Archive

Oz NDY – Vetwest Animal Hospital.

Introduction

Introduced previously is my current short-term project; designing a fitout for a Vetwest animal hospital. This is my first project as a Project Leader (PL), essentially project managing from start to finish. Before leave I/we submitted a concept design solution for review by our client, the managing contractor, Perth Citi Fitout (PCF) and their client, the building occupier, Vetwest. This blog discusses the on-going project and challenges.

Concept Solution Review

Reading my first client email correspondence, with reference to the concept design, I am already sensing the commercial challenges of the client facing side of design consultancy. PCF are concerned about changes we have made from their initial thoughts, particularly referring to the mechanical design of the air-conditioning (A/C) system. This is because we have included additional equipment which will increase their costs and eat into their profit margin. Without seeing the contract between Vetwest and PCF it’s hard to know if PCF are on a fixed price contract or not. I think they are as indicated by the technical data sheets they supplied us for the air conditioning units, which included a supplier quote of AUD $55k for 3 x Daikin split DX Variable Refrigerant Volume/Variable Refrigerant Flow (VRV/VRF) units.

Our concept design suggested 4 x packaged units costing circa AUD $70 – 100k. This was based on the layout split into four zones and included a dedicated unit for the HEPA filter in the surgery room. Packaged units aid in mitigating operational interruptions for maintenance as they will all be roof mounted. But PCF’s proposed split DX units would mean the indoor unit being located in the ceiling void which would disrupt operational use, including treatment/surgical operations. There are also other benefits of using packaged units but PCF, with confirmation from Vetwest, want to keep the costs down. That’s absolutely their prerogative but our view is split DX units are more suited to domestic buildings rather than commercial.

Although not our contractual duty, we feel we must look out for the interests of Vetwest and provide a design solution to their requirements, especially as they are seeking Australian Veterinary Association (AVA) hospital accreditation. This will indirectly aid PCF because if they fail to deliver the scope of works in accordance with Vetwest’s specification then they will become liable for variation charges.

How to manage this…

In order to tackle this I set about highlighting the benefits, via justification, of our design. Annoyingly, this information had already been submitted, written into a Consultants Advice Note (CAN). But, not wanting to simply reiterate this information, I set about giving the problem its due diligence by providing additional information which I gained from further research. This gave me the opportunity to review our design myself and pick-up on a couple of improvements that could be made. For example, the specific requirements of the Accreditation Scheme for the AVA (ASAVA) referring to the prohibition of any Air Transfer Grilles (ATG) and requiring a dedicated exhaust fan to outside the facility for the isolation room. This also included a dedicated exhaust fan and a motorised volume control damper connected up-stream of the supply air (SA) grille. This ensures the design’s ability to maintain negative pressure and if the exhaust fan should fail the SA damper can be completely closed to avoid positive pressure build-up.

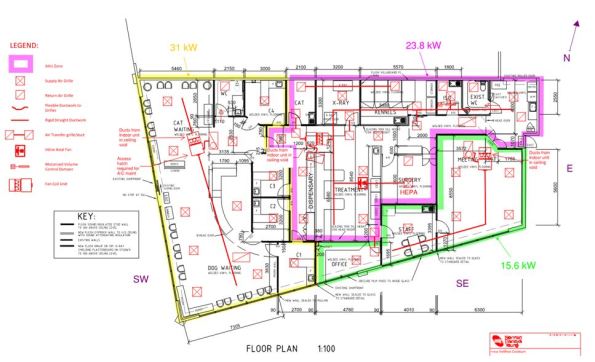

Talking this through with the Project Director (PD) we came up with a compromise and amended the concept design, see figure 1. We reduced the number of A/C units to three, utilising the split DX units PCF proposed to keep costs down, by combining the surgery room with the rooms in the purple zone. The surgery room would therefore require its own SA leg of ductwork and a dedicated inline booster fan to overcome pressure losses from the HEPA filter unit. It would also still require a dedicated exhaust fan as air from the surgery room cannot be returned to the main A/C unit.

Other changes were: combining exhausting air from the cat and kennel rooms, via linked ducting, which reduced the number of exhaust fans by one; reducing rigid ducting and replacing with flexible ducting where possible, but still in accordance with BCA guidelines where maximum lengths of flexi duct must not exceed 6m; and; designing in two options for drainage, one using bucket and floor waste traps, the other a grease trap. This was TBC by Vetwest as to the outcome of their application to Water Corp for a trade waste permit. Ideally this should have been done before so we knew the exact requirements for which we are being asked to design to rather than us having to suggest multiple solutions.

I also drew-up three hydraulic concept designs for: hot and cold water, oxygen and suction, and drainage.

Figure 1. Revised Mech Concept Design.

Next steps

These changes were submitted to PCF and Vetwest for review and I am awaiting their feedback. Vetwest physically gain access to the building on the 1 Feb so is the earliest any on-site works can commence. Therefore, once the concept design has been approved and frozen (hopefully in the next two days) we have said we can complete final detailed design two weeks from then. So hopefully ready by the 1 Feb. In the mean time I am cracking on with software based heat load calculations so I can size the A/C units for the supplier to order in and stay inside lead times.

