Archive

Snowmageddon

In case you’ve been living under a rock for the last week you’ve probably heard that the East Coast of the US has had some snow. The fervor of the media attention has been comparable with the chance of a dusting in London. We have had about 2 ft so the panic is perhaps a little more justified. In contrast this is considered normal in places such as the mid-west so why is it an issue for the D.C./Baltimore region.

Like most things I suppose it all comes down to risk as the area doesn’t get snow in these quantities it is not as prepared for the volume as other areas. Looking from a Facilities Management/Design Planning perspective I note a couple of things. We design drainage for 100 year rain events but also should think of the snow equivalent:

- Where to put it. Snow takes up quite a lot of space. You can compress it, but only so far. So what? In our condo there are, or should I say were, some outside parking spaces for visitors. Large grass verges have also been optimized, alongside peoples’ front gardens; any grass area is now a snow store. Also side walks, clearly Americans don’t walk so they are considered fair game.

- How to move it. Shoveling 2ft deep snow out of a driveway manually must be hard work; I can see why people died. Snow blowers are awesome for pathways and you could probably do a short road with determination and planning. Snow ploughs are a given. But the rate limiting step seems to be wheeled loading shovels or skid steer loaders. These have the capability of both heaping the snow higher and of moving it around in a more deliberate fashion than just pushing it to the end of a run. In the middle of the city dump trucks have been used to transport snow out of the narrow residential streets.

- Don’t wait for the end. 2ft of snow is difficult to manage, far easier is 1ft of snow twice. This keeps essential lines of communication open, gets everything open quicker and means that smaller equipment isn’t overwhelmed, therefore a broader range of equipment is useful.

- Drainage plans; three things on this.

- Firstly, knowing where the drains are so that they can be cleared to allow the snow melt in, by either marking them with wands, having a site plan of them or both.

- Secondly, putting drains, close to but not in the middle of the forecast snow collection areas. Close to so that there is not a long stream of water to freeze overnight, but not underneath so water can actually get down the drains. This hasn’t been done so well where I live.

- Finally, and another one that isn’t so great in our condo, is making sure there is actually a fall to a drain. I’ll leave that one as it is.

- Finally communication seems to be pretty key. I could talk about American authoritarianism but I would be descending down a slippery slope towards ranting there.

Obviously the whole experience has been harrowing being locked in with only the TMR 4 deadline for company and in no way did we get any skiing or any fun in at all.

Friday Night in Harrisburg

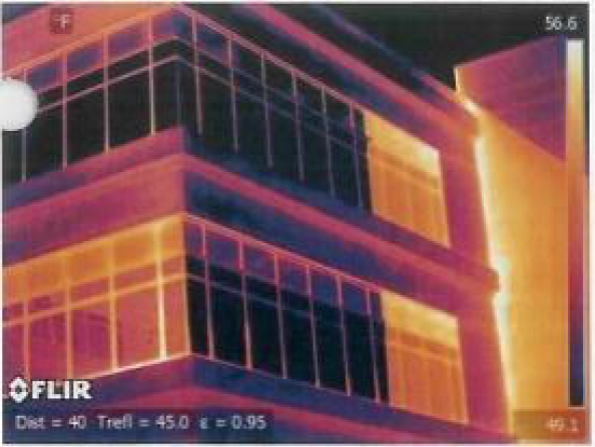

All new buildings are required to complete an Air Barrier Test (ABT) and the Defense Logistics Agency (DLA) HQ is no exception. The leakage rate is important because it indicates how much conditioned air is being lost to the outside environment. It costs money and energy to condition the air inside the building and so it is wasteful to allow it to leak out. More specifically, as the client USACE specifies an allowable leakage rate and if the building fails then the issue must be resolved. Given that the leakage rate is determined by the construction method of the building and this building is very much in the stage of finishes being applied there would be no quick fixes if it fails; so it’s important.

The test was completed on a Friday evening a couple of weeks ago with a provision for a test early on Saturday if required in order to avoid interfering with other trades as the building had to be sealed for the test. Dusk is generally considered the best conditions for testing as the dT between the building and outside is the greatest to be able to detect leak causes using thermal imagery. Sadly, as you will see below this doesn’t necessarily make for the best photographic conditions.

The test consisted of sealing up all ‘intentional’ openings, sealing a number of fans into one of the doorways and pressurising the building. The test was completed twice, first subjecting the building to a negative pressure and second subjecting it to a positive pressure. After a short while to allow the building to reach steady state it (where the pressure is not rising/falling) it could be assumed that the air leaking through the building’s skin was equal to the air the fans were blowing into, or out of, the building. The later was measured through a range of differential pressures to give the leakage rate. Whilst the an operator recorded these measurements for the first test, depressurising the building, the air tester and I walked around the building with the thermal imaging camera, and the less technical back of the hand, to identify any significant leaks. Any cold spots in the building skin or cool air blowing into the building were subject to investigation. For the second, pressurisation test, we walked around the outside to do similar but given the scale of the building this was less effective.

