Archive

Progressing like an asthmatic tortoise……

Since my last report the project has not really advanced. In 2 weeks we have had enough conduit installed that we can now think about putting in the first Big Ass Fan. The Contractor is still claiming that we are slowing him down by actually reviewing the submittals he sends us and rejecting them. However he has finally admitted that he would like my team to review the submissions prior to official submission or in other words can we do his job for him! He has employed a new Safety Officer and the quality of submissions has improved 10 fold and yet we are only just in a position to let work go ahead.

One stumbling block has been how the contractor is going to install the roof drain in the 85ft high bay storage area. The design contractor stated a hydraulic platform “must” be used to install the pipes but gave the wrong dimensions for the storage shelves in the building on one diagram (although it was caveated approximate dimensions). There is no platform small enough to fit between the shelves so the contractor is claiming a change in site conditions because he based his estimate on this drawing. In reality the contractor only discovered his mistake in May as he could not be bothered to do a site recce to confirm his requirements and now he looks foolish. This change means the Government will owe him money and no one here wants to give this guy any more because of his appalling attitude. As the contract managers were discussing how to deal with this I was given the chance to find a solution with in the contract (thus saving money!). These shelves go up to the ceiling and access to the shelves cannot be denied for longer that 8 hours so a permanent scaffold is out of the question. In half of the building there are horizontal beams in the shelves 6ft from the roof on which scaffolding planks could be placed to create a walkway down the aisle (325ft long). In the other half of the building the beams are not present. The Contractor has spent weeks trying to find the manufacturer to get custom made beams fabricated so he can use the scaffold boards in this half of the building but nothing could be found. Having looked at the problem it was simple: use the “required” platform (as per the contract) to get up and install the planks in the area with the beams, starting from one end and working out because of the limited access, then use the same platform to install wooden beams in the other half of the building, again working from the accessible end out, so that the planks could be laid on these when required. I took the news back to the office, ran it past the project engineer who saw it was viable and would actually be a solution at cost to the Contractor with in the contract and not us. However the managers decided to give the Contractor the money for the modification ($30,000 so far for the planks ) especially as he has now found the original shelf manufacturer and is having custom made beams produced (bill to follow) as a goodwill gesture and show that we really are partnering. They will be using the scaffold plank concept.

However this week I have been going through the contract, working on ways to deny the contractor any further chance to blame us for his delays. This has taken the form of an enormous spread sheet which details when all submittals were handed in, when they were meant to be handed in, how long we took to review and the knock on effect any delays had on the project. A great piece of work which has taken me all week and has lots of hi lighting to illustrate points. Most importantly it shows that despite some of our delays the contractor is still taking months to action any of the returns. A further letter is being drafted that now states the Contractor is solely responsible for all delays and will be getting an interim project report of “Unsatisfactory” unless there is a radical change in attitude and a revised schedule showing how they are going to make up 8 months of in activity. This is actually a big deal because if they overall project report is an “Unsatisfactory” then the Contractor is banned from bidding on any Government contracts for 5 years and the grade is published in Engineering circles. Nuff said.

I was invited to attend a Solicitation Site Visit too. This is when Contractors are invited to a potential site to access the ground prior to putting in their tenders. A fairly unremarkable experience as it is just lots of people looking at a waste water treatment facility (that was interesting) that needs up grading with very few questions allowed. It did get really interesting when one guy stepped in to a ground hog trap (think a smaller version of a bear trap) and could not escape. It took two guys to get his shoe back whilst the rest gingerly crept out of the long grass.

As work is drying up here I am investigating Aberdeen Proving Grounds next week. This is a huge project that is similar to Ben’s Biological Research Facility in that it is a Chemical Agent Research facility of equal, if not greater, complexity and with a shed load of E & M stuff going on. And they have already asked if I can help!

Road Kill Round Up

2 deer

1 Racoon

(It is 35 degrees with thunder storms everyday – I don’t go out in that!)

And in other news..

We have had quite a few parties including Warrick’s Pre Kindergarten Graduation the Baltimore District Picnic, numerous leaving function for Matt, Ulli, Ben and Sarah as well as Warrick’s 5th Birthday party. We have gone to the beach at an old quarry and the timing belt in my car went which cost me $2600 and a new cylinder head.

And it is set to get hotter. Time to plan a summer vacation.

Sittin’ On The Dock Of The Bay (or the hard at Peterhead).

