Archive

Zero Trim Piling

As infrastructure become bigger, heavier and more demanding of their foundations, piles are becoming more frequently used to support the projects. Piles can be either driven (eg. precast concrete or steel sections) or bored (eg. rotary bored, continuous flight auger, full displacement) into the ground depending on requirements for the finished pile and any restrictions or limitations on construction methodology. Bored piles are often filled with a polymer or bentonite fluid to support the open excavation before steel reinforcement bars (re-bar) is lowered in and concrete is poured into the excavation.

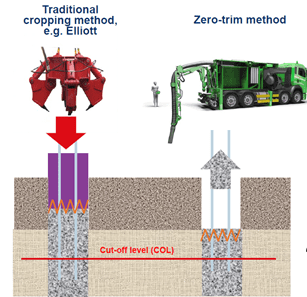

When a pile is cast, the concrete at the top layer is contaminated with polymer or bentonite fluid that’s used to retain granular material and support the excavation. The concrete is over poured above the cut off level (COL) and then after curing is removed leaving the re-bars exposed to act as starter bars for the structure or capping beam being constructed above. The adoption of a suitable pile breaking method can result in financial and programme savings and most importantly will address and reduce potential health and safety issues in relation to this phase of the works.

Traditionally this task of breaking out the concrete above the COL was done with a breaker or jackhammer, with operatives carefully trying to break out just the contaminated concrete and not damage the re-bar or good concrete below the COL. Other established methods use a pile cropper mounted on a 3600 excavator or high pressure water to remove the concrete above the COL.

The traditional method has health and safety risks associated with HAVS, confined space work, silicosis and working at height. Using a pile cropper eliminates some of these risks but still creates dust and risks damage to the concrete below the COL or the steel starter bars and using high pressure water requires specialist equipment and contractors onsite.

The “zero trim” pile technique that has been trialled and will be used by SCS JV for contiguous piles in Area East and D-walls in Area Central involves the use of a vacuum excavator (vac-ex) to immediately suck up the over poured, contaminated concrete down to cut off level before curing. The pile is then backfilled with shingle and the vacuumed concrete recycled. This has benefits in time, cost and quality as well as health and safety – over the 750 contiguous piles in Area East it is expected to save 60,000 working hours breaking piles and save over £374k of costs associated with pile cropping.

Methodology

The pile is drilled as normal under the support of bentonite or polymer support fluid. Reinforcement cages are lowered into place as required. Tremie pipes are lowered into the pile and concrete poured through them to fill the pile from the bottom up with the support fluid being taken away for treatment and reuse. The concrete is poured above the cut off level (COL) as the top layer of concrete will be contaminated with the fluid. The vac-ex is used to take the excess concrete and fluid mix away and reduce the level to the cut off level, exposing the re-bar to be used as starter bars. If required (generally for tension piles where the COL is a long way below ground level) the casing is then filled with shingle and removed.

Benefits of Zero Trim Piling

- This technique removes the need for any work that will cause HAVS, silicosis or confined space work. There is no noise from breaking the concrete out however the vac-ex is noisy and PPE as well as collective noise barriers can be used to mitigate this risk.

- The vac-ex is compact and can fit onto any site where a concrete wagon will discharge and its small boom allows it to operate close to site boundaries (including ones with restrictions such as Network Rail (NR) boundaries without additional restrictions in place.

- There are significant carbon savings in the technique as the over pour is less than with traditional methods. For the 1,140 piles in Area East of the SCS JV work on HS2 it is estimated there will be a saving of 820,000 kg of carbon dioxide emissions.

- There are further positive benefits, including noise reduction which is important for projects like HS2 where construction is taking place within communities and near operational businesses. There are also considerable cost savings and environmental benefits as the new technique uses less concrete, reducing carbon. On the SCS sites the extracted concrete is being retained on site and being reused in construction elsewhere. This reduces carbon in construction, including through reduced lorry movements to and from site.

Trials of the method have been completed and the concept proved. Further data proving the quality and refining the method are ongoing on both temporary and permanent works for SCS on HS2.

