Archive

Thoughts on Quality Assurance

Introduction. From my time on phase 2 I have been heavily involved with quality management and, for the sake of discussion, I thought I’d articulate what I’ve learnt. If anybody in the UK or Aus has been similarly involved in QA or would like to provide additional comments on the alternative perspective, I welcome your thoughts and insights.

Quality Assurance is an interesting and broad topic that:

- forms an integral element of USACE’s role as the client’s representative

- comprised a large majority of my day-to-day activity on phase 2, and

- provided good links into the full breadth of engineering activities from project scheduling, contract management, finance, safety, and technical engineering.

The following paragraphs highlight what I believe to be the key elements of QA from my experience to date, pointers on how to ensure it is covered effectively along with a little info on some issues faced on the JOC project. It is not exhaustive and it began to run the risk of progressing into a full-blown essay – Please feel free to ask for more detail on anything you’d like to know more on.

The Preconstruction Conference. Prior to any construction work, these are held in order to ensure mutual understanding i.e between the client and principle contractor. It is apparent that these are often not done properly with patchy attendance from the quality team. The Contractor quality control (CQC) team is fundamental to ensuring the quality of the finished product so the whole CQC chain of command should be included in these meetings. This ensures a proper understanding of the client’s priorities and design intent are passed on to the QC and QA team members with less opportunity for misunderstanding or interpretation.

The Quality Assurance Plan. This are an excellent management tool but is often neglected or not even written but, without them, co-ordination of QA objectives can be extremely difficult. This must be considered a high priority for anybody involved in the management of a large project and is particularly pertinent to our future role as PQEs. East Campus is fortunate to be in possession of a detailed QA plan and its content can be broken down into the following sections:

- Govt staffing requirements and the functions of each QA team member

- Govt trg requirements and qualification levels required for each team member

- Govt pre-award activities

- DFOW list (see below)

- Govt monitoring and testing activities (responsibilities, frequency, detail, standards referenced)

QA reports. Similar to a site diary for supervision of site work, quality management requires accurate daily reports. These often seem tedious and unnecessary at the time of writing but invaluable several months later when a claim is received from the Contractor. As a rule, the daily reports should include details of:

- Meetings attended and instructions given

- Results of tests, deficiencies observed in work and actions taken.

- Developments that may lead to a change order or claim against the government (bad weather, RFIs received or design conflicts/deficiencies identified).

- Progress of work (incl manpower and equipment on site), causes and extent of delays.

- Safety Issues.

Deficiency tracking system. Elements of work which the QA team believe fail to meet the requirements of the contract must be recorded in a database for monitoring. This allows the client to know how much work was completed right first time and also prevents deficient work being covered up and forgotten. This is particularly important as, from my experience, contractors prefer to separate their production and CQC with deficient work often being monitored and corrected by a separate ‘Tiger team’ once work has moved forward. The deficiency list must be updated regularly with status, and dates of corrective action. From experience, I can confirm that this action is always best performed before the sub-contractor leaves the site!

Defined Features of Work (DFOWs). Any item of work with a separate and distinct method of applied QC including inspection, testing and reporting can be considered a DFOW. The principal is close to that of producing a product or work breakdown (PBS or WBS) with the addition of each DFOW item containing detailed lists of paperwork required from the contractor, products to be used, preparation and execution requirements, and testing & inspection regime for acceptance. For me, I often found myself relying on this paperwork more than the drawings to understand and QA the work I was responsible for.

Control phases. USACE conceptualize quality control into a three phase process consisting of a preparatory phase, initial phase and, finally, an acceptance phase. More often than not, quality issues on site can be attributed to a failure in the preparatory phase, making it the most important from a QA perspective. This may run counter-intuitively to anybody that views the QA team as primarily focused on the acceptance process. Briefly, the ‘prep phase’ should answer the following questions:

- Are materials on hand, and if not, when and how will they be arriving & stored?

- Are delivered materials as per the contract requirements and stored properly?

- What exactly do the contract specifications and submitted paperwork require to happen?

- What is the procedure for accomplishing the work? i.e sub contractor’s method of works, including health and safety assessment and sources of potential conflict etc…

- Are we all happy? This is a final chance for parties to air concerns with the plan or nature of work. The cost and time implications of discussing these concerns later will often be much higher so is quite important.

As built drawings. This is an important product for the end-user. The team here in East Campus hopes for updated drawings every month but the contract only requires them upon final completion. This can frustrate attempts to review work and identify conflicts before they become issues. It is recommended that, if possible, submission of these is specific and agreed in writing with appropriate penalties for failing to comply. To be effective, a review procedure must be in place.

Quality Assurance Testing. The general rule followed by USACE is that QA should test the work at approximately 5% of the Contractor’s QC frequency. This commitment to, basically, duplicate work the client has already paid the Contractor to do should be understood and appreciated in terms of the workload generated for the QA team as well as the value gained by the client in terms of verifying the Contractor’s efforts. I have, at times, felt that the Contractor has taken advantage of this overlap of responsibilities, making the following point even more relevant.

Quality Control Requirements. The Contractor must be required to provide the CQC function in terms of the roles performed and the qualifications of those that perform them. My greatest issues with the CQC team on the JOC project have been:

- QC being performed by unqualified personnel (an electrical engineer inspecting the placement of reinforcement for structural concrete)

- Double-hatting manpower (fine until you have a full day of concrete placement and your QC rep has to supervise it “remotely” as they’re elsewhere on site inspecting other features of work – ensure the contract specifies different roles as “not to be performed by an individual performing other role” if possible)

- 3rd Party testing inspectors being considered sufficient (Relying on the concrete testing technician to QC a concrete placement – the contractor is now demolishing $44,000 of concrete pavement because of this. Unsurprisingly, the technician was only concerned with slump testing etc… and not the location of expansion joints or texture applied during finishing).

