Anyone know about Friction?

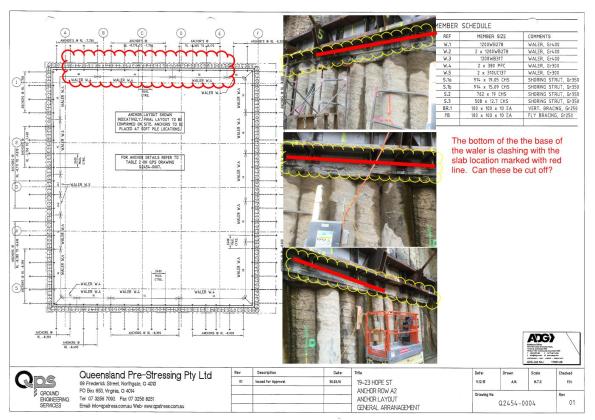

I have another problem, the bottom brackets of my walers clashes with my basement level 5 slab-exactly what we wanted to avoid. So I need to cut the brackets off before I can lay the slab. My sub contractor who designed the waler is not so happy with this idea.

My email below:

There are currently 12 bolts either side of the anchor. If we removed the four bottom bolts this would leave 8 bolts remaining.

These bolts are AS1252 M30 8.8/s with a shear capacity of 214 KN. Which would leave the bolts with a total shear capacity of 1712 KN not including the friction of steel on concrete. If I look at the anchor summary Q2454-0007 and apply the vertical shear at 45 degrees from the safe working load I get the following:

| Zone | Anchor SWL (KN) | Calculated vertical shear (KN) 45 degrees | Factor of safety |

| 3E | 1244 | 880 | 1.95 |

| 4A | 1316 | 930 | 1.84 |

| 4B | 1280 | 905 | 1.89 |

| 3D | 1160 | 820 | 2.09 |

Even if we factored the SWL by 1.5 this would still be within the capacity of the 8 bolts. Please slap me down if I am being an upstart…

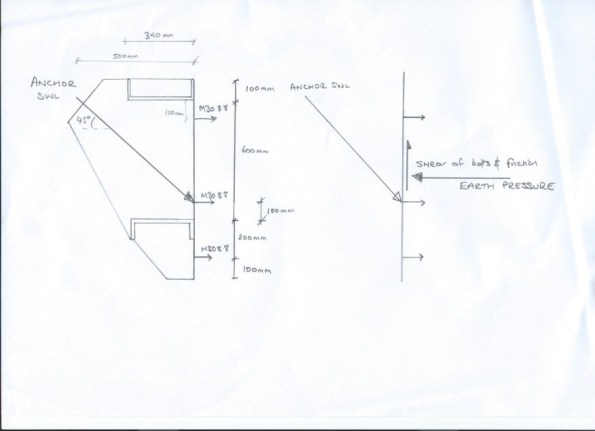

I have since read a paper that indicated the coefficient of steel on dry shotcrete as 0.57, which could potentially reduce my shearing force by 467 KN. Now part of the problem I believe is that the ground anchor does not act through the ‘middle third’ of the waler and so there is a moment induced and the bolts therefore act in tension and shear reducing their capacity. How do I get around this and still cut off the brackets?

I have had a look at the UK’s Steel Bluebook and I think that with the bolts in tension the shear capacity is reduced to 80% – I am having issues looking at Australian Standards at the moment though to confirm what they use here. Any help gratefully received.

The offensive article:![Q2454-0102[A]](https://pewpetblog.com/wp-content/uploads/2016/08/q2454-0102a1.jpg?w=595)

For you Richard:

Arching effect in soils

Secant wall bending in towards the soil

Secant wall bending in towards the soil

Those of you that have read my blogs will realise I am having a few issues on site. I have now stopped excavating and have started to build back up. In order to build our stairs we needed to remove an anchor waler. We asked permission from the designers 6 weeks ago, but were ignored. We asked several times more and the designers refused to take our calls. So needing to make progress we sent an ultimatum on Aconex, email and in writing, we would remove the waler on a given date and if they didn’t get back to us then they agreed that it is safe to proceed (for my own sanity I did a free earth model and compared against the wallap analysis for the new case). That date passed and we removed the waler on Friday 19th. The stairs will be built in the next 2 days and will restrain the piles from then.