Fan bank 1. A second bank of 3 was put in a nearby doorway to provide sufficient flow rate to achieve steady state.

The system needs to read the same pressure at both fan banks. As the right hand bank has twice the number of fans of the left one it has twice the flow rate.

The standard.

The USACE standard is 0.25 CFM/75 sq ft enclosure, meaning cubic feet per minute per square foot of envelope at 75 Pa differential pressure. This, peculiarly for the USA is a single standard whereas in the UK we have a variety of rates to choose from depending on building usage. The units of measure in the UK are m3/hr50/m2, which is m3 per hour, per m2 of building floor area at 50Pa differential pressure. 2 m3/hr50/m2 is the UK standard for a low energy air conditioned office which is about 0.14 CFM/75 sq ft.

In an office building most of the floor area falls into this however, broadly speaking, unconditioned spaces are exempted; meaning that they have to be sealed off from the main building. Large complex buildings such as skyscrapers or buildings with significant restrictions to airflow, such as a single door separating two halves may be split into zones. The DLA HQ can be treated as one zone as there are large open plan areas and multiple stairwells and lift shafts. The building envelope is usually calculated by the Designer of Record (DOR) but in this case was calculated by the contractor, after a year of asking the DOR. The building is 309,240 sq ft, therefore:

0.25 x 309,240 = 77,310CFM is allowable for this building.

The leakage rate is tested at a differential pressure (between outside and inside) of 75Pa, which compares to 50Pa in the UK.

The practicalities of the test.

The sealing of ‘Intentional’ openings refers to closing all of the doors within the doorframes as well as any HVAC vents, kitchen flues and the waste vents. To ensure optimal pressure equlaisation within the building a few measures had to be taken:

- For every 500 sq ft of suspended ceiling at least 4 sq ft of ceiling tiles must be removed to promote pressure equalisation.

- All internal doors had to be wedged open; fortunately many aren’t fitted yet.

- The doors to the lift shaft had to be wedged open to ensure equalisation to the rooftop mechanical room.

The biggest issue was doors blowing open on the tests destabilising the pressure. The prime contractor had let all of their guys go, for the day, to ensure good running of the test having people, with some form of comms, ready to chase down open doors would have made the whole process a lot simpler. Having plenty of guys on standby would be something I imagine the RE would have got right!

Six of the nine fans used drew a maximum of 3kW. Each of the 230V circuits (the building has 110 and 230V circuits) had a 15A breaker meaning that it could only support one of these fans, or two of the smaller 1.5kW fans. This resulted in about 30 minutes of getting out electrical drawings, resetting breakers and moving extension leads around. The master electrician could have planned this prior to the test.

Results.

In the end the building passed with ease however there were still some interesting elements. The biggest loss areas are:

- Doors. Being freely moving there is always going to be a level of leakage through these. If the building had failed by a small amount then upgrading the seals would have been a way of marginally improving performance.

- Although none of the windows open, as they are penetrations into the buildings skin they act as a potential break and pathway. One window had a good breeze blowing through it that could have been sealed with a bit of mastic if required.

- Sockets and fittings, both internal and external. Again a penetration into the building’s internal skin where air can finally leak through.

- Architectural Interfaces. This would have been the main problem at the DLA HQ. Where differing building methods meet the interface can cause an issue if it is not properly sealed. An example is the auditorium on the DLA HQ which is essentially another building tacked onto the side of the main building. It was built using prefabricated panels, whereas the main building was cast in place. This had been identified as a risk in construction and was mitigated by the liberal application of spray foam.

A doorway. This is taken on the depressurisation test therefore the dark section is showing cold air blowing through the door seal.

The normal picture comparison was black. This shows an architectural interface between a precast structure and a clockwork construction with facade. As this is taken from the outside the bright yellow is showing warm air escaping.

The results came in last week showing that the building had leakages of 0.143 and 0.132 CFM/ft2 for pressurisation and depressurisation respectively. So it passed with ease in the USA, but might have only scraped through the UK equivalent test because of its complex architectural features.

Leaky Pipes

The main fun last week was that the boilers in FtIG shutdown unexpectedly. The contractor has left site temporarily making things more difficult. The issue is not yet resolved so I will blog it when further progressed. In lieu of that excitement here is a thought on sustainability/serviceability.

