Archive

Translating Technical Documents

I was wondering if anyone had any advice on how to translate large technical documents to a high standard whilst maintaining the original formatting and pictures etc. Google translate is the only free software I can find and the standard and quality of translation isn’t good enough.

Heathrow back on telly tonight – ITV 19 Aug 8pm

Tonight sees the 12-part series begin again which follows Heathrow as ‘Britain’s busiest airport’ (at time of filming during Winter months 2019!). The soothing tones of the national treasure Joanna Lumley provide narration. If my attachment lasts long enough I hope to appear in the coming 2020 series at the new-guy-on-site.

You’ll Need a Circa 700 kVA, £784,000 Temporary Heating Solution to Deal with Winter Conditions!

Replacing the East Wing Low Temperature Hot Water (LTHW) or ‘heating’ system in a Listed Building context isn’t straightforward, the key element examined in this blog post is the provision of temporary heating. During the winter period it is critical that the building fabric temperature is adequately controlled to reduce the risk of condensation and the destructive consequences.

You could build an entirely new LTHW distribution system to provide heat whilst you replace the old system… this has been discounted already due to cost and complexity. The chosen solution is to power electric heaters and dehumidifiers, bearing in mind there are approximately 200 rooms across 6 floors (basement, ground, mezzanine and so on up to the attic) to provide heat to.

The conservator on site has explained that the building fabric/internal temperature must be maintained at >= 5°C to manage the risk of condensation and building fabric damage. Due to fire safety measures doors need to be shut at night, doors cannot be altered to allow cable runs underneath them, therefore the current solution revolves around the hope that the rooms (old, large rooms with large single glazing windows) retain sufficient temperatures throughout the night when the heaters have to be withdrawn from the rooms to the corridors and operated through closed doors… The contractor in charge of the electric heating system articulated that ‘the London ambient temperature doesn’t often drop below 5°C in the winter and the building usually retains its heat quite well’. I am pessimistic about the ability of the rooms to retain the heat, we are still waiting for detailed heat loss calculations from the principle designer.

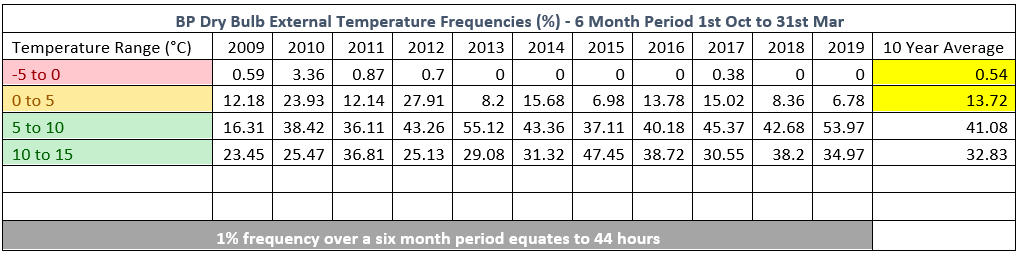

The table I collated below disputes the ‘doesn’t often drop below 5°C’ assertion, over a 10 year average from onsite external temperature data it can be shown that for approximately 14.26% of a six month period the external temperature will drop below 5°C. The passive fabric heating effects of a LTHW system cannot be relied upon to maintain the buildings usual thermal mass, the rooms could haemorrhage heat due to infiltration and the current solution cannot remedy this at night time. Rather than trusting in belated heat loss calculations I believe it will be necessary to carefully monitor the rooms heat retention capabilities via existing temperature monitors and we should be prepared to upscale/adjust the heating solution (or relax certain constraints if possible) where necessary.

Moving onto the power supply… the contractor has supplied a quote for plant hire (heaters, dehumidifers, generators) and power infrastructure (cables, installation, maintenance, operation, refueling etc.) based on a perceived 700 kVA load, no diversity has been designed for as it has been assumed that worst case scenario is all heaters are required at the same time.

At normal operating capacity the building in question draws approximately 550 kVa at peak loading (Lunch time). 12 months ago when the building was at full occupancy (Pre-COVID) and the primary transformer and CHP hadn’t been upgraded it was decided that the power supply for the temporary heating should be self-sufficient and was based on a generator solution with a cost of £188,700 from Oct 20 – Apr 21.

