Archive

Transition to the USACE Design Office at 2 Hopkins Plaza

With the cobwebs of Christmas and New Year finally gone (along with AER 4) I thought it was about time I wrote an update of my attachment in the USA.

As of mid-December, I was able to handover the majority of my work at the East Campus in Fort Meade to a young and overly energetic intern. With the majority of the project complete and the main effort shifted to the architectural team’s handover of internal rooms and the mechanical team’s underfloor air distribution (UFAD) testing and commissioning, I almost felt a little sorry for the guy – arriving with so little civil works left to complete. From me, he inherited responsibility for:

- Processing and distributing the daily submittals from the contractor,

- Supervising the production of as-built data for the site’s sustainable storm water management (SWM) systems.

- Supervising the placement of internal roads (a combination of pervious, and impervious concrete), and

- Supervising the contractor’s application of erosion and sediment controls on behalf of the State’s department of the environment.

Surprisingly, he seemed a little overwhelmed and concerned that some of the work allowed him to make decisions and issue site instructions. I hadn’t realised how accustomed the army and such a short time spent on Phase 2 had made me to making decisions and accepting responsibility. In his defence, I suppose he hadn’t even been qualified for a year and speaking to him later, it became apparent that USACE severely warns them against obligating the government to anything not already in a contract (for those just finishing up on Phase 1, remember this and don’t be overly critical of yourself when it comes to judging attribute competences).

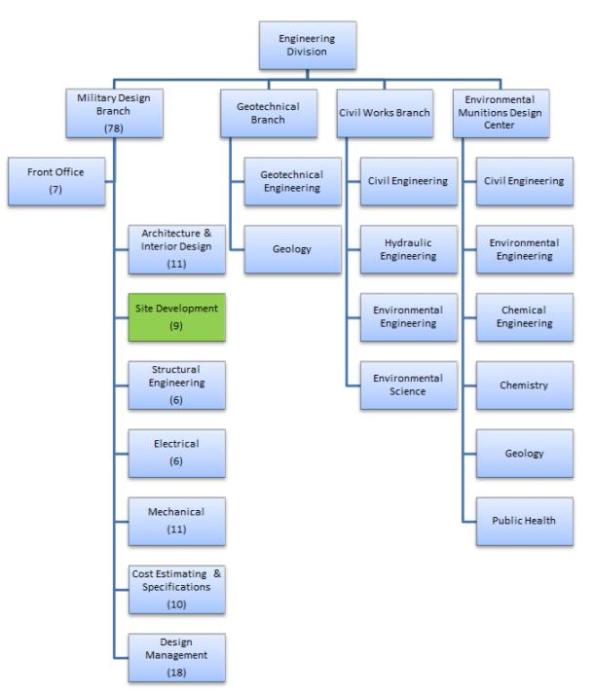

Closer to the present, January in Baltimore has been an intense combination of very, very, very cold weather and also my re-introduction to technical engineering. After a full 8 months of performing QA of “horizontal construction” (drainage and grading, pavements and slab-on-grade with a little bit of footing work), I have commenced Phase 3 by assuming a design engineer role in Baltimore City. From now until the end of June, the intent is to work within the USACE Site Development Section performing a broad range of infrastructure and site design tasks. A small hierarchy made for AER4 showing my location within what is effectively USACE’s Baltimore design office is shown below:

The parent organisation of the site development section is the Military Design Branch. These approx. 80 personnel design and supervise the construction of DoD facilities across an area of responsibility approximately similar in size to England and Wales. This work includes “in-house” design for DoD organisations and the technical review of in-progress or completed Architect/Engineer designs by third parties.

My main role includes a number of small tasks that essentially see me designing sustainable drainage solutions for DoD installations. The scale varies from designing systems to manage surface water volumes from design storms (normally the 1 in 2 and the 1 in 100 year storms) to designing retrofits that ensure pollutant loads such as Nitrogen, Phosphorous, and total suspended solids are reduced in the “first flush” of 1.0 inches of rainfall.

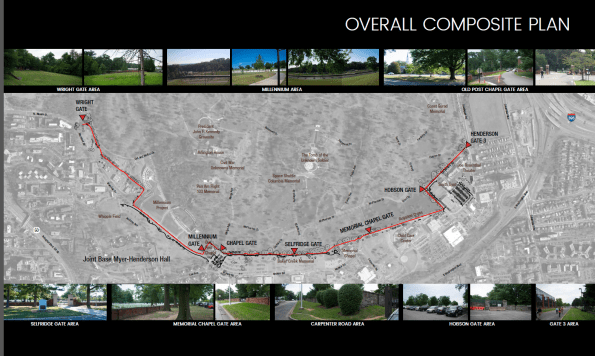

I will also soon be designing stormwater management aspects of a 2km perimeter fence that is going to be installed in Ft Myers, not far from DC and the Pentagon. Strangely for the US military, a large section of the perimeter since the late 19th century has been a 4-ft high stone wall. A number of recent incidents have occurred involving French tourists getting lost in the neighbouring Arlington National Cemetary and ‘hopping the wall’ to get to what they think is a nearby strip-mall. Unsurprisingly, the DoD has decided it may be time to increase the level of security. In addition to designing the profile and construction details of the fence plus integrated cameras etc… the project also requires consideration of bisecting drainage channels, the construction of a new car park and creation of additional SWM to account for the increase in impervious surface areas.

As we’re still waiting for the client to decide on the contract vehicle for this work, USACE and I are still a little unsure on the level of design work required but we hope to get an answer fairly soon. Until then, here are some unclassified graphics pilfered (with permission) from the department’s project folder (yes, that is a design engineer’s attempt at doing before and after concept work using photo-shop):

Thoughts on Quality Assurance

Introduction. From my time on phase 2 I have been heavily involved with quality management and, for the sake of discussion, I thought I’d articulate what I’ve learnt. If anybody in the UK or Aus has been similarly involved in QA or would like to provide additional comments on the alternative perspective, I welcome your thoughts and insights.