After the shutdowns of the dual temperature distribution piping from my mechanical room in FtIG we noticed that significant quantities of make up water are required to return the system to pressure; this means that there is a leak somewhere. To do my bit for sustainability I mentioned this to the client and was met by little in the way of enthusiasm.

Replacing the pipe work had initially been part of the scope of the project but as there was no cost benefit attached to it this element was removed to improve the pay back period of the project. This is because the project was funded based on energy conservancy it had to have a 10 year pay back period. The client that the pipes were leaking however didn’t attach a cost to this.

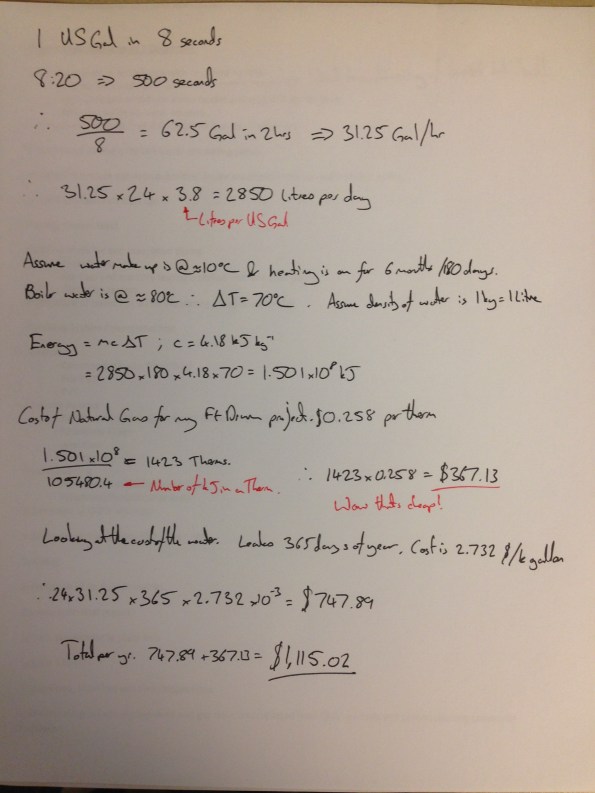

The cost is inconsequential now but for the opportunity to exercise my calculator I have had a stab at it. I conducted a test on site to work out the leakage rate before plunging into a heat loss calculation.

I shut off the pumps and make up water valve and left the system to rest. The static pressure was initially 10psi. To get a representative flow rate for the make up water I used the local tap off to fill a 1 gallon jug, this took on average 8 seconds.

After 2 hours I opened the make up water valve again and timed how long it took to refill the system. By now there was plenty of air in the system from the leaks and so once the valve stopped gushing I restarted the pumps to cycle the system through the air separator with the make up water valve closed to remove the air and ensure the pressure rebuilt to 10 psi. I repeated this process 3 further times until the system balanced. The time on the stopwatch for the make up water valve being open was 8:20. So

This method is clearly riddled with errors, for a start:

- Water leaking whilst I was refilling the system.

- Stop watch error.

- A static condition is not the same as when the system is operating.

- How representative the local tap flow rate test was to the flow rate of the system when nearing 10psi.

- The exact cost of energy and water; I used some figures from Ft Drum. I did an initial calculation using my electricity cost, this came out at $5,400 a year!

However the discussion has to start somewhere and some data, even with a large error value, is better than none.

Either way, had this test been done a few years ago it might have added $11,000 to the budget (or $12,500 if accounting for 2.5% inflation), which might have brought the system within the payback period. I have tried chasing down some of the early paperwork but to no avail.

More pressingly, we are due to treat the system with chemical to preserve the inside of the pipework. The contract calls for testing and topping up the system every month At 31.25 gal/hr the lost water rate is 31.25 x 24 x 30 = 22,500 gallons a month. I don’t know the exact size of the system but assuming 2000′ of 4″ pipework it would be 1300 gallons, which is about 2 days work for our leak. Therefore the contractor will be paying to completely re treat the system each month, significant quantities of chemical will be released into the ground and the treatment of the system will be totally ineffective in preventing corrosion.

I continue to beat my head against the proverbial brick wall on this one…

Non Commissioned Officer Academy Ft Drum

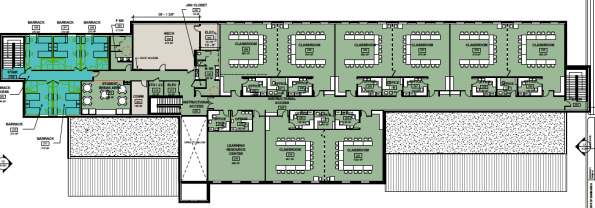

The NCOA will be a mixed use building to house routine NCO promotion training, similar to the Royal Engineer Section Commanders’ Course. The building will house the instructional classrooms, administrative offices, some accommodation, an auditorium, changing facilities and personal weapons storage. It will also house a 15 ft high training area (Room 140 on Figure 1) to be used for drill practice and physical training when weather precludes it from being conducted outside.