Heat load calculations

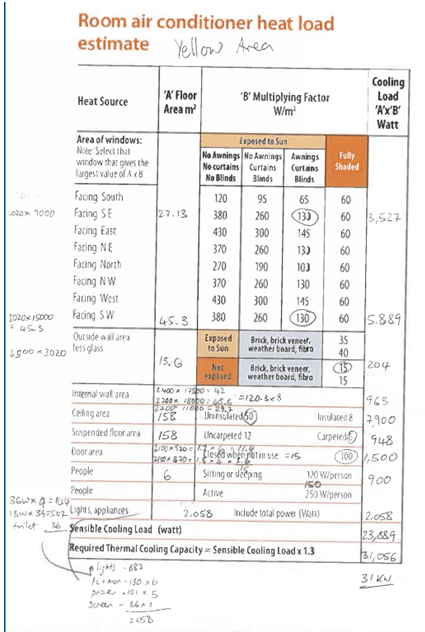

Figure 2 shows an example of my initial estimated heat load calculations – using the Australian Institute of Refrigeration, Air Conditioning and Heating (AIRAH) template.

Figure 2. Estimated Heat Load Calculations for the yellow Zone.

For detailed design NDY currently use a software package called TRACE to calculate heating and cooling loads in order to aid sizing of key plant, such as, A/C units, boilers, etc. It is shortly to be superseded by an advanced programme called CAMEL; I vaguely remember Ben Foster making a pun about it when comparing it to Hevacomp. CAMEL has the added bonus of integrating its building details and input data with another software package called BEAVER. BEAVER is a building energy simulation programme which is used by the majority of building owners/occupiers to estimate: heating, cooling, fan, equipment and lighting energy consumption. However, for this project I will be using TRACE.

What did I learn?

In summary, so far – a lot! It really is just like conducting one of the projects from Phase 1, so in that respect that was perfect training. The only real difference is the standards being Australian – but then they are very similar and searching for them is the same.

Stakeholder engagement is key. We had an initial project meeting before Christmas and followed it up with a site recce. Getting stuck into the detail this past week has highlighted a number of areas that needed clarification. Therefore a number of RFIs, directed at both Vetwest and PCF, were sent, all to aid project management. The good old fashioned telephone being the preferred method, with all communications followed up in writing, be it by email or CAN.

Thames Tideway Epic induction

Thames Tideway Epic induction

I attended the Thames Tideway Induction this week. Even if Carlsberg did health and safety inductions it would not be half as good as this was. It was simply Epic, which actually stands for Employee Project Induction Centre.

The Problem

The Tideway Project approach to Health and Safety is an attempt to re-set precedence where currently major projects (such as Olympics, Cross Rail, Heathrow) tend to have an increase in RIDDOR incidents at the start of a project (as new employees get bedded in) with a peak a few months in, then a decline to a plateau and a rising spike at the end (towards handover). I think this is pretty similar to operational accidents in theatre where there was a learning period which caused injuries, then lessons are learned but by the end there is some complacency resulting in a final spike.

Graph of RIDDOR incidents – representative only and recreated from induction slide – hence magnitude of numbers removed.

Using the accident numbers from previous projects against the number of hours planned to be worked on the Tideway project would mean:

- 2 deaths

- 1500 life changing injuries

- 10,000 lost working hours

Clearly you can’t accept that (or effectively plan to kill 2 people and injury 100s more) and so the whole push from even before starting is to set the standard at high in hope that will result in a better outcome.

The induction

Tideway have rented office space next to MI6 and have created a mock up accident scenario. I’ll be light on the details in case anyone else goes through it but effectively the day starts with you in the site canteen and 2 workers arrive (taking us, the audience, by surprise). They chat about random day to day stuff. They then leave to work on site (audience follows to site). There is then an accident of one of the workers who later dies (scenario, not real). The audience then moves to another room – HSE investigation which is pretty tough for the audience too, then the flat where the employee lived (heavy play on consequences of such an event), then a room split between a site office and a head office to hear background conversations leading up to the event. Back to the canteen (to recover) and start the practical training.

The day is run by a team of actors from the Active Training Team company who role play through the scenario but then are there to re-run the scenario to talk through what the causes were and what actions might have resulted in a different outcome. This is similar to the role play equality and diversity training the Army now do but far more interactive.

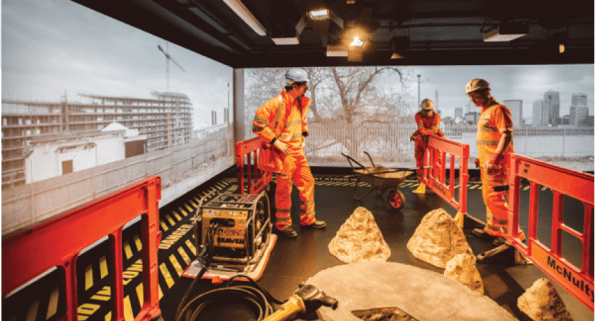

Scene from the induction centre – actors playing very convincing construction workers

The afternoon was filled with behaviour based learning – all practical group discussions which included at some stages going toe to toe with the actors on various other scenarios. The point being to learn techniques and methods for all levels of construction workers to improve their behaviour and mind-set towards health and safety.

Level of Engagement

There was one 15 minute presentation which was delivered by the CEO of Tideway (Andy Mitchell – recently on the front of NCE magazine for different reasons) of a £4bn project so it is clear where his focus is.

Methods

The health and safety approach is pretty impressive, especially if this is to be the standard that every employee (over 5000 expected) over 5 years goes through it. They have got a comprehensive approach covering worker language skills, issuing of the best PPE, lessons learned from Heathrow, Cross rail and the Olympics, 3-monthly stand downs across all sites to discuss H&S issues, and a drive to have the most secure sites with the best welfare facilities.

Will it work?