Quality Assurance is an interesting and broad topic that:

- forms an integral element of USACE’s role as the client’s representative

- comprised a large majority of my day-to-day activity on phase 2, and

- provided good links into the full breadth of engineering activities from project scheduling, contract management, finance, safety, and technical engineering.

The following paragraphs highlight what I believe to be the key elements of QA from my experience to date, pointers on how to ensure it is covered effectively along with a little info on some issues faced on the JOC project. It is not exhaustive and it began to run the risk of progressing into a full-blown essay – Please feel free to ask for more detail on anything you’d like to know more on.

The Preconstruction Conference. Prior to any construction work, these are held in order to ensure mutual understanding i.e between the client and principle contractor. It is apparent that these are often not done properly with patchy attendance from the quality team. The Contractor quality control (CQC) team is fundamental to ensuring the quality of the finished product so the whole CQC chain of command should be included in these meetings. This ensures a proper understanding of the client’s priorities and design intent are passed on to the QC and QA team members with less opportunity for misunderstanding or interpretation.

The Quality Assurance Plan. This are an excellent management tool but is often neglected or not even written but, without them, co-ordination of QA objectives can be extremely difficult. This must be considered a high priority for anybody involved in the management of a large project and is particularly pertinent to our future role as PQEs. East Campus is fortunate to be in possession of a detailed QA plan and its content can be broken down into the following sections:

- Govt staffing requirements and the functions of each QA team member

- Govt trg requirements and qualification levels required for each team member

- Govt pre-award activities

- DFOW list (see below)

- Govt monitoring and testing activities (responsibilities, frequency, detail, standards referenced)

QA reports. Similar to a site diary for supervision of site work, quality management requires accurate daily reports. These often seem tedious and unnecessary at the time of writing but invaluable several months later when a claim is received from the Contractor. As a rule, the daily reports should include details of:

- Meetings attended and instructions given

- Results of tests, deficiencies observed in work and actions taken.

- Developments that may lead to a change order or claim against the government (bad weather, RFIs received or design conflicts/deficiencies identified).

- Progress of work (incl manpower and equipment on site), causes and extent of delays.

- Safety Issues.

Deficiency tracking system. Elements of work which the QA team believe fail to meet the requirements of the contract must be recorded in a database for monitoring. This allows the client to know how much work was completed right first time and also prevents deficient work being covered up and forgotten. This is particularly important as, from my experience, contractors prefer to separate their production and CQC with deficient work often being monitored and corrected by a separate ‘Tiger team’ once work has moved forward. The deficiency list must be updated regularly with status, and dates of corrective action. From experience, I can confirm that this action is always best performed before the sub-contractor leaves the site!

Defined Features of Work (DFOWs). Any item of work with a separate and distinct method of applied QC including inspection, testing and reporting can be considered a DFOW. The principal is close to that of producing a product or work breakdown (PBS or WBS) with the addition of each DFOW item containing detailed lists of paperwork required from the contractor, products to be used, preparation and execution requirements, and testing & inspection regime for acceptance. For me, I often found myself relying on this paperwork more than the drawings to understand and QA the work I was responsible for.

Control phases. USACE conceptualize quality control into a three phase process consisting of a preparatory phase, initial phase and, finally, an acceptance phase. More often than not, quality issues on site can be attributed to a failure in the preparatory phase, making it the most important from a QA perspective. This may run counter-intuitively to anybody that views the QA team as primarily focused on the acceptance process. Briefly, the ‘prep phase’ should answer the following questions:

- Are materials on hand, and if not, when and how will they be arriving & stored?

- Are delivered materials as per the contract requirements and stored properly?

- What exactly do the contract specifications and submitted paperwork require to happen?

- What is the procedure for accomplishing the work? i.e sub contractor’s method of works, including health and safety assessment and sources of potential conflict etc…

- Are we all happy? This is a final chance for parties to air concerns with the plan or nature of work. The cost and time implications of discussing these concerns later will often be much higher so is quite important.

As built drawings. This is an important product for the end-user. The team here in East Campus hopes for updated drawings every month but the contract only requires them upon final completion. This can frustrate attempts to review work and identify conflicts before they become issues. It is recommended that, if possible, submission of these is specific and agreed in writing with appropriate penalties for failing to comply. To be effective, a review procedure must be in place.

Quality Assurance Testing. The general rule followed by USACE is that QA should test the work at approximately 5% of the Contractor’s QC frequency. This commitment to, basically, duplicate work the client has already paid the Contractor to do should be understood and appreciated in terms of the workload generated for the QA team as well as the value gained by the client in terms of verifying the Contractor’s efforts. I have, at times, felt that the Contractor has taken advantage of this overlap of responsibilities, making the following point even more relevant.

Quality Control Requirements. The Contractor must be required to provide the CQC function in terms of the roles performed and the qualifications of those that perform them. My greatest issues with the CQC team on the JOC project have been:

- QC being performed by unqualified personnel (an electrical engineer inspecting the placement of reinforcement for structural concrete)

- Double-hatting manpower (fine until you have a full day of concrete placement and your QC rep has to supervise it “remotely” as they’re elsewhere on site inspecting other features of work – ensure the contract specifies different roles as “not to be performed by an individual performing other role” if possible)

- 3rd Party testing inspectors being considered sufficient (Relying on the concrete testing technician to QC a concrete placement – the contractor is now demolishing $44,000 of concrete pavement because of this. Unsurprisingly, the technician was only concerned with slump testing etc… and not the location of expansion joints or texture applied during finishing).