Figure 1: Ground Floor Plan.

Figure 2: First Floor Plan

The project proposal form had to demonstrate the need for the building, which was that it will replace twenty World War II temporary structures. This will result in a better training environment and reduced utility and maintenance costs. The new building will cover 45,700 sq ft and the project value is currently set at $19 million USD. In order to justify this cost a qualitative economic analysis was executed looking at the alternatives of renovation, maintaining the status quo, leasing and new construction. The status quo was deemed to be unacceptable and other alternatives would have only been a temporary solution.

The project is being contracted as a design, bid, build and the design timetable is organised such that the build contract is due to be awarded on 30 September 2016. This is the last day of the current financial year for USACE and so allows funds to be attributed from this financial year. This presents a risk because if the contract is not awarded on this date then the money attributed to this year will need to be spent on another project or will be lost to the Garrison. I am not privy to information on other mitigating circumstances at programme level, however if some float time had been built into the design schedule this would mitigate the issue at project level. The current design schedule has the following significant deadlines:

35% Design Stop – 18 December 2015.

35% Design Review Conference – 20 January 2016.

65% Design Stop – 28 March 2016.

90% Design Stop – 2 June 2016.

95% Design Review Conference – 28 June 2016.

The date of the planned 90% Design Stop means that I should be able, negating the chance of delays, to see the design work through to this stage.

Given the date of the 90% Design Review Conference it is unlikely that I will be able to see the design through to this point, although the most important experience will have been gained by this point on the design front. The contractual affairs will be dealt with by USACE NY District so there will be no loss of experience by leaving at the 90% design stage.

The design team structure being used by USACE for this design is spread across two USACE Districts and a Design Consultant located in three separate States. The project and the Project Manager is stationed at Fort Drum, NY and is part of NY District. Therefore the design contract naturally falls to NY District’s Engineering Division. Therefore the Design Manager, Architect, Plumbing and Electrical elements are from NY District’s Engineering Branch. Because NY District had insufficient staff to conduct the design of the structural, civil, mechanical and fire protection elements requests were sent to the other Districts within North Atlantic Division. From these Baltimore District was able to staff the Mechanical and Fire Protection elements. As no districts within the Division could support the civil and structural elements these were subcontracted to Pond Consulting, a design consultancy based in Ft Worth, Texas.

Because of the extended lines of communication liaison has already been difficult. A notable occurrence was the design model having to be rotated as it was created 180 degrees out of orientation. As each of the designers across three sites had different linked models this took a week of emails and phone calls to rectify. The issue would have been mitigated against if a central BIM manager was employed on the project, however neither Baltimore nor NY District currently have the post filled.

The new building is to be built on Fort Drum which is in the North of NY State for which the design temperature ranges from a winter design temperature of -30°F to a summer design temperature of 90°F. Significant measures, such as the inclusion of glycol in the hot water system, will have to be taken to ensure the winter design temperature can be met without causing equipment damage.

My part in the design will be to assist the mechanical engineer, Tim Wheeler, in the design of the HVAC system for the entire building. Work for the 35% design is a simple design analysis, setting out of the mechanical rooms, as shown in Figure 3, and specifying the HVAC system type. At the 35% design the room layouts, and therefore volumes, should be fixed to allow the detailed design to take place.

Figure 3: Mechanical Room at 35% design, the eagle eyed will notice that it does not line up with the ever changing floor plan. hence waiting until the 35% design stop to continue.

To 35%, as they are discrete elements I have been given a radiant floor design and a Building Lifecycle Cost Analysis (BLCCA) to complete. The radiant floor will be in the training area (Room 140), which is to be used when it is too cold to train outside. The BLCCA is to assess the viability, or otherwise, of using a Ground Coupled Heat Pump (GCHP) system in place of the air-cooled chiller and 70% of the heating load, the remaining 30% being supplied by a Natural Gas powered boiler.

And that’s the situation as it stands at the moment.

The blind leading the blind.

I have now started my design attachment in the USACE’s Baltimore District Headquarters and am currently working on two projects. One of which is a ‘server room’ cooling survey at Fort McNair in Washington DC, which this blog will focus on outlining.

I have realised my utility, I am cheap, and so have used this to secure some responsibility early. The project budget is $50,000 and, in the mechanical section, the average engineer’s time is billed at $135 per hour. The basic sum on this gives an engineer 370 hours, but add in project manager time, vehicles and other overheads and it can soon be eroded. This is something I will research into for a further blog but the upshot is that this is now my project, and a handsome little mess it looks like to. The scope of the work currently is to write a report on the cooling within a number of server and communication rooms within the Military District of Washington (MDW) office buildings. There are 15 different rooms spread across 8 buildings, built circa 1900, all with vastly different loads and in different conditions.