I think the recognition of the problem and desire and motivation to change history is fantastic. However the difficultly will be in getting everybody to embrace it when budgets are squeezed, timelines are reduced and concrete wagons are ready waiting on site. If the collection of parties play their roles well – designers design safe and buildable structures, contractors allow for safe working methods, invest in employee training and Tideway live up to the standards they are talking about then I see no reason why the injury levels cannot be reduced. I do not believe there is an argument for the irreducible minimum in this instance with money and time, quality (in health and safety) can be achieved.

Summary

It will be interesting to see how it plays out. There are some particularly hazardous working environments: underground, confined spaces, deep excavations and over water. The 3 sets of joint ventures (8 different contractors) will have a far more onerous task of getting people to acknowledge the risks and how to mitigate them. A balance between having to produce paperwork against the level of risk an activity possesses will have to be considered to make sure effort is best placed to achieve the desired effect. Finally, with this significant investment and change (improvement?) in mind-set to health and safety what happens if it does not work – are all major infrastructure projects doomed to kill and maim people. It is clear there is buy-in at the top and this is being pushed from the highest level so hopefully it will succeed.

CCB – Phase 3

I started to transition to phase three very shortly before Christmas leave. I factored in around 6 full days of sitting at the Baltimore City Crescent Building (CCB) split over a two week period to settle. This would allow me time to meet and greet; sort out a desk space, IT and scope out the work. Amazingly it only took around half a day to sort out IT and I had a desk space waiting for me, which I gather is at odds with Henry’s experience. For me transitioning 3-2 has been much easier than 1-2. I started full time at CCB on 4 Jan, however have retained my access cards to site so I can go and get ‘a cheeky shufty’ before departing the States.

The Structures team I am working in now sits in a different Division to the Construction Division where I was previously housed and is physically sited in the Baltimore District headquarters building in downtown Baltimore.

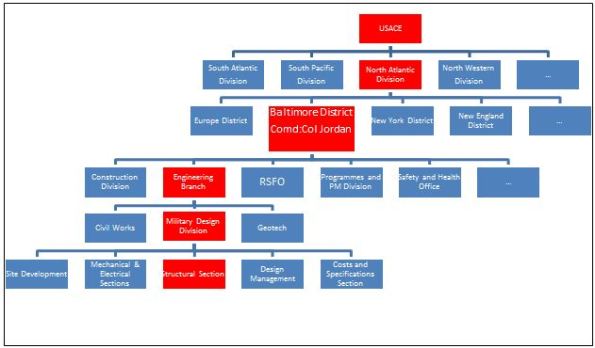

USACE Organisation

The figure above shows the organization, with red signifying where I sit. The Area Office where I was previously working was, like Henry’s, part of the Construction Division. Phase 3 sees me shift to the Military Design Division, which is a part of the Engineering Branch. Rather confusingly for a military organization the term ‘Division’ is no indicator of the position of the department in the hierarchy; Construction Division and Engineering Branch are equivalent departments, Construction Division and Military Design Division are not.

The Engineering Branch is responsible for the procurement, design and overall project management of federal and publicly funded projects. This is different to the Construction Division, who physically executes the works. Civil Works deals with levees and dams; Military Design deals with new construction and refurbishment projects; Geotech deals with geotechnical analysis, design of foundations and soil testing.

First tasks as part of the structures team include gathering an appreciation of the work available, described below, and becoming familiar with the US design codes and their application. Where opportunity and time permits I also hope to take on small portions of work from the geotechnical branch and site development (civils) team. This is fairly usual for the USACE placed students.

Below is the breakdown of what has been proposed so far.

Fort Lee Training Support Facility, Virginia. This is a $33m project which will be procured on a traditional contract with USACE conducting the design. It being undertaken by the Baltimore District, despite the site being situated geographically in the Virginia District. This is because Baltimore District has capacity whereas Virginia District does not.

The training facility requires a largely column free 120,000 sqft footprint in which various military artefacts and exhibits can be housed and moved around, depending on training requirements of the end user. As well as lecture theatres, toilets and workshops, associated with typical training facilities, there is also a requirement for an armoury, which must conform to its own set of construction standards. The training facility project could be defined as a museum, however because this would invoke more stringent, regulations and because it is not open to the public this is not the case. The requirements for humidity control and airflow are however being taken from museum standards in order to ensure the protection of some of the more delicate training aids and artefacts. The requirements for the movement of training aids, some weighing up to 90T also means that the typical reinforced concrete slab on grade (ground slab) has certain strength and ‘finished flatness’ requirements so will be designed more like a pavement, similar to runway design. It can be seen therefore that the design of the training facility allows for some freedom in the selection of which standards apply.

Example Training Aid

Example Training Aids

The project is at 65% review stage, however is recognised as being more like 30 – 40% complete. This is mainly due to issues with the completion of the Site Investigation (SI) and subsequent Geotechnical Design Report. This was sub-contracted out, however issues with the scope meant that the SI required completing twice as insufficient information was gathered first time around. A comprehensive GDR for the project is still forthcoming, however for the purposes of project progress assumptions have been made about the bearing capacity of the soil. This means that a large risk to the project lies in the ground conditions since design is being based on assumptions which have not been fully verified. This has the potential to increase the project costs to the client at the execution phase and highlights the importance of a sound scope for the SI in the first place.

The site itself is a forested marshy area, which has been largely created by surrounding projects, which have drained their sites into the proposed area. It slopes across the length of the project causing an 11’ elevation difference between one end of the training facility and the other. At around 30’ depth there is a thin highly compressible clay layer. This makes the project susceptible to long term continued settlement issues, in particular due to the large surcharge placed on the ground due to fill the fill required to level the site. The current design stipulates that shallow foundations should be adequate, which surprised me on hearing the outline ground conditions.