Baseline schedule. Is it submitted by the contractor and accepted by the relevant engineer / manager? Is it resource loaded, with updates (complete or just status) submitted monthly? A function of QA is to identify potential delays and to do this, comparison must be made between the schedule and actual progress on site. Identifying potential delays or poor progress early can help prompt the contractor into recovering time before it becomes an issue.

Summary. Ultimately, a much longer post than I had originally intended. Hopefully, it gives you a flavor of the nature of QA work and can function as a starting block for anybody responsible for establishing the quality management process on future projects.

Damage to buried pipelines

Whilst enjoying a Friday morning lull in tempo, I thought I’d produce a quick post updating everyone on a small portion of my work on the Joint Operations Centre (JOC) Project; a part of the wider East Campus program.

Work thus far has been varied with business as usual mostly focused on construction contract administration, quality control management, and project engineering. Additionally, the project’s lead engineer often gives me additional tasks which can almost be viewed as projects. The latter mostly concern issues on site that need a combination of both project management and technical understanding to resolve. As an example, one of the first tasks given to me concerned cracked valves in one of the underground pipe networks, which will be the topic of this blog post:

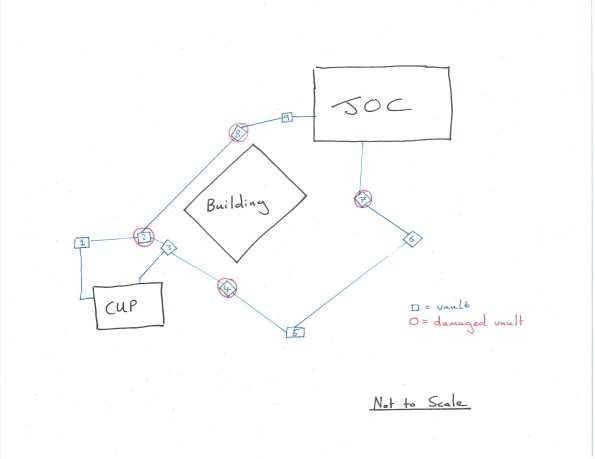

The majority of the JOC’s cooling is performed by chilling water in a separate building, the central utility plant (CUP). Chilled water is pumped from this plant to the JOC, where it is warmed at heat exchangers before returning to the CUP to repeat the cycle. The path between CUP and JOC is interspersed with mechanical vaults that allow maintenance and access to a number of valves on the underground pipe network (See hand sketch below – the blue line indicates the pipeline and includes both supply and return pipes; note the redundancy with two paths). Unfortunately, a number of valves within these vaults became damaged with large cracks appearing in the fittings. Testing of the valves confirmed the damage was to be caused by flaws in the design or fabrication of the valves. I was tasked with leading the root cause analysis and resolution of the issue.

Surveys of the damage suggested the cause lay in excessive settlement of the pipes between several mechanical vaults. By modelling the pipes as strip foundations, I was able to use Burland and Burbidge’s method to produce a ‘fag-packet’ calculation of expected settlement that corroborated this hypothesis (survey data indicated actual settlement almost 3x greater than predicted).

I was then responsible for co-ordinating numerous meetings between contractor, client, the designer of record and ourselves (USACE are the client’s representative) in order to agree a path forward. As you can imagine, nobody admitted fault and neither was anybody prepared to spend money to prove where fault actually lay. Stuck in a catch-22 situation, I was able to persuade the general contractor, Hensel Phelps (HP) into hiring a geotechnical engineer to investigate the issue. I was also able to secure financial authorization to get the designer (AECOM) to evaluate the results of my own investigations and provide recommendations. This was to also include copies of the designer’s original work, confirming the expected settlement of the pipe under assumed loading. This report, after a number of returns due to missing information, finally arrived yesterday. AECOM’s design used the modified Iowa formula – a well-recognized method of calculating displacement in laterally loaded “flexible” pipes (I must admit, one of the surprising revelations during my analysis was the fact such large steel pipes are considered flexible). The difference between using my Burland and Burbidge method and the modified Iowa formula was my results suggesting 50% more settlement (3/8 inch compared to ¼ inch). However, this may have also been caused by AECOM’s grillage analysis and subsequent live loading on the pipe being slightly less than my own.

On site, HP, has already completed replacement of damaged pipe sections. They have also performed additional remedial work within the vaults by unbolting undamaged connections, allowing free ends to deflect and reconnecting with specially fabricated ‘offsets’. On the basis that the soil is coarse grained (so long term settlement is less of a concern) and the stresses from settlement have been released through the disconnection program, it is “hoped” that the issue has therefore been resolved.

Presently, the plan is to attach strain gages to the newly connected sections and monitor for future settlement; my work to confirm what happens (and who pays) if the strain goes beyond the agreed threshold continues. The contractor is only liable for damages and the costs of repair and replacement for a year after final acceptance – after which, the costs sits with the government who would then need to prove fault and take legal action to cover damages from either the contractor or designer.

The whole experience has taught me a lot about the contractual relationships within both construction and also large government projects. It’s also developed my management skills in terms of co-ordinating multi-disciplinary and stakeholder meetings (in this instance mostly mechanical engineers are involved as it concerns their feature of work, but I’m also getting a lot of exposure to electrical and commissioning engineers in another of my roles).

Finally, I’ve noticed that I’m far more understanding of the general contractor’s stance during periods of conflict compared to USACE management, who are often very untrusting; I put this down to my relative independence compared to the rest of the team here but I suppose it could also be a result of something personal, cultural, or my military background. Has anybody else observed something similar or different on their projects?