After meeting with the USACE project manager, the client and the HVAC engineer for the buildings, Don Ruhl (my partner from the mechanical section) and I toured a number of the rooms. As we travelled around it became apparent that not only did the client not know what they wanted; they also didn’t know what they had in the rooms. The photos give an idea of a couple of the rooms and the varying conditions.

Don inspecting the many unsealed penetrations in a small converted basement broom closet. This room had about 12U of switches and had a retrofitted ductless cooling system. It also had a condensate drain to a sump, thus allowing the condensate to re-evaporate and continually cycle through the cooling system.

Another basement room with abandoned hardwiring to the Pentagon. About 45U of high grade servers in here. The pipe on the floor is for chilled water with heavily damaged insulation allowing condensate to form on it in the summer.

Server rooms are ideally internal within a building in order to avoid solar heat gains and also because servers don’t need a window to stare forlornly out of. They are usually sealed from infiltration; tidy, to control airflow and have some form of HVAC. The current standard for low and medium density data centres and server rooms is to use a hot aisle, cold aisle system as illustrated below. Cold air is fed from low down in the ‘cold aisle’, either through the floor or by retrofitted ducts; the server blade draws it in through the front and rejects warm air through the rear into the ‘hot aisle’. This rises and is collected by the return air system. As the photos above indicate this was not the case.

So what. Well given the conditions in many of the rooms, even doing a complete survey would be incredibly costly on time. After this initial assessment we need to engage in some expectation management in what we will be able to provide and re-write the scope of our work, which is currently pretty open ended. I see this largely as focusing effort on the more important rooms in terms of upgrades and identifying the risks of each room to the client so that they can make an informed decision.

In an age of BIM, I have been told that the best we can get is a floor plan for some of the buildings so it appears that even a set of out of date as built drawings are a wish too far. Due to this if construction work is ever completed on this then the contract will almost certainly have to be a design and build as the potential for change orders on a traditional contract would be immense!

Finally, a little leadership challenge.

I mentioned earlier that I had been given the lead on this project but I am working with another engineer. Don has worked for USACE design section for at least 30 years and is probably the most intelligent person I have met out here. He has no aspirations of leadership and is very happy to let me control things; however his ability to take a tangent and dive too far into the details too early are something to behold. Certainly a different management challenge from both soldiers and contractors!

Hospital Pass

Part of the role of USACE, as the client’s representative, is to conduct design reviews for design-bid-build contracts (read traditional contracts). These are done at 35, 65 and 95% with comments provided back to the project manager and design team, be it in house or a consultant, through an online system (Dr Checks). The designs are reviewed by us at construction division as well as the design division and are passed out to the clients and facilities managers, probably amongst others.

A couple of weeks ago, due to staff being on leave, I was given one of these to look at the pumps, seemingly alone. Having no idea what to do I browsed the drawings to work out what the issues might be. The project is a new 750,000 U.S. gallon water tower for domestic water and as a fire supply so my pavlovian response was Bernoullis!

After checking the answer it seemed about right although there were no accompanying design calculations to the contract and drawings so I chalked up my first comment. The rest of the checking passed with less excitement. There were a few clauses that had been missed from the contract, some ill thought out processes and demolition elements missing from the drawings. It seems a common theme though that construction division give the most comments, usually about build ability and, as discussed in the past, what is actually existing at the site.

So what have I learnt:

Hopefully I’ve done Bernoulli’s right; simplify the problem and sketches work.

Designers, it appears, live in a magic construction dreamland and it is always the same build ability issues that are picked up. By using traditional contracts USACE does assume a lot off risk and pays handsomely for the privilege if elements aren’t caught by the construction team prior to tendering. Having recently moved into dreamland, albeit part time at present, the fine detail is easy to forget.

