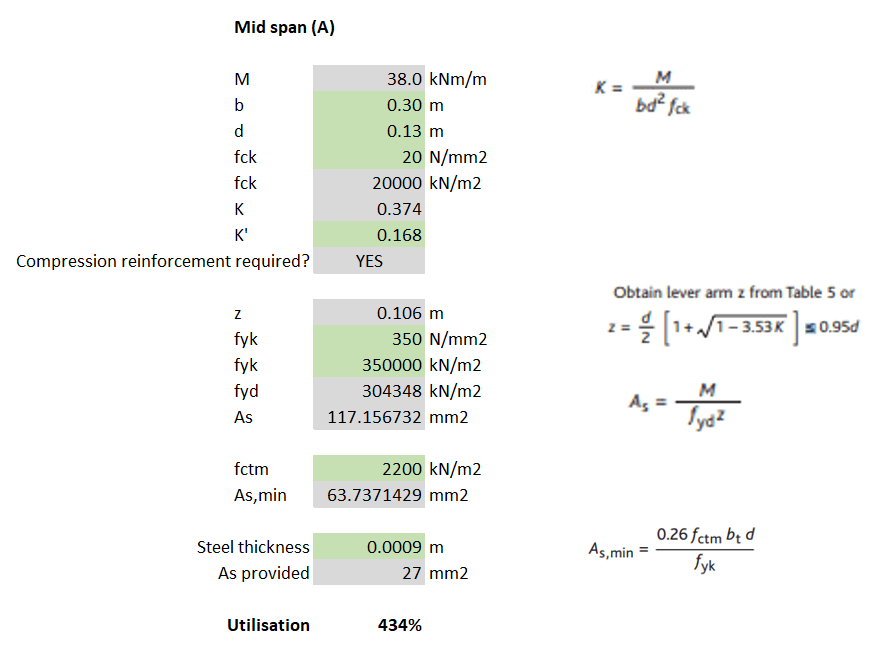

Check 3 – Slab Section Analysis

If check 2 failed then the checker should check the section properties of the slab for capacity against the max SF and BM developed in the slab due to the combination of plant loading, slab self-weight and any other loads that may not be removed during the soft strip. Whilst the plant is positioned at the mid-span, the max BM will be at the mid-span.

Note – For this check the loads should be factored.

For my example, I calculated that for loading case (A) the max BM was 38kNm and then used EC2 to determine the steel reinforcement required. Because the slabs I was analysing were 130mm deep composite (steel deck) slabs, the 0.9mm thickness of the steel deck can be assumed to work as the tensile reinforcement.

Note – The yield stress of steel deck is unlikely to be the same as that for structural rebar (500N/mm2). I found it ranged between 280-350N/mm2 but check the manufacturer’s technical literature. The assessor should also check that the steel deck allows for sufficient bonding with the concrete for it to act compositely (normally achieved with dimples in the steel and shear studs).

A fundamental part of the check requires the slab (section) width to be considered. I noticed that when I considered load cases (A) and (C), where the slab width = track width = 0.3m, the section did not have sufficient bending resistance (failed by 334%) – see calculations below.