Finally, a teaser for anybody on phase 1 currently considering the USA as your attachment location. the rendering below shows the initial architectural concept for the East Campus program (It’s one of the few images of work that are releasable – The JOC and its large rounded roof is on the far left of the picture). There will be work here for at least another decade with multiple opportunities to cover several projects simultaneously, all at different stages of construction. If you’re interested and would like to know more (both civil and E&M), just get in touch!

First forays in America

Introduction

Howdy Y’all! Before coming out here Stu made me promise three things:

- Not to go native

- not to go ‘off grid’

- Not to get arrested/shot.

Because of that, I thought I’d at least try and stick to promise #2 by entering the blogosphere to provide an update on my attachment to date.

In all, getting Helen and I settled into the USA took the better part of an entire month. This was mostly spent running around trying to do things that we would otherwise take for granted in the UK but which are actually quite hard to do when you’re an alien in a foreign country. In America, you can’t do much without a social security number and a credit rating and this can complicate the already large task of setting up bank accounts, transferring a large amount of money from the UK, renting a house, buying a car, signing up for utilities and getting a phone. Most is solved by providing a very large security deposit for everything that you would normally pay by direct debit (which the US banking sector still don’t seem to have quite right…). To give a few examples, we had to pay the gas and electric supplier $300 dollars as security, COMCAST got a $150 advance for our internet, and AT&T wanted $1,000 as a security deposit for Helen and I to take out a phone contract – it was more than the cost of the handset and bundled tablet so we cancelled that transaction, opting for pay and go with a phone bought outright!). The arrivals process is also quite linear in so much as the outcome of one admin piece provides an additional proof of identity that gets you one rung higher on the ladder. Unfortunately, this means that any delays caused by an incorrectly filled out form, an absent member of staff, or freak weather event and you’re stuck treading water until you can complete that activity. Thankfully, most American institutions are surprisingly helpful and forward leaning. The process isn’t seamless (I’ve been to the Maryland Vehicle Authority twice and still haven’t finished the application for my driving license – a requirement for owning a car). Thankfully, the accent and a military ID gets you far; Helen was enrolled onto health care without a birth certificate despite it being an essential document… and I’ve only been able to get to work this last fortnight thanks to the MVA and car dealership allowing me to drive around with a set of trade plates.

…I am, however, less impressed by the embassy’s role in the arrival process who seem to hinder things more than they support…

But anyway; on to the engineering!!

The Project

Similar to earlier iterations, my attachment with the US Army Corps of Engineers (USACE) has placed me in the ‘East Campus’. This is located in Fort Meade, Maryland, which is just under an hour north of Washington, DC, and half an hour south of Helen and I’s new home in Baltimore. The East Campus “project” is actually a programme of smaller design and build projects, the focus of which currently sits with the Joint Operations Centre and its supporting infrastructure; the facility is essentially an attempt to create a “campus feel” and center of excellence attracting talent to an area that is already home to US Cyber Command, the NSA Headquarters, and a few other interesting organisations.

The main elements within the JOC project are:

- A 24/7 operation centre with “battle bridge” – Think of something akin to the Bourne series or even NASA mission control… but bigger.

- Collaboration areas / meeting rooms

- Office space

- Break rooms and canteen space

- E&M services and systems. This is going to become critical national infrastructure and pretty much everything has backups to the backup.

- IT and comms

- Security systems including everything needed to prevent surveillance such as EM and acoustic shielding (required for the structure to serve as a Sensitive Compartmented Information Facility – SCIF)

- Environmental and architectural features such as storm water management, replanted woodlands, and boulevards to create an “aesthetic open space” that earn the project LEED points (similar to BREEAM).

Where I fit in

Unfortunately, there’s not a lot I can write about yet… I have now been in the office for an entire fortnight but I’m still only part way through the bureaucracy of getting un-escorted access to the site and government IT systems. USACE is not the contractor for this project, but rather the client’s representative. As the interface between Henson Phelps (the principle contractor)and the government, USACE conduct quality assurance, investigate and respond to RFIs and administer contract changes on behalf of the clients (the ultimate owner of the site will be the NSA but different government departments are providing the funding for different elements of the project – current work is a mix of Air Force and Marine Corps).

There is also a project management element in terms of keeping an eye on the activity schedule and holding the contractor to account. By providing a pragmatic and technically-capable buffer between client and the principle contractor, I also believe USACE helps control the budget and schedule . In my two weeks here, I have already seen issues quickly resolved by USACE staff taking positions both in support of and against the principle contractor. This demonstrates a professional working relationship and makes sense. On issues where the contractor is more than likely ‘right’ or at least deserves the benefit of the doubt, USACE’s team can hasten a change in the contract and maintain momentum. At the same time, when there is doubt, the added rigor of the USACE team encourages the principle contractor to admit fault quickly and preventing unjustifiable increases to the client’s costs.

Are people in the UK or AUS seeing similar relationships, maybe with independent auditors?

My tasks thus far:

- Support to the QA team. After shadowing team members on site visits and observing their interaction with the contractors. I’ve now supervised a handful of relatively small concrete pours and a close-in inspection (prior to an internal wall having the plasterboard fitted, there is a detailed inspection of all the features inside to ensure it’s according to the specification – due to the nature of the site, this is taken very seriously). There’s an interesting dynamic that sees construction supervisors from the NSA providing a QC/QA function over sub-contractors, the principle contractor, AND USACE. It’s been interesting watching the resulting discussion when the NSA reps make demands that both the contractor and USACE disagree with… potentially a topic for a future blog post.

