Archive

Life as a mechy

With less than a fortnight before I relocate 40 miles up the road to Kinloss I thought I’d give a quick update on my life as a mechy.

Flowserve. I had a look at what I was achieving here and quickly came to the conclusion that the limited gain I got from it was not commensurate with the travelling and general faff that came with it and as such have pretty much removed myself from the project. My lasting legacy? Communication has improved between Flowserve and Woodgroup and I produced a small piece of paperwork (TMR length) on sticking points from a Flowserve perspective that was greatfully received from the BP management. It was essentially a constructive critique of Phil the package engineer – who sits opposite me within WGPSN and is technically very competent but personally a bit of a knob and as such can be a real hindrance to the project. His abrasiveness and unwillingness to communicate has greatly stalled things but understandably he is not without blame. Anyway, with over £500k of project variations and the expected completion date now 6 months to the right I’m not unhappy to be letting that one go.

Sparging. My sparging pipe (OK, Swift’s sparging pipe really) is looking pretty good. We had the design review last week and I’m currently doing check calcs in Finglow to ensure the vessel into which it is being installed is suitable. It blatantly is, but it’s good for me to be doing the calcs. I did my own designs for connection methods and ran them up on Autocad too (I figured I needed to become proficient in it sooner or later) so that was good.

Pressure Vessel Calcs. I’ll be spending tomorrow and maybe Thursday reviewing some pressure vessel calcs against ASME VIII. These are for the Lube Oil Skid on the PWRI Pump – a beast I can’t escape!

SPA work. With the TAR due to start in a month I’m still chasing round BP engineers to get projects signed off. This is a common occurrence with all SPAs as the BP management realise that yes, they too need to take some accountability for the modifications. All going well though.

Touching children’s minds. Imran and I have been down the local school teaching kids how to build cars from shoe boxes and dowel. We’ve done two sessions now and go back next week (they’re decorating them this week) to see how they fair going in a straight line down a ramp. This is part of the primary engineer programme, stimulating interest in Britain’s future engineers.

Next Week. As well as an obligatory leaving drinks/dinner in town and the car race at Kingswells Primary School I’ll be mostly handing over my Mechy and SPA work and reminding myself what I’ve done since last April so I can impress the IMechE panel on 1st August!

And away from work.

- Been swimming with dolphins in the North Sea – the water’s actually quite nice once you get used to it but the dolphins had disappeared by the time I got far enough out.

- The move to a quarter in Kinloss “seems” to be sorted and we’ll be moving in in a fortnight’s time. Housewarming on 13th July if anyone fancies it?

- I officially smashed the Edinburgh marathon with a time of 2:56:54, raising £550 for Combat Stress – that’s over £3,000 for the charity in the last year!

- And Imran’s found himself a new line of work… having been asked to see Pete (Head of Projects and Mods) yesterday he thought there may be some high-level project work for BP on the horizon. Turns out that Pete was after someone to dress up in “Army rig” and do a little display on Beaver Camp this coming weekend! Get in!!!

Very slow progress!!!! (Nothing to do with me)

There has been some slow progress on site. Last week came to a grinding stop, as a conflict between the four parties (client, designer, contractor and subcontractor) forced all excavation to cease.

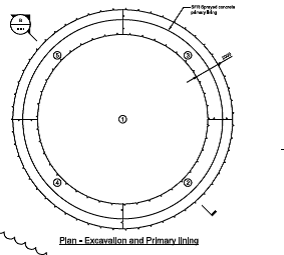

The access shaft is broken down into a number of components. The Secant piles have been designed under the contract C123, by Jacobs. The remainder of the shaft has been designed under the contract C121 by Mott Macdonald. This has caused several issues as there appears to have been very limited communication between the two designers.

Jacobs insisted that once the Secant piles had been driven into place, propping would be necessary during the excavation phase. Additionally they insisted that the shaft was excavated in quadrants, sprayed with a regulating layer before moving onto the next quadrant.

However Mott Macdonald, who is the designers for the Sprayed Concrete Lining (which covers the Secant piles), insisted that the shaft did not require propping. BFK, who have the construction contract (C300) to build the shaft, decided to excavate the shaft without propping. This was agreed by CRL and Mott Macdonald. However after 8m of excavation the project was stopped as Jacobs had not agreed with the decision not to prop the shaft. The site subsequently fell silent for a week until CRL finalised an agreement between both its designers.

As a result BFK have been able to continue the further 2m to the required Ring-beam depth. However this has forced Barhale (sub-contractor) and BFK (contractor) to issue a compensation notice.

The ordeal has not stopped there. We have now got to the Ring-beam depth of 10m and the next phase is to pour the concrete Ring-beam. This process involves excavating the shingle away from the bottom of the piles and behind the piles in order to create a cavity for the Ring-beam to be poured. Again the sub-contractors were under the impression they could construct the Ring-beam in one go. However the reinforcement bars from the piles does not allow for excavation of the shingle, as they protrude into the shingle. They had planned to cut the reinforcement bars away however the bars are required to provide shear reinforcement between the Secant Piles and the Ring-beam. Additionally the reinforcement bars that protrude from the piles and eventually into the Ring-beam are required to suspend the Ring-beam when the next phase of excavation takes place (Stage 6 in the sketch).

So it is now back with the designers, because if the sub-contractors have to cut each reinforcement bar in each pile, then attach them again it will take 3 weeks instead of 1 to construct the Ring-beam. The governing factor in my opinion will be how many bars will be required for the Shear reinforcement between the Secant Piles and the Ring-beam. The issue of suspending the Ring-beam in ‘stage 6’ of the excavation can be done by increasing the embedment depth or increasing the strength of the concrete (currently designed at 35N at 3 days), A decision needs to be made today or the project will go on hold again!!!!!

On another theme, I will be meeting Chris Sexton (Ex-RE, now Tech director of CRL) and the CGS on the 26th June. I’m sure to have a great time.