Archive

Integrated Environmental Solutions (IES) Virtual Environment

As I have arrived at the design office the Mechanical section has just got a new design program called IES (https://www.iesve.com/). Until now they have been using a manufacturer specific free to use program which obviously comes with some significant restraints, mainly that you can only use that manufacturers equipment. It seems they have been using this for some time to estimate design loads for the LEED reports which seems very inefficient to me!

I have been tasked with learning how to use IES, teaching it to the rest of the section and using it to complete the Mechanical 65% design for a fire station. One of the main focuses of using IES is that it will generate the LEED report based on what I design in the program, perfect for hitting my sustainable development competency! Appropriately the IES tagline is “Make every element of your building sustainable”.

So has anybody had any experience with IES? If so, any pointers on some good tutorials?

Is IES any good? How does it perform compared to other programs anyone has experience with?

Also, what design programs are people using outside of AutoCAD and Revit?

Non Commissioned Officer Academy Ft Drum

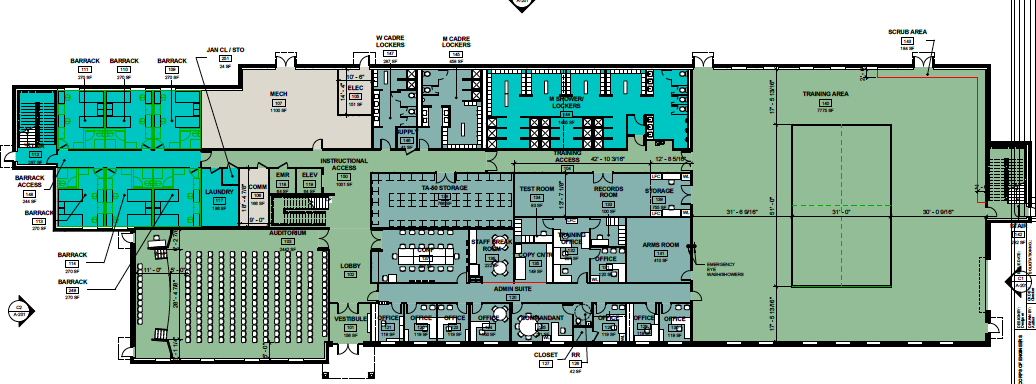

The NCOA will be a mixed use building to house routine NCO promotion training, similar to the Royal Engineer Section Commanders’ Course. The building will house the instructional classrooms, administrative offices, some accommodation, an auditorium, changing facilities and personal weapons storage. It will also house a 15 ft high training area (Room 140 on Figure 1) to be used for drill practice and physical training when weather precludes it from being conducted outside.

Figure 1: Ground Floor Plan.

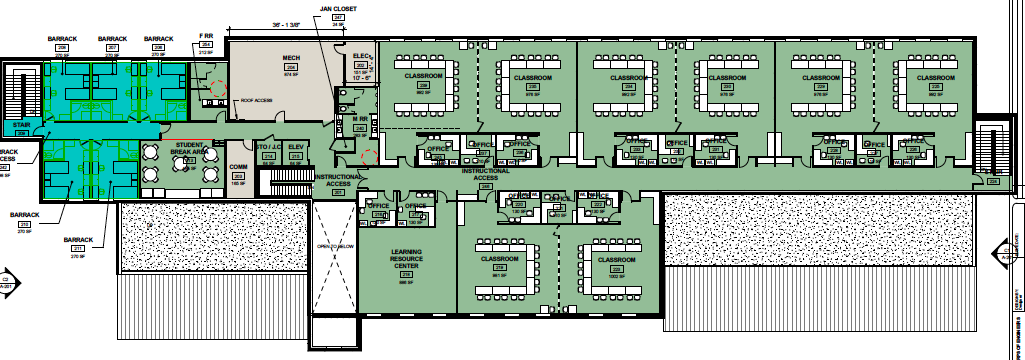

Figure 2: First Floor Plan

The project proposal form had to demonstrate the need for the building, which was that it will replace twenty World War II temporary structures. This will result in a better training environment and reduced utility and maintenance costs. The new building will cover 45,700 sq ft and the project value is currently set at $19 million USD. In order to justify this cost a qualitative economic analysis was executed looking at the alternatives of renovation, maintaining the status quo, leasing and new construction. The status quo was deemed to be unacceptable and other alternatives would have only been a temporary solution.