- Oversight of the construction of 18 small concrete footings for columns that will support cables connecting two generator farms. This is a simple job complicated by one of those farms being active and inside a separate and very restricted area of this already secure site. The task is made even more difficult thanks to the following:

– critical underground services (gas, electric and diesel) very close to the surface.

– a large open excavation adjacent to the only route in.

– the need for continued work in the generator yard (including testing and commissioning!)The contractor is avoiding the problem so USACE plan on presenting them a construction method to force them into action.

- Oversight of the construction of large numbers of bio-swales (flood attenuation and contamination control features) across the site.

- Investigation of cracked flanges in a series of “vaults”, underground chambers for electrical/mechanical works. There are a number of theories as to what might be happening ranging from subsidence of the pipes connecting them all, buoyancy of the vaults themselves, or simply damage caused by trafficking of overweight vehicles.

Hopefully, I’ll have enough for a decent blog post on the above over the next couple of weeks. I may also post some more detail on the arrivals process and the issues Helen and I have faced. The US attachment has a tradition of updating and passing down an admin instruction to those preparing to come out, however, a quick summary might be useful to those at the start of phase one or in case anybody else is assigned here in the future.

In other news.

As I can’t really upload photos from the site, I thought I’d post a picture of the new car (or at least a picture from google of the same model and colour):

If you drive really carefully and turn the A/C off she almost manages 24mpg; compared to the 50mpg in the old estate, it pretty much counteracts any savings I make from fuel being half the price! Now I just need to go out into the wilderness and justify the fact I own an SUV.

You also can’t take personal vehicles onto site so I’m also now driving these bad boys around (standby for the emergency CASEVAC to the UK once I get un-escorted access and decide to test out the off-road capabilities!):

Chalk and Cheese

I am by no means the computer room cooling specialist at the design office but I have been given another computer room cooling survey job to do. When the work was suggested I jumped at the chance to actually put into practice some lessons learnt from my work at Ft McNair by repeating the process, something I haven’t had the chance to do too much of. A good tick for C4.

The job is a survey and cooling design solutions for the communications closets in the ‘big shop’, USACE’s HQ in Washington DC and the reason I was selected is again because I am the cheapest engineer in the office. This has led me to two thoughts. Why is it always the communication closets that we get called in for? And to compare the clients.

Please won’t somebody think of the communication closets!

Both at USACE HQ and Ft McNair (https://htstrial.wordpress.com/2015/11/11/the-blind-leading-the-blind/) the main server rooms are well served with independent cooling systems. However the communication closets, which largely contain switches for VOIP phones and computers as well as some AV equipment, do not have specialist systems if they have cooling at all. My thoughts of why are:

- If communication closets are added retrospectively as part of a small refurbishment dedicated cooling is either not considered or gets deleted to bring a project under budget because it is a discrete, and possibly disproportionally large, cost.

- In new builds or large office fit outs, because the rooms are small and dispersed by their nature, they are just tied into other systems. Again either because it is easy, or cheap unlike dedicated DX or VRF systems.

- Modern equipment has a higher heat density than its predecessors.

- Creeping regulation. It has been recognised for a while that server rooms require security, indeed I wasn’t allowed into one as I am a dirty foreigner. However the security regulations for communications closets has more recently upgraded them noting their risk. Therefore putting a large efficient grille in the door, leaving the door open or even just putting the switches in the main office are no longer acceptable. But asking the ‘so what’ has been a little slower…

- Any other opinions welcome.

Differing clients.

These clients really are chalk and cheese. This was highlighted by a number of the actions of the USACE HQ team.

- They invited stakeholders. Though I didn’t see who would be paying, I got the warm fuzzy feeling that it wouldn’t be an issue. The facility manager and his assistant, who understand the building which is leased, were there as well as the guys who actually worked on the systems in the rooms. And they were all engaged with the effect they wanted to achieve. At Ft McNair we had a quick chat with the FM, were told they wanted portable coolers, and palmed off with a disinterested programmer who roughly knew where the rooms were.

- They were compiling lists of equipment and its heat rejection. This really is the boring part of the job, which I would be doing, so in my eyes they can pretty much do no wrong. Ft McNair did not have equipment lists. Though presumably they would need them for other purposes than just ours.

- I won’t labour the point but they also had as built plans, answered our RFIs on the spot and were able to talk about emergency power and would research more into the availability of capacity.

So what? Well they actually seemed engaged which made the survey straight forward so, rather than measuring rooms and photographing nameplates, we were able to think and talk through wider issues and solutions. The budget is a lot smaller at $3,000, vs $50,000 for Ft McNair, and Mary has spent half of this just by spending a day out of the office. However, it doesn’t appear that access to money is an issue and as I will be doing most of the work it is irrelevant. My conclusion is not that they are doing the legwork for us because they are short of money, but rather that they are engaged with the project and want to get a positive solution.

CCB – Ft LEE Training Facility

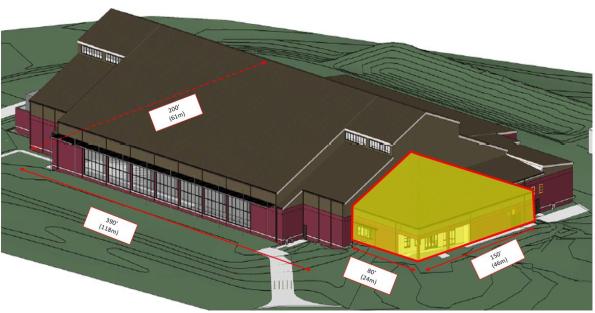

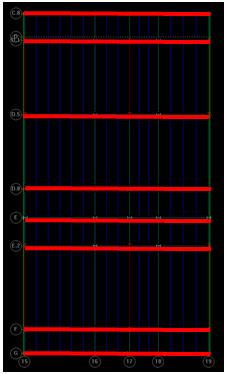

The ‘museum’ is still behind schedule. 95% submission is due mid – late march, a 3 month delay on the original. A rendering of the building is below, with my portion of responsibility shaded.