The requirement for open space means that the proposed steel construction will not be braced. Instead a steel portal frame design is chosen. Spans of up to 60’ mean that both standard and built up girders are insufficient and so a truss system has been chosen to try to maintain ‘a lighter appearance to the members.’ The sizes of the outer faces of the building mean that lateral wind loading and seismic loads are high. This means that the moment connections and details require careful consideration to ensure that lateral loads can suitably be transferred through the trusses into the columns and foundations.

My responsibilities will be to assist the lead structural engineer with verification and detailing requirements. I will also be involved with the shallow foundation design. The 95% design submission is due in June 16.

Building 8607 Renovation, Ft Meade. This is a design build project and so USACE is only required to produce the technical specifications and tender documentation on behalf of the client. Because there are Anti-Terrorism Force Protection considerations (ATFP) it is, however, likely that there will be some more focus paid to conceptual design. This may extend to some initial element sizing and direction as to which ATFP approach is suitable I have been told to get a software license for STAAD Pro to assist with a bit of modelling to test assumptions that go into the specification (so thanks NJP).

The project scope is to turn existing accommodation buildings into administrative space within the existing Ft Meade camp. The tender documentation is required to be complete by mid Jul 16. This is likely to be background work in addition to the main training facility project described previously.

Access Control Point, Ft Meade. This is a $20m project procured on a traditional contract with USACE conducting the design work. The requirement is for a fairly generic access control point to be installed at Ft Meade, consisting of several inspection lanes and indoor areas for security staff. The inspection lanes are simply steel hollow section columns with steel deck canopies spanning across the point of entry. The canopies won’t resist lateral forces and so essentially the steel columns will resist gravity and lateral forces as cantilevers. The indoor areas and inspection lanes also require to provide some element of protection for security staff and so will require design for impact and ATFP.

Other. As stated there may also be scope to grab some civils work from the Site Development team. They deal with horizontal construction such as pavement, storm water drainage etc and could be good for some additional sustainable development exposure as well as exposure to a broader range of engineering. This combined with the different structural projects which are at different stages of design should provide a fairly rounded design experience.

In Other News

Mike O’Callaghan–Pat Tillman Memorial

This…

and this.

Hoover Dam

Friday Night in Harrisburg

All new buildings are required to complete an Air Barrier Test (ABT) and the Defense Logistics Agency (DLA) HQ is no exception. The leakage rate is important because it indicates how much conditioned air is being lost to the outside environment. It costs money and energy to condition the air inside the building and so it is wasteful to allow it to leak out. More specifically, as the client USACE specifies an allowable leakage rate and if the building fails then the issue must be resolved. Given that the leakage rate is determined by the construction method of the building and this building is very much in the stage of finishes being applied there would be no quick fixes if it fails; so it’s important.

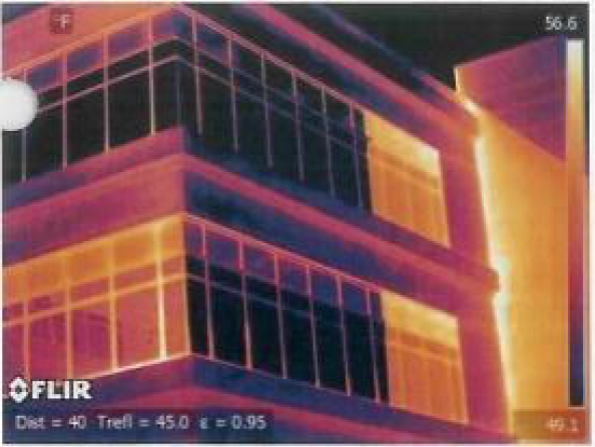

The test was completed on a Friday evening a couple of weeks ago with a provision for a test early on Saturday if required in order to avoid interfering with other trades as the building had to be sealed for the test. Dusk is generally considered the best conditions for testing as the dT between the building and outside is the greatest to be able to detect leak causes using thermal imagery. Sadly, as you will see below this doesn’t necessarily make for the best photographic conditions.

The test consisted of sealing up all ‘intentional’ openings, sealing a number of fans into one of the doorways and pressurising the building. The test was completed twice, first subjecting the building to a negative pressure and second subjecting it to a positive pressure. After a short while to allow the building to reach steady state it (where the pressure is not rising/falling) it could be assumed that the air leaking through the building’s skin was equal to the air the fans were blowing into, or out of, the building. The later was measured through a range of differential pressures to give the leakage rate. Whilst the an operator recorded these measurements for the first test, depressurising the building, the air tester and I walked around the building with the thermal imaging camera, and the less technical back of the hand, to identify any significant leaks. Any cold spots in the building skin or cool air blowing into the building were subject to investigation. For the second, pressurisation test, we walked around the outside to do similar but given the scale of the building this was less effective.

Fan bank 1. A second bank of 3 was put in a nearby doorway to provide sufficient flow rate to achieve steady state.

The system needs to read the same pressure at both fan banks. As the right hand bank has twice the number of fans of the left one it has twice the flow rate.

The standard.

The USACE standard is 0.25 CFM/75 sq ft enclosure, meaning cubic feet per minute per square foot of envelope at 75 Pa differential pressure. This, peculiarly for the USA is a single standard whereas in the UK we have a variety of rates to choose from depending on building usage. The units of measure in the UK are m3/hr50/m2, which is m3 per hour, per m2 of building floor area at 50Pa differential pressure. 2 m3/hr50/m2 is the UK standard for a low energy air conditioned office which is about 0.14 CFM/75 sq ft.