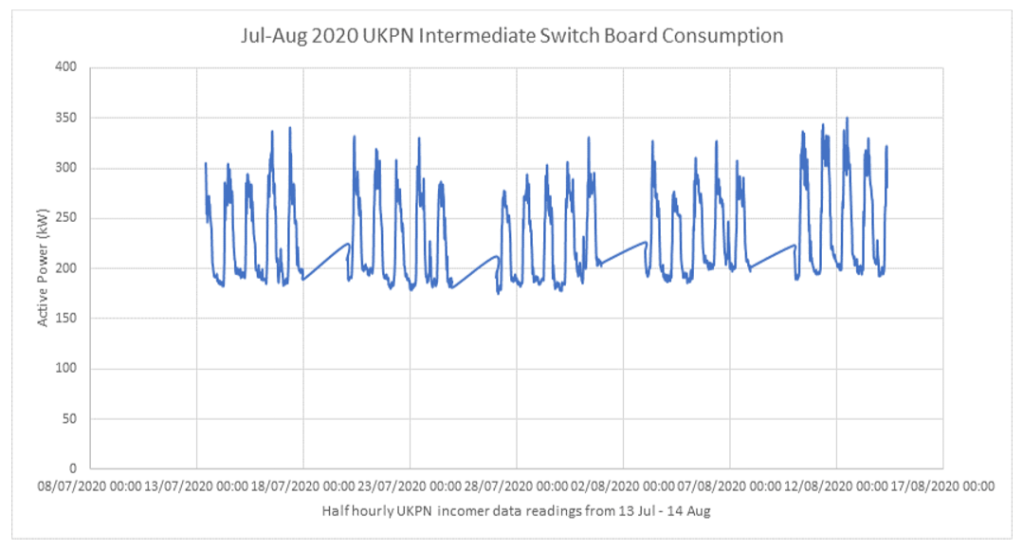

We now find ourselves with a 250 kVA CHP unit and a transformer rated at 866 kVA that could comfortably be loaded for extended periods of time to 120% of its rated capacity (1.039 MVA). The building is now only experiencing 400 kVA (Assuming a p.f of 0.7 and based on the monthly weekday average loading profile between 0900 and 1500 during maximum usage) loading at peak times as per the meter data analysed below from the Building Management System.

With an infrastructure spare capacity of 600 – 850 kVA I believe there is sufficient scope to incorporate it as the temporary heating baseload with generators for peak loads and as the secondary means of power supply in the event that the building loads increase with a return to normal occupancy levels.

Again this is something that is now being looked at in more detail in an attempt to reduce generator usage and the associated carbon emissions and cost of hire and operation, this means more design work for the contractor in terms of safely loading and integrating with the pre-existing electrical distribution system.

As of today it has been decided that the use of a stealth generator or a battery pack solution for night time operation (Where the battery solution would have cost in excess of £200,00) are not necessary and that the existing infrastructure will be utilised… a step in the right direction.

Melbourne Skyline 2012 vs 2020

Innovative Bolt Tensioning

Ever had issues on site with proving bolts are tightened correctly? Normally this results in using the part turn method or a torque bar/gun but often there are challenges determining the correct ‘torque’ compared to the required bolt tension. What if there was another way?

This American company (Smart Bolts) are offering smart bolts with an indicator that changes colour as the bolt is tightened. The colour change is based on bolt extension which is linked to tensile force (F = ke in the elastic range). Below is a video demonstration/sales pitch of how it works.

Pros:

- Visual indication when ‘correct’ tension is reached.

- Simplicity on site.

- Torque equipment or testing of bolts isn’t required.

- Bolts can be re-used provided elastic limit is not exceeded.

- Ease of checking during operational use/maintenance.

Cons:

- Bolts cost more than standard bolts.

- Codes/APoC may not recognise the installation method.

- Increased to me to verify each bolt’s colour change.

- Colour changes are at set increments based on bolt design limit and may not correlate to site purpose/requirements.

- Operational service life ‘over 20 years’ may not be long enough for structural steel applications.