Ft Lee Training Facility

The larger space is largely progressed however the shaded portion, which is structurally separate, had not been looked at, other than producing a column grid and an interior plan. The promoter intends the space to be open plan admin and teaching space. Therefore a rigid frame layout is required instead of braced. This is comprised of lateral and gravity beams and columns, (with the latter being pinned at the ends, hence not transferring moment). I designed the frame keeping the lateral frames symmetrical as much as possible to reduce torsional effects induced by any wind or seismic loading. If there is not enough rigidity in the structure after running the seismic calculations I have enough ‘spare’ gravity columns which I can make into lateral columns to stiffen up the frame and retain some symmetry.

Structural Frame Design

The loading of the structure has been affected by the Protective Design Center (Sic) (PDC) who have said that the cold formed steel truss system proposed for the roof doesn’t meet blast requirements. This is strange because stud walls and metal decks, which also consist of cold formed steel, are adequate systems. To me this means that either they haven’t been able to test the particular roof truss system in question, or there is an issue with the truss connections. The roof system is ‘designed by others’ so options were to either specify a requirement for hot rolled angles to form the roof truss or provide a second roof. The first option would greatly increase the weight of the roof and affect seismic design as well as costs whilst the second (selected) requires joists and decking. That means that the load paths need to be considered and modelled appropriately. Instead of having the ‘high roof’ which will transfer the wind and snow loads into the frame, sitting across the joists it will sit directly onto the main frame. Modelling roof loading across the flat roof decking would incorrectly increase the joist size and would increase the costs unnecessarily. I will therefore model the ‘high roof’ loading as line loads running across the beam lines as shown below.

High Roof Loading Model

I will input the permanent and variable loads for the roof based on the relevant standards (in the same way as we get our values form the ECs) but I will also need to manually calculate and input the snow drift loads. These, along with the seismic loads have not been calculated for my portion of the building so I am grabbing as many design examples, codes and text books as I can, to handrail. The computer will automatically model the wind and seismic loading which I can cross reference with hand calcs.

Environmentally the site as a whole is legally required to maintain similar conditions to the pre-construction water run off conditions, in line with the Energy Independence and Security Act 07 (EISA 07). This ‘low impact development’ (LID) approach is managed by the civils (site development) department who will design in methods to ensure the targets are met. These targets will be set by the initial site assessment which will look at things such as hazmat risks (POL), asbestos water quality and quantity of run off.

The promoter will budget the costs of the designed measures (swales, pervious parking areas, filter strips, and vegetated buffers etc) which are required to maintain the site at or close to its pre-construction state. The estimated costs are entered as a separate line item on the form that is required to request project funds from congress and are based on 2% of the overall ‘supporting facilities’ cost. This policy is intended to ensure that all government projects have adequate funds available to cover any LID requirements. ‘Supporting facilities’ are anything that isn’t the constructed asset itself and includes such things as the electric, gas and sewer service costs, pavements, storm drains, ATFP and any other site improvement / demo costs. For this project the ‘supporting facilities costs are estimated to be $5.5 million, therefore implementing the LID measures has $110,000 budgeted. This will presumably form one of the constraints on the design. To me the figure feels low considering some of the effort that is required to treat water before it is discharged from site in line with EISA 07, however this line item will be added to all the others for the project and a 5% contingency added to it.

Building 8607 Renovation, Ft Meade. The Design Build RFP (aka ITT) sections are produced by the different departments in the Engineering Branch. I helped the costing effort by producing a rough schedule of quantities expected in the ATFP upgrades. I based this on drawings which were used in the upgrade of a similar project which used the alternate path method of hanging floors using tension rods in the event of a column removal.

With the odd exception most values required by the estimating department were in tonnes, so fixtures and fittings (bolts etc) had to be converted from individual units. Other bits of work, for example welding or demolition of walls, was required in linear or square feet. I was a bit stumped by how I should tackle the installation of the lift but was advised that a line saying ‘1 x lift’ was sufficient! Whilst I was happy enough with that it occurred to me that it would probably be a bit of a waste of time for me to do that because there are people who are much better placed to do it. My value came in understanding the structural components of the ATFP system and being able to dig into the weeds of that. The selected ‘preferred’ ATFP method has been based on the fact that it has been done before, and that is what has dictated the government estimate. However, the contractor may well decide to completely re-build the concrete framing and install a tie force method of ATFP while he’s at it. This could potentially mean that the government estimate is a long way off the contractor estimate which, if realised, will introduce a bit of risk into the tender process because it will increase the complexity, hence increase the duration, of the negotiation process. Having said that we had to start somewhere and using precedent seems as good a place as any in this instance.

Access Control Point, Ft Meade – This project is now due to start in July 16.

CCB – MPD at the Pentagon

Me and Henry got swept up last week in the Baltimore Military Professional Development visit, part of which was to the Pentagon to see a failed project. This portion only lasted a short while so I don’t know all the the ins and outs, but it was interesting none the less and raised some interesting points.