In an office building most of the floor area falls into this however, broadly speaking, unconditioned spaces are exempted; meaning that they have to be sealed off from the main building. Large complex buildings such as skyscrapers or buildings with significant restrictions to airflow, such as a single door separating two halves may be split into zones. The DLA HQ can be treated as one zone as there are large open plan areas and multiple stairwells and lift shafts. The building envelope is usually calculated by the Designer of Record (DOR) but in this case was calculated by the contractor, after a year of asking the DOR. The building is 309,240 sq ft, therefore:

0.25 x 309,240 = 77,310CFM is allowable for this building.

The leakage rate is tested at a differential pressure (between outside and inside) of 75Pa, which compares to 50Pa in the UK.

The practicalities of the test.

The sealing of ‘Intentional’ openings refers to closing all of the doors within the doorframes as well as any HVAC vents, kitchen flues and the waste vents. To ensure optimal pressure equlaisation within the building a few measures had to be taken:

- For every 500 sq ft of suspended ceiling at least 4 sq ft of ceiling tiles must be removed to promote pressure equalisation.

- All internal doors had to be wedged open; fortunately many aren’t fitted yet.

- The doors to the lift shaft had to be wedged open to ensure equalisation to the rooftop mechanical room.

The biggest issue was doors blowing open on the tests destabilising the pressure. The prime contractor had let all of their guys go, for the day, to ensure good running of the test having people, with some form of comms, ready to chase down open doors would have made the whole process a lot simpler. Having plenty of guys on standby would be something I imagine the RE would have got right!

Six of the nine fans used drew a maximum of 3kW. Each of the 230V circuits (the building has 110 and 230V circuits) had a 15A breaker meaning that it could only support one of these fans, or two of the smaller 1.5kW fans. This resulted in about 30 minutes of getting out electrical drawings, resetting breakers and moving extension leads around. The master electrician could have planned this prior to the test.

Results.

In the end the building passed with ease however there were still some interesting elements. The biggest loss areas are:

- Doors. Being freely moving there is always going to be a level of leakage through these. If the building had failed by a small amount then upgrading the seals would have been a way of marginally improving performance.

- Although none of the windows open, as they are penetrations into the buildings skin they act as a potential break and pathway. One window had a good breeze blowing through it that could have been sealed with a bit of mastic if required.

- Sockets and fittings, both internal and external. Again a penetration into the building’s internal skin where air can finally leak through.

- Architectural Interfaces. This would have been the main problem at the DLA HQ. Where differing building methods meet the interface can cause an issue if it is not properly sealed. An example is the auditorium on the DLA HQ which is essentially another building tacked onto the side of the main building. It was built using prefabricated panels, whereas the main building was cast in place. This had been identified as a risk in construction and was mitigated by the liberal application of spray foam.

A doorway. This is taken on the depressurisation test therefore the dark section is showing cold air blowing through the door seal.

The normal picture comparison was black. This shows an architectural interface between a precast structure and a clockwork construction with facade. As this is taken from the outside the bright yellow is showing warm air escaping.

The results came in last week showing that the building had leakages of 0.143 and 0.132 CFM/ft2 for pressurisation and depressurisation respectively. So it passed with ease in the USA, but might have only scraped through the UK equivalent test because of its complex architectural features.

Oz NDY – From One Hospital to Another.

Introduction

I’ve now been in the design office for 2 whole weeks, working in the Interiors/Tenancy Section in the Existing Buildings Department. In summary, we design all mech, elec and hydraulic services for existing building refurbishments, usually office/business fitouts. Overall office work leading up to Christmas has been a little frantic, mainly involving clearing deadlines and getting tenders out for new business for the start of the New Year. I have undertaken a few interim tasks as stated below with my first real project role coming in the form of an animal hospital fitout – kind of apt coming from the PCH project.

Interim Tasks

The following three tasks were given to me as more of a filler and introduction to the types of projects I’ll be getting involved in.

- Fee Proposal Review. A review of NDY’s fee proposal for the replacement of a generator exhaust. The mechanical contractor originally approached by the client were only a small company and felt the proposal was too detailed and consisted of too much management terminology for the simple requirement. There was nothing wrong with the proposal and we deemed it fit for purpose so advised the client to explain this to the contractor. If they still didn’t agree then we advised them to re-tender to a more suitable one; who could see past the management procedures and policies, that I feel they were deeming too complex.

- Giving Technical Advice via a Consultant’s Advice Note (CAN). The CAN was for the reprogramming of the BMS in a recent office fitout we had completed where two separate floors were adjoined by a central stair. The CAN gave a technical explanation for the need to consider both floors as one in terms of smoke management in a fire event when creating the fire and smoke cause and effect matrix.

- Restricted Return Air Path. This consisted of a study of the AHU return air path in a new office fitout where, due to the type of return air system used, being via extract grilles straight in to the ceiling void acting as a large plenum, it was found that obstruction from sections of full-height partition walls were restricting return airflow. We came up with a solution to install a number of transfer grilles through particular sections of the full-height walls. The trade off being potentially increased noise levels for better recirculation.

Short-term Projects

I have just started my first main project, my role being the Project Leader (PL) for the fitout of a new animal hospital. The current space if no more than an empty warehouse serviced by 3 No. Evaporative air-conditioning system linked through flexible ducting (which they seem to love over here). There is also an existing toilet and lighting throughout.

