Pump It

Just a quick post today, more on friday is the plan…

Now that Clair Coolers is winding down, Clair Minox Blower B is starting to wind up for off shore execute on 2 Feb. That gives me 19 days to the 12 week gate and while we are mostly there, there is a fair bit of work to get us through. The Minox system uses nitrogen to strip oxygen from sea water for use in re-pressurising wells to increase extraction rates. Removing the oxygen presumably reduces the compressibility of the injected water which protects the plant and pipes used to do so (water hammer?), but I have a little more reading to do on that front. Either way we are upgrading the ‘B’ blower on Clair to increase water injection capacity.

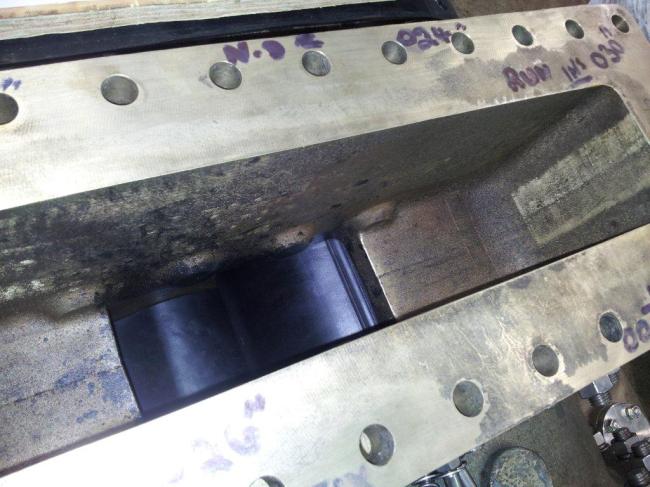

The project itself is another fixer that has been attempted previously but not completed. To that end the equipment below has been sitting out in the elements (at a cost of £20k a month) rather than in a covered hanger being regularly inspected and turned over. QA issues with the storage company. It is now down for re-conditioning / testing with the manufacturer, the photos below are proof from them that it is actually in a better condition than I first thought. My question to you is, from the information below, what kind of pump is it? It is a blower and it sends nitrogen around a closed system.

Mark, if you read this, I can send you the photos and GA for one of your pump lessons…

The nitrogen injection is more likely to be for corrosion and, presumably in oil and gas, explosion protection. Fluid compressibility is more about the bulk modulus rather than dissolved gas content and water hammer is asssociated with rapid valve closing – your next TMR beckons!

Looks like you answered your own question, its a blower! Looks like a Roots blower (positive displacement lobe type).

Any info you have is always appreciated, send it my way.

Mark

The nitrogen is used to catalytically strip oxygen from the sea water prior to the sea water being injected into the sub sea formation, but yes, after a little research it is for corrosion reasons. Dissolved O2 in steam condensate is very corrosive in steam return pipes and at the temperatures and pressures we are talking about, then this oxygen removal would be to protect the injection piping.

Possibly a TMR, but several options are presenting at the moment.

Ah, my ignorance, I didnt realise steam was involved. steam systems and oxygen aren’t a good mix!

Oh, and ‘positive displacement lobe type’ was the correct answer. You win a bottle of Kingswells Home Brew, collection either in Aberdeen or delivery in 9 months.