The project itself is to upgrade a goods and service entry point to the Pentagon, and is one of the final upgrades required for the whole site. It’s a job worth a relatively small figure but is fairly high on the Pentagon list of priorities. It was procured on a traditional contract and awarded to what is called an 8A contractor. That is, it was awarded to a smaller ‘disadvantaged’ company in line with the government social sustainability responsibilities. To qualify as a smaller company doesn’t necessarily mean it’s a ‘pikey’ outfit with a white van for a head office, and the company that won the award employs c. 500 personnel. It must also have a history of successful contracts which it will have submitted as part of its tender. As mentioned the contract was terminated by the government for non performance. It seemed that the contractor felt that it couldn’t complete the awarded contract due to the amount of variations it was presented with when it arrived on site. Apparently some of the SI was incomplete and there were a number of underground utilities which were encountered unexpectedly. This seemed strange given that to a contractor variation typically means additional money? Especially on government contracts where I’ve been told that some of the larger principal contractors have a reputation of tendering for work with the aim of tying the government contracts in knots (driving a bus through) and making small fortunes. One theory I can think of is that in adhering to government requirements there are certain administrative obligations placed on contractors. If the contractor was not used to this, which implies a lack of rigour at the contractor selection board, then perhaps it was not especially well set up to comply. This could potentially mean that payments (or a percentage of them) for work were held back by the government. This would affect the contractor cashflow and may have had the opposite effect to that intended. (ie demotivated the contractor)

The contract duration was around 12 months, however in 12 months all that had been installed was some signage and fencing and 4 manholes with connecting runs. Certainly not the progress I’d expect from a competent contractor this hints at a level of ineptitude or lack of direction. At present the Pentagon is demanding of USACE a resolution, which USACE is currently administering. The bonds will be cashed in and go towards paying the contract sum lost for payment of work to date. This will draw a line under the old contractor’s responsibilities under contract which will probably be novated to another principal contractor. The whys and wherefores are probably more interesting the deeper you dig, however because the case is current the guide was very tight lipped. What struck me was the risk that the government takes on in discharging its social sustainability responsibility, particularly on a project at the Pentagon, and the seemingly missed opportunity by the ‘disadvantaged’ contractor which will now likely never win another government job in its future

Design management and leadership

Sorry Mike. No pictures.

You are sure to have heard this phrase before: ‘Sandhurst is the best leadership academy in the world’. I have always had mixed feelings about all that and whether we as the military are as good as the rhetoric, but maybe I’m wrong. I’m not sure if others have had similar experiences in the industry. There were plenty of ‘tense meetings’ in construction, though I can imagine more shouting goes on away from the client; I didn’t really expect it in design though.

I’m not sure if there is any more background to him but the project manager on the Ft Drum NCOA is apparently a known bully. This week’s conference call a shouting match ensued between him and the generally mild mannered design manager. It certainly wasn’t my place to jump in and so I joined my colleagues in gently turning down the phone volume and letting the storm pass. Why? The issue was about a design freeze that had been issued by the project manager due to a VE modification (cutting a 12” slice out of the centre of the building, which clearly has architectural and structural implications). The project manager was arguing that although drawings couldn’t be updated there was still other work that could be done.

So what? The issue with the management of the project in my opinion comes down to two things: communication and the long handled screwdriver:

- On the communication front the project is terribly managed. Meeting minutes are only produced because the Fire Protection Engineer and I produce them as a de facto rather than de jure Other information is continually asked about despite there being a well set up folder structure for IM. Finally, and most relevant in this case, no one had actually told my office that we were to stop modeling; which I pretty much spent the whole of last week doing!

- As for the long handled screwdriver, the project manager is stepping on the design manager’s toes. He has been directing some of the designers and clearly keeping the design manager out of the loop; linking back to communication. Also, and it may just be a bugbear of mine but he uses the word ‘I’ too much as if all the decisions are his; which clearly they are not as he is neither the designer nor the client, rather a conduit for information.

Coming back to the shouting match what really surprised me, and the other Baltimore designers, was that they were arguing in front of us. Whether there are issues in the background or not this does not appear to be the basis of good team building.

CCB – Security is A Very Dirty Word

Doing a Guz “two-fer.”

I’ve been working, briefly, on another renovation. An old laboratory built in the 60’s which is now to have some very heavy server equipment put in it. I say briefly because I’ve been kicked off the project by the client, annoyingly.

The request was to assess whether or not the existing floor could facilitate the server equipment loading. A preferred loading arrangement was given, along with the loads of the individual server equipment. The existing floor is a composite slab, 16″ deep steel beams with a 4″ thick slab on top. The slab should be 5″ but destructive testing proves otherwise. The beams are 10″ o.c and span 30′. I calculated that the capacity of the system was around 240kip.ft [325kN.m] and that an increase in capacity would be required due to the loads imposed by the new equipment. I proposed (or at least I would have) a simple framing system which could either a) tie into the existing steel columns, above the existing floor level thereby effectively suspending the equipment above the slab, which wouldn’t see any of the additional load or b) sit on top of the slab tying in structurally – forming (for want of a better phrase) a concrete sandwich between two steel beams. Both have various pros and cons that I could think of, but what I was surprised about was the magnitude of the additional capacity provided by a steel plate which had been welded to the base of the existing composite beam arrangement. It was a lot! It was an accidental discovery made from messing around with simple hand calcs, and an error I made in missing out the base plate initially. Fortunately I recognised that things were off and I went back to check why, otherwise I might never have thought twice about the numbers. The plate itself is welded to the bottom of the existing steel beam and is .5″ (12mm) deep by 8″ (203mm). So not insignificant. The reason it increases the capacity so much though is because of the change it makes to the second moment of inertia (I) of the whole composite section. The original composite section minus the plate has I of c. 975inch^4. The composite section plus the plate has I of c.1985inc^4. When you apply this to the MIFY equation you can no doubt see the gain in moment capacity; The I has pretty much doubled for a very minor change in y. This could be a neat trick to remember if additional capacity is required but other methods of engineering (say replacing beams, or installing propping) are not viable.

