Archive

Assumptions are the mother of all…..’£120k regains’?

Assumptions are the mother of all…..’£120k regains’?

Drilling & TaM Grouting

Bachy Soletranche (owned by Vinci) have a NEC3 Option A – Fixed Price (Activity Schedule) of £1.2m, to Drill & Tube a Manchette (TaM) Grout. The Activity Schedule was based on drilling, inserting TaMs, and grouting 384 fans of 4 holes (1,536 holes, each of 4 – 5m lengths) at 1.2m intervals along 230m of brick lined twin and single tunnel.

The objective of the permeation grouting was: “To mitigate the risk of high volume water ingress from groundwater sources derived from the upper aquifer and trapped aquifers in the Lambeth group strata into the tunnel works, especially in the form of scour or ‘piping’ of the made ground that remains surrounding the tunnels from their original construction.”

The design was intended to reduce the mass permeability of the made ground and any buried temporary work structures to that of a fine sand (1×10-7). The design ground parameters and geological strata were estimated using a series of boreholes along and adjacent to the tunnel. This information, combined with historical data about the original tunnel construction (believed to be ‘Cut and Cover’) was interpolated and transposed onto the existing tunnel structure to produce design sections along the length of the tunnel.

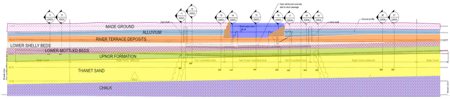

Design geological cross section of tunnel derived from borehole data.

Design geological cross section of tunnel derived from borehole data.

Design location of grout holes in relation to assumed geological strata in West (referred to by Bachy as North) Single Tunnel.

Design location of grout holes in relation to assumed geological strata in West (referred to by Bachy as North) Single Tunnel.

The Drilling & Grouting design was ‘accepted’ by the Client on the proviso, that grouting did not start until a trial was carried out to measure the pressure exerted on the existing tunnel structure as a result of grout injection. This parameters and methodology for this trial have been agreed and it is due to take place next week. Bachy were, however given permission to start drilling and are now 4 weeks into their programme. The Contracts Manager predicted 26 holes (13 per rig) per day and a 10 week programme. A series of problems (mechanical faults with rigs, poorly manufactured drill casings (manufactured specifically to fit in the Twin Tunnels), and high water pressures), meant that an average of 4 holes per day have been drilled, taking the programme to 16 weeks.

The use of a Stuffing Box to control high water pressures encountered during drilling operations.

The use of a Stuffing Box to control high water pressures encountered during drilling operations.

The consequences of this delay have a significant impact of subsequent works (replacement of the concrete invert slab and Twin Tunnel replacement by construction of a cofferdam). The financial impact for Bachy has the potential to be disastrous, reflected in the change in attitude of the Contracts Manager to recoup every penny available by scouring the ‘attendances’ on the contract and submitting Early Warning Notices (EWN) for any potential cause of delay. This has sparked yet more tension with the Vinci Works Manager and Works Supervisors, who feel they are ‘baby sitting’ the sub-contractors.

There is a 10% cap on delayed damages, which at this initial rate of progress, would equates to £120k of costs and ultimately lost profit for Bachy. However, once the cap is reached, arguably Bachy have no financial incentive to continue working extended hours and weekends to complete the job (a measure introduced in an attempt to regain lost time).

Drilling rig drilling (left), grouting tube from silos at surface down ventilation shaft to grouting plant (back centre) and making up TaMs for insertion into the holes (right).

Drilling rig drilling (left), grouting tube from silos at surface down ventilation shaft to grouting plant (back centre) and making up TaMs for insertion into the holes (right).

Grout silos and agitator tank on central compound from where grout lines are run down ventilation shaft into the tunnel.

Grout silos and agitator tank on central compound from where grout lines are run down ventilation shaft into the tunnel.

Fortunately for both Bachy and Vinci (who are also liable for delay damages to Crossrail), it has transpired that the geological assumptions were not wholly reflective of the in-situ conditions. All the holes drilled in the West Single and Twin Tunnel showed there to be varying degrees of Made Ground between the tunnel structure and the natural ground (all of which was clay derived), and also proved that at the level of drilling, the adjacent strata was Lambeth Group, and not as anticipated, River Terrace Deposits.

The high volume and pressure of water in the initial holes, as well as the high uptake of sleeve grout intended to fill the void between the TaM and the hole, suggests whilst there is no permeable Made Ground, there is a ‘Contact Zone’ (a void usually filled with water) between the tunnel structure and the natural ground. The question now sat with the Geological Consultants is how the tunnel was actually constructed (temporary propping in the clay layers with cut and cover above, backfilled with excavated clay?), and most importantly what assumptions must be redefined in anticipation of the Twin Tunnel replacement.

A series of Bachy, Vinci and Crossrail design meetings have now agreed to Bachy’s proposal that grout holes along the section already drilled must extend 0.5m into the natural ground, thus shortening the design length (which accounted for Made Ground) by up to 2m. Concurrently, a trial of Contact Grouting (i.e. without TaMs) using just the top and bottom grout hole, will be carried out on the opposite wall. Already, the reduction in grout hole lengths has increased Bachy’s production rate by 200%, and providing the Contact Grouting trial is successful, the significant reduction in anticipated scope could potentially be the difference between breaking even or making a substantial loss.

What does the contract say?

From a project perspective, encountering clay at a higher level than anticipated is certainly good news, particularly for the Twin Tunnel replacemnet. From a contractual perspective however, Bachy based their design on geological assumptions. These assumptions have now changed, and so therefore must their design and methodology. The change in methodology, once agreed may have implications on their payment. Currently, monthly payments are made in accordance with an Activity Schedule (e.g. holes drilled – per meter length). This is set to reduce by over 50% and therefore, the current system of payment would never allow Bachy to claim for the total tendered amount. Clearly, Bachy have every intention of claiming their full Fixed Price payment (albeit less delay damages), equally Vinci will be looking offset their delay damages against the reduction in scope. As the Section Engineer responsible for the works, and more often than not the ‘buffer’ between the 2 parties, I think I may have the ‘Eastenders’ of a TMR 2 on Contractual Relationships…?!