And as ever, time spent on recce…

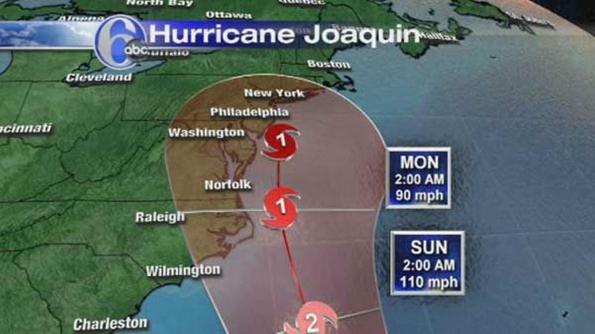

Stormy Weather

Quite an eclectic blog, due to the range of ‘stuff’ going on at the moment…

Safety

My Chiller plant is progressing well with CMU going up, albeit at a fairly modest rate, and MEP being hung. One of the over-arching requirements of the project engineers is to keep an eye on the safety aspects of the work. The CMU walls are braced as they are erected until they are tied in to the structure. This occurs when the top bond beam is in place and secured to the roof joists. As the walls get higher so do the braces. I hadn’t seen any braces being moved so I thought I would take the charts, which were discussed at the prep meeting, on my site walk and have a look. For some reason the braces hadn’t been moved, a fact which I highlighted through the principal contractors’ safety chain. They were fairly swift in rectifying the issue with minimal fuss. Below is a copy of the chart which is in the manufacturers product data, submitted as part of the prep meeting. I measured the brace run as 10’ but the wall had progressed to c. 28’ in height.

Changes

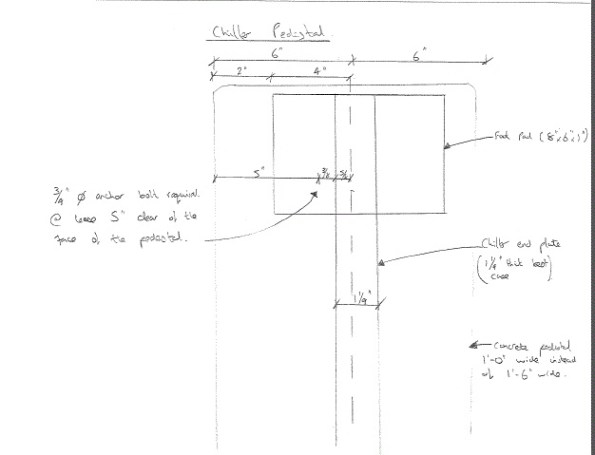

I am drafting a Basic Change Document (BCD) for some concrete pedestals onto which a large piece of mechanical equipment will sit. The contract documents call for a wall of 12” width, which is what the PC has built. The mechanical equipment features in other areas of the programme, except in those projects the support pedestals are 18” wide…

The picture above shows the mechanical equipment with the anchorage points circled. These have ¾” anchor bolts drilled through them and epoxied into the concrete pedestal to a depth of 4’. An RFI was sent to the Designer of Record (DOR) who confirmed that there had been a design bust and sent a bulletin updating the contract drawings. Since the PC didn’t want to demo the pedestals the DOR also sent out an option to anchor the equipment to the thinner pedestals. This option required the mechanical manufacturer to add extra anchorage points to their equipment, along with some restrictions on anchorage distances. I didn’t think anything of it at this point; the PC was happy that they were no longer required to demo the pedestals and could engage with the manufacturer to arrange for the fabrication of additional anchor points and USACE was happy because the change was fairly minimal. I then sketched out the dimensions (below).

Now, it is easy at this point to berate the DOR however it should, in fairness, be noted that the mechanical equipment in question had not been firmly agreed by the promoter at this point and hence some of the dimensions were ‘a bit fuzzy.’ So. Plan A it is then; demolish the pedestals.

I will write the BCD which is essentially a Request for Proposal (RFP). It will go to the PC who will send us their proposal for how much they think the change of scope will cost. Independently we will produce a Government Estimate (IGE) which will be followed by negotiations to agree a ‘fair and reasonable’ price for the work. The contract will then be adjusted to incorporate the change and reflect the increased project cost. The last BCD I wrote produced a $200k debit, so I’m hoping to still be in the black after this change. Provisionally $28k has been set aside! Seems a lot but I’m doing the IGE shortly so we’ll see.

As Builts

Another area where I’ve been addressing issues is with regard to red line drawings and as builts. The focus was bought to this area due to a drainage run which was installed at the wrong elevation. When the adjacent project ‘found’ the drainage run with their plant, somewhat unexpectedly, we asked the PC for their red lines, which took about 3 days to get a hold of. This set alarm bells ringing – it became clear that, in some areas at least, they were not properly being maintained. I was tasked to write a letter and attach an agreed Memorandum of Understanding (MoU) relating to as builts, highlighting the contractual requirements for the PC to maintain 2 sets of red line drawings, hard copy, which should be inspected weekly and submitted monthly with the pay application. (Note: A letter is a contractual ‘lever’ USACE uses because a formal letter obliges the PC to respond with positive action or a letter of explanation)