The PL roles sees me being the client facing project manager reporting to a Project Director (PD) who is also doubling-up as the mech technical lead. My boss (also mech biased) has been helping out and accompanied me to my first client meeting and site inspection; he will be on extended leave post Christmas till the end of Jan so has basically helped me get the project rolling.

In terms of detail at this stage our client, Perth Citi Fitout, are the Managing Contractor who have already put together construction force of various subcontractors based on the scope of works from their client, Vetwest. They have Nagel, architects, who have designed the fitout so we have a pretty good idea of what they want. The services are pretty straightforward with the bulk of design work being the mech air-conditioning system.

At present the MC has budgeted for a complete strip-out and new installed system so that’s exactly what we are going to design. We did see if the existing evap units might be useable but decided pretty quickly to replace them. This was mainly based on the poor effectiveness of evaporative cooling in high humidity conditions. Granted that the Perth climate conditions produce mostly dry heat but there are occasional humid spells in the winter months, which realistically would only offer a small delta T due to evaporation becoming more difficult proportional to the water content present in the air.

The MC issued us a concept mech layout but from our meeting and discussions over the number of HEPA filtration units required we went away and conducted our own research. The two main points were, the requirement for a grease trap for the wastewater drainage system and HEPA filtered units to be installed in all locations where animals would be.

Both of these are being investigated and I am awaiting specialist confirmation. My initial thoughts being thus:

Grease Trap. After stakeholder engagement it was identified that the areas where animals (primarily dogs) will be kept for long periods of time, the kennels and cages are fitted with special chemicals that soak up urine and water content in faeces. These are regularly cleaned out and disposed of in specific excrement waste bags so it is my view that normal wastewater drainage will be suitable. Of course the Water Corps may have a different view and I also need to check the Building Code of Australia (BCA) Guidelines.

Multiple HEPA Filters. Again after stakeholder engagement it was found that Vetwest are wishing to apply to the Australian Veterinary Association (AVA) to seek accreditation of their hospital accreditation scheme. The Vetwest proj mgr stated that under the AVA’s standard they required all air-conditioned spaces where animals are present to be HEPA filtered. It was evident in the mtg that they didn’t actually know how this worked as they were talking about mixing normal supply air and HEPA filtered air in the same space – which obviously negates the very clean air provided by the HEPA filters. What we did know was that just like in a human hospital the surgery room needs to be supplied by HEPA filtered air but I don’t think other areas do. To confirm I researched the AVA standards and found nothing relating to HEPA filtration at all so posed the question to one of their standards testers – I’m awaiting a reply.

NDY’s Concept Design

With these answers outstanding I cracked on and came up with a concept mech (air-conditioning) layout. I split the space into four zones and plan on using 4 No. Packaged DX Units (yet to be specified). These DX units will be mounted on the roof (where there’s plenty of space) and consist of ridged ducting for the main run with flexible ducting to each supply air grille. Figure 1 shows the draft concept design. This along with a Consultant’s Advice Note (CAN) explaining our justifications for the system type will be finished off and sent to the MC for comment before Christmas.

Post Leave Continuation

On my return from leave and after consultation with the MC over our concept design I will then begin the detailed design. This will initially consist of using a software package called Trace which gives you heat load calculation so I can then size my packaged units. I’ve had a quick play with it already and it’s very similar to Hevacomp but with more experience I’ll try and draw out some more detailed comparisons. Then I’ll have to size all the ductwork to achieve the correct flow rates etc that will lead to cost planning. At the moment the MC has quoted AUD $55k for 3 No. units and our 4 No. Packaged DX Units is looking around the AUD $70k mark. I will then move on to the hydraulic system, mainly consisting of a reticulated Oxygen supply and Suction system.

Project Reflection

Being part of the Interiors/Tenancy Section means that I will hopefully have a number of short-term design projects to PL on. This will provide me with a good basis for reflection and help steer subsequent projects in order to build on my professional development and focus on any outstanding UK-SPEC requirements.

Figure 1. NDY Concept Mech Layout

This just leaves me to say I won’t be blogging for about 4 weeks as I’m now on Christmas leave…have a Merry Christmas and a Happy New Year!

Why?

This blog aims to give those heading out on phase 2 another reason to keep annoying people by asking ‘why’.

Civil students might remember John Moran talking about the Specification for the concrete on a bridge being built in Australia in 2014 (I think it was Pete Mackintosh?). His joke was that the only thing that would see the bridge was a dingo, and that the aesthetics were irrelevant. I am also with JHG, and may have spotted a dingo of my own.

My thesis is centred on the use of GRP over concrete jacking pipes in medium diameter (1720mm OD) drainage schemes. Amidst the mad panic of downloading and attempting to speed read every document imaginable off the IHS, I stumbled across the Technical Design Guide from the CPSA (Concrete Pipeline Systems Association).

Interestingly, it states that for design purposes, Water UK recommends a Ks (roughness) value of 0.6mm for storm water, and 1.5mm for foul sewers – irrespective of pipe material. The Client’s specification on my project (and the Client is a local water authority) states the internal surface roughness of the sewer pipe must have a Colebrook White Roughness Coefficient of 0.01mm or less. I would understand (sort of) if it was a storm water drainage scheme, but we are constructing a foul sewer. Fortunately, the GRP pipes we are using do comply with the 0.01mm Ks, but why should they?