Baseline schedule. Is it submitted by the contractor and accepted by the relevant engineer / manager? Is it resource loaded, with updates (complete or just status) submitted monthly? A function of QA is to identify potential delays and to do this, comparison must be made between the schedule and actual progress on site. Identifying potential delays or poor progress early can help prompt the contractor into recovering time before it becomes an issue.

Summary. Ultimately, a much longer post than I had originally intended. Hopefully, it gives you a flavor of the nature of QA work and can function as a starting block for anybody responsible for establishing the quality management process on future projects.

Quantity vs Quality

Quantity vs Quality

3 months into my placement, I have learnt a number of lessons. However, the most prolific, which seems to define the difference between success and failure, is that quantity (or at least payment thereof) is irrelevant without quality. Whilst this should evoke confidence that the final product is ‘defect free’, rigid insistence that the final product is 100% compliant with the original specification, can cause costly and at times unnecessary delays. A couple of examples are as follows:

Re-profiling

Re-profiling works are almost complete….well, according to the Contractor?! With only 60m left to go, Vinci are understandably looking to the Client to sign the Substantial Completion Certificate in order to receive payment for the works. The key problem is agreeing the methodology for checking levels, agreeing what substantial completion actually means and trying to interject a level of common sense into the process. Approximately 80% of the re-profiled area is within the -45mm tolerance, inevitably however, there are a few spots which are outside this tolerance. It has been deemed that a laser level will be most suitable for checking the entire 6.6km2 area, by dividing the slab into sections of even gradient. The Client is proposing that all points outside the tolerance be raised in a Non-Conformance Report, and a Substantial Completion Certificate will not be issued until the works are 100% compliant with the original Project Managers Instruction (PMI) (i.e. lowered or ‘raised’ to be within tolerance). The Vinci stance, (well at least at Section Engineer level) is that the slab will be covered by a minimum of 80mm of blinding before the final rail slab is placed, therefore what is driving this degree of accuracy? A decision is yet to be made but at £800 per day to hire the Rockwheel, Vinci are understandably keen to reach an agreement soon.

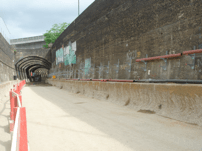

Western Approach Ramp re-profiled to SSL (note constant seepage).

Western Approach Ramp re-profiled to SSL (note constant seepage).

Eastern Approach Ramp re-profiled to SSL (note drying out of ramp following initial seepage).

Eastern Approach Ramp re-profiled to SSL (note drying out of ramp following initial seepage).

Piling

Piling is now progressing well and the Continuous Flight Auger Piles (CFA) and Controlled Modulus Columns (CMC) are finally complete on the West Surface Site, and have since moved to the East Surface Site. The piling works are considerably over budget and more than 8 weeks delayed. 6 changes of sub-contractor team would suggest there were some internal problems, however, a substantial percentage of delays were attributed to stringent Client quality control procedures. Whilst there is no arguing that the Client has every right to check contractor and sub-contractor works, a team based approach to problem solving, and a spirit of ‘mutual co-operation’ was often replaced with inflexible procedures and unpredictable responses at inspection points.

The last of the CMC piles on the West Surface Site, from the site boundary to the top of the Approach Ramp

The last of the CMC piles on the West Surface Site, from the site boundary to the top of the Approach Ramp

Whilst the examples given demonstrate how a degree of Client flexibility could facilitate the construction and handover process, the bottom line remains that the contractor proposes and agrees the Inspection & Test Plan (ITP) before works start. The difficulty I have experienced when writing ITPs, is knowing how much detail is required to effectively monitor work and control quality, without impacting too much on production (i.e. ‘quantity’). The key is including sufficient Witness Points, whilst ensuring that the parameters for Hold Points are fully understood, agreed, and can be met.

In my opinion, a consequence of convoluted Client ‘Acceptance’ procedures, is that not enough time and consideration (by both Client and Contractor) is dedicated to devising suitable ITPs. The focus is gaining Client ‘Acceptance’ by the quickest possible means in order to start production. Inevitably, the problem then comes at the first Hold Point, where ‘quantity’, if it is not of the agreed ‘quality’ rapidly becomes wasted effort.

The risk for a contractor or sub-contractor of not providing the predicted ‘quantity’ within an agreed time is mitigated by an elevated tender price, and the ‘unforeseeable/exceptional circumstances’ clause. However, the impact of not fully understanding, or being 100% compliant with the pre-agreed ITP can have far wider reaching consequences; and there are no clauses for damages!

An exception to the rule….

Dewatering The Chalk and Thannet dewatering wells were turned on 3 weeks ago and the ground water is now being pumped into the docks. Piezometer readings are being used to gauge progress, and a Chalk well pump was replaced with a smaller one, after results showed that the well was actively (as opposed to passively) drawing down the water level thus risking differential settlement in surrounding strata. In this example, the ‘quantity’ of water, is inextricably linked to the success of the works, and unlike the examples above, is ultimately a measure of the ‘quality’ of the scheme. Interestingly however, if the dewatering is unsuccessful the risk sits with the Vinci. The sub-contractor carries no responsibility, despite the dewatering scheme being their design. And presumably, if the proposed scheme is not effective (i.e. the ‘quantity’ of water draw down not achieved), the sub-contractor will revise it – for a price!