I wanted to negate too much to-ing and fro-ing between USACE and the PC, so I approached the MoU in an open manner, inviting the PC to meet up and discuss the issue; the inability of the PC to access that one red line when requested led to a lot of background information. It transpired that a verbal agreement had been made between a USACE employee (who typically was responsible for checking the red line drawings) and the PC such that the requirement for hard copy red lines was ignored and all red lines were electronically kept up to date. Since each PC site engineer has a field iPad which can access the drawings on site this seems sensible, however the arrangement was not communicated to USACE. I have incorporated this into the new MoU to do just that. It was also negotiated that USACE receives the weekly update onto our shared drives (using an external hard drive to do a data dump). This includes hyperlinks to all RFIs, mods, changes, specs etc and is a huge improvement on what USACE currently has and will make it much simpler to keep tabs on how up to date the PC is keeping their red lines. This should prevent a recurrence of the incident which kicked off issue in the first place. I have been asked to give a presentation to the rest of the project delivery team highlighting what the PC is contractually required to do with regards to red line drawings and propose the mechanism to keep tabs on their compliance with the MoU.

RFIs

We’ve ran out! Because the job is a design bid build RFIs go back to the designer of record, something I’ve noted before causes a lot of frustration to the PC because they are accustomed to design-build jobs and have a fairly good design capability in house. Anyhow, there was a set number of RFIs negotiated into the contract price with the designer, with design busts, errors and omissions being answered for free. At last count there was just shy of 1000 RFIs since the start of the project (Apr 14) and there is no money on the contract to pay the designer to answer any more. We can’t stop the RFIs because assumptions made by the contractor mean he becomes liable which is a false transfer of the risk because he is, likely, not indemnified for design faults or errors. So, USACE ‘tech assist’ which is already a busy department is now being consulted on RFIs. This is less than ideal because 1, in my opinion, you are not well suited to answer design / clarification questions if you haven’t got the background of actually designing the thing in the first place; 2 USACE is in danger of picking up some of the risk it has already paid to transfer by having somebody else design the project and 3 because it takes ages!

In other news

This…

Fame!

To follow on from Brad’s blog the internal media department have flexed their literary muscles to create this on our time with the DA and about the exchange programme. It is now hidden in the vastness of the US Army website:

Brad and I have crates available for collection at our respective houses, just come around and collect.

Offer closes 24 December 2015, all unused crates will be disposed of semi responsibly.

Erection Plans, Payments, and Visits

Following on from the cryptic erection plan for the steel truss roof a meeting was called; the contractor was livid that their plan had been E coded. The start of the meeting was uncomfortable to say the least, but when we got into the crux of the meeting, ie them talking us through their plan it was evident that there was confusion even between the sub-contractor and the principal contractor as to what was going on. In the end the USACE contingent didn’t have to say much.

Whilst I have no doubt that the very experienced sub contractor would have been able to build the truss, and would have done so safely, probably – if we hadn’t insisted on a properly thought out and communicated plan that was understood by all it would no doubt have been a lot more painful. Simple things like staging areas, order of material delivery to site and sequencing may have gone wrong, resulting in on site fixes to get the thing up. The new plan was submitted while I was away and is much better, essentially being an isometric contract drawing that is coloured in to indicate different stages of construction with notes.

Although the document is still not paginated (chinned me right off) the step by step process is crystal clear through the use of drawings as included above.

Whilst I was away the CUP was pretty much completed (structurally) and is now a mass of Mechanical, electrical and Plumbing (MEP) hangars and Concrete Masonry Unit (CMU) walls. The CMU has a lot more to it than I thought and has been fairly interesting to see, but so far only minor deconfliction issues have arisen.

I’ve also got involved with the site ‘pencil walk’ to determine the percentages complete of on site activities and ultimately the payments to the PC. This process starts with the PC who submits their proposed percentages of works complete for the month to USACE. We then verify the percentages and negotiate discrepancies with the PC. I was surprised at how amicable this was, especially when I knocked back a few estimates. Some of the ‘agressive’ percentages are a floor in the system, which has a given data date by when percentages are required. This is not at the end of the month, and so field engineers are required in some instances to estimate how much work will be completed by the end of the month.

The agreed percentages are put into the cost loaded schedule and a narrative produced by the PC. This is agreed once and for all by the Contracting Officer who then agrees payment in the sum of whatever the monetary value of the percentages complete works out to be. The updated schedule is then published with the output being the ability to track the progress of the project in terms of project finances. By comparing the actual S curve to the baseline S curve you can get a feel for how the project has/is progressing and make assessments about manning levels and payment dates as well (payment requests are made 90 days before 85% of the funds are used up). The process is lengthy and requires considerable input to mitigate the risk of the PC over/under estimating his work but the utility of the output is in the ability to accurately report progress. The downside is that the most up to date conformed schedule is a month behind!