I’ve been trying to get this post up for the last 2 weeks, but after a slow start, things are really motoring along in the North. Summer has arrived, which means the heating is now only on in the evenings and it only rains every other day.

P 60 Bridge inspection platforms

This project is starting to see a little more life now. At about 51% completion I am on target for close out of Define by the beginning of September, although with no funding in FY 14/15 all the work will get kicked into the long grass. With Cessation of Production for Bruce sitting around the 2017 mark, there is no appetite for this work, the asset is more interested in squeezing the field for all it is worth.

At 51% most of the design work is now complete and the engineering is about to take over. My input has been limited to ensuring off-shore involvement and digging up answers to design team queries i.e. what are the standard railing panels used on the installation, will the current design allow sufficient access, are we too close to the process lines….with the general low profile of this project, getting answers to these questions has been like getting blood out of a stone.

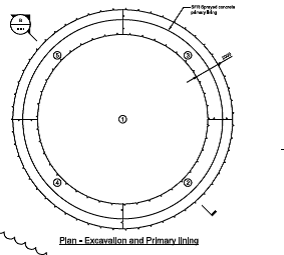

The picture about is the layout of the inspection platform (inside the black circle) beneath the PUQ side of the P60 bridge. The query has been around the proximity of process flow lines (in yellow) and whether the jacking procedure can be conducted within the constrained space. My answer is yes, mainly as this is where the original scaffold would have sat anyhow, but getting confirmation from the inspection team is not going well at the moment. At the end of the day the design will go through a constructability review and the HAZID where an representative from the asset will be able to comment on these issues, but it would be preferable to put them to bed earlier.

All in all, it’s a fairly easy going project and it has been mostly running in the back ground. 16 July will see the HAZID (Hazard ID) meeting take place although I am yet to see any forward movement from WGPSN Tech Safety who are contractually obliged to run this process. Chris has warned me that if the Tech Safety rep is a dud, I will probably need to chair the HAZID, but I am fairly happy with that as my recent experiences with the Clair Coolers project have set me up well to step in should the need arise.

Bruce Caissons

Due to the project below, this one dropped off my radar the last couple of weeks until it appeared on the weekly Engineering Services update where specific projects and task are highlighted as a specific priority. Getting the decision to defer the re-instatement of the C13 Caisson has now become a high priority and so I am re-applying myself. I originally put together the document and analysis that brought together structural and operational reasons for deferring this project until 2015. While the decision to defer was taken verbally, nothing was documented leaving the collective Project and Mods arse flying in the wind. However, over the last couple of days I’ve re-invigorated the issue and look to be on track to get the decision signed off over the next few weeks.

Clair Coolers

This has had almost all of my attention over the last 3 weeks or so. From being brought into the project, I effectively took on the job of developing the Management of Change strategy in order to close out the project. BP has a relatively robust MOC system, but it is not designed for emergent projects such as this. Originally cited as a ‘like for like plus’ replacement this should not have been an issue, with very limited actual change being brought about. However, various opportunities to add value to the project surfaced and as previously described, the project is like for like no longer. Whereas a normal project would have had an Appraise, Select and Define stage prior to Execute, in this case Appraise and Select were skipped (Appriase – No project=no gas production=no money / Select – ‘Like for like’ = Previous version lasted 10 years, Life of field is about 10 years). Define and execute were essentially compressed into about 9 months with the Prime contractor responsible for the overall project, but with BP mech and process teams designing the coolers themselves. My role has been to manage the output of the most recent risk assessment, drive forward the process of ratification of these risks by the BP technical authorities, develop the strategy for engaging these individuals, examine technical issues surrounding residual risk and compile the evidence supporting the mitigation of said risks.

Picture of the Clair Coolers sitting in a hangar at Peterhead.

Cooler transport frames to get them off-shore safely.

This job has really developed my understanding of how BP do business. More importantly it has increased my understanding of how critical risk appreciation and management are to successfully executing a project. Ideal considering the up-coming HAZID for the Bruce bridge inspection platforms. There is a plan afoot to get off-shore over the next month or so to actually see the coolers getting fitted, but I am not raising my hopes to high as there is unlikely to be a lot of space off shore during the TAR.