I’ve anecdotally been old this method has been trialled in other parts of the world but have not been able to find any literature to evidence it. As far as we are aware at SCS this method hasn’t been used in the UK ever. If anyone can shed any light or knows otherwise please let me know.

Further information can be found in various media articles in the comments and if anyone is interested in more details I can send you a TMR on the topic.

An alternative view of the South Bank Tower from Tower Crane 1

A flavour of Mace projects in the city

Last week I visited 5 Broadgate which is another Mace site. It is right by Liverpool Street Station and is prime banking territory. UBS is having built a 700,000 sq ft building, based on a single block form, with a gun- metal grey finish. At 12 floors it will include up to four trading floors, each able to accommodate approximately 750 traders, allowing UBS to consolidate its London trading operations into one building.

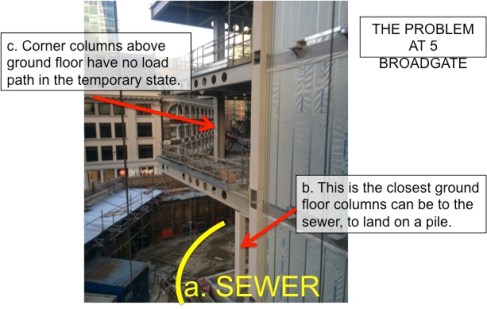

So here is the problem:

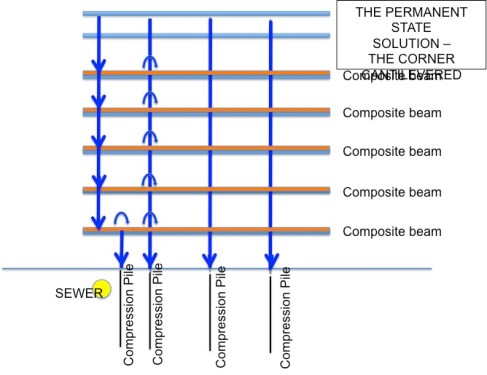

In order to overcome this issue the corner would be hung from a truss on the roof as well as Macalloy hangers on the 1st and 2nd floors.

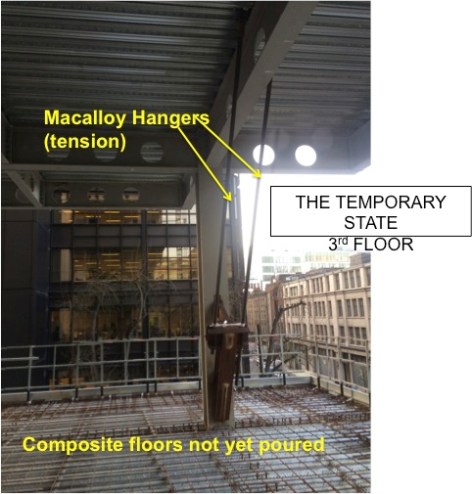

Here is a picture of the 3rd floor with the Macalloys in use

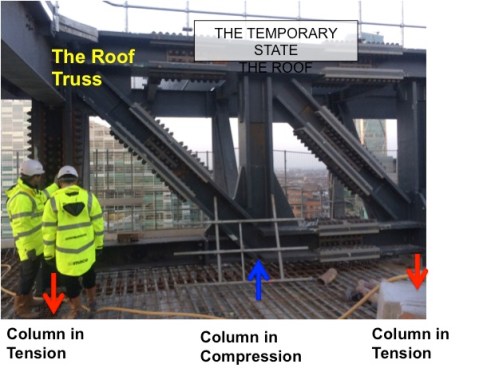

The (big) truss on the roof cantilevers out to allow the perimeter column to hang in tension and suspend the corner. Jacking was used to ensure it had ‘picked up’ the perimeter.

This system seems to have worked well on site. It is reasonably simple to set up and control (with jacking). Mace plan to pour all 11 floors of corner concrete at once so that there is no differential movement between the floors. The Macalloys and roof truss will be ‘stressed’ so that any elastic extension is accounted for with pre camber.

On the South Bank Tower we will also be using Macalloy cables, but ours will be used in the permanent design. The proposed force in them will be 7600kN. Anyone else got any experience with them?