I’m interested to see how this technology develops in structural engineering applications. There may already be some military engineering applications where the bolts would be useful. What do you think?

Contract Dits from Siemens Gas Turbine Servicing

Background

Siemens offer Servicing Contracts for their Engines known as Long Term Plans (LTP), these broadly fit under two categories:

1. Preventative – Siemens will send Engineers to site to preemptively service the Engine in order to guarantee 100% running time (aside from during periods of planned servicing). The engineer on site, in consultation with experts back in Lincoln, will balance the cost of servicing/replacing components against the likelihood of failure during in the next running period (24000-36000 hours). “Over servicing” engines gives a higher degree of confidence that engines meet 100% running time, but also increases cost (components, time on site, Engineer expenses – hotel etc). “Under servicing” engines gives a lower degree of certainty. Civils if you’re still reading – think John Moran screaming RISK!

2. Corrective – Siemens will send Engineers to site only when an Engine Fault Occurs. Siemens has Engineers based all over the world to minimise travel time.

Siemens offer a remote Engine monitoring service that feeds engine telemetry data to Lincoln, from here Siemens can analyse the data to give advice to the customer in the event of a small fault without physically needing to be at site. Additionally, all this data allows Siemens to better predict component failure – a bonus for the preventative plans.

Generally speaking:

1. Smaller companies opt for LTPs to mitigate risk.

2. Larger companies such as Oil Majors (Total, Shell etc) prefer to remain as ad hoc customers for servicing. Why you may ask….. Because they are so valuable in terms of servicing revenue and potential new Engine revenue, that Siemens will drop more or less everything to get engineers out to site to fix the problem. If Siemens didn’t adopt this attitude, the likes of the Oil Majors would go elsewhere for New Engines (Solar, GE) and Servicing (Centrax), to name but a few competitors.

Dit from Last Week – Qatar Petroleum (QP)

QP don’t have an LTP with Siemens, however, Engine ceases to run Friday 3pm UK time with QP demanding an Engineer on site (offshore rig) within 24 hours. Cue much flapping, however an Engineer was on site within the time frame and reaching back to experts in Lincoln. Would Siemens extend this level of service to a smaller company at a more difficult location? Absolutely not, they would be told to wait in line.

Covid-19 Frictions

1. Mandated 2 week quarantines either side of international travel in some countries.

2. Some customers won’t allow engineers on site to conduct servicing at this point in time.

So What

Siemens have a growing back log of customers requiring servicing, however are unable to deliver it due to the frictions mentioned above. In the coming months there will be a time when Siemens will predict the likely failure of one of their Engines through remote Engine monitoring, but be powerless to send an engineer out to site to prevent it. In the event of a failed engine on a preventative plan, and in the eyes of the customer, Siemens have failed to meet the servicing contractual arrangements.

Bottom Line

Siemens will be looking to use Covid-19 as a Force majeure to free itself from the obligations in some of its Servicing contracts. I’ll be reaching for the popcorn when this happens.

Question – How do I get the best and fastest work from a subby?

If you have any thoughts, please let me know in the comments. Here’s the reason for asking:

In a recent job, I had 5 days to get a number of activities completed, one of which was a bunch of test pits drilled and samples supplied to geotech labs. I had employed a geotech company to complete this work on a lump sum contract, and they sub-contracted out the drilling work to another company.

The subbed drilling company found out that they had a 5 day window, and went about ensuring that the job took this amount of time. I am not sure of the motives for doing this, but that’s what they did. The first few days was ‘real slow going’, the last few days they completed drilling and able to knock off 8 hours into a 12 hour shift.

I didn’t have a problem with any of this until I realised all the things on days rates that I had on site supporting their activity.

- They ended up the last company on site, and so I had traffic management just for them.

- Labourers with excavators and dump trucks to move spoil away from the drilling areas.

- My supervisor was costing this job per day.

- Rail safety supervisor.

- Me! I wasn’t costing the job as such but I did have other locations I wanted to be!

There were more but these were the biggest things. So to my question. Instead of a lump sum, would a pain/gain clause work here, noting that the traditional Pain/Gain doesn’t work at this low level (what do ‘we’ gain?). And how does ‘pain’ work? I am cognisant that too much pain and I might put a small company under.