In Other News

Hugo had his first birthday party last weekend and it was a great success. Next week he starts nursery as Corines parent will be heading home and she will be working half the week for Grampian housing association. I and Chris attended Kingswells Primary school yesterday for the third leg of our involvement in the Primary Engineer Scheme. This saw the children racing the shoebox cars that they had made over the previous two sessions. The vehicles were rolled down a ramp and measured for distance traveled and deviation from a center-line, with the children doing the launching, measuring and scoring. Chris’ teams put in a valiant effort but at the end of the day were resoundingly defeated, he might be the fastest man in all of Nairnshire but I am the king of the classroom!

Army chief visits Crossrail

A few photos of me chilling with an ex Squadron airborne brother under London.

It was ‘Uniform to Work Day’ yesterday and as a result I was instructed to show the CGS around some of the tunnels under London. I managed to get some good ‘facetime’ under my belt and even mentioned in the CRL news letter ‘working at Crossrail is full time Army officer Capt Mike Burton, currently on a nine month secondment to Bam Nuttall as part of his Professional Engineer Training and based at Fisher Street.’ Well done me!!!!

Thats right SQUADRON!!!!!!!!!

The Ring Beam Trilogy

Ok, so the last post took us to the point of trials taking place, in order to ascertain the correct construction method. As a result the number of reinforcement bars, from the piles into the ringbeam reinforcement, was reduced. THe designers conceded that there was only a requirement for 3 x bars/male pile to protrude into the ringbeam. These 3 bars would provide sufficient shear reinforcement and bond length (in order for the next phase of excavation, where the ring beam will be temporarily suspended). The designers did specify that 2 of the bars had to be on the near face and the other on the far face of the shaft.

With the reduced amount of bars requiring coupling, the 200mm SCL profile was easily achieved and the time required to couple the bars greatly reduced (from 8 per pile to 3 per pile). The ring beam reinforcement cage was put in place and the shuttering positioned ready for the concrete pour.

However, before the concrete pour can be started I had to do a pre pour check. This includes checking the reinforcement of the ring beam, ensuring the connections between the piles and ringbeam, checking the shuttering is as per the shuttering design etc. After reading Rich Farmers comment about the couplers on my last post, I had done some investigation and found that the Lenton Lock couplers ‘bolt heads will shear off when proper installation tightness has been reached, which allows for completely visual inspection’. AS you can see from the photo below, they had not!!!

In fact the sub contractors, nor the CRL supervisors had realised the huge oversight. I then checked the bolts and not only had they not been tightened sufficiently to shear off the bolt heads, they weren’t even finger tight. The result was the concrete pour was cancelled, the shuttering taken down and the couplers all tightened untill the bolt heads sheared off. I was as popular as a pork chop in a synagogue. However the cancelled concrete pour was a fraction of the price it would have been to rip out the concrete ring beam and start again, as there was no way of proving to CRL that the couplers would have held.

You would like to think the fun stopped there but it didn’t. The next saga was the concrete mix. The idea was to spray the concrete (C32/40) in behind the shuttering using the SCL machinery all ready in place. This apparatus had already sprayed the shaft piles with a regulating layer of 75mm and would be used later to do the 400mm layer once we got below the ring beam. However SCL concrete mix is very much different to the C32/40 mix that the ring beam is constructed from. THe first batch arrived, loaded into the pump and sent down the steel tube and then into the flexible rubber hose. However within 30 sec the dryer C32/40 mix had blocked the hose and steel tubes. THey then tried dropping the mix in behind the shuttering with the skip, it didn’t work. Because the concrete had by now been on site for so long we took another slump test and it failed so the entire load had to be dumped. THis then lead onto the next issue, because Barhale had cancelled two concrete deliveries and then dumped the third the concrete supplier couldn’t deliver another batch till the morning. THis meant that the small amount of concrete that had got in behind the shuttering would have been curing to long before the next batch arrived. This would have led to a cold joint forming, as a result bthe shuttering had to come down for a second time. The small amount of concrete removed and the ring beam reinforcement cleaned.

We are now in the position to pour the concrete again. The spraying of the C32/40 mix has been scrapped and they are using a skip with a tremi on it. This should result in the first quarter of the ring beam being poured within the next few hours. In reality it is about an 8th because either end of the ring beam reinforcement cage can not have concrete poured onto it., as it must be left open in order to tie in the next quater of the ring beam reinforcement cage.

Witnessed: Civilian Equivalent of Cowardice!

Wait all this time then 2 posts come along at the same time.