Ground waler removed from wall so stair can be built.

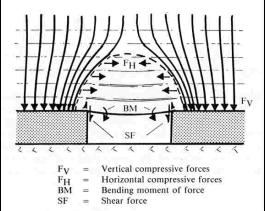

When I inspected the wall after the waler had been removed I expected movement towards the hole. What I found was the wall had actually moved outwards. The wall is buried in low to medium strength phyllite and this is clearly stiffer than the piles so the ground has arched to the remaining ground anchor walers.

I have regularly inspected the wall and there are no signs of cracking or further deformation. The load has moved elsewhere! If you look at the first photo you will see a slight bow inwards of the shotcrete.

Here comes the science:

“Arching occurs when there is a difference of the stiffness between the installed structure and the surrounding soil. If the structure is stiffer than the soil then load arches onto the structure. Otherwise, if the structure is less stiff than the soil then load arches away from the structure.

For instance, if part of a rigid support of soil mass yields, the adjoining particles move withrespect to the remainder of the soil mass. This movement is resisted by shearing stresses which reduce the pressure on the yielding portion of the support while increasing the pressure on the adjacent rigid zones. This phenomenon is called the arching effect.”

Piling by estimation

This slide show lays out the basic process to piling at Paradise.

Piling began in Paradise three weeks ago. The piles are 1200mm bored RC piles working in end bearing. Each pile requires a rock socket length of approximately 6D.

Despite the management issues with the demolition subcontractor being currently 9 weeks behind schedule and still on site, the piling has been going well. The target has been to complete 2.5 piles per day and the pilers are currently hitting around 3 per day.

The estimation that the piling is working on is that of the rock head level (m AOD of the incredibly weak and completely underwhelmingly named “Bromsgrove Sandstone”). The rock head level is required 10 days before the piles are installed and this has been assumed based on previous construction drawings that show the underside of foundation levels. This level effects the overall length of the pile and more importantly the length of the steel reinforcement cages, hence the lead time.

The issue I had yesterday on site was an obstruction encountered below the presumed rock head level. This obstruction appeared to be a concrete slab, possibly blinding, at about 5.5m below piling mat, the rock head should be 4.25m below. A quick inspection of the piling hole identified the sandstone was collapsing above the obstruction and water was trickling in to the base.

The piling designer was contacted and assured everyone that the rock socket length could still be achieved by increasing the depth of the pile, but not the length of the cage, so the bottom 1.25m would have no structural steel. (Revision – due to additional length in the cages the actual length without steel is only 600mm). This pile will be recorded as a non-conformity by the piling sub-contractor and I will advise that further testing be carried out on this pile.

This pile is located in the core of the structure and as such I am now concerned that the surrounding piles will also have a rock head level lower than expected. When we do the surrounding piles (Approx 3 days after that pile in question – Monday) I will be able to get a better idea of what the obstruction is.

SITE FATALITY: INVESTIGATION PROCESS

Moving on to the investigation side of things. As in the UK, the situation is slightly complicated by the fact that the incident took place on military/federal/government property. There will be no less than 4 separate investigations, and potentially 2 separate court cases. I will do my best to explain them, and what has happened so far:

CID (Criminal Investigation Division): The equivalent of our SIB, this is a military body that immediately took control of the site, closing it down and undertaking the initial ‘crime scene’ investigation, including taking photographs and evidence etc. The investigation is military and aimed at documenting the incident, as well as trying to determine if there is any criminal negligence. This report is not necessarily made available to the public, but can feed a potential criminal investigation.

