Defects and deflection walls

The past couple of weeks has seen gradual progress on Dickson Rd as we try to complete the deflection walls so that the stage 1 backfill can start. We now have the two inner walls of abutment A side to ppur and they will be complete. It has been a frustrating two weeks to try and keep the subcontractor working at an acceptable pace and realistically we should have finished the deflection walls by the end of last week. The subcontractor is really trying to drag out the work at the moment and now seem to knock off at 1500 every day so that they are paying their workforce for only 8 hours rather than the usual 10 hours.

I have been liaising with the Civil team last week to organise the stage 1 backfill to begin as soon as the abutment B side deflection walls are complete which they now are. I mad it as simple as possible for them and gave them a sketch of exactly how I want them to do the backfill but to be honest they have a reputation for freestyling somewhat so I will have to keep a close eye on what they are doing! They will start to backfill on abutment B side first and once we have completed the delection walls on the other abutment side this week and the required curing period has passed they should be able to start on the other side the following week.

The majority of my time has been spent on closing out defect work on the other three bridges as last week was my first offical week with full responsibility for the section. These defects are mainly patching work but there are also a few outstanding jobs to complete such as abutment access stairs at Kemps Creek. I also have a rather annoying outstanding defect that is lingering about on Scalabrini which was raised by the client. This defect is simple but could cause a lot of remedial work in the not too distant future. It was originally a broken cable conduit between the Expansion joint (deck-approach slab) which was damaged during the stripping of formwork but has raised other issues as to whether we have installed the conduits according to the specification to allow movement. My supervisor being the pro-active chap he is went ahead and fixed the problem without infoming me of how and when as I am required to notifiy the client 48hrs before any remedial work is carried out. Sending this notification is a ‘Hold’ point and the actual message informs them of the ‘Witness’ point. In this case they wanted to know what our COA would be and I probably should have sent an RFI to get our approved solution verified by the designer although for something this simple I think it is debatable. The design shows the female connector cast in the approach slab side flush to the expansion joint and the male end from the deck side inserting stright into the female end. Any movement of the approach slab/deck is then not transmitted to the conduits as they are able to move in and out of the un-glued connector – fine for trains going down main but probably not going up main as the joint is pushed flush togther. The problem is the damaged conduit is right on this connector and the adjacent conduit clearly shows the join in the centre of the joint which poses questions about the other conduits and whether we have followed the drawings. We have stated that we have and it is hard to disprove as they are cast in the concrete so there would be nothing to see and we have said that the conduit with the connector in the centre of the joint is a ‘one off’ and that from a spec point of view it would work in the the same way as originally designed. A simple defect which may grow in size and at its worst lead to us breaking out part of the conduits to either prove or rectify the issue. Coupled with the fact that the joint cover plates, waterproofing and shock matting have now all been laid over the area ready for ballst to be laid could mean a lot of time and money for such a simple issue.

Regarding other news I decided to join the Sydney Harbour 10Km race last Sun to assess how unfit I have become since working 12 hour days and commuting 2 hours every day. I managed a time of 45.31 which is certainly not quick but was better than I thought given that I only managed to pass this 11 year old kid I had in my sights since the start at the 8k mark! I bought all my triathlon kit out with me thinking I must at least do one race while I am out hear but 5 months in and I been on the bike once to go to the park. I have signed up the whole family for the City2surf in Aug which is 14km from the city centre to Bondi beach but as Ethan will only be 1 its going to be more of a family walk with the buggy followed by a well deserved BBQ at the end on the beach courtesy of JHG.

![IMG_2097[1]](https://pewpetblog.com/wp-content/uploads/2013/07/img_20971.jpg?w=300&h=225)

Jon,

I know if I was the client I’d require you to open up and show good on the conduits at Kemp’s Creek. If it all turned out to be as per the drawings I’d carry the cost but at least I’d have covered my risk. If there was only one out of spec connection I’d claim the whole lot back, particularly if I’d recieved an erroneous assurance that they were all OK. The best way to deal with this is probably to head it off by proposing a sensible openning up and making good and making sure it’s all agreed with the client without making it sound like a big deal. One trick is to introduce a diversion i.e. find an easy to fix issue and make a song and dance about ti so it becomes the focus. When that’s fixed there will be a big “I told you to do it better” and you can eat humble pie on the cheap option and walk away smuggly grinning to yourself! Enjoy managing this 🙂

I opened up two sides this morning and had the client down to look and discuss. This issue has the potential to affect all the bridges now and our integrity has been questioned due to an earlier claim that we had carried out the work as per the specification. After this morning the issue has at least been contained to Scalabrini Creek bridge for now and I have reassured them that although I have inherited this issue I will resolve it and everyone seems happy – including our borderline neurotic Quality Coordinator. My next move is to talk to the designer first follwed by a formal RFI with the preferred result being they authorise the completed work as acceptable. I also need to look at a repair method for the broken conduit and have this approved through an RFI – looking at heat appliaction shrink wrap method which apparently is a common method used by the elctricians working on Leppington station.

Jon

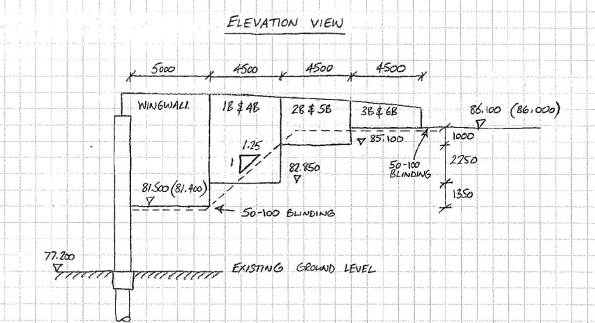

Are you backfilling equal amounts on each side of the bridge? If not I assume that the structure can take the unsymmetrical loading.

Regards

Neil

Neil,

Stage 1 backfill is to the underside of the wingwalls only which is the heighest we are allowed to go before the deck and diaphragm need to be installed to prop the walls. Bearing this in mind I have no obligation to backfill both sides simultaneously as they are two independent structures until we cast the deck. The beams are just sitting on top of the abutments and as you can see from the lack of track being laid the time pressure we were placed under to install the beams before we lost access to the area between the abutment walls now looks unnecessary. Having known that the track would be delayed for as long as it has – I have no idea when they are now supposed to arrive at Dickson Rd – the beams would probably not be installed until either now or after the stage 1 backfill.