Anyway, like I say I’ve been kicked off the project for being Australian. This was discovered when I called the client to ask for specifics about the server equipment; exact weights, how the loads are transmitted to the ground, sizes etc. Clearly alarmed as to why there was an “Alien” poking about he fobbed me off to somebody else, who wouldn’t pick up his phone and presumably called USACE. Turns out its a classified project. Shouldn’t be a problem thinks my line manager, who knew this. Well it is.

Alan. I’ve said it before, you are entering a foreign country. Brace yourself.

And also:

Since hearing that local Dunkin Do’nuts is closing me and Henry have been doing our bit to increase their take.

CCB – 8607 Renovation

Work has been distinctly ‘bitty’ so far with the proposed work on the Fort Lee Training facility still being just that. A proposal. This is mainly down to IT issues which have now been sorted, thanks to a bit of a whinge to my line manager. To fill the void I have been working on the other renovation project I mentioned in my last post.

ATFP / Progressive Collapse

The output required is the technical specification and tender documentation, which is being produced by a number of different USACE departments (electrical, mechanical, architectural, structural etc) with support from the costing department and PM section. The structure in question is being transformed from an old barrack block into office and administrative space. The main considerations for the structural section have been to do with the anti terrorist force protection and progressive collapse system. The ATFP considerations are required because the costs of the renovation are more than 50% of the total value of the building, which is one of several potential ‘triggers’ in the Unified Facilities Criteria (UFC) documentation. UFC is suite of standardised Department of Defense building codes applicable to all branches of the military. There is currently no progressive collapse or ATFP installed because the construction of the original structure pre-dates the current requirements. The ATFP requirements are classed as minimal, limited to such things as stand off and observation requirements. These are fairly cheap and easy to achieve and can be designed in early provided the designer is given enough real estate to play with. In this case this not a problem and as long as the car park is sufficiently far enough away and no trees get planted with branches lower than 5’ all should be ok. The progressive collapse requirements, triggered by the fact that the structure is three storeys and will be a ‘primary gathering area,’ are more onerous. The UFCs say that for this category of building either Tie Force measures or Alternative Path design is acceptable. This renovation is part of an ongoing programme and both methods have previously been used in similar buildings. The preference is to use a tie force method which will see a large steel beam placed in the roof of the building supporting hanging steel rods in tension at the column locations. These tie into each floor slab, supporting it in the event of column removal. When I say ‘preference’ I mean this is the USACE preference, not necessarily the client’s (the client doesn’t really care how the building is made compliant with the UFCs, just that it is). This is likely because its been used before and is simpler practically than a retrofit alternative path solution. To this end the UFC requirements have been quoted, but only examples of tie force have been provided. But why not just state outright that tie force is preferred? The technical spec seems somewhat to be leading the eventual tenders to arrive at a pre-determined conclusion but is still allowing some room for design innovation. One of the things required for the project, which will not form part of the invite to tender documents is a cost estimate. This allows USACE to get a feel for what the incoming tenders could / should be. I provided a list of quantities of materials I expect will be required for the ‘preferred’ progressive collapse system to the costing team who will build the cost estimate. USACE policy dictates that if incoming tenders are within 10% of the government estimate there is no requirement to go through a negotiation phase to consolidate the difference. So in leading the designers to use the same system then perhaps the cost estimates will be in the same region, potentially speeding up the tender process. Time is, from what I have seen so far, the predominant driving factor on most USACE projects. In allowing some discretion however some cost savings may be realised.

Existing Capacities

The client’s brief will contain a list of requirements to turn the accommodation building into the required administrative and office space. From looking in the UFC I anticipate that this will involve interpreting the requirements and allocating enough space for conference rooms, partitions, storage and general office space. All of these have minimum loading, much like you can find in EN1991. The designer will presumably be trying to find a combination of the above space to meet the client requirements whilst trying to do as little structurally as possible. To help both us and the designer understand how much, if any, work will be involved I’ve provided an annex to the documentation highlighting the existing capacities of the floors.

These are formed from cast in place concrete T sections; 5” beams supporting a 2.5” thick 26” on centre one way slab spanning 24’. The beams have 2 #5 rebar top and bottom (#5 being 5/8” dia.) and the slab has a mesh of undetermined diameter, therefore assumed not to exist. Destructive testing was carried out at numerous locations and most of the above has been confirmed, except mesh was only observed in a few locations. I calculate* that the existing system has a capacity in the region of 17 kip. ft [23kN.m] moment capacity (positive moment) and 16 kip.ft [21kN.m] negative moment capacity and about 4.5 kips [20kN] shear capacity. Using a computer system called Enercalc structural library (if anyones heard of that?) I applied various loading conditions and assess that the designer can do almost nothing without the requirement to increase the capacity of the existing structure. Why is this important, and what have I learned? Its important to know as a client how much you expect your requests to cost. Like taking your car to the garage, you’re much less likely to get ripped off if you know what the likely costs of replacing your brake pads will be. You can either research this yourself or get someone else to do the research, perhaps because you don’t know what a ‘brake pads’ is. In this case USACE is doing the research on behalf of the client so the government department requesting the work won’t get ripped off and can appropriate enough funds from senate to do the work. I learned that clients can be a nuisance. They have yet to identify an end user, but have a few in mind. One of these few has requirements for Sensitive Compartmentalised Information Facility space which sent the electrical and mechanical team into a tizzy. I learned that technical specs and tender documents can provide more than just a bus route for Steve if they are considered properly. They can also do more by saying less in a good way as much as a bad way. I also learned that youtube has lots of really boring videos.

In other news

The snow has gone and I paid $550 to Nissan to fix something on my car. I don’t know what it was called but the flashing light on my dashboard has stopped flashing.

* using a mixture of class notes, text books and a helpful youtube video.