Another snippet that I gleaned is a floor in the proposal stage. At tender all the contractors submit a cost loaded schedule as part of the tender package. This is, for one, so that USACE can assess that the project can be built on time. The schedule is required by the contract to conform to a number of specification requirements, such as nil redundant logic, must be cost loaded, costs for procurement are to be included in the installation activity (to encourage performance), must be in the approved programme etc. This conformity, however, is not checked as part of the proposal grading when USACE is selecting a contractor to complete the works. This is interesting because the initial schedule is required by USACE 30 days after contract award as part of the pre-construction submittals. It is at this stage that scheduling issues are highlighted. An example of this issue is highlighted by one of the other projects on site which was recently awarded. Their initial schedule, and the one which they used to win the contract, has been rejected because it doesn’t conform to the specification and so they are having to resubmit as part of their pre-con submittals. To USACE its a bit of a non issue, because the contract has been awarded for a set price and duration, however it can put the PC on the back foot from the start. Fortunately though, the sooner you get behind the longer you have to make it up.

I’m also mid way through writing a Basic Change Document (BCD). This will alter the scope of the initial contract based on realities of site conditions. Initially the client wanted all underground power to be concreted in (in red concrete), including the electrical ducting to all the site lighting. Congestion of utilities across the whole site has led to a re-think of this requirement. The 3700 yards of schedule 40 piping initially specified has been up-scaled to schedule 80 piping but the requirement to concrete completely removed. This was after negotiation with the client who agreed based upon the likelihood of conflicts and the required time to place. The numbers are not yet confirmed yet but, across the whole site, there will likely be a $200,000 credit for the client and the relief of some un-needed headaches for the PC. I can’t help feel that if somebody had checked with the client at an earlier stage, that he actually meant ALL electric utilities should be concreted in, this might have been averted.

In other news: This.

And this.

President Obama visits the site…

Which was interesting, not least because the entire job site was shut down for his arrival on half a days notice from the Client. Cue the e-mails from the PC requesting adjustments for delays. Fair one.

The Lost Thome

Apologies its been so long since I lost posted, you poor people! I found this post drafted and ready, from before I went on summer leave. I must have neglected to actually put it on the site in the rush to get out of the door.

The Chiller Plant is nearing completion (structurally) and the steel sub contractor building it is starting to prepare for its next large steel erection task on site. Construction of the Chiller plant has been somewhat of a rehearsal for the construction of a large steel truss roof, architecturally designed to be the crown jewel of not just the JOC project but also an icon of the campus. Colloquially known as the ‘Bridge of the Enterprise’ because of its elliptical shape, it will be more of a challenge than the chiller plant. So far it has been high on peoples agenda because of the proximity to an adjacent site which will make de-confliction of crane picks impossible. Cue the start of night work. This is an interesting issue in itself because the adjacent project is c. 1 year behind schedule and so the impossible deconfliction issue is not of our making. In the ‘real world’ I am sure that there would be much less accommodation made for the late contractor and numerous claims for LDs and delays etc. However USACE is required to manage the programme and so the success of both projects must be considered.

We also had to throw the erection plan back to the PC this week. I was part of the team reviewing it and gave general input about compliance to the USACE health and safety manual (EM-385) as well as being the ‘Structural Lead’ for the JOC, whose real Structural Lead was in Hospital with his wife who had broken her fingers playing American Football. The plan seemed OK on the face of it; containing all elements required by EM-385 (the USACE H&S document). These include details of site location, material deliveries, staging and storage, co-ordination with other construction, crane type and capacity, lifting methods, pick path, site preparation descriptions, stability of the erection, certifications …etc. The main bit of concern to me was the actual description of the steel erection activities. Fairly key then.

The subbie had done a brilliant job of communicating the first stages of the job on a simple on pager with different colours corresponding to different stages of the phase. It highlighted what the safe ‘walk away’ point was, was easy to read and clear (PSB)

Unfortunately –

that’s where it stopped. I looked to the narrative for help, but it kept referencing other pages of the document, which was not paginated. It left me filling in the next stages based on assumptions and wooly assertions based on my knowledge of the project and a narrative that said ‘repeat steps 3 – 7’. To my mind totally inadequate. The erection plan itself should be a simple document that you could give to pretty much anybody who should then be able to look through and clearly identify at what stage the construction is at, what’s coming next and at what stage it is safe to terminate construction such that what’s already been built won’t fall down. If the subbie had simply done away with the narrative and continued with ten one-pagers I think the plan would have been much better.

So what’s the point of this bit of the post? 2 things: In the army we are gently encouraged to communicate on paper in set formats. This helps, and it’s a skill/requirement we perhaps take for granted. We can add a lot of value to a site / task / project through non-technical skills like these. But secondly the most complex of tasks can be communicated through the use of some simple, well thought out sketches. In this case, it would have been a lot better to have done so.