The sewer system we are building is in a greenfield site – the land will be progressively developed and expects a population growth of 260,000 over the next 25 years. The CPSA notes that when there is a small flow, it is unwise to select too large a pipe ‘to allow for possible development’ as it may lead to settling out of solids, long retention periods, blockages and build-up of septicity. Obviously the 110,000 homes and their 260,000 residents are not going to magically appear when the sewer is completed next year – the demands placed on the sewer will increase gradually. Perhaps the ‘over-specified’ roughness coefficient is the result of clever design for the entire life cycle of the sewer, with greater emphasis placed on the hydraulic performance of the pipes in its early years to ensure that the risk of blockages etc. is mitigated without the need to install a greater number of smaller diameter pipe networks at an increased cost.

My opinion is that the Client is focussed on delivering sustainable solutions through design. Maybe it was not a dingo after all.

Have a good Christmas break.

Forth Road Bridge

Hello all,

You may or may not have heard about the problems associated with the Forth Road Bridge near Edinburgh. I have been passed some info that I though may interest some of you out there….

The images below are from a load test done a couple of weeks ago. Achieved using lots of full gritter lorries with drivers on danger money wearing armbands! Some interesting facts:

- The bridge spans just over a kilometre between the piers. It was the 4thlongest suspension bridge in the world when opened in 1964.

- The piers are 156m tall (about half the height of the Eiffel tower, and about the same as Lomond or NEV from seabed to flare tip)

- The bridge contains 40,000Te of steel

- The maximum tension in the main cables is about 25,000 tonnes at the mid span

- The main cable tensile stress is incredibly high at 1050MPa (N/mm2), which is about the same as a 17 stone man suspended from a 1mm2guitar string (nice image there – sorry)

- Each tower supports 8000Te imparted from the main cables.

The part that failed was an inverted steel ‘goalpost’ that is attached to the bottom of one of the deck hanger cables. It almost certainly suffered fatigue damage, ie too much stress cycling caused by heavy lorries. When it was opened in 1964 it was designed for 25,000 vehicles/day, and the maximum lorry weight was 24Te. Today it sees 70,000 vehicles/day and the maximum lorry weight is 44Te. If the steel component had completely parted, the consequences are debatable. In the worst case it could have caused a section of the road deck between the hangers to tip, possibly causing the combination of 4 or 5 heavy lorries (that would cause such a failure) to crash.

Bedding In – Ph3

I’m in my second week working CH2M (previously known as Halcrow) working for the Ports and Maritime Division and suprisinly…I’m enjoying it!!!

I don’t intend to go into any detail in this blog but rather set the scene and prompt questions should anyone have any.

I have joined the Queen Elizabeth Class (QEC) project which is designing the dock that will birth the new aircraft carriers in Portsmouth. DIO are the client and VolkerStevin are the contractor.

The dock is an existing 19th century sea wall with a 1930s and 1970s series of jetty attached to it. The water depth alongside the jetty is sufficient for the new boats however, the jetty capacity is well below the new requirement.

The key loading on the jetty platform will be :

Vertical – bogie point loads from the mobile cranes. The jetty will also house a new M&E shed that will house all of the ‘wizards boxes’ used to generate the electrical feed required for recharge (these are pretty big and heavy). Finally, the jetty will be expected to support lorries and container stacks all over the place.

Lateral – the boat hitting the dock when it parks (technical term), 100tn.

The plan

– Two large section of the jetty deck will be demolished and rebuilt.

– One strip of the deck will be cut out to allow new piles to be threaded through the existing.

– A number of holes will be cut out to allow new piles to be fed through, many racked to facilitate the lateral loads.

– 2m concrete deep beams will be inserted under the deck across the top of the new piles.

– Pre-cast slabs will fill the holes.

– A new deck will be cast in-situ to thicken the whole deck with a single in-land crossfall.

ICE CPR

Two of my identified weaknesses when moving to Ph3 were technical design/analysis and working with existing structures. I think this project will serve me well!

Remove the reins

My first job has been to conduct a shear check between the existing and the new decks where the mooring bollards are located. The bollard rating is sufficient and the bolting down design has been verified but it was unknown whether the deck would simply rip apart. EN 1992-1 has a section on concrete poured at different times so that became my starting block however, it assumes the shear failure would occur due to bending so attempts to use the lever arm from the bottom steal to the shear plane (it assumes you are looking at a composite beam and slab arrangement). I knew this made no sense and after a long time (a very, very , very long time) I realised what the problem was and substituted to for F/A. The rest became code bashing exercise of mumble jumble Greek. The key take for me is that I knew it wasn’t right and knew where to go to sort it out. That may sound like a small thing but the kudos of presenting output without direction on my first tasks seems to have served me well and boosted my confidence for the next six months!……….Who’d a thunk I could produce a calc with Damo’s help 🙂

In other news

My office has the design contract for the Middle East Basing (think Op Shader). I was asked to look at a deployment order to send some CH2M Engrs out for technical design support to delivery. Page two of the doc had the CoC outlined and OC STRE sat at the top of the tree…like a slap in the face I was reminded of my day job after this process ends.

I did that!

A074754 – 229 – 300 – Drainage Layout

…Unless it doesn’t work in which case someone else did it!

Today I received a pdf of the drainage design I did back from the drafty in Nottingham who drew it for me (see link above).

The site is an old National Grid gas storage site. A large part of it was sold off to Barrett homes who then built houses on it. In doing so they destroyed the drainage outlet and so now the site floods. A lot. So much so that the water is spilling over a small retaining wall at the north of the site and into a timber yard. The timber yard then floods and they claim against National Grid for the damage to their stock. National Grid have been saying to them for ages (the houses were build nearly 10 years ago) that they would do something about it and are only getting around to it now because they want to demolish the northern gas storage tank and the ground it too wet and soft to get the plant across.

