Archive

Importance of Understanding

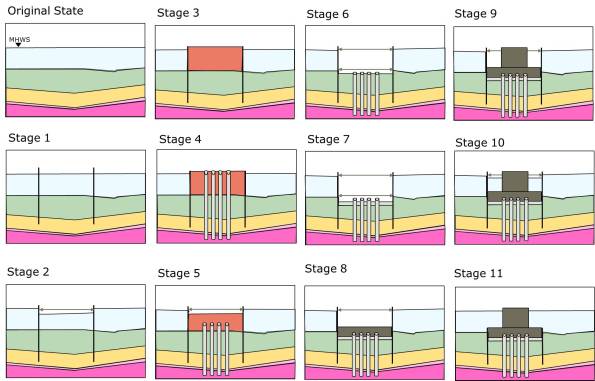

Option 2 – Cofferdam construction sequence.

The Importance of Understanding – Initial Sequence

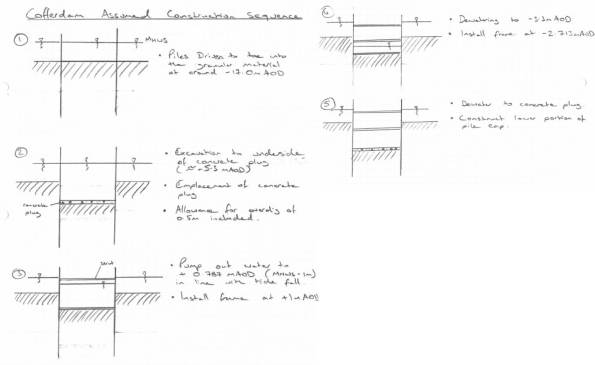

This is my initial construction sequence sketch. Sorry the sketches don’t want to embed in the document.

The Importance of Understanding

John Moran and the SI can be feeling justifiably smug right now. During both COFFERDAM and SOFT BOTTOM JM continual told us to understand the construction sequence or method statement of what we were doing before embarking on calculations. DB frequently told and re-told of how he would first spend time drawing stuff for design exercised before calculations.

I mentioned my encounter with bridge abutment design a little while ago where I picked up a slight error in my calculations in time when I realised the maximum retained height of a wall was in the temporary case during a road excavation. My point at the time was by knowing how things are actually built I didn’t publish erroneous calculations and felt quite good about my contribution, assuming that an engineer with less construction experience wouldn’t have picked it up. But my point should have been a lesson learnt, if I had thought about (and yes sketched) the construction sequence I would have picked up the issue even sooner and saved time.

I’ve previously mentioned the Barrow Bridge Tender which is a cable stayed bridge of around 1km in total length. On Monday I was tasked to answer questions on a couple of cofferdams that will be required to construct the foundations. The output is so the contractor can price an outline solution for tender purposes, the final design will fall to the temporary works designer for the project. Therefore the design needs to be economic enough to win the work but without spending too much time (and fee) on it, therefore not to Eurocode, old fashioned lumped factors of safety are the order of the day so detailed design might squeeze some savings.

One of the cofferdams will be mid-river (within the tidal range which can be used as a benefit when pumping out). The questions just wanted to know sizes of walings, props, sheets and likely toe depths. The really simplistic solution (though I don’t think even a true idiot would do this) would be to consider the whole thing wished in place props at the varying heights to ratios according to ‘h’ and produce that as the answer. This would be extremely wrong. A more sophisticated solution might be to consider the construction stages and check at each, again placing props at the recommended ratios of ‘h’. However it’s only when you consider what you’re making the cofferdam (Moran, 2012, his office with a disappointed Dad look) for that you realise that props need to accommodate the construction of the 3 metre deep pile cap and so props in the bottom of the hole are silly. It is easiest to reach all these conclusions with a pencil and a sheet of paper (Blow, 2012, tea and toast during misty eyed reminiscence). So having no idea how to construct an inter-tidal cofferdam with ‘I told you so’ echoing in stereo in my ears I picked up a pencil and sketched.

I started with the assumption that the piling and excavations would be conducted from a barge/jack up. The result is shown below.

The WALLAP analysis could then be run building each of these construction stages into the sequence. This would give me maximum BMs and SF in the sheets, and axial loads in the props. The software also gives the point at which the FOS is at a minimum which is after the water is pumped out prior to installation of the second frame so I can highlight it to the contractor. Feeling pretty please with myself I skipped along to a meeting on my own into the den of the bridges (a soul less place with engineers stacked tighter than baked beans in Tesco, I even spotted one asleep at his desk!).

My smugness was shortlived. The last time I talked about construction stages I missed the lesson, this time I didn’t. I can guess what I think might happen but the contractor has a very different plan, well 2 different plans in fact and he wants each of them sized. So this time I’ve drawn up the sketches for both options (Powerpoint beats pencils) and am seeking agreement on the sequence before doing any more numbers.

So JM and DB feel free to use me as the example of a PET student who though he knew better and Phase 1 really think about how things get built before you design them. I don’t know how relevant this is to building structures, I think it’s a little more subtle for example on site we couldn’t store a pallet of plasterboard on the floors because the design loadings were so small, they had to be split before storage.

This whole episode does again reflect on the difficulties of managing the design office environment, I was put on an element of the Barrow Bridge permanent design 4 weeks ago because there was nobody else, the Design Engineer working above me has had to return to site for 5 weeks on another bridge crossing (New Forth Crossing) and so I have become the only geotech bloke working on it. So when the extra work came in it was me to carry on, the design brief was given to me in isolation and the first chance to discuss it was during the meeting with the bridges team. Once again the matrix structure fails because people are given work because they are available. In reality there should have been yesterday’s meeting before I embarked on more detailed design, or perhaps I should have chased bridges for an outline sequence of construction?