We are going to be installing a large transfer beam at the beginning of next week, this thing is going to be a 20 tonne beast, with next to no tolerance for line and level. In order to try and give us the best chance of success we are using lengths of steel angle to act as a template for the holding down bolts (don’t ask me why, this was a decision that was reached between the fabricator and the consultant) the steel erecting team from the fabricators arrived on site today. The project manager decided that his total involvement consisted of introducing the foreman to the steel erectors and then quietly slipping away so that once the general name exchanging and such had finished everyone just turned around and looked at me. The setting out engineer had no idea what was going on and so apparently I became the one in charge, not a single person more senior that me visited that part of site for the rest of the day, after the fabricators had left. However in my one trip back to the office to get some lunch I was asked an irrelevant question about brickwork, where do these people come from?

It’s Been A Long Time

TMR 1, some leave, Lizzie not well, the CI’s visit and healthy dose of laziness have all conspired to prevent me from completing a blog for sometime.

Update Artesian Water – The 2 dodgy men that turned up with big drills and a few bags of cement did manage to stem the flow of the water. It took a while and wet feet (not mine) but eventually a chemical grout managed to stop the water. I have to admit I was skeptical right up to the point where the water stopped, it seemed like a very amateurish outfit but it made me laugh to see a Celtic supporting Glaswegian and Rangers supporting N Irishman step out of the same van. The death of water problems combined with a couple of other long awaited solutions have finally opened up the last part of Block B for construction and by the middle of next week I expect to have a water tight plant room.

The project continues to be plagued with design issues a constant stream of RFIs come in from the concrete contractor, I’m trying my best to get ahead and stay there of the construction process but with more trades on site now I can’t dedicate all my time to structural stuff. The M&E types are slowly dribbling on to site and dangling a few things from the soffit in my plant room.

I have been conducting all the inductions on site at the moment and because of that handle a lot of CSCS cards and one didn’t look quite right this morning, apparently the line in fake cards didn’t extend to a fake phone number on the back and eventually it was confirmed that it was a fake card. Free breakfast care of the contracts manager for Rich!

Ring Beam update

My last post got us to the point of reaching the excavation depth of the Ring Beam. THis post will go into a little more detail.

Due to the amount of reinforcement of the piles, the construction sequence of the Ring Beam had to be modified. As you can see from the sequence below, the reinforcement in the piles needed to be cut.

However in order to decide how much-needed to be cut a quick calculation was required to see what bond length was required in order to hold the Ring Beam up.

Once the reinforcement requirements for the Ring Beam were calculated, the decision to cut the reinforcement could be made. However although the calculations demonstrated that all the reinforcement was not necessary, the decision was still made that all the reinforcement bars had to be coupled back together, once the SCL had been completed. I am in the process of trying to find out why this decision was made.

The next issue is trying to obtain the 200mm SCL required in the cavity below the piles, where the Ring Beam will sit. There has been several modifications, but it now seems that with design #4 (as seen below) we are managing to get the correct SCL profile.

Trials are taking place as I write, we will see if this construction method works

Life as a mechy

With less than a fortnight before I relocate 40 miles up the road to Kinloss I thought I’d give a quick update on my life as a mechy.

Flowserve. I had a look at what I was achieving here and quickly came to the conclusion that the limited gain I got from it was not commensurate with the travelling and general faff that came with it and as such have pretty much removed myself from the project. My lasting legacy? Communication has improved between Flowserve and Woodgroup and I produced a small piece of paperwork (TMR length) on sticking points from a Flowserve perspective that was greatfully received from the BP management. It was essentially a constructive critique of Phil the package engineer – who sits opposite me within WGPSN and is technically very competent but personally a bit of a knob and as such can be a real hindrance to the project. His abrasiveness and unwillingness to communicate has greatly stalled things but understandably he is not without blame. Anyway, with over £500k of project variations and the expected completion date now 6 months to the right I’m not unhappy to be letting that one go.

Sparging. My sparging pipe (OK, Swift’s sparging pipe really) is looking pretty good. We had the design review last week and I’m currently doing check calcs in Finglow to ensure the vessel into which it is being installed is suitable. It blatantly is, but it’s good for me to be doing the calcs. I did my own designs for connection methods and ran them up on Autocad too (I figured I needed to become proficient in it sooner or later) so that was good.