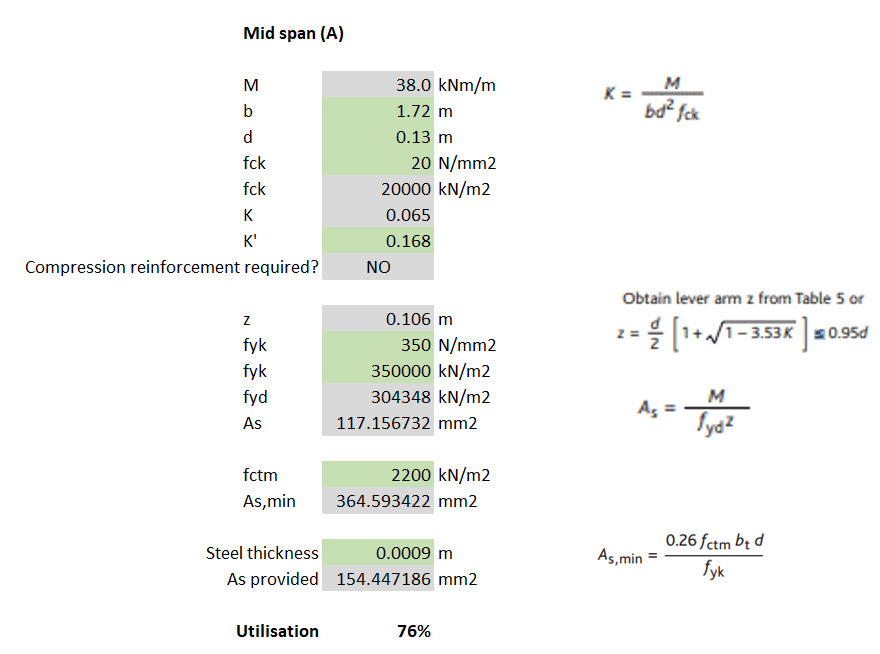

Check 4 – Assume load dissipates at 30 degrees

The assumption I had made from the very beginning was that, because the slab was one-way spanning, it was only the width of slab that was being loaded that could provide any resistance to bending/shear. However, according to BS8110-1, similarly to the way a concrete beam without shear links will normally fail on a plane inclined at an angle of about 30° to the horizontal, it can also be assumed that even a one-way spanning slab will utilise the strength of the surrounding slab, at an angle of 30 degrees.

Using the principle described above, a new b (slab width) can be determined which can be inputted into the same section analysis conducted in Check 3. For load case (A), I calculated that at the slab support, the slab width was now 1.72m. This new slab width allowed me to calculate that the slab did have sufficient tensile steel.

Note – The issue with utilising this 30 degree spread is that the same checks should be conducted with the plant moved from mid-span to close to the supports. As the plant is placed closer to the support, the max BM will reduce but so will the effective width of the slab (due to the 30 degree spread).

Additional checks required

- Whilst max bending occurs whilst the plant is at the mid-span, max SF occurs when the plant is closest to the slab support, this should be modelled to check shear capacity and punching shear.

- If check 4 (the 30 degree spread) is conducted, checks should be conducted for all 4 load combinations with both the plant at mid-span and close to the supports.

- If the slab is continuous, checks for tensile reinforcement in the top of the slab to deal with hogging should also be conducted.

Summary

When working for a design consultancy, the efficiency with which we carry out these kind of checks is what makes the company the most money. This post demonstrates a hierarchy of checks that can be used, from most basic to more complex until I reached the stage where my check passed. Whilst the labour intensive check 4 gives the highest chance of a check passing, a quick check might show that the simpler checks 1 or 2 might also pass (and take a fraction of the time to complete).

If even check 4 fails then FE analysis may be required. Otherwise it might be time to tell the contractor that they either need to downsize their plant, or back-prop their slabs.

Novel vehicle protection against IEDs

Well over half of the deaths of British troops in Iraq and Afghanistan over the past twenty years were due to improvised explosive devices (IEDs). As these operations progressed, military vehicle designs were adjusted to mitigate this threat, namely in the form of V-shaped hulls and extra armour to re-direct the blast wave and protect the occupants from shrapnel.

Advanced Blast And Ballistic Systems LTD has developed a new approach to IED defence which uses the same principle as that seen in the Explosive Reactive Armour (ERA) used by modern day main battle tanks; namely the use of an equal and opposite reaction (Newton, 1687). This novel system employs rockets to provide a counteractive force during an IED blast, keeping the vehicle stable and thereby reducing injury to those inside. A more thorough explanation can be found in the video below:

RMD Megashors: Failing by over 30%

Project: Fulham Riverside.

Context: RC framed multi storey building. Constructed. Columns needed to be replaced. This required temporary propping. Propping designed by external company consisting of RMD Megashors. The consultancy I’m working for were asked to check the scheme.