Could I offer them more money to complete a day or two earlier?

How can I write into a subbies contract something to incentivise them to get the work cracked out and get off my site?! Is there something I can tell them on site? Does anyone have any experiences?

Is the Target Flawed? (≈ 5 minute read)

As 1 of 12 benefits forming the business case for the current project I’m working on it was identified that the installation of more efficient primary plant (CHP and boilers) along with more sophisticated and energy efficient control systems, pipework insulation, wireless thermostatic radiator valves (TRV) etc. would reduce the carbon emissions of the building.

Based on the improvements mentioned above and gas and electric meter readings of the building it was estimated from the antiquated 2017 SAP carbon intensities (0.218 kgCO2/kWh for gas and 0.399 kgCO2/kWh for electricity) that a saving of 554 tonnes of carbon per annum would be achieved, this figure is enshrined in the business case and needs to be met.

Flaws…

The project identified that the building was insufficiently heated and has upgraded both the capacity of the primary plant and the pipe sizes to accomodate faster mass flow rates and therefore an adequate delivery of heat as per the only equation I remember from phase 1, Q=mdot*Cp*DeltaT… joking of course.

More heat at a better efficiency = net carbon emission increase or decrease?

The metering strategy within the building is crude with little sub-metering, coupled with the fact that the occupancy patterns and building use are highly variable increases the difficulty with assessing in any detail the realisation of the target. It was also found that the lack of insulation on the pipework was actually relied upon in some areas (Like underfloor heating) to heat the bulding fabric. Therefore by introducing pipework insulation you’re reducing the heat losses in one place (the pipe) which increases the heat demand in other places (the emitters/radiators) to compensate for the removal of the indirect heating effect. Maybe there is a net reduction in consumption from the pipework insulation, no detail exists yet.

When the target was set there was no methodology for how to track and measure its achievement, no appreciation for the diffculties involved in being able to state, with a high degree of surety, this target has been met. It is assumed that the blanket energy meter readings will be looked at when the project is finished and the hope is that they’ve reduced by 554 tonnes of carbon…

Mission creep has led to enhancements and improvements that compromise the carbon target. Design ommissions such as the removal of wireless TRVs and large scale PV arrays just increase the burden for whatever solution (Likely a closed loop heat pump) is decided upon to address the delta in the carbon target.

Was the target SMART. Specific? Yes, Measurable? Yes but with sophisticated sub-metering and an accurate baseline with extensive data to start from. Achievable? Mission creep with a lack of cohesion across the programme may have resulted in net carbon emission increase, the data isn’t there yet.

White lies? Lets say your overall carbon emissions increased from 100 tonnes to 200 tonnes, but the plant you are now using is 93% efficient whereas before it was 75%. The argument could be made that as a direct result of having higher efficiency plant, the saving you have realised over the original plant is 18 tonnes of carbon, irrespective of the net carbon emission increase. The original wording in the business case was ‘reduce emissions by 554 carbon tonnes’ not ‘achieve a net carbon emission reduction of 554 tonnes’.

Whilst I see the importance for Bottom Line up Front business cases, in this situation the lack of detail with no technical justification completely discredit the benefit and the pressing environmental need for reduced ‘NET’ carbon emissions.

Food for thought.

Use of UV light in air disinfection (12min read)

BLUF: Recent industry guidance has suggested that increased fresh air proportion is one of the best ways to de-risk person-to-person transmission of COVID pathogen. This approach brings with it significantly increased energy costs in fresh air heating (winter) and cooling (summer). There are a number of companies that have been offering Ultraviolet Germicidal Irradiation (UVGI) as a potential solution to disinfect the recirculated air of any pathogen so that plant duty is reduced to pre-COVID levels. The technology is not new but comes with uncertainties and health warnings of ozone production.

The use of UV light to render pathogens (virus, bacteria, fungi etc.) has been around for a fair while and was predominantly used to disinfect bulk water. Similarly, the study of virus susceptibility in when airborne is not a new topic. Link here to a 1936 study on just that.