The project is being contracted as a design, bid, build and the design timetable is organised such that the build contract is due to be awarded on 30 September 2016. This is the last day of the current financial year for USACE and so allows funds to be attributed from this financial year. This presents a risk because if the contract is not awarded on this date then the money attributed to this year will need to be spent on another project or will be lost to the Garrison. I am not privy to information on other mitigating circumstances at programme level, however if some float time had been built into the design schedule this would mitigate the issue at project level. The current design schedule has the following significant deadlines:

35% Design Stop – 18 December 2015.

35% Design Review Conference – 20 January 2016.

65% Design Stop – 28 March 2016.

90% Design Stop – 2 June 2016.

95% Design Review Conference – 28 June 2016.

The date of the planned 90% Design Stop means that I should be able, negating the chance of delays, to see the design work through to this stage.

Given the date of the 90% Design Review Conference it is unlikely that I will be able to see the design through to this point, although the most important experience will have been gained by this point on the design front. The contractual affairs will be dealt with by USACE NY District so there will be no loss of experience by leaving at the 90% design stage.

The design team structure being used by USACE for this design is spread across two USACE Districts and a Design Consultant located in three separate States. The project and the Project Manager is stationed at Fort Drum, NY and is part of NY District. Therefore the design contract naturally falls to NY District’s Engineering Division. Therefore the Design Manager, Architect, Plumbing and Electrical elements are from NY District’s Engineering Branch. Because NY District had insufficient staff to conduct the design of the structural, civil, mechanical and fire protection elements requests were sent to the other Districts within North Atlantic Division. From these Baltimore District was able to staff the Mechanical and Fire Protection elements. As no districts within the Division could support the civil and structural elements these were subcontracted to Pond Consulting, a design consultancy based in Ft Worth, Texas.

Because of the extended lines of communication liaison has already been difficult. A notable occurrence was the design model having to be rotated as it was created 180 degrees out of orientation. As each of the designers across three sites had different linked models this took a week of emails and phone calls to rectify. The issue would have been mitigated against if a central BIM manager was employed on the project, however neither Baltimore nor NY District currently have the post filled.

The new building is to be built on Fort Drum which is in the North of NY State for which the design temperature ranges from a winter design temperature of -30°F to a summer design temperature of 90°F. Significant measures, such as the inclusion of glycol in the hot water system, will have to be taken to ensure the winter design temperature can be met without causing equipment damage.

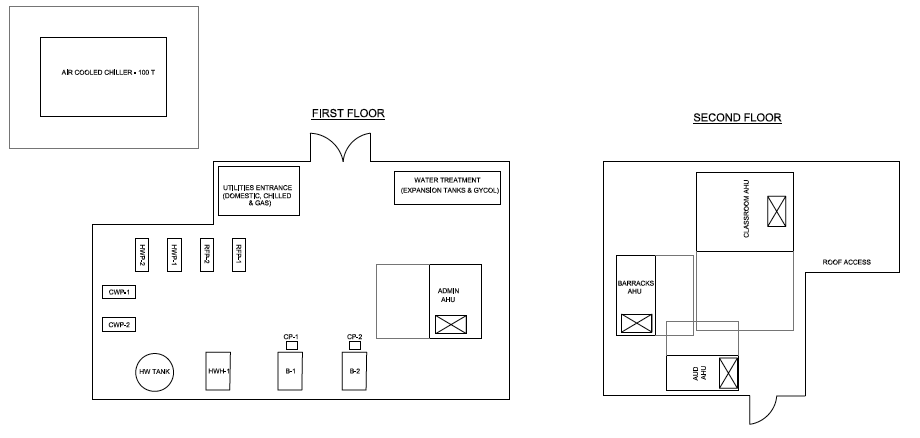

My part in the design will be to assist the mechanical engineer, Tim Wheeler, in the design of the HVAC system for the entire building. Work for the 35% design is a simple design analysis, setting out of the mechanical rooms, as shown in Figure 3, and specifying the HVAC system type. At the 35% design the room layouts, and therefore volumes, should be fixed to allow the detailed design to take place.

Figure 3: Mechanical Room at 35% design, the eagle eyed will notice that it does not line up with the ever changing floor plan. hence waiting until the 35% design stop to continue.

To 35%, as they are discrete elements I have been given a radiant floor design and a Building Lifecycle Cost Analysis (BLCCA) to complete. The radiant floor will be in the training area (Room 140), which is to be used when it is too cold to train outside. The BLCCA is to assess the viability, or otherwise, of using a Ground Coupled Heat Pump (GCHP) system in place of the air-cooled chiller and 70% of the heating load, the remaining 30% being supplied by a Natural Gas powered boiler.

And that’s the situation as it stands at the moment.