Pressure Vessel Calcs. I’ll be spending tomorrow and maybe Thursday reviewing some pressure vessel calcs against ASME VIII. These are for the Lube Oil Skid on the PWRI Pump – a beast I can’t escape!

SPA work. With the TAR due to start in a month I’m still chasing round BP engineers to get projects signed off. This is a common occurrence with all SPAs as the BP management realise that yes, they too need to take some accountability for the modifications. All going well though.

Touching children’s minds. Imran and I have been down the local school teaching kids how to build cars from shoe boxes and dowel. We’ve done two sessions now and go back next week (they’re decorating them this week) to see how they fair going in a straight line down a ramp. This is part of the primary engineer programme, stimulating interest in Britain’s future engineers.

Next Week. As well as an obligatory leaving drinks/dinner in town and the car race at Kingswells Primary School I’ll be mostly handing over my Mechy and SPA work and reminding myself what I’ve done since last April so I can impress the IMechE panel on 1st August!

And away from work.

- Been swimming with dolphins in the North Sea – the water’s actually quite nice once you get used to it but the dolphins had disappeared by the time I got far enough out.

- The move to a quarter in Kinloss “seems” to be sorted and we’ll be moving in in a fortnight’s time. Housewarming on 13th July if anyone fancies it?

- I officially smashed the Edinburgh marathon with a time of 2:56:54, raising £550 for Combat Stress – that’s over £3,000 for the charity in the last year!

- And Imran’s found himself a new line of work… having been asked to see Pete (Head of Projects and Mods) yesterday he thought there may be some high-level project work for BP on the horizon. Turns out that Pete was after someone to dress up in “Army rig” and do a little display on Beaver Camp this coming weekend! Get in!!!

Very slow progress!!!! (Nothing to do with me)

There has been some slow progress on site. Last week came to a grinding stop, as a conflict between the four parties (client, designer, contractor and subcontractor) forced all excavation to cease.

The access shaft is broken down into a number of components. The Secant piles have been designed under the contract C123, by Jacobs. The remainder of the shaft has been designed under the contract C121 by Mott Macdonald. This has caused several issues as there appears to have been very limited communication between the two designers.

Jacobs insisted that once the Secant piles had been driven into place, propping would be necessary during the excavation phase. Additionally they insisted that the shaft was excavated in quadrants, sprayed with a regulating layer before moving onto the next quadrant.

However Mott Macdonald, who is the designers for the Sprayed Concrete Lining (which covers the Secant piles), insisted that the shaft did not require propping. BFK, who have the construction contract (C300) to build the shaft, decided to excavate the shaft without propping. This was agreed by CRL and Mott Macdonald. However after 8m of excavation the project was stopped as Jacobs had not agreed with the decision not to prop the shaft. The site subsequently fell silent for a week until CRL finalised an agreement between both its designers.

As a result BFK have been able to continue the further 2m to the required Ring-beam depth. However this has forced Barhale (sub-contractor) and BFK (contractor) to issue a compensation notice.

The ordeal has not stopped there. We have now got to the Ring-beam depth of 10m and the next phase is to pour the concrete Ring-beam. This process involves excavating the shingle away from the bottom of the piles and behind the piles in order to create a cavity for the Ring-beam to be poured. Again the sub-contractors were under the impression they could construct the Ring-beam in one go. However the reinforcement bars from the piles does not allow for excavation of the shingle, as they protrude into the shingle. They had planned to cut the reinforcement bars away however the bars are required to provide shear reinforcement between the Secant Piles and the Ring-beam. Additionally the reinforcement bars that protrude from the piles and eventually into the Ring-beam are required to suspend the Ring-beam when the next phase of excavation takes place (Stage 6 in the sketch).

So it is now back with the designers, because if the sub-contractors have to cut each reinforcement bar in each pile, then attach them again it will take 3 weeks instead of 1 to construct the Ring-beam. The governing factor in my opinion will be how many bars will be required for the Shear reinforcement between the Secant Piles and the Ring-beam. The issue of suspending the Ring-beam in ‘stage 6’ of the excavation can be done by increasing the embedment depth or increasing the strength of the concrete (currently designed at 35N at 3 days), A decision needs to be made today or the project will go on hold again!!!!!

On another theme, I will be meeting Chris Sexton (Ex-RE, now Tech director of CRL) and the CGS on the 26th June. I’m sure to have a great time.

We have a bridge!