There are many commercial products available today that use UVGI but they largely fall into three main categories; duct-mounted, upper-room and individual unitary systems.

- Designed to disinfect EITHER static elements such as coils/plenums/condensate pans or a moving air stream. The two applications require largely different power UV bulbs given the different exposure times.

- CAPEX for installation can be large and building service set-up may not always lend itself to the components.

- Designed to disinfect the upper proportion of air within a room that is served by traditional mixed-ventilation. It is unsuitable for typically larger spaces that employ displacement ventilation, unless CFD is employed to confirm air-flow patterns.

- There is an inherent risk of exposure to UV light during the typical 24-hour operation and the use of occupied space must be considered. Dangers and safe use practice have been covered in the past; example papers here and here.

- These ‘plug and play’ solutions typically serve smaller areas (up to 30m2) and have a flow rate of around 20 litres/s. The ease of installation makes them favourable in places that may not be directly served by fresh air but only have an extract, such as bathrooms whish can be designed to be in negative air pressure.

Risk

In all of these solutions UV light is the main mechanism of rendering the pathogen unable to replicate. Many of the manufacturers also actively publicise that the production of ozone (O3) is beneficial in rendering pathogens and odours neutral. Whilst the mechanism is not disputed, the use of ozone to disinfect water and air has been longstanding, there is no universally accepted limit of human exposure to ozone within the built environment. ASHRAE have stated that safe ozone levels ‘would be lower than 10 ppb and that introduction of ozone to indoor spaces should be reduced to as low as reasonably achievable’.

All of the above solutions will go some way to preventing large-scale person-to-person transmission or the movement of virus-laden air from one space to another. There still exists the risk of person-to-person transmission from coughing/sneezing/breathing in close proximity so the array of distancing/cleaning measures could not be abandoned in favour of a ‘silver bullet’ approach.

Has anybody else been approached by contractors promising a wholesale return to work if only a magic HVAC solution is employed?

Compensation Events for a change to British Standards?

BLUF: We have been working to one standard, the standard has been superseded, and now we’re being asked to work to the new standard… Without a compensation event.

Question: The following 3 paragraphs have been ripped from a TMR I’m currently writing (so excuse the lack of colour) but led me to wonder if anyone else had come across similar instances. For example when BS 7671 (requirements for electrical installations) moved from 17th to 18th edition in 2019, would you expect to be given a PMI and CE to compensate the possible increase to the cost of your works?

The Issue:

To understand CSJV’s BIM strategy, the author sought to identify the specific BIM related clauses in their contract with the Client. However, in an interview with Matthew, CSJV’s BIM Manager (2020), it was explained that a BIM level was not specified in the contract, in fact only the requirement to work to PAS 1192-2:2013 (British Standards Institute, 2013) was specified. PAS 1192-2:2013 focuses on the construction phase and specifies the requirements for Level 2 maturity; sets out the framework, roles and responsibilities and expands the scope of the Common Data Environment (CDE). When questioned on the lack of specifics in the contract, Matthew quoted guidance issued by the UK BIM Alliance, the UK’s largest community lead institution for BIM.

The UK BIM Alliance, and specifically its legal community, recommend that BIM levels are not specified in contracts. This is because, according to Matthew, that it would require the contractor to take too much risk. The perceived risk reflects the idea that it would be impossible for the Client to effectively define the BIM requirements of level 2 as they are too many in number, and simultaneously too complex and too vague. It is also relevant to mention that whilst more recent revisions to the PAS have reduced ambiguity, at the inception of HS2 Ltd. the standards were in their infancy.

The standards of BIM expected to be met by CSJV have become more ambiguous since the Client has recently been requesting elements of the BEP (BIM Execution Plan) to be delivered to ISO19650, a new standard superseding PAS 1992-2. CSJV claim that this would require a Project Manager’s Instruction (PMI) and an expensive Compensation Event (CE) as it is a change to the scope and would require a change to internal process. The Client claims that by requiring the latest standard at the time of contract signing, there was an implication that the latest standard would always be required – this has not yet been resolved but Matthew explained that without a PMI and CE they continue to work to the older PAS 1192-2.