OSHA (Occupational Safety & health Administration): The closest thing to our HSE. Under Federal law OSHA were contacted within 8 hours and took over the site once it was handed over to them by CID. OSHA represent the Federal Department of Labor [sic], this investigation is open to the public and transparent. This investigation will focus on what caused the accident, and who was at fault. It focuses on any violations that may have taken place, and particularly on any ‘willful violations’. It can apportion fines to those responsible, all of which are paid to the Department of Labor.

Contractor Investigation: The sub-contractor have five days to produce their own incident report, which is then passed on to USACE and feeds the USACE investigation.

USACE: An internal investigation aimed at understanding what went wrong, as well as making recommendations and generating ‘lessons learned’. The investigation establishes an ‘Executive Incident Board’ comprising 6 personnel from across the Corps (military and civilian), who are experts in their fields and are given considerable powers to investigate the incident from a military (non-criminal) perspective.

Once these investigation have been concluded, which could be as soon as six months, but likely to be much longer, there are then court proceedings to consider:

Civil Court Case: Likely to be sought by the family of the deceased in order to claim compensation from those deemed to be responsible. Any awards here would be made to the relatives of the deceased, as opposed to fines paid to the Department of Labor under the OSHA investigation.

Criminal Court Case: Potentially sought by some branch of the government against anyone likely to be criminally liable. As in the UK a higher burden of proof is required to obtain a conviction in a criminal case over a civil one. Depending on the investigation(s) the truck driver could potentially face a charge of ‘vehicular homicide’, which in Maryland can carry a custodial sentence of ten years.

Both civil and criminal trials have the ability to subpoena information from any of the plethora of investigations conducted.

SITE FATALITY: INCIDENT UPDATE

So following on from my SITE FATALITY blog on Friday. After speaking to the project Safety Manager and others the situation has become a little clearer. Without wanting to overrun the blog, I’m going to write a piece confirming the circumstances of the accident, and a second outlining the investigation process so far, and moving forwards.

Firstly, the incident: As expected, the information I received on Friday was generally correct, but wrong in a few key areas. Here is an update:

A third-party (AI) delivery of aggregate was received on site. This delivery was ordered by the concrete sub-contractor (DCB), who were therefore responsible for the delivery for the whole duration of his time on site. The truck drove around to the specified delivery site, then reversed off the road and down an incline in order to discharge the aggregate. The surface of the incline was dusty, so once the mass of the aggregate had been removed from the flatbed, the truck lost traction with the surface, which is why it got stuck and needed to be recovered. So potentially some culpability for the General Contractor (MG) who failed to provide safe site access (no matting or aggregate etc. etc.). There was no tow-bar on the front of the truck (potential culpability for AI), so a tow-strap was attached to the front axle and the vehicle recovered to the track. At which point the truck driver exited the vehicle (left-hand side), and walked around to the rear of the truck in order to secure the tailgate. Whilst this was happening two sub-contractors (DCB) moved forwards (from the right of the vehicle) to undo the tow-strap. One wedged himself under the front right tire to give himself enough leverage to work the straps, whilst the second handed him tools. There was no spotter or banksman (so potential culpability on behalf of both DCB and MG for not following site best-practice). The truck driver, unaware of this activity climbed back into the cab and without doing a vehicle walk-around or checking that he was clear drove off crushing the first man, and knocking the second over (potential culpability for both the delivery driver (AI) and also MG for not properly briefing, training or supervising him). It appears that all of this happened so quickly that the MG foreman was not aware of it until after the incident. There could quite easily have been two fatalities that day.

The investigations have started, but it is likely to take some time for conclusions to be reached. It is the opinion of the Project Safety Manager (and myself) that all three parties will be found liable to some extent; it is just a question of the proportionality of blame. Ultimately, according to the contract and site-practice over here, the delivery was the full responsibility of the sub-contractor DCB (not the General Contractor (MG)), who may be found more liable than the others. Though this is just conjecture on my part at this stage.

SITE FATALITY

Unfortunately a concrete sub-contractor was killed on the East Campus site earlier today.