To the west of the site and atop a retaining wall is another development. The drainage behind the retaining wall discharges onto the National Grid site and is causing the majority of the flooding. A manhole was once constructed there but never connected to anything. We’ve devised a ground drain to deal with the surface water while also lowering the ground water. This feeds into a new underground drainage system which then discharges into the river the far side of the road in the east.

The drainage design was pretty straight forward. I designed a similar temporary drainage solution during Phase 2 when the basement flooded (there is a blog about that one too). For this one all the leg work had been done for me, a drainage specialist in another office had run simulations and done other clever computer things and advised on a 150mm dia pipe running at a minimum fall of 150mm.

So all I had to do was draw some straight lines on a site diagram and specify the manhole types, invert levels and a few other bits and pieces that i’s learnt when doing it on site. Doing it on site previously actually gave me a huge advantage, I knew to specify a rocker pipe connection, a geotextile membrane and rocker pipe connections. All that stuff which is easily overlooked but important to making it work and not looking like a knob.

National Grid want to sell this bit of land as soon as the gas storage site is gone (probably to Barrett again) and so don’t want any on-going maintenance issues. Therefore the design must comply with the Anglian water adoptable sewers regs. So with a bit of reading I made sure the manholes, falls, diameters and all the other bits met the spec.

Now comes the hard part… In order to discharge into the river I need two things:

- Consent from the Environment agency to discharge into the river – this is actually easier than you’d think. We tested the water so we know it’s clean enough, so all we do is show them how we’ll be working safely next to the river and how we won’t constrict the flow. They then give us consent.

- Section 50 consent to dig up the road from the highways agency. This is more difficult. I’ve submitted our design Colchester tomorrow to meet with some bloke to take about crossing the road. Apparently they can only talk to me on site, they wouldn’t even tell me what depth they wanted it under the road in order to miss other services until I’ve met the bloke. Not sure what all the cloak and dagger stuff is about but it’s a day out of the office I suppose! The really kicker is that before they’ll give you consent you have to give them a cheque for however much they think it’ll cost to reinstate the road in case you dig a massive hole then leave it (or go bust).They also charge you for maintenance of whatever service you’re instating despite the fact that they also ask you to prove it will be adopted by the relevant undertaker.

I’m also told the bloke in question is mega boring, I’ll let you know how it goes…

Chartered – Tick VG

Nothing significant to report from site, where there is a bit of a hiatus as paperwork catches up to progress and the design office where I am writing up results of surveys. However in the sidelines I am now Chartered, as a manager. So I thought it worthy of a blog.

For those who haven’t seen 2014DIN07-093, here it is hosted from the Chartered Management Institute (CMI) website.

The offer runs out in April 2016, though new direction may/may have come out. This DIN allows you to apply for a qualification from either the CMI or the Institute of Leadership and Management (ILM). I elected for a level 5 certificate in Management and Leadership from the CMI, which came with a year’s free membership. I elected to go with the CMI qualification as it led towards Chartering through the CMI’s fast track route and I thought that this would be a good way of demonstrating management capability in the future. Clearly I am now on the hook for both future management CPD and further professional fees, but at present I see it as complimentary to my engineering development. It also provides another independent verification on elements of competencies C – E.

I have to say the application process underwhelmed me; I put a couple of evenings into my 1200 word application form and was told I would be informed within 10 days. This turned out to be less than 24 hours which either says there was a super fast-track approval system where they see the words ‘Army Captain’ and reached for the ‘Tick VG’ stamp. When comparing the system to Chartering as an Engineer the two biggest differences are:

- Education: A level 5 certificate is clearly significantly lower than a Masters degree. This is true in volume when one considers finishing phase 1 of PET would count as a certificate. It is also true in level of thinking, with a Masters sitting at level 7 in the NVQ scale; I’m sure everyone is familiar with the term ‘Masters level learning’ by now…

- Application and interview. Whether it is the 1,000 words for the CMI, 3,000 for IMechE or 6,000+ for the ICE the form is about demonstrating applying theory into practice, experience and lying about keeping up a CPD record. The interview though I think is very different though, because of the lying piece. I spent a bit of time putting together my application but without seeing me how can the CMI verify it was me that wrote the application form or even did the work. It makes it difficult to maintain a standard.

I have not looked into any other industries to see what their requirements are but I think, unlike George Orwell’s animals, all Charters weren’t created equal. To track back to engineering the American equivalent of CEng is P.E., simply Professional Engineer. This is considered a licence and like most professional licences is administered at State level. The prerequisites are a Batchelor’s Degree and 4 years of experience. Then you are able to take the PE exam, this is a 4-hour morning paper followed by the same in the afternoon. This appears to have scarred the people in my office to an equivalent degree to Ex Longreach or Worst Encounter as it often pops up in conversation. So as far as comparing the UK and US approaches they appear equivalent to me as I think, without seeing a copy of the paper, that it will be at ‘Master’s Level’. That said, I would say that the PET course has caused me to be far more analytical as a result of writing TMRs and AERs, something I wouldn’t have got from a big exam.

Conscious that I haven’t given Mike any pictures yet, one thing that is better over here is you can buy a PE bumper sticker:

If you want one get your bids in…

In other news, don’t go to New York City in December, it is full of people. As you can see below even Picasso’s goat is unimpressed with the crowds.