Event: We identified that the Megashors were inadequate for the loads. Failing by over 30%. The external temporary works designers had calculated the prop loading correctly, however they used an incorrect prop capacity. The capacities used were taken from an out of date datasheet.

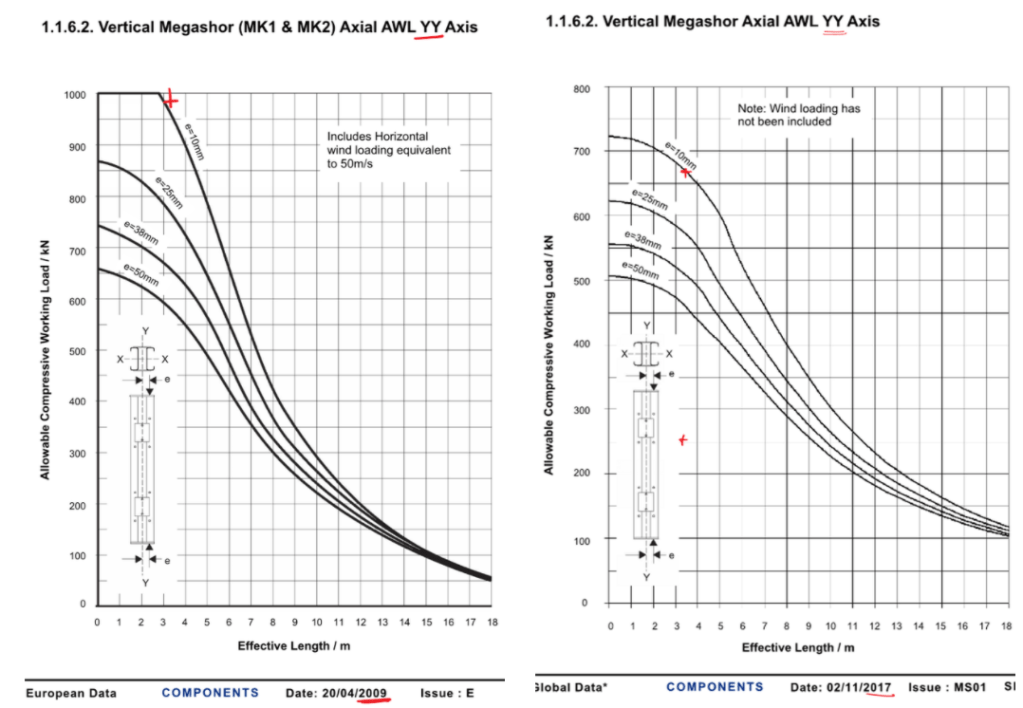

A few years ago, the published capacities of RMD Megashors were significantly reduced. This occurred because one of the manufacturers had used an inferior grade of steel for a period of time. You can see from the diagrams below, taken from the technical literature from 2009 and 2017, that for a 3.5m effective length, the capacity has been downgraded by nearly 250kN!

Interestingly, the external temporary works designer knew about this however he was led to believe by his supplier that the RMD props that were being provided to him were of the higher grade. However, when asked, the supplier was not able to confirm this with documentation.

To compound the issue, when RMD originally published this, they announced that they had no method of identification (e.g. batch number or serial number) on the props, so determining the age of a prop and therefore which grade of steel is near impossible. This is why they took the huge commercial decision to downrate all of their Megashors. I guess it could be easier for a supplier as they would know when they bought their props, rather than RMD who I’d assume have a floating stock that is regularly replenished.

It is also interesting to note that the old spec allows for 50m/s wind as a horizontal load, but the new one doesn’t allow for any.

Lessons Learnt: When using RMD megashors, ensure that you are using the latest technical datasheet. If a supplier says that their grade is of superior grade, then the onus is on them to prove this.

The 2017 Megashore datasheet can be found here so you don’t get caught out although this demonstrates that it’s always worth checking to see if there’s a newer version!