I wasn’t on site at the time, and the accident didn’t occur on the JOC project. However there are four construction projects taking place concurrently across the East Campus site, all of which utilise the same access routes and co-ordinate closely. The incident took place only a few meters from the JOC building, and JOC personnel where amongst the first on the scene, and to attempt first aid. All USACE personnel are based in the same site-office, and a number of them (including Safety Managers) are double-hatted across two or more projects. The accident appears to have been entirely preventable.

In my first blog I made the following off-handed remark with regards to site traffic: “someone had a cunning plan which involves not enforcing any sort of traffic management plan and only vaguely checking who moves to and from site, which has alleviated some of the congestion”. Perhaps traffic management was a contributing factor, and maybe I should have pushed this further at the time rather than brushing it aside. The fact is someone who turned up to work today isn’t going home. Here are the salient facts as I understand them at the moment:

A dumper truck arrived on site and was directed to the appropriate area. When he arrived at the designated spot he pulled off the site access road in a forwards direction in order to discharge his aggregate. At which point he became stuck. A recovery vehicle was called for, which, after attaching a sling to the rear axle of the dumper truck pulled the truck back onto the access road. The sub-contractor in question moved forwards and crawled under the truck in order to detach the haul-sling from the rear-axle. The driver of the dumper truck, unaware of this, put the vehicle in reverse and accelerated off in order to maneuver his vehicle around so that he was facing the right direction to exit the site. Workers quickly stopped the driver, but by this time it was too late. The sub-contractor was crushed under the wheels of the truck, and despite attempts could not be revived. I haven’t been able to ascertain what if any hand signals or communications there were between the truck driver and any banksmen/site workers, or if there had been any specific (beyond the obvious) breaches of site safety protocol.

Obviously work was stopped across the site for the day and an investigation has been opened, which may provide some answers.

It seems slightly macabre to turn this into a discussion topic so soon after the event, shocking as it is. I’m sure lots will come out of the investigation, but from what I understand so far it looks like a combination of poor communication, corner-cutting and an uncertain/ever-evolving traffic management plan. This accident should not have happened!

I’ll update as the situation develops, but if anyone has any initial thoughts please let me know.

Self build crane

![IMG_4244[1]](https://pewpetblog.com/wp-content/uploads/2016/08/img_42441.jpg?w=595)

A few weeks ago someone asked how cranes can self build. My neighbouring job is, as I type, building the next level of the crane. The sections of tower are placed on the platform to the left of the tower and the tower is the jacked up so the next section can slide in. You can see one piece about to be slid in and the next on the hook.

![IMG_4245[1]](https://pewpetblog.com/wp-content/uploads/2016/08/img_42451.jpg?w=595)

The first piece has been slid in and the crane is jacking itself up to take the second piece.

I need to have a word with myself because I thought this was cool.

Contractor Corner Cutting Question

As most of you are probably aware, the US placement is a little different to what most of you are probably up to on site. I’m not working for a contractor per se, our role as USACE is really one of contract management, i.e. being the client’s representative on site, and making sure the contractor delivers what he’s meant to as per the (unbelievably strict) contract. This (apparently) was relatively easy during the heavy civils stage; what could possibly go wrong with concrete columns and slabs etc.? Anyway, now that the project has progressed to the close-in and fit-out stages the contractor is struggling, and has started cutting as many corners as possible whilst taking as many liberties as he can. Seemingly in an attempt to try and get the job done to the lowest possible acceptable standard (though this is doubtful at the moment).

The suspicion is that the contractor (more used to building hotels and apartments for developers rather than “weapons systems” for the government) has massively underbid on the project, and is now facing a catastrophic loss. They appear to have completely abandoned their QC plan in order to try and pull the plug and get out as quickly and painlessly (for themselves) as possible. Unfortunately the Federal government has rather large pockets (and me working for them) so it’s unlikely they’ll get far. It appears that the contractor simply wasn’t expecting the level of QA and scrutiny into every aspect of the build that USACE are now applying. Also, as a design, bid, build, project the contractor is struggling to some extent with the idea that every single change needs to be approved, rather than having the freedoms afforded by the more ‘traditional’ design and build type contracts.