This week has by far been the most enjoyable and rewarding since arriving on the project as within 3 days the site now looks like a bridge – a somewhat unfinished bridge but we are now technically bridging one side to the other. At the start of day 1 of the lift programme I thought it was going to be one of the worst weeks so far as the 220T crane arrived on site 2 hrs before we were expecting the first delivery but when I asked to inspect the lifting gear in accordance with the lift plan they did not have the correct swift lifts. As the cast in lifting points are manufactured by a company called Reid we are required to use swift lift clutches that are also manufactured by Reid due to an early lift failure incident. Their swift lifts were not but they were also so battered they had no identifiable marks or inspection tags on them so I had to stop the lift from going ahead. When talking to the crane company head offfice they then said they don’t own any swift lifts manfactured by Reid and that then would have to hire them in. The fact that they had been told about this over month ago and the point had been reiterated to them on several occassions and the fact that this particular crane company does the majority of lifts across the project suddenly highlighted that this had been previously sweeped under the carpet, until they came across the ‘by the book army bloke’ as my supervisor jokingly referred to me as. To me there was very clear direction from the Construction Manager about the use of proprietary lifting systems following on from the lifting incident earlier in the year so how this hadn’t been spotted before I don’t know. In the end we managed to find technical literature about the Reid anchor points and swift lifts regarding the tolerances and compatibility of other makes and the crane cmpany delivered suiatable swift lifts with the correct certification and we had special dispesation from the Construction Manager under the guidance of the superintendent to proceed. We finally lifted the first bean at 1330 which was about 4.5 hours late with all the other extendabale flatbeds lined up down the main road. Once we got going we managed to rig, lift and place very quickly and we positioned the 9 beams for that day by 1600 so we made some time up but this did have an effect on later delivery’s.

This is not actually above my head! H&S has been followed.

This is not actually above my head! H&S has been followed.

The pre-cast yard told me later that day we would have 10 beams coming the following morning as they had managed to get hold of an additional truck. We actually received 8 trucks has they said because we had been too slow on the first day they had other priorities and so did not have time to load the last 2. Later on the second day they called agian saying the knock on effect would be they now couldn’t deliver the final 5 beams on sat so would mon be OK. I said that mon would not be OK at all and that they were contracted to deliver the remaining beams on the saturday and any additional costs ( the crane was $8000 per day plus a $6000 call out charge) would be forwarded to them. It then all got a little ugly and they refused to deliver on principle. It transpired they were trying to save themselves a little money by using a particular haulage company over the other and due to the time lost on the first day they didn’t have time to load the final trucks on fri afternoon. If they had loaded the trucks in the correct order or gone with the other haulage company which is based locally to them in Newcastle as oposed to the other in Sydney (3 hour drive) they/we wouldn’t have had this problem. They then said that we would have to pay for them opening up their yard on a saturday to load the remaining beams which we refused as by the second day we had made the time up and the first 5 trucks had planty of time to get back to the yard to be loaded. In the end everyone calmed down as they realised it was fri afternoon and we agreed to argue about the cost after the beams have been delivered. So the fallout of last week is that the pre-cast yard (civilbuild) want to claim for their yard opening on sat which they have unofficailaly quoted as about $4000 and we will be claiming aginst the crane company for loss of working hours and possibly the yard opening costs if it is decided we have to pay. The advice of the commercial team is that this is just civilbuild getting touchey at the end of their contract as they are trying to place a number of similar claims for past work. Considering we paid them a shade under $200,000 for 22 PSC beams of dubious quality (some of the finish and height levels are terrible and noted by the clients visits during the lifts) which equals about $9000 per beam they should probably stay quiet as we could make their life very difficult and insist remedial work is carried out on alot of the beams which we may yet do.

As the beams have now all been installed there is a sense of relief as rail can now come through without us getting in each others way. For me the pressure is about to increase as the Project Engineer who’s wing I am under is being send to another project so I am to receive rapid promotion by default I think rather than ability. I will be the only engineer on the bridge and there will be a few wrap up issues for the other 3 bridges so I seem to have jumped up to a Senior Project Engineer and will report directly to the Construction Manager. This really means I need to fully understand the cost/commercail aspect of what I am doing as I will be responsible for every dollar sepnt on the bridge and will have to justify it to the construction manager every month as part of the forecast and accrual process. We are currently about $50,000 over budget when compared against the tender costs – I just need to understand whether that is good or bad!