I’ll break here, unfortunately, due to the sneaky-beaky nature of the site I’m working on I’m not actually allowed to take any pictures of the work I’m doing, which could be interesting with upcoming presentations and reports etc… So to keep you all interested (vaguely) and to prevent this from being just a big block of writing here are some nice architects impressions of how the fancy building I’m working on will look once it’s finish.

The US Government’s new toy

Back to the blog, here are some examples of the kind of corner cutting being taken by the contractor:

- Building block walls to the wrong specifications (including using weak mortar, and failing to install lintels above penetrations), then deliberately painting over and installing services on top of deficiencies to try and cover up the issues in the hope that they won’t be noticed. Or, they might be gambling that our QA checks will take so long to uncover the issues that we wouldn’t then order defective work to be corrected because it will have too much of an adverse impact on the rest of the project?

- Using inadequate stud walling systems, being notified of the errors, then completing the wall anyway and installing doors and services etc.. Basically a continuation of the first point!

- Running out of concrete during the pour of a footing, then instead of creating a construction joint with appropriate dowel-bar and correctly positioned re-bar, just covering it up and hoping to finish the pour the following day without us noticing!

- On a slightly different note: I walked the site with one of the contractor’s representatives in order to agree on the ‘cost of work done to date’ so that payment could be made for the months work. The whole process took about three to four hours; we came to schedule/percentage agreements on site. But when the claim was subsequently submitted the figures in a number of key areas had been adjusted in their favour; which I found quite insulting. I know this isn’t quite the same as producing sub-standard work and trying to cover it up, but it does none-the less seem to be symptomatic and consistent with poor practices at the management level?

Some of the issues are quite innocuous, but others are more serious. If the contractor was allowed to get away with everything he’s tried then a truly sub-standard building would be delivered at the end.

My question (in many parts) to all of you working for contractors is this:

I wouldn’t expect anyone to be working for a company that is quite as blatant as this, and I know the situation is slightly different. But has anyone encountered similar issues on site from the perspective of the contractor? And if so what did you/the company do about it? Also, in this particular instance the (contractor’s) QC manager is in the process of losing his job, and whilst there has undoubtedly been a complete failure of their QC process, I believe he is something of a fall-guy for managerial failures elsewhere in the company. Has anyone encountered any other particular drivers of bad performance on site?

You have to laugh

![IMG_4126[1]](https://pewpetblog.com/wp-content/uploads/2016/08/img_41261.jpg?w=595)

A comedy of errors

In reverse order.

![IMG_4116[1]](https://pewpetblog.com/wp-content/uploads/2016/08/img_41161.jpg?w=595)

Spot the oddity

3. A column orientated in the wrong direction. If you look to the left of the wall you will see a column orientated left to right and not up and down. The bars had to be cut out and drilled 800 mm then grouted in the right direction. See below. Cause lack of supervision and not looking at the drawings.

![IMG_4117[1]](https://pewpetblog.com/wp-content/uploads/2016/08/img_41171.jpg?w=595)

Cutting the bars then redrilling to change orientation.

![IMG_4126[1].JPG](https://pewpetblog.com/wp-content/uploads/2016/08/img_412611.jpg?w=595)

1. The plumber who are sorting the drainage for site were due to backfill around the water tanks with gravel (in top left of photo). They decided to save a buck and used recycled concrete. Not a problem I was on site and when they were dropping it in and although this is not my area, I am responsible for environmental issues, so I asked them for their free from contamination certificate – they didn’t have one. I gave them time to chase it down but they still didn’t have one. We have now had a union walkout for potentially importing asbestos on to site. Cause – lack of supervision and corner cutting by subbie. Solution take a sample then cover in concrete -